SIST EN 14081-1:2016+A1:2019

(Main)Timber structures - Strength graded structural timber with rectangular cross section - Part 1: General requirements

Timber structures - Strength graded structural timber with rectangular cross section - Part 1: General requirements

This European Standard specifies requirements for strength graded structural timber with rectangular cross-sections either visual or machine graded, shaped by sawing, planning or other methods and with cross-sectional dimensions complying with EN 336 (referred to as structural timber in the following clauses).

This European Standard includes provisions for test methods, Assessment and Verification of Constancy of Performance and marking of structural timber.

NOTE 1 For machine strength graded timber additional provisions for type testing (TT) are given in EN 14081-2 and for factory production control (FPC) in EN 14081-3.

NOTE 2 An acceptance procedure for verification of a lot is given in EN 14358 which may be used for a delivery of structural timber.

This European Standard identifies characteristics for which limits have to be given in visual grading standards.

This European Standard covers structural timber, untreated or treated against biological attack.

This European Standard does not cover:

- timber treated by fire retardant products to improve its fire performance;

- thermally and/or chemically modified timber;

- structural finger jointed timber.

Holzbauwerke - Nach Festigkeit sortiertes Bauholz für tragende zwecke mit rechteckigem Querschnitt - Teil 1: Allgemeine Anforderungen

Diese Europäische Norm legt Anforderungen an visuell oder maschinell nach der Festigkeit sortiertes Bauholz für tragende Zwecke mit rechteckigem Querschnitt fest, das durch Sägen, Hobeln oder andere Verfahren erzeugt wurde und Querschnittsmaße nach EN 336 aufweist (nachfolgend als „Bauholz für tragende Zwecke“ bezeichnet).

Die vorliegende Europäische Norm enthält Festlegungen für Prüfverfahren, die Bewertung und Überprüfung der Leistungsbeständigkeit sowie die Kennzeichnung von Bauholz für tragende Zwecke.

ANMERKUNG 1 Für maschinell nach der Festigkeit sortiertes Bauholz sind zusätzliche Festlegungen für die Typprüfung (TT) in EN 14081 2 sowie für die werkseigene Produktionskontrolle (WPK) in EN 14081 3 angegeben.

ANMERKUNG 2 Ein Annahmeverfahren für die Prüfung von Losen, das für Lieferungen von Bauholz für tragende Zwecke verwendet werden darf, ist in EN 14358 angegeben.

Diese Europäische Norm legt Sortiermerkmale fest, für die in den Normen zur visuellen Sortierung Grenzwerte anzugeben sind.

Diese Europäische Norm gilt für Bauholz für tragende Zwecke, das entweder unbehandelt ist oder gegen biologischen Befall behandelt wurde.

Diese Europäische Norm gilt nicht für:

— Bauholz, das mit Feuerschutzmitteln behandelt wurde, um sein Verhalten bei Brandeinwirkung zu verbessern;

— thermisch und/oder chemisch modifiziertes Bauholz;

— keilgezinktes Bauholz für tragende Zwecke.

Structures en bois - Bois de structure à section rectangulaire classé pour sa résistance - Partie 1 : Exigences générales

La présente Norme européenne prescrit les exigences applicables au bois de structure à section rectangulaire classé soit visuellement soit par machine, profilé par sciage, rabotage ou d’autres méthodes, et ayant des dimensions minimales de section conformes à l'EN 336 (désigné comme bois de structure dans les articles suivants).

La présente Norme européenne comprend des dispositions relatives aux méthodes d'essai, à l'évaluation et la vérification de la constance des performances et au marquage du bois de structure.

NOTE 1 Pour le bois dont la résistance est classée par machine, des dispositions supplémentaires pour les essais de type (TT) sont spécifiées dans l'EN 14081-2 et pour le contrôle de production interne (CPU) dans l'EN 14081-3.

NOTE 2 Une procédure d’acceptation pour la vérification d’un lot est indiquées dans l’EN 14358 et celle-ci peut être utilisée pour la livraison de bois de structure.

La présente Norme européenne identifie, les caractéristiques pour lesquelles des limites sont établies dans les règles de classement visuel.

La présente Norme européenne couvre le bois de structure, non traité ou traité contre les attaques biologiques.

La présente Norme européenne ne couvre pas :

- le bois traité par des produits ignifuges pour améliorer sa performance au feu ;

- les bois modifiés thermiquement et/ou chimiquement ;

- le bois avec aboutages à entures multiples.

Lesene konstrukcije - Po trdnosti razvrščen konstrukcijski les pravokotnega prečnega prereza - 1. del: Splošne zahteve

Ta evropski standard določa zahteve za vizualno in strojno razvrščen konstrukcijski les pravokotnega prečnega prereza po trdnosti, ki je oblikovan z žaganjem, struženjem ali z drugimi metodami in izpolnjuje zahteve standarda EN 336 glede najmanjših dimenzij prečnega prereza.

Ta evropski standard vključuje določbe za preskusne metode, ocenjevanje in preverjanje nespremenljivosti lastnosti ter označevanjem po trdnosti razvrščenega konstrukcijskega lesa.

