oSIST prEN 13040-1:2025

(Main)Soil improvers and growing media - Sample preparation - Part 1: Sample preparation for chemical and physical tests, determination of dry matter content, moisture content and laboratory bulk density

Soil improvers and growing media - Sample preparation - Part 1: Sample preparation for chemical and physical tests, determination of dry matter content, moisture content and laboratory bulk density

This document specifies a routine method for preparing a sample of organic soil improver, inorganic soil improver, growing medium, compost or digestate prior to chemical analysis and physical testing. The procedures described herein apply only to those samples that are supplied to a laboratory in the form in which they will be used for their intended purpose and to samples with a manufacturer’s guidance for reconstitution.

NOTE 1 The determination of the laboratory bulk density is given in Annex A.

NOTE 2 The results of an interlaboratory trial to determine moisture content are given in Annex B.

NOTE 3 The results of an interlaboratory trial to determine laboratory bulk density are given in Annex B.

Bodenverbesserungsmittel und Kultursubstrate - Probenvorbereitung - Teil 1: Probenvorbereitung für chemische und physikalische Untersuchungen, Bestimmung des Trockensubstanzgehalts, des Feuchtigkeitsgehalts und der Laborschüttdichte

Dieses Dokument legt ein Routineverfahren für die Herstellung von Proben von organischen Bodenverbesserungsmitteln, anorganischen Bodenverbesserungsmitteln, Kultursubstraten, Kompost oder Gärrückständen vor der chemischen und physikalischen Untersuchung fest. Die hierin beschriebenen Verfahren sind nur auf solche Proben anwendbar, die einem Labor in dem Zustand zur Verfügung gestellt werden, in dem sie für einen bestimmten Zweck verwendet werden, sowie auf Proben, denen eine Anleitung des Herstellers für die Rekonstitution beiliegt.

ANMERKUNG 1 Die Bestimmung der Laborschüttdichte wird in Anhang A beschrieben.

ANMERKUNG 2 Die Ergebnisse eines Ringversuchs zur Bestimmung des Feuchtegehaltes sind in Anhang B zusammengestellt.

ANMERKUNG 3 Die Ergebnisse eines Ringversuchs zur Bestimmung der Laborschüttdichte sind in Anhang B zusammengestellt.

Amendements du sol et supports de culture - Préparation des échantillons - Partie 1 : Préparation des échantillons pour les essais chimiques et physiques, détermination de la teneur en matière sèche, du taux d’humidité et de la masse volumique apparente en laboratoire

Le présent document spécifie une méthode de routine pour préparer un échantillon d’amendement organique, d’amendement inorganique, de support de culture, de compost ou de digestat avant analyse chimique et essais physiques. Les modes opératoires décrits s’appliquent aux échantillons fournis au laboratoire sous la forme qui sera celle de leur utilisation finale et aux échantillons dont la reconstitution est recommandée par le fabricant.

NOTE 1 L’Annexe A décrit une méthode de détermination de la masse volumique apparente en laboratoire.

NOTE 2 L’Annexe B donne les résultats d’un essai interlaboratoires relatif à la détermination du taux d’humidité.

NOTE 3 L’Annexe B donne les résultats d’un essai interlaboratoires destiné à déterminer la masse volumique apparente en laboratoire.

Izboljševalci tal in rastni substrati - Priprava vzorcev - 1. del: Priprava vzorcev za kemijske in fizikalne preskuse, določanje suhe snovi, vlage in laboratorijsko stisnjene prostorninske gostote

General Information

- Status

- Not Published

- Public Enquiry End Date

- 19-Dec-2025

- Technical Committee

- KAT - Soil quality

- Current Stage

- 4020 - Public enquire (PE) (Adopted Project)

- Start Date

- 17-Oct-2025

- Due Date

- 06-Mar-2026

- Completion Date

- 19-Dec-2025

Relations

- Effective Date

- 01-Dec-2025

Overview

prEN 13040-1 (CEN draft, 2025) defines a routine sample preparation method for soil improvers and growing media prior to chemical and physical testing. It covers preparation of laboratory samples of organic and inorganic soil improvers, growing media, compost and digestate, and specifies determination of dry matter content, moisture content and laboratory bulk density. The draft will supersede EN 13040:2007 and is produced by CEN/TC 223.

Key topics and technical requirements

- Scope and applicability

- Applies to samples supplied to a laboratory in the form they will be used, or reconstituted per manufacturer guidance.

