SIST EN 1482-1:2025

(Main)Fertilizers, liming materials and inhibitors - Sampling and sample preparation - Part 1: General sampling provisions

Fertilizers, liming materials and inhibitors - Sampling and sample preparation - Part 1: General sampling provisions

This document specifies sampling plans and methods of representative sampling of inorganic fertilizers, liming materials and inhibitors for physical and chemical analysis, from packages and containers up to and including 1 000 kg, in liquid and solid form. This document covers sampling of products in bulk only while in motion.

NOTE 1 The sampling of bulk heaps of specified types of fertilizers is covered in prEN 1482 3. Sampling for detection of microbial presence is covered by prEN 1482 4.

NOTE 2 The term product is used throughout the body of this document and is understood to include inorganic fertilizers, liming materials and inhibitors unless otherwise indicated.

It is applicable to the sampling of batches of fertilizer, liming material and inhibitors supplied or ready for supply to third parties, as such, or in smaller batches, each of which would be subject to local, national or regional legislation.

This document does not cover complete, statistical sampling plans.

This document is also applicable to the blends of products where inorganic fertilizers, liming materials, or inhibitors are the main part of the blend in quantity. If fertilizers, liming materials, or inhibitors are not the main part of the blend, the European Standard for the main part of the blend applies. In case a blend of fertilizing products is composed of parts in equal quantity, the user decides which standard to apply. Special care is needed to ensure that the blend is/stays homogeneous and well mixed when sampled.

NOTE 3 It is the responsibility of manufacturers, importers and sellers, however, to ensure they supply a product that complies with its label declaration at the moment of delivery and fulfils the expectations of the end user at the moment of application.

Düngemittel, Kalkdünger und Hemmstoffe - Probenahme und Probenvorbereitung - Teil 1: Allgemeine Festlegungen zur Probenahme

Dieses Dokument legt Probenahmepläne und Verfahren für die repräsentative Probenahme von mineralischen Düngemitteln, Kalkdünger und Inhibitoren für physikalische und chemische Prüfverfahren aus Verpackungen und Behältern bis einschließlich 1 000 kg Inhalt in flüssiger und fester Form, fest. Für Schüttgut deckt dieses Dokument nur Probenahmen von Produkten in Bewegung ab.

ANMERKUNG 1 Die Probenahme von Schüttguthaufen bestimmter Düngemittel wird in prEN 1482 3 behandelt. Die Probenahme für den Nachweis des Vorhandenseins von Mikroben wird in prEN 1482 4 behandelt.

ANMERKUNG 2 Der Begriff Produkt wird durchgängig in diesem Dokument verwendet und schließt, wenn nicht anders angegeben, mineralische Düngemittel, Kalkdünger und Hemmstoffe ein.

Es ist anwendbar auf die Probenahme aus Losen von Düngemitteln, Kalkdünger und Hemmstoffen für den Weiterverkauf oder die Vorbereitung für den Weiterverkauf an Dritte als solche oder in kleineren Chargen, die der lokalen, nationalen oder regionalen Gesetzgebung unterliegen.

Dieses Dokument enthält keine vollständigen statistischen Probenahmepläne.

Dieses Dokument ist auch für Mischungen von Produkten anwendbar, in denen mineralische Düngemittel, Kalkdünger oder Hemmstoffe der quantitative Hauptbestandteil der Mischung sind. Wenn mineralische Düngemittel, Kalkdünger und Hemmstoffe nicht den Hauptbestandteil der Mischung ausmachen, ist die für den Hauptbestandteil geltende Europäische Norm anwendbar. Falls eine Düngemittelmischung aus Bestandteilen gleicher Menge besteht, entscheidet der Anwender, welche Norm angewendet wird. Es ist besonders darauf zu achten, dass die Mischung während der Probenahme homogen und gut vermischt ist und bleibt.

ANMERKUNG 3 Es liegt jedoch in der Verantwortung der Hersteller, Importeure und Verkäufer sicherzustellen, dass sie ein Produkt bereitstellen, das zum Zeitpunkt der Lieferung mit den Angaben auf dem Etikett übereinstimmt, und die Erwartungen des Endnutzers zum Zeitpunkt der Anwendung erfüllt.

Engrais, amendements minéraux basiques et inhibiteurs - Échantillonnage et préparation de l’échantillon - Partie 1 : Dispositions générales pour l’échantillonnage

Le présent document spécifie les plans d’échantillonnage et méthodes d’échantillonnage représentatif des engrais inorganiques, des amendements minéraux basiques et des inhibiteurs en vue d’une analyse physique et chimique, à partir d’emballages et de récipients d’une masse allant jusqu’à 1 000 kg inclus, sous forme liquide et sous forme solide. Le présent document traite de l’échantillonnage des produits en vrac uniquement lorsqu’ils sont en mouvement.

NOTE 1 L’échantillonnage de tas en vrac de types spécifiés d’engrais est traité dans le prEN 1482-3. L’échantillonnage pour la détection de la présence microbienne est traité dans le prEN 1482-4.