OPOMBA: V standardu EN 14081-2 so za strojno razvrščen konstrukcijski les po trdnosti podane dodatne določbe za tipsko preskušanje (TT), v standardu EN 14081-3 pa za kontrolo proizvodnje v obratu (FPC).

Ta evropski standard opredeljuje lastnosti, za katere so podane omejitve v standardih za vizualno razvrščanje. Ta evropski standard obravnava pravokotni konstrukcijski les, zaščiten ali nezaščiten pred biološkimi dejavniki.

Ta evropski standard ne obravnava:

– lesa, obdelanega z zaščitnimi sredstvi proti ognju, ki izboljšujejo odpornost proti ognju;

– zobato spojenega lesa.

General Information

- Status

- Published

- Publication Date

- 13-Oct-2019

- Technical Committee

- KON.005 - Timber structures

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 27-Aug-2019

- Due Date

- 01-Nov-2019

- Completion Date

- 14-Oct-2019

Relations

- Effective Date

- 01-Nov-2019

- Effective Date

- 18-Jan-2023

Overview

EN 14081-1:2016+A1:2019 - published by CEN - specifies the general requirements for strength graded structural timber with rectangular cross-sections. It applies to timber shaped by sawing, planning or other methods with cross-sectional dimensions in accordance with EN 336. The standard covers both visual grading and machine grading, and includes provisions for test methods, marking and the Assessment and Verification of Constancy of Performance (AVCP) required under the Construction Products Regulation.

Key topics and requirements

- Scope and exclusions: Applies to untreated timber or timber treated against biological attack. Does not cover timber treated with fire retardants to improve fire performance, thermally/chemically modified timber, or structural finger‑jointed timber.

- Strength grading methods: Defines principles for visual strength grading and machine strength grading, including the need for visual override inspections and the two machine-control approaches (output control and machine control).

- Performance characteristics: Specifies mechanical resistance, charring rate (fire resistance), reaction to fire, release of dangerous substances, biological durability, and geometrical data.

- Testing and verification (AVCP): Clause 6 sets out requirements for type testing, factory production control and the overall AVCP system aligned with EU Regulation No. 305/2011.

- Factory production control (FPC) and type testing (TT): Additional, more detailed provisions for machine grading TT and FPC are provided in EN 14081-2 and EN 14081-3 respectively.

- Marking and documentation: Requirements for marking methods, information on timber/packaging, and documentation accompanying deliveries (including species codes in Annex B).

- Annexes and measurement: Normative annexes include limits for strength‑reducing characteristics used in visual grading, marking codes for species, and moisture content measurement (Annex C).

Applications and who uses it

- Timber manufacturers, sawmills and grading facilities - to implement compliant strength grading, FPC and marking procedures.

- Structural engineers, architects and specifiers - to select appropriate strength graded structural timber for load-bearing applications.

- Certification bodies and notified bodies - to assess AVCP, review type testing and perform factory inspections.

- Traders, wholesalers and construction contractors - to verify conformity, traceability and required documentation for structural timber deliveries.

Related standards

- EN 14081-2 - Machine grading: additional type testing requirements

- EN 14081-3 - Machine grading: additional FPC requirements

- EN 14358 - Lot verification / acceptance procedure

- EN 336, EN 338, EN 350, EN 384 - referenced for dimensions, strength classes, durability and characteristic values

Keywords: EN 14081-1:2016+A1:2019, strength graded structural timber, visual grading, machine grading, AVCP, factory production control, timber marking, timber standards, CEN.

Frequently Asked Questions

SIST EN 14081-1:2016+A1:2019 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Timber structures - Strength graded structural timber with rectangular cross section - Part 1: General requirements". This standard covers: This European Standard specifies requirements for strength graded structural timber with rectangular cross-sections either visual or machine graded, shaped by sawing, planning or other methods and with cross-sectional dimensions complying with EN 336 (referred to as structural timber in the following clauses). This European Standard includes provisions for test methods, Assessment and Verification of Constancy of Performance and marking of structural timber. NOTE 1 For machine strength graded timber additional provisions for type testing (TT) are given in EN 14081-2 and for factory production control (FPC) in EN 14081-3. NOTE 2 An acceptance procedure for verification of a lot is given in EN 14358 which may be used for a delivery of structural timber. This European Standard identifies characteristics for which limits have to be given in visual grading standards. This European Standard covers structural timber, untreated or treated against biological attack. This European Standard does not cover: - timber treated by fire retardant products to improve its fire performance; - thermally and/or chemically modified timber; - structural finger jointed timber.