- Matrix classification

- Four matrix types determine pre-treatment:

- Solid (estimated dry matter ≥ 30% m/m)

- Shear‑resistant pasty (15–30% m/m)

- Liquid / aqueous pasty (< 15% m/m)

- Pre‑shaped (e.g., mineral wool, PU blocks)

- Four matrix types determine pre-treatment:

- Sample handling and storage

- Sampling itself is out of scope (see EN 12579:2024).

- On receipt, samples must be identified and sufficient for required tests.

- Storage recommendations: closed polyethylene bag, fill container, 3 °C ± 2 °C; fresh materials analysed within 2 weeks; retain samples a minimum of 28 days after reporting.

- Preparation procedures

- Mixing, gentle de‑agglomeration, removal of macroscopic impurities (unless required), and sub‑sampling (coning and quartering) to produce representative test samples.

- Apparatus examples include sieves (20, 25, 40, 60 mm), analytical balance, laboratory blender, and cutting tools.

- Analytical principles

- Dry matter and moisture: determined by oven drying (residual moisture procedures also addressed).

- Laboratory bulk density: measured by weighting a defined volume (Annex A normative).

- Validation: performance and interlaboratory trial results provided (Annex B informative).

Applications and users

This standard is essential for:

- Testing laboratories performing chemical and physical analysis of compost, digestate, potting media and soil amendments.

- Manufacturers and quality control teams of growing media, soil improvers and pre‑shaped substrates.

- Regulators, certification bodies and buyers requiring reproducible moisture, dry matter and bulk density data.

- Research organizations comparing products or monitoring production consistency.

Related standards

- EN 12579:2024 - Soil improvers and growing media - Sampling

- CEN/TS 17732:2022 - Terminology for soil improvers and growing media

- EN 12580:2022 - Determination of a quantity

- prEN 15761:2022 - Pre‑shaped growing media dimensions and bulk density

Keywords: prEN 13040-1, soil improvers, growing media, sample preparation, dry matter content, moisture content, laboratory bulk density, compost, digestate, CEN.

Frequently Asked Questions

oSIST prEN 13040-1:2025 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Soil improvers and growing media - Sample preparation - Part 1: Sample preparation for chemical and physical tests, determination of dry matter content, moisture content and laboratory bulk density". This standard covers: This document specifies a routine method for preparing a sample of organic soil improver, inorganic soil improver, growing medium, compost or digestate prior to chemical analysis and physical testing. The procedures described herein apply only to those samples that are supplied to a laboratory in the form in which they will be used for their intended purpose and to samples with a manufacturer’s guidance for reconstitution. NOTE 1 The determination of the laboratory bulk density is given in Annex A. NOTE 2 The results of an interlaboratory trial to determine moisture content are given in Annex B. NOTE 3 The results of an interlaboratory trial to determine laboratory bulk density are given in Annex B.

This document specifies a routine method for preparing a sample of organic soil improver, inorganic soil improver, growing medium, compost or digestate prior to chemical analysis and physical testing. The procedures described herein apply only to those samples that are supplied to a laboratory in the form in which they will be used for their intended purpose and to samples with a manufacturer’s guidance for reconstitution. NOTE 1 The determination of the laboratory bulk density is given in Annex A. NOTE 2 The results of an interlaboratory trial to determine moisture content are given in Annex B. NOTE 3 The results of an interlaboratory trial to determine laboratory bulk density are given in Annex B.

oSIST prEN 13040-1:2025 is classified under the following ICS (International Classification for Standards) categories: 65.080 - Fertilizers. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN 13040-1:2025 has the following relationships with other standards: It is inter standard links to SIST EN 13040:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

oSIST prEN 13040-1:2025 is associated with the following European legislation: EU Directives/Regulations: 2019/1009; Standardization Mandates: M/564, M/564 AMD 1, M/564 AMD 2, M/XXX. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

oSIST prEN 13040-1:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2025

Izboljševalci tal in rastni substrati - Priprava vzorcev - 1. del: Priprava vzorcev za

kemijske in fizikalne preskuse, določanje suhe snovi, vlage in laboratorijsko

stisnjene prostorninske gostote

Soil improvers and growing media - Sample preparation - Part 1: Sample preparation for

chemical and physical tests, determination of dry matter content, moisture content and

laboratory bulk density

Bodenverbesserungsmittel und Kultursubstrate - Probenvorbereitung - Teil 1:

Probenvorbereitung für chemische und physikalische Untersuchungen, Bestimmung des