NOTE 2 Le terme « produit » est utilisé tout au long du présent document et s’entend comme incluant les engrais inorganiques, les amendements minéraux basiques et les inhibiteurs, sauf indication contraire.

Il s’applique aux lots d’engrais, d’amendements minéraux basiques et d’inhibiteurs livrés ou prêts à être livrés à une tierce partie, en l’état ou sous forme de lots plus petits, chacun étant soumis à la législation locale, nationale ou régionale en vigueur.

Le présent document ne couvre pas les plans d’échantillonnage statistiques complets.

Le présent document est également applicable aux mélanges de produits dans lesquels les engrais inorganiques, les amendements minéraux basiques ou les inhibiteurs représentent la majorité du mélange en quantité. Si les engrais inorganiques, les amendements minéraux basiques ou les inhibiteurs ne représentent pas la majorité du mélange, la Norme européenne du constituant principal du mélange s’applique. Dans le cas où un mélange de fertilisants est constitué de composants en quantités égales, l’utilisateur décide quelle norme appliquer. Une attention particulière est nécessaire pour s'assurer que le mélange soit/reste homogène et bien mélangé lors de l’échantillonnage.

NOTE 3 Il relève toutefois de la responsabilité des fabricants, importateurs et vendeurs de s’assurer qu’ils fournissent un produit qui est conforme à la déclaration sur son étiquette au moment de la livraison et qui répond aux attentes de l’utilisateur final au moment de son application.

Gnojila, sredstva za apnjenje in inhibitorji - Vzorčenje in priprava vzorcev - 1. del: Splošne zahteve za vzorčenje

Ta dokument določa načrte vzorčenja in metode reprezentativnega vzorčenja gnojil, sredstev za apnjenje in inhibitorjev v tekoči ter trdni obliki za fizikalno in kemijsko analizo. Ta dokument zajema vzorčenje proizvodov v razsutem stanju, samo če so v gibanju, ter iz embalaže in posod do vključno 1000 kg proizvoda v trdni obliki oziroma 1000 l proizvoda v tekoči obliki.

OPOMBA 1: Vzorčenje kupov določenih vrst gnojil in sredstev za apnjenje je zajeto v standardu EN 1482-3.

Vzorčenje za ugotavljanje prisotnosti mikroorganizmov je zajeto v standardu EN 1482-4.

OPOMBA 2: Izraz »proizvod« se uporablja v celotnem glavnem delu tega dokumenta in vključuje tudi gnojila, sredstva za apnjenje in inhibitorje, če ni navedeno drugače.

Uporablja se za vzorčenje serij gnojil, sredstev za apnjenje in inhibitorjev, ki so dobavljeni oziroma pripravljeni za dobavo tretjim osebam, kot takih ali v manjših serijah, pri čemer za vsako od teh serij velja lokalna, nacionalna ali regionalna zakonodaja.

Ta dokument ne zajema načrtov celovitega, statističnega vzorčenja.

Ta dokument se uporablja za mešanice sredstev za gnojenje, ki vsebujejo najmanj dve od naslednjih komponent: gnojila, sredstva za apnjenje, izboljševalci tal, rastni substrati, inhibitorji in rastlinski biostimulanti, pri čemer organska gnojila, organsko-mineralna gnojila, anorganska gnojila, sredstva za apnjenje oziroma inhibitorji predstavljajo največji masni ali prostorninski odstotek mešanice ali, v primeru tekoče oblike, odstotek suhe mase. Če organska gnojila, organsko-mineralna gnojila, anorganska gnojila, sredstva za apnjenje oziroma inhibitorji ne predstavljajo največjega odstotka v mešanici sredstva za gnojenje, se uporablja evropski standard za največji odstotek mešanice. Če vsebuje mešanica sredstva za gnojenje komponente v enakih količinah, standard za uporabo izbere uporabnik. Posebno pozornost je treba nameniti temu, da je mešanica sredstva za gnojenje ob vzorčenju homogena in dobro premešana.

OPOMBA 3: Proizvajalci, uvozniki in prodajalci morajo zagotoviti, da je dobavljeni proizvod v skladu z navedbo na oznaki v času njegove dostave in izpolnjuje pričakovanja končnega uporabnika v času njegove uporabe.

General Information

- Status

- Published

- Public Enquiry End Date

- 02-Nov-2023

- Publication Date

- 27-Jan-2025

- Technical Committee

- KAT - Soil quality

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 09-Jan-2025

- Due Date

- 16-Mar-2025

- Completion Date

- 28-Jan-2025

Relations

- Effective Date

- 01-Mar-2025

Overview

EN 1482-1:2024 (CEN) - Fertilizers, liming materials and inhibitors - Sampling and sample preparation - Part 1: General sampling provisions - specifies representative sampling plans and methods for inorganic fertilizers, liming materials and inhibitors (solid and liquid) from packages and containers up to and including 1 000 kg. The standard covers sampling of products in bulk only while in motion and is intended to ensure samples are suitable for reliable physical and chemical analysis.

Key topics and requirements

- Scope and applicability: Sampling of batches supplied or ready for supply to third parties; applies to blends where fertilizers/liming materials/inhibitors are the main component. Does not cover complete statistical sampling plans.