This European Standard specifies requirements for strength graded structural timber with rectangular cross-sections either visual or machine graded, shaped by sawing, planning or other methods and with cross-sectional dimensions complying with EN 336 (referred to as structural timber in the following clauses). This European Standard includes provisions for test methods, Assessment and Verification of Constancy of Performance and marking of structural timber. NOTE 1 For machine strength graded timber additional provisions for type testing (TT) are given in EN 14081-2 and for factory production control (FPC) in EN 14081-3. NOTE 2 An acceptance procedure for verification of a lot is given in EN 14358 which may be used for a delivery of structural timber. This European Standard identifies characteristics for which limits have to be given in visual grading standards. This European Standard covers structural timber, untreated or treated against biological attack. This European Standard does not cover: - timber treated by fire retardant products to improve its fire performance; - thermally and/or chemically modified timber; - structural finger jointed timber.

SIST EN 14081-1:2016+A1:2019 is classified under the following ICS (International Classification for Standards) categories: 79.040 - Wood, sawlogs and sawn timber; 91.080.20 - Timber structures. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14081-1:2016+A1:2019 has the following relationships with other standards: It is inter standard links to SIST EN 14081-1:2016, SIST EN 14081-1:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14081-1:2016+A1:2019 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/112_AM1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 14081-1:2016+A1:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2019

Nadomešča:

SIST EN 14081-1:2016

Lesene konstrukcije - Po trdnosti razvrščen konstrukcijski les pravokotnega

prečnega prereza - 1. del: Splošne zahteve

Timber structures - Strength graded structural timber with rectangular cross section -

Part 1: General requirements

Holzbauwerke - Nach Festigkeit sortiertes Bauholz für tragende zwecke mit

rechteckigem Querschnitt - Teil 1: Allgemeine Anforderungen

Structures en bois - Bois de structure à section rectangulaire classé pour sa résistance -

Partie 1 : Exigences générales

Ta slovenski standard je istoveten z: EN 14081-1:2016+A1:2019

ICS:

79.040 Les, hlodovina in žagan les Wood, sawlogs and sawn

timber

91.080.20 Lesene konstrukcije Timber structures

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14081-1:2016+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2019

EUROPÄISCHE NORM

ICS 79.040 Supersedes EN 14081-1:2016

English Version

Timber structures - Strength graded structural timber

with rectangular cross section - Part 1: General

requirements

Structures en bois - Bois de structure à section Holzbauwerke - Nach Festigkeit sortiertes Bauholz für

rectangulaire classé pour sa résistance - Partie 1 : tragende zwecke mit rechteckigem Querschnitt - Teil 1:

Exigences générales Allgemeine Anforderungen

This European Standard was approved by CEN on 9 February 2016 and includes Amendment 1 approved by CEN on 14 May

2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14081-1:2016+A1:2019 E

worldwide for CEN national Members.

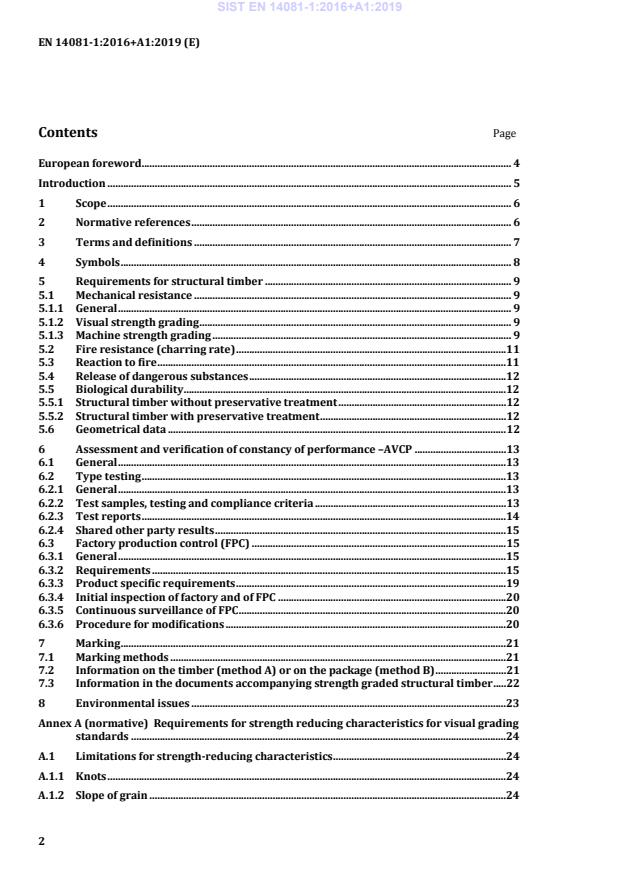

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Symbols . 8

5 Requirements for structural timber . 9

5.1 Mechanical resistance . 9

5.1.1 General . 9

5.1.2 Visual strength grading . 9

5.1.3 Machine strength grading . 9

5.2 Fire resistance (charring rate) .11

5.3 Reaction to fire .11

5.4 Release of dangerous substances .12

5.5 Biological durability .12

5.5.1 Structural timber without preservative treatment .12

5.5.2 Structural timber with preservative treatment .12

5.6 Geometrical data .12

6 Assessment and verification of constancy of performance –AVCP .13

6.1 General .13

6.2 Type testing .13

6.2.1 General .13

6.2.2 Test samples, testing and compliance criteria .13

6.2.3 Test reports .14

6.2.4 Shared other party results .15

6.3 Factory production control (FPC) .15

6.3.1 General .15

6.3.2 Requirements .15

6.3.3 Product specific requirements .19

6.3.4 Initial inspection of factory and of FPC .20

6.3.5 Continuous surveillance of FPC .20

6.3.6 Procedure for modifications .20

7 Marking .21

7.1 Marking methods .21

7.2 Information on the timber (method A) or on the package (method B) .21

7.3 Information in the documents accompanying strength graded structural timber .22

8 Environmental issues .23

Annex A (normative) Requirements for strength reducing characteristics for visual grading