Trockensubstanzgehalts, des Feuchtigkeitsgehalts und der Laborschüttdichte

Amendements du sol et supports de culture - Préparation des échantillons - Partie 1 :

Préparation des échantillons pour les essais chimiques et physiques, détermination de la

teneur en matière sèche, du taux d’humidité et de la masse volumique apparente en

laboratoire

Ta slovenski standard je istoveten z: prEN 13040-1

ICS:

65.080 Gnojila Fertilizers

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

October 2025

ICS 65.080 Will supersede EN 13040:2007

English Version

Soil improvers and growing media - Sample preparation -

Part 1: Sample preparation for chemical and physical tests,

determination of dry matter content, moisture content and

laboratory bulk density

Amendements du sol et supports de culture - Bodenverbesserungsmittel und Kultursubstrate -

Préparation des échantillons - Partie 1 : Préparation Probenvorbereitung - Teil 1: Probenvorbereitung für

des échantillons pour les essais chimiques et chemische und physikalische Untersuchungen,

physiques, détermination de la teneur en matière Bestimmung des Trockensubstanzgehalts, des

sèche, du taux d'humidité et de la masse volumique Feuchtigkeitsgehalts und der Laborschüttdichte

apparente en laboratoire

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 223.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 13040-1:2025 E

worldwide for CEN national Members.