- Sampling plans and quantitative data: Guidance on determining number and identification of sampling units, required masses for incremental, combined and final samples.

- Incremental sampling methods: Methods for solids in motion (conveyor belt stop, mechanical samplers, manual sampling from falling streams), manual moving-bulk sampling, and package sampling.

- Sample reduction and division: Use of rotating mechanical sample dividers, riffle dividers, reduction procedures to obtain representative laboratory samples.

- Sampling of liquids and IBCs: Procedures, apparatus, mixing and controlled-flow sampling for intermediate bulk containers (IBCs) and tanks; Annexes give examples of apparatus and mixing methods.

- Practical arrangements: Container selection, sealing, labelling, storage, transport and dispatch of final samples; required contents of sampling reports.

- Quality checks: Normative annexes for testing bias in mechanical samplers and rotary dividers to verify sampler performance.

- Safety and homogeneity considerations: Emphasis on ensuring blends are well mixed when sampled and on safe sampling of IBCs and moving equipment.

Practical applications

- Quality control and acceptance testing for fertilizer manufacturers, packers and blenders.

- Incoming inspection by importers, distributors and retailers to verify label claims.

- Sampling at ports, terminals and during transport for regulatory compliance and dispute resolution.

- Preparation of representative laboratory samples for physical and chemical analysis used in certification, claims verification and R&D.

Who should use this standard

- Manufacturers, importers and sellers of inorganic fertilizers, liming materials and inhibitors.

- Laboratory managers and analysts performing chemical/physical tests.

- Quality assurance, regulatory inspectors, port operators and third-party sampling services.

- Equipment suppliers and site managers implementing sampling routines for bulk flows and IBCs.

Related standards

- prEN 1482-3 - sampling of bulk heaps (under development)

- prEN 1482-4 - sampling for microbial detection (under development)

Keywords: EN 1482-1:2024, fertilizer sampling, liming materials, inhibitors, sample preparation, CEN, bulk sampling, IBC sampling, representative sample, sampling plan.

Frequently Asked Questions

SIST EN 1482-1:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Fertilizers, liming materials and inhibitors - Sampling and sample preparation - Part 1: General sampling provisions". This standard covers: This document specifies sampling plans and methods of representative sampling of inorganic fertilizers, liming materials and inhibitors for physical and chemical analysis, from packages and containers up to and including 1 000 kg, in liquid and solid form. This document covers sampling of products in bulk only while in motion. NOTE 1 The sampling of bulk heaps of specified types of fertilizers is covered in prEN 1482 3. Sampling for detection of microbial presence is covered by prEN 1482 4. NOTE 2 The term product is used throughout the body of this document and is understood to include inorganic fertilizers, liming materials and inhibitors unless otherwise indicated. It is applicable to the sampling of batches of fertilizer, liming material and inhibitors supplied or ready for supply to third parties, as such, or in smaller batches, each of which would be subject to local, national or regional legislation. This document does not cover complete, statistical sampling plans. This document is also applicable to the blends of products where inorganic fertilizers, liming materials, or inhibitors are the main part of the blend in quantity. If fertilizers, liming materials, or inhibitors are not the main part of the blend, the European Standard for the main part of the blend applies. In case a blend of fertilizing products is composed of parts in equal quantity, the user decides which standard to apply. Special care is needed to ensure that the blend is/stays homogeneous and well mixed when sampled. NOTE 3 It is the responsibility of manufacturers, importers and sellers, however, to ensure they supply a product that complies with its label declaration at the moment of delivery and fulfils the expectations of the end user at the moment of application.

This document specifies sampling plans and methods of representative sampling of inorganic fertilizers, liming materials and inhibitors for physical and chemical analysis, from packages and containers up to and including 1 000 kg, in liquid and solid form. This document covers sampling of products in bulk only while in motion. NOTE 1 The sampling of bulk heaps of specified types of fertilizers is covered in prEN 1482 3. Sampling for detection of microbial presence is covered by prEN 1482 4. NOTE 2 The term product is used throughout the body of this document and is understood to include inorganic fertilizers, liming materials and inhibitors unless otherwise indicated. It is applicable to the sampling of batches of fertilizer, liming material and inhibitors supplied or ready for supply to third parties, as such, or in smaller batches, each of which would be subject to local, national or regional legislation. This document does not cover complete, statistical sampling plans. This document is also applicable to the blends of products where inorganic fertilizers, liming materials, or inhibitors are the main part of the blend in quantity. If fertilizers, liming materials, or inhibitors are not the main part of the blend, the European Standard for the main part of the blend applies. In case a blend of fertilizing products is composed of parts in equal quantity, the user decides which standard to apply. Special care is needed to ensure that the blend is/stays homogeneous and well mixed when sampled. NOTE 3 It is the responsibility of manufacturers, importers and sellers, however, to ensure they supply a product that complies with its label declaration at the moment of delivery and fulfils the expectations of the end user at the moment of application.

SIST EN 1482-1:2025 is classified under the following ICS (International Classification for Standards