standards .24

A.1 Limitations for strength-reducing characteristics .24

A.1.1 Knots .24

A.1.2 Slope of grain .24

A.1.3 Density and rate of growth . 24

A.1.4 Fissures . 25

A.2 Limitations for geometrical characteristics . 25

A.2.1 Wane . 25

A.2.2 Warp . 25

A.3 Limitations for biological characteristics . 26

A.4 Other characteristics . 26

A.4.1 Reaction wood . 26

A.4.2 Other criteria . 26

Annex B (normative) Marking codes for species . 27

B.1 Marking codes for single species . 27

B.2 Marking codes for species combination . 28

Annex C (normative) Measurement of moisture content . 30

C.1 General . 30

C.2 Measurement of moisture content of timber during production. 30

Annex ZA (informative) Relationship of this European Standard with Regulation (EU)

No.305/2011 . 31

ZA.1 Scope and relevant characteristics . 31

ZA.2 System of Assessment and Verification of Constancy of Performance (AVCP) . 33

ZA.3 Assignment of AVCP tasks . 33

Bibliography . 36

European foreword

This document (EN 14081-1:2016) has been prepared by Technical Committee CEN/TC 124 “Timber

structures”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2020, and conflicting national standards

shall be withdrawn at the latest by May 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1, approved by CEN on 2019-05-14.

This document supersedes !EN 14081-1:2016".

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Regulation n°305/2011.

For relationship with EU Regulation, see informative Annex ZA, which is an integral part of this

document.

EN 14081-4:2009 will be withdrawn and replaced by 5.1.3, paragraph 2 of this document.

Compared to EN 14081-1:2005+A1:2011, the following modifications have been made:

— new Clause 6 for Assessment and Verification of Constancy of Performance linked to the CPR;

— Annex ZA has been adapted to the CPR;

— new clauses on Fire Resistance, release of dangerous substances, geometrical data and

environmental issues have been added;

— marking codes for species combinations have been moved to Annex B;

— improvement of several definitions.

Other parts of the series of EN 14081 are:

— EN 14081-2, Timber structures - Strength graded structural timber with rectangular cross section -

Part 2: Machine grading; additional requirements for initial type testing;

— EN 14081-3, Timber structures - Strength graded structural timber with rectangular cross section -

Part 3: Machine grading; additional requirements for factory production control.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

There are basically two methods of strength grading: visual grading and machine grading.

Machine grading is in common use in a number of countries. The countries use two basic systems,

referred to as 'output control' and 'machine control'. Both systems require a visual override inspection

to cater for strength-reducing characteristics that are not automatically sensed by the machine.

Output control is suitable for use where the grading machines are situated in manufacturing units

grading limited sizes, species and grades in repeated production runs. This enables the system to be

controlled by testing timber specimens from the daily output. These tests, together with statistical

procedures, are used to monitor and adjust the machine settings to maintain the required strength

properties for each strength class. With this system it is permissible for machine approval requirements

to be less demanding and for machines of the same type to have non-identical performance.

Machine control was developed in Europe. Because of the large number of sizes, species and grades

used it was not possible to carry out quality control tests on timber specimens drawn from production.

Machine control relies, therefore, on the machines being strictly assessed and controlled, and on

considerable research effort to derive the machines settings, which remain constant for all machines of

the same type.

Visual grading is also in common use in a number of countries. There are many different visual strength

grading standards for timber in use in Europe. These have come into existence to allow for:

— different species or groups of species;

— geographic origin;

— different dimensional requirements;

— varying requirements for different uses;

— quality of material available;

— historic influences or traditions.

Because of the diversity of existing visual grading standards in use in different countries, it is currently

impossible to lay down a single standard for all Member States.

The requirements given in this European Standard on visual strength grading are therefore basic

principles, which should be followed when drawing up requirements for limits for some of the

characteristics.

The assignments to strength classes are based on grading reports.

When these grading reports are evaluated and approved by CEN/TC 124/WG2/TG1, they become

Approved Grading Reports (AGR) which are required for assigning visual grades to EN 1912 and for

machine control.

1 Scope

This European Standard specifies requirements for strength graded structural timber with rectangular

cross-sections either visual or machine graded, shaped by sawing, planning or other methods and with

cross-sectional dimensions complying with EN 336 (referred to as structural timber in the following

clauses).

This European Standard includes provisions for test methods, Assessment and Verification of Constancy

of Performance and marking of structural timber.