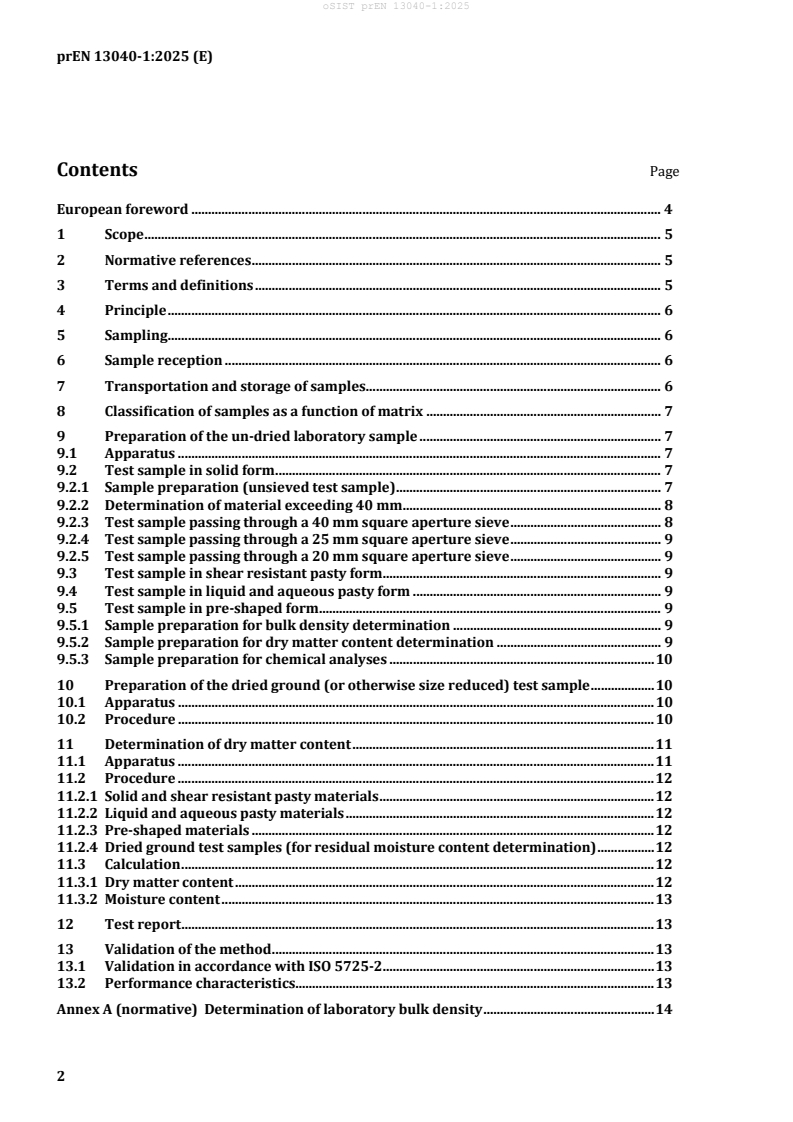

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Principle . 6

5 Sampling . 6

6 Sample reception . 6

7 Transportation and storage of samples . 6

8 Classification of samples as a function of matrix . 7

9 Preparation of the un-dried laboratory sample . 7

9.1 Apparatus . 7

9.2 Test sample in solid form . 7

9.2.1 Sample preparation (unsieved test sample) . 7

9.2.2 Determination of material exceeding 40 mm . 8

9.2.3 Test sample passing through a 40 mm square aperture sieve . 8

9.2.4 Test sample passing through a 25 mm square aperture sieve . 9

9.2.5 Test sample passing through a 20 mm square aperture sieve . 9

9.3 Test sample in shear resistant pasty form. 9

9.4 Test sample in liquid and aqueous pasty form . 9

9.5 Test sample in pre-shaped form . 9

9.5.1 Sample preparation for bulk density determination . 9

9.5.2 Sample preparation for dry matter content determination . 9

9.5.3 Sample preparation for chemical analyses . 10

10 Preparation of the dried ground (or otherwise size reduced) test sample . 10

10.1 Apparatus . 10

10.2 Procedure . 10

11 Determination of dry matter content . 11

11.1 Apparatus . 11

11.2 Procedure . 12

11.2.1 Solid and shear resistant pasty materials . 12

11.2.2 Liquid and aqueous pasty materials . 12

11.2.3 Pre-shaped materials . 12

11.2.4 Dried ground test samples (for residual moisture content determination) . 12

11.3 Calculation . 12

11.3.1 Dry matter content . 12

11.3.2 Moisture content . 13

12 Test report . 13

13 Validation of the method . 13

13.1 Validation in accordance with ISO 5725-2. 13

13.2 Performance characteristics. 13

Annex A (normative) Determination of laboratory bulk density . 14

Annex B (informative) Performance characteristics of the method . 19

Bibliography . 22

European foreword

This document (prEN 13040-1:2025) has been prepared by Technical Committee CEN/TC 223 “Soil

improvers and growing media”, the secretariat of which is held by NEN.

This document is currently submitted to CEN Enquiry.

This document will supersede EN 13040:2007.

— The title has been changed;

— Clause 7 (Transportation and storage of samples) has been completed;

— Clause 8 (Classification of samples as function of matrix) has been introduced;

— In Clause 9 (Preparation of the un-dried laboratory sample) new types of test samples have been

added;

— Clause 10 (Preparation of the dried ground (or otherwise size reduced) test samples) has been

updated;

— In Clause 11 (Determination of dry matter content) new types of test samples included the dried

ground sample for the residual moisture content determination, have been added;

— Annex A has been completed considering different procedures to determine laboratory bulk density

depending on the classification of samples as function of matrix (Clause 8);

— Formula (A.1) and A.2 have been modified.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

1 Scope

This document specifies a routine method for preparing a sample of organic soil improver, inorganic soil

improver, growing medium, compost or digestate prior to chemical analysis and physical testing. The

procedures described herein apply only to those samples that are supplied to a laboratory in the form in

which they will be used for their intended purpose and to samples with a manufacturer’s guidance for

reconstitution.

NOTE 1 The determination of the laboratory bulk density is given in Annex A.

NOTE 2 The results of an interlaboratory trial to determine moisture content are given in Annex B.

NOTE 3 The results of an interlaboratory trial to determine laboratory bulk density are given in Annex B.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

CEN/TS 17732:2022, Soil improvers and growing media — Terminology

EN 12579:2024, Soil improvers and growing media — Sampling

EN 12580:2022, Soil improvers and growing media — Determination of a quantity

prEN 15761:2022, Pre-shaped growing media — Determination of the dimensions measured and bulk

density

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 12579:2024,

CEN/TS 17732:2022 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

test sample

sample prepared from the laboratory sample and from which test portions will be taken

3.2

test portion

quantity of material drawn from the test sample (or from the laboratory sample if both are the same) and

on which the tests or observations are actually carried out

3.3

laboratory compacted bulk density

density, expressed in grams per litre of the material as determined in the laboratory using a cylinder of

known volume; the sample being compacted under defined conditions

4 Principle

The laboratory sample is coded and sub-divided to prepare the test sample in such a manner as to be

representative of the sample as submitted to the laboratory. Dry matter and humidity content are

determined by oven drying and laboratory bulk density is determined by weighting a known volume of

the material.

5 Sampling

Sampling is not part of the method specified in this document. Follow EN 12579:2024 dealing with soil

improvers and growing media. It is important that the laboratory receives a sample that is representative

of the product under consideration. The sample should not have been damaged or changed during

transport or storage.