NOTE 1 For machine strength graded timber additional provisions for type testing (TT) are given in EN 14081–

2 and for factory production control (FPC) in EN 14081–3.

NOTE 2 An acceptance procedure for verification of a lot is given in EN 14358 which may be used for a delivery

of structural timber.

This European Standard identifies characteristics for which limits have to be given in visual grading

standards.

This European Standard covers structural timber, untreated or treated against biological attack.

This European Standard does not cover:

— timber treated by fire retardant products to improve its fire performance;

— thermally and/or chemically modified timber;

— structural finger jointed timber.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 338, Structural timber — Strength classes

EN 350-1, Durability of wood and wood-based products — Natural durability of solid wood — Part 1:

Guide to the principles of testing and classification of the natural durability of wood

EN 350-2, Durability of wood and wood-based products — Natural durability of solid wood — Part 2:

Guide to natural durability and treatability of selected wood species of importance in Europe

EN 384, Structural timber — Determination of characteristic values of mechanical properties and density

EN 844-7, Round and sawn timber — Terminology — Part 7: Terms relating to anatomical structure of

timber

EN 844-9, Round and sawn timber — Terminology — Part 9: Terms relating to features of sawn timber

EN 844-10, Round and sawn timber — Terminology — Part 10: Terms relating to stain and fungal attack

EN 1310:1997, Round and sawn timber — Method of measurement of features

EN 1912, Structural Timber — Strength classes — Assignment of visual grades and species

EN 1995-1-2, Eurocode 5: Design of timber structures — Part 1-2: General — Structural fire design

EN 13183-2, Moisture content of a piece of sawn timber — Part 2: Estimation by electrical resistance

method

EN 13183-3, Moisture content of a piece of sawn timber — Part 3: Estimation by capacitance method

EN 13238, Reaction to fire tests for building products — Conditioning procedures and general rules for

selection of substrates

EN 13501-1, Fire classification of construction products and building elements — Part 1: Classification

using test data from reaction to fire tests

EN 13501-2, Fire classification of construction products and building elements — Part 2: Classification

using data from fire resistance tests, excluding ventilation services

EN 13556, Round and sawn timber — Nomenclature of timbers used in Europe

EN 13823, Reaction to fire tests for building products — Building products excluding floorings exposed to

the thermal attack by a single burning item

EN 14081-2, Timber structures — Strength graded structural timber with rectangular cross section —

Part 2: Machine grading; additional requirements for initial type testing

EN 14081-3, Timber structures — Strength graded structural timber with rectangular cross section —

Part 3: Machine grading; additional requirements for factory production control

EN 15804, Sustainability of construction works — Environmental product declarations — Core rules for

the product category of construction products

EN 15228:2009, Structural timber — Structural timber preservative treated against biological attack

EN 16485, Round and sawn timber — Environmental Product Declarations — Product category rules for

wood and wood-based products for use in construction

EN ISO 3166-1, Codes for the representation of names of countries and their subdivisions — Part 1:

Country codes (ISO 3166-1)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

dry-graded structural timber

timber for which grading has been completed after it has been dried

3.2

grading standard

a set of grading rules contained in a National Standard or a proprietary document that is publically

available

3.3

machine strength grading

process by which structural timber is sorted by a machine sensing, non-destructively, one or more

properties of the timber, with any necessary visual overriding inspection, into grades or strength

classes to which characteristic values of strength, stiffness and density may be allocated

3.4

package

structural timber of one grade, of one species or species combination, to be delivered to one customer

3.5

settings

values associated with the variable controls of a grading machine which determine the acceptance to

each grade or strength class of structural timber graded by the machine

3.6

strength class

result of the classification of structural timber based on particular values of its mechanical properties

and density

3.7

structural timber

timber with rectangular cross section strength graded either by visual means or by machine

3.8

strength-reducing characteristic

property or feature of a piece of structural timber that reduces its load bearing capacity

Note 1 to entry: Can result from natural growth of the tree (e.g. knots, slope of grain), changes in moisture

content (e.g. fissures), conversion of the log (e.g. the inclusion of wane), attack from fungi, insects or mechanical

damage.

3.9

timber source

identifiable geographical origin of a species or species combination from which timber is, or is intended

to be, strength graded

3.10

visual strength grading

process by which structural timber is sorted, by visual inspection and assessment, into grades to which

characteristic values of strength, stiffness and density can be allocated

Note 1 to entry: Electronic or mechanical instruments can be used to assist the visual grader in this process.

3.11

thickness

smaller dimension perpendicular to the longitudinal axis of a piece of timber

3.12

width

greater dimension perpendicular to the longitudinal axis of a piece of timber

4 Symbols

M machine graded structural timber

DG dry-graded structural timber

PT preservative treated structural timber

5 Requirements for structural timber

5.1 Mechanical resistance

5.1.1 General

Mechanical resistance covers modulus of elasticity, bending strength, compressive strength, tension

strength, shear strength and density.

Structural timber shall be either visually graded according to 5.1.2, or machine graded according to

5.1.3, and have characteristic values for the bending strength, tension strength, compression strength,

shear strength, modulus of elasticity and density according to 5.1.2 or 5.1.3. Characteristic values shall

be determined in accordance with EN 384.

If the structural timber is assigned to a strength class from EN 338, the characteristic values for the

properties shall be those given for the strength class in EN 338.

If the grading has been carried out before processing, provided that the processing reduction is not

greater than 5 mm for dimensions greater than or equal to 22 mm but less than or equal to 100 mm, or

not greater than 10 mm for dimensions greater than 100 mm, the grade shall be considered not to have

changed. If the reduction is greater, the structural timber shall be re-graded.

Structural timber that has previously been graded shall not be re-graded to the same or different grades

unless the method of determining characteristic values has made allowances for changes to the timber

population caused by the previous grading.

Since some geometrical characteristics (fissures, distortion) depend on the moisture content and affect

the strength properties, marking shall consider the moisture content at the time of grading.

Moisture content shall be determined in accordance with EN 13183-2 or EN 13183-3 with an accuracy

of ± 3 % moisture content (see Annex C).

Dry graded structural timber shall have at the time it is graded for fissures and distortion, a mean

moisture content of 20 % or less with no individual measurement exceeding 24 %.

If the grading method restricts the structural timber to a special use, e.g. flatwise bending or

compression, this shall be reflected in the marking.

5.1.2 Visual strength grading

Structural timber shall be graded visually in accordance with a grading standard which meets the

requirements given in Annex A. This grading standard shall be publically available.

If the grade and species or species combination have been assigned to a strength class by EN 1912, the

characteristic values for the properties shall be those given for the assigned strength class in EN 338.

Assignments according to EN 384 to be included in EN 1912 should be reported and evaluated by

CEN/TC 124. Accepted reports shall be documented in Approved Grading Reports (AGR).

NOTE Approved Grading Reports are intended to give basic documentation for the certification by a Notified

Body of a manufacturer's factory production control (FPC) needed for the CE marking. A current list of AGRs may

be obtained through CEN/TC 124 secretariat.

If there are any restrictions or additional criteria related to the strength or use of structural timber,

resulting from the method of grading or species or species combination, they shall be stated in the

grading standard.

5.1.3 Machine strength grading

For a grade and species (or species combination) graded by a machine control system, the settings shall

be derived for the total growth area from which the structural timber will be sourced.

Grading machines shall use settings determined in accordance with EN 14081-2. Grading machines and

settings used in machine control system should be evaluated by CEN/TC 124. Settings which have been

accepted by CEN/TC 124 shall be documented in Approved Grading Reports (AGR).

NOTE Approved Grading Reports are intended to give basic documentation for the certification by a Notified

Body of a manufacturer's factory production control (FPC) needed for the CE marking. A current list of AGRs may

be obtained through CEN/TC 124 secretariat.

The visual characteristics of each piece of machine graded structural timber shall meet the

requirements given in Table 1.

Table 1 — Visual override inspection requirements for machine strength graded structural

timber

Strength class according to C18, D18, T11 and below Above C18, D18, T11

a

EN 338

f

Max. length Fissures not

Fissures less than half the thickness may be ignored

b

going through

of fissures

Not greater than 1,5 m or 1/2 the length Not greater than 1 m or 1/4 the

the thickness

of the piece, whichever is the lesser length of the piece, whichever is

the lesser

Fissures going Not greater than 1 m or 1/4 the length of Only permitted at the ends with

through the the piece, whichever is the lesser. If at a length not greater than the

thickness the ends, a length not greater than two width of the piece

times the width of the piece

c

Bow 20 mm 10 mm

Max. warp

in mm over

Spring 12 mm 8 mm

2 m of length

Twist 2 mm/25 mm width 2 mm/25 mm width

Cup Unrestricted Unrestricted

Wane Wane shall not be greater than one third of the full edge and/or face

dimensions of the piece

d

Soft rot shall not be permitted Soft rot shall not be permitted

Soft rot and dote (see

EN 844–10)

Dote is permitted Dote shall not be permitted

Insect damage Active infestation shall not be permitted. Insect holes above 2 mm diameter

shall not be permitted. Smaller holes shall be assessed as other defects

e

Where the reduction in strength caused by another defect is obviously less

Other defects

than caused by defects permitted by this table, the piece may be accepted

provided the defect is of a type that will not increase after conversion and

drying

a

For alternative strength classes, visual overrides are checked with corresponding strength value limits

b

The length of fissures is linked with moisture content and therefore the limits given apply only at the time of grading.

Permitted limits for both the depth and length of fissures refer to the sum of fissures in one plane in a piece of timber.

c

Warp is influenced by moisture content, so the limits apply only at the time of grading. Longitudinal curvature in

square section pieces may be assessed using the limits for bow.

d

Stain is not a structural defect and is acceptable without limitation.

e

Other defects include for example mechanical damage, top rupture, and included bark.

f

A 0,2 mm feeler gauge is a suitable device for measuring fissure depth.