6 Sample reception

Upon receipt of the laboratory sample, the laboratory shall confirm that the sample relates to the

accompanying documentation. The sampler shall submit with the sample, at least the following minimum

requirements:

a) name of the client;

b) to whom the results shall be reported, if different from a);

c) place and date the sample was taken;

d) name of the sampler;

e) discrete sample identification;

f) analysis required.

The laboratory shall confirm that a sufficient sample has been provided for the analyses to be undertaken

by recording the date the sample was received and giving the sample a unique laboratory identification

code. This code shall be recorded on all subsequent sub sample containers and on the documentation

supplied with the sample.

7 Transportation and storage of samples

The laboratory sample shall be transported and stored without compaction or any other treatment which

may irreversibly alter its moisture content, particle size, packing characteristics or any feature which

affects density.

A sample, as submitted to the laboratory shall be stored so that it shall not undergo any further

decomposition, physical damage, hydration or dehydration. Recommended storage should be at

3 °C ± 2 °C, in a closed polyethylene bag so that the sample fills volume of the container completely. The

storage period depends on several factors including what is the normal custom in the analysing

laboratory or country. Analysis of fresh materials shall be undertaken within 2 weeks of receipt of the

sample. When transport takes place, the sampling plan shall consider:

a) the time between sampling and start of transport;

b) transport time;

c) starting time of analysis in the laboratory.

The sum of these 3 periods is limited to the maximum storage times.

It is recommended that all such samples should be stored for a minimum of 28 days from the date of

reporting the results to the client.

8 Classification of samples as a function of matrix

The sample pre-treatment shall be differentiated accordingly to the physical state. The following 4 matrix

types are distinguished for performing the sample pre-treatment:

a) Solid samples: these samples have an estimated dry matter content of at least 30 % m/m.

NOTE 1 Examples are compost, dried digestate, peat, coir, wood fibre.

b) Shear resistant pasty samples: these samples have an estimated dry matter content between

15 % m/m and 30 % m/m.

NOTE 2 Examples are sludge, thick fraction of digestate.

c) Liquid and aqueous pasty samples: these samples have an estimated dry matter content of less than

15 % m/m.

NOTE 3 Examples are sludge, crude digestate, thin fraction of digestate.

d) Pre-shaped samples.

NOTE 4 Examples are mineral wool and polyurethane products (slabs, blocks).

The classification of the delivered laboratory sample in the relevant matrix type and the associated

sample pre-treatment can be performed on the basis of visual assessment in combination with the

estimated dry matter content. However, the physical state based on the visual observation is decisive for

performing the sample pre-treatment.

9 Preparation of the un-dried laboratory sample

9.1 Apparatus

9.1.1 Sieves 20 mm, 25 mm, 40 mm and 60 mm square aperture size.

9.1.2 Analytical balance with a scale interval of 0,1 g and a capacity of weighing 6 000 g.

9.1.3 Laboratory blender.

9.1.4 Sharp knife or a saw.

9.2 Test sample in solid form

9.2.1 Sample preparation (unsieved test sample)

Thoroughly mix the laboratory sample, gently breaking any lump or agglomerate of the sample that has

been caused, by, for example, compression during transportation. If the parameters “macroscopic

impurities and stones” do not have to be determined, discard visible macroscopic impurities that are not

naturally occurring in the materials. Some samples (e.g. compressed coir brick) shall be reconstituted

before the previous step following manufacturer’s guidance if the procedure has not been performed

during sampling.

Handle with care to avoid breaking intrinsic parts and to avoid a loss of moisture.

If necessary, divide the sample to form sub-samples. Recognized procedures such as coning and

quartering shall be used for sub-sampling. The size of the final test sample shall be large enough to truly

represent the laboratory sample and to provide sufficient uniform material for all defined physical and

chemical tests that are required to be carried out. It is unlikely that a laboratory sample of less than 10 l

shall be sufficient for all physical and chemical analyses.

During preparation the sample shall not be cut or ground.

9.2.2 Determination of material exceeding 40 mm

Weigh approximately 1 000 ml of the unsieved test sample (m ) and pass it through a 40 mm square

a

aperture sieve and agitate gently if required.

Record the weight (m ) of the amount of sample that does not pass the sieve and express this value (c) as

b

a fraction of the total sub-sample mass, see Formula (1).

m

b

c= (1)

m

a

where

m is the mass in grams of the sub-sample;

a

m is the mass in grams of material retained on a 40 mm square aperture sieve;

b

c is the fraction retained on a 40 mm square aperture sieve.

This value may be helpful in choosing the sieving steps.