Where a machine does not grade completely to the ends of each piece of structural timber (as in

bending type machines) the ungraded portions shall be visually inspected and assessed.

If the diameter of knots and slope of grain in the incompletely graded portions exceeds the limits given

in Table 2, then the piece of structural timber shall be rejected. Knots and slope of grain shall be

measured in accordance with EN 1310:1997, 4.1.2.

Table 2 — Visual override inspection requirements for incompletely machine graded portions

a

Strength class according to EN 338

C18, D18, T11 and below Above C18, D18, T11

Knot diameter on face up to 1/2 x width of piece up to 1/4 x width of piece

Knot diameter on edge up to 3/4 x thickness of piece up to 1/2 x thickness of piece

Slope of grain 1 in 6 1 in 10

NOTE 1 These limits are applicable only where the size of knots and slope of grain in the non-fully graded portion

exceeds the size of similar characteristics in the fully graded portion of the same piece.

NOTE 2 The knot diameter is measured perpendicular to the longitudinal axis of the piece of timber. For arris knots

the above limits apply to the portion of the knot visible on the particular face or edge being considered.

a

For alternative strength classes, visual overrides are checked with corresponding strength value limits.

5.2 Fire resistance (charring rate)

Where required, the fire resistance performance of the structural timber whether treated against

biological attack or not, shall be tested and declared according to EN 13501-2 or determined by

calculation according to EN 1995-1-2. When calculating the fire resistance, the charring rate shall be

evaluated on the basis of the species and characteristic density.

5.3 Reaction to fire

The class of reaction to fire performance of the structural timber (including the additional classification

on smoke production and flaming droplets/particles, if any), shall be determined and declared

according to EN 13501-1:

a) either without the need for further testing (CWFT), as given in Table 3 , if the structural timber is

proved to meet the requirements of the class also given therein;

b) or based on testing of the timber according to the standards, referred to in EN 13501-1, when the

timber does not meet the requirements of Table 3 or where a higher classification than the one in a)

is sought.

Table 3 — Structural timber considered as classified without the need for further testing (CWFT)

b

Product Product detail Minimum Minimum

Class

a

mean overall

(excluding

c

thickness

density floorings)

(mm)

(kg/m )

Structural Visual and machine graded structural timber 350 22 D-s2, d0

timber with rectangular cross-sections shaped by

sawing, planing or other methods or with

round cross-sections

a

Applies to all species covered by the product standards.

b

Class as provided for in Table 1 of the Annex to Decision 2000/147/EC.

c

Conditioned according to EN 13238.

This table is the same as given in the Decision of the Commission 2003/43/EC of 2003-01-17 (see OJEU L13 of 2003-01-18), as amended

firstly by 2003/593/EC of 2003-08-07 (see OJEU L201 of 2003-08-08).

NOTE The minimum mean density is the minimum value of the mean density for which the table applies. This

density may be taken from tables as in EN 338.

When tested according to EN 13823 under option b), the structural timber shall be mounted and fixed

in accordance with the following:

a) the whole area of both wings in the SBI apparatus shall be covered with timber pieces mounted

edge to edge (butt jointed), without jointing or bonding and orientated horizontally or vertically,

supported by;

b) timber battens, minimum (40 × 40) mm, fixed to the test backing boards at 400 mm to 600 mm

centres horizontally or vertically (perpendicular to the orientation of the timber pieces).

In the case of preservative treated timber, it may be necessary to take into account additional

provisions set by EN 15228.

5.4 Release of dangerous substances

National Regulations on dangerous substances may require verification and declaration on release

/content of dangerous substances when construction products covered by this standard are placed on

those markets.

NOTE 1 This only concerns treated timber.

In the absence of European harmonized test methods, verification and declaration on release/content

on dangerous substances should be done taking into account national provisions in the place of use.

NOTE 2 An informative database covering European and national provisions on dangerous substances is

available at the Construction website on EUROPA accessed through:

http://ec.europa.eu/enterprise/construction/cpd-ds

5.5 Biological durability

5.5.1 Structural timber without preservative treatment

The natural durability in accordance with EN 350-2 shall be declared with specific reference being

made to sapwood if the producer makes no special provision for its exclusion.

For species and origins not listed in EN 350-2, the natural durability shall be assessed according to

EN 350-1.

5.5.2 Structural timber with preservative treatment

If a preservative treatment is used, information in accordance with EN 15228 shall be declared.

NOTE 1 It is acceptable to use a safe relationship which has been established between the penetration and/or

retention requirements and measurable features of the treatment process used as described in EN 351–1.

NOTE 2 Guidance on the relationship between treatment variables and the application of the product into

particular Use Class (EN 335) may be found in national documents, which cross reference the appropriate

European Standard

5.6 Geometrical data

The target sizes, in accordance with EN 336, are specified in the accompanying commercial documents.

Deviations from the target sizes shall not exceed the limits of the appropriate tolerance class declared.