9.2.3 Test sample passing through a 40 mm square aperture sieve

Take approximately 5 l of the unsieved sample (9.2.1) and pass through a 40 mm sieve.

a) When 20 % m/m or less of the sample has been retained on the 40 mm sieve, the retained particles

shall be physically reduced in equal parts as few times as necessary to permit the entire sample to

pass through the sieve. Thoroughly mix the whole sub-sample with the broken particles that have

been retained on the sieve taking care to minimize physical damage to the sample as a whole.

Particles with length of more than 80 mm that pass through the sieve may be reduced to a length of

approximately 40 mm.

b) When 20-40 % of the sample has been retained on the 40 mm sieve, repeat the sieving with a 60 mm

sieve. The retained particles shall be physically reduced in equal parts as few times as necessary to

permit the entire sample to pass through the 60 mm sieve. Thoroughly mix the whole sub-sample

with the broken particles that have been retained on the sieve taking care to minimize physical

damage to the sample as a whole.

Particles with length of more than 80 mm that pass through the sieve may be reduced to a length of

approximately 40 mm.

c) When more than 40 % of the sample has been retained on the 40 mm sieve, the bulk density shall be

measured according to EN 12580:2022. For subsequent analyses on volume (e.g. pH, EC, CAT

extraction etc.) a test portion of about 5 l should be sieved on the 60 mm sieve, and the retained

particles shall be physically reduced in equal parts as few times as necessary to permit the entire

sample to pass through the sieve.

9.2.4 Test sample passing through a 25 mm square aperture sieve

Take approximately 5 l of the unsieved sample (9.2.1) and pass through a 25 mm sieve. Any particle of

the sample > 25 mm and/or flexible fibres > 80 mm shall be physically reduced in equal parts and as few

times as are necessary to be ≤ 25 mm and ≤ 80 mm for flexible fibres.

Thoroughly mix the whole sub-sample with the broken particles that have been retained on the sieve

taking care to minimize physical damage to the sample as a whole.

NOTE This test sample is suitable for physical methods of analyses (see EN 13041:2011).

9.2.5 Test sample passing through a 20 mm square aperture sieve

Take about 5 l of the unsieved sample (9.2.1) and using a scoop, pass the material through a 20 mm screen

and agitate gently if required. If more than 10 % m/m is retained on the screen, then the procedure shall

be inappropriate to the material under test. If less than 10 % is retained, this material shall be broken

down in equal parts and as few times as necessary to permit the entire sample to pass through the sieve.

Particles with length of more than 60 mm that pass through the sieve may be reduced to a length of

approximately 20 mm.

9.3 Test sample in shear resistant pasty form

Shear resistant pasty laboratory samples are homogenized by manual conversion. If the pasty samples

contain coarser parts, the sample shall be homogenized by mechanical mixing.

Mechanical homogenization is not allowed if the parameters “stones and impurities” have to be

determined.

9.4 Test sample in liquid and aqueous pasty form

Liquid and aqueous pasty samples containing less than 15 % of dry matter are often heterogeneous and

can consist of, e.g. a sludge layer and a liquid layer. These samples shall, after shaking and stirring with a

spatula, be homogenized with a robust blender. Ensure that any solid sludge layer on the bottom is

loosened and well mixed. Place the sample bottle under the blender, with the rotor knife approximately

3 cm from the bottom of the sample bottle. Homogenize the sample with the greatest possible rotational

speed, while avoiding excessive foaming. The blender may be moved vertically back and forth during

homogenization to optimize homogenization. After homogenization, the sample bottle is closed. After

mixing, immediately take sub-samples and/or test samples for the analyses to be performed. If, after

storage of the homogenized samples, additional test portions shall be taken, the sample shall be re-

homogenized with a blender.

The use of a blender is not allowed for the determination of the oxygen uptake rate (OUR) and residual

gas production. Mechanical homogenization is not allowed if the parameters “stones and impurities” have

to be determined.

9.5 Test sample in pre-shaped form

9.5.1 Sample preparation for bulk density determination

For slabs and blocks, remove the wrap or cover and proceed according to prEN 15761:2022.

For plugs, proceed according to prEN 15761:2022.

9.5.2 Sample preparation for dry matter content determination

Slabs and blocks: remove the wrap or cover and, using a sharp knife or a saw, make pieces of

approximately 60 ml. When cut from a common slab of 7,5 cm height that would mean a piece with a

length of 4,0 cm and a width of approximately 2,0 cm. Obtain a final volume of e.g. 2 l from different

specimen.

p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...