6 Assessment and verification of constancy of performance –AVCP

6.1 General

The compliance of strength graded timber with the requirements of this standard and with the

performances (including strength grades or strength classes) declared by the manufacturer shall be

demonstrated by:

— determination of the product-type on the basis of type testing;

— factory production control by the manufacturer, including product assessment if applicable.

The manufacturer shall always retain the overall control and shall have the necessary means to take

responsibility for the conformity of the product with its declared performance(s).

6.2 Type testing

6.2.1 General

All performances related to essential characteristics included in this standard (see characteristics

written in bold letters in Table 4) shall be determined when the manufacturer intends to declare the

respective performances unless the standard gives provisions for declaring them without performing

tests (e.g. use of previously existing data, Classification Without Further Testing (CWFT) and

conventionally accepted performance).

For machine strength graded timber, product-type determination shall be carried out in accordance

with EN 14081-2.

Assessment previously performed in accordance with the provisions of this standard, may be taken into

account provided that this was made to the same or a more rigorous test method, under the same AVCP

system on the same product type, such that the results are applicable to the product type in question.

For the purposes of assessment, the manufacturer's products may be grouped into families, where it is

considered that the results for one or more characteristics from any one product within the family are

representative for that same characteristics for all products within that same family.

NOTE Products may be grouped in different families for different essential characteristics.

Reference to the assessment method standards (e.g. EN 384 in general, and EN 14081–2 for machine

graded timber) should be made to allow the selection of a suitable representative sample.

In addition, the determination of the product-type shall be carried out for all essential characteristics

included in the standard for which the manufacturer declares the performance:

— at the beginning of the production of a new or modified strength graded timber (unless a member

of the same product range), or

— at the beginning of a new or modified method of production (where this may affect the stated

properties); or

— they shall be repeated for the appropriate essential characteristic(s), whenever a change occurs in,

the raw material, or in the method of production (subject to the definition of a family), which would

affect significantly one or more of the essential characteristics.

6.2.2 Test samples, testing and compliance criteria

The number of samples of strength graded timber to be tested/ assessed shall be in accordance with

Table 4.

Table 4 — Number of samples to be tested and compliance criteria for strength graded

structural timber with rectangular cross section

Characteristics Requirement Assessment method No. of samples Compliance criteria

Mechanical resistance of strength graded timber expressed as modulus of elasticity, bending strength,

compressive strength, tensile strength and shear strength

Strength, stiffness Visual grading: EN 384 (test) According to EN 384 Characteristic values

and density 5.1.1 and 5.1.2 determined according

properties of to EN 384 shall not be

timber less than declared

values.

Machine EN 14081–2 and According to Characteristic values

grading: EN 384 (test) EN 14081–2 shall be determined in

accordance with

5.1.1 and 5.1.3

EN 14081–2.

Fire resistance (charring rate)

Fire resistance 5.2 Test according to According to EN 13501–2

(charring rate) EN 13501–2, or EN 13501–2

According to EN 384

Determine, According to EN 384

characteristic density,

and species

Reaction to fire

Reaction to fire 5.3 Table 3 (CWFT) – Table 3

or 5.3b)(test) according to Classes according to

EN 13501–1 EN 13501–1

Durability of all characteristics expressed as durability against biological attack

Without 5.5.1 For species listed in – Natural durability in

preservative EN 350–2 accordance with

treatment (assessment) EN 350–2

For species and origins

not listed in EN 350–2,

assessed according to

EN 350–1

With 5.5.2 According to EN 15228 According to According to EN 15228

preservative (test) EN 15228

treatment

Release of dangerous substances

Release of 5.4 As relevant, according to 5.4

dangerous

substances

6.2.3 Test reports

All test reports and Approved Grading Reports (where applicable) shall be documented and retained by

the manufacturer for at least 10 years after the last date of production of the strength graded timber to

which they relate.

6.2.4 Shared other party results

A manufacturer may use the results of the product-type determination obtained by someone else (e.g.

by another manufacturer, as a common service to manufacturers, or by a product developer), to justify

his own declaration of performance regarding a product that is manufactured with raw materials, and

manufacturing methods of the same kind, provided that:

— the results are known to be valid for products with the same essential characteristics relevant for

the product performance;

— in addition to any information essential for confirming that the product has such same

performances related to specific essential characteristics, the other party who has carried out the

determination of the product-type concerned or has had it carried out, has expressly accepted to

transmit to the manufacturer the results and the test report to be used for the latter’s product-type

determination, as well as information regarding production facilities and the production control

process that can be taken into account for FPC;

— the manufacturer using other party results:

— ensures that the product has the same characteristics relevant for performance as the one that

has been subjected to the determination of the product-type, and that there are no significant

differences with regard to production facilities and the production control process compared

to that used for the product that was subjected to the determination of the product-type; and

— keeps available a copy of the determination of the product-type report that also contains the

information needed for verifying that the product is manufactured with raw materials and

manufacturing methods of the same kind.

6.3 Factory production control (FPC)

6.3.1 General

The manufacturer shall establish, document and maintain an FPC system to ensure that the products

placed

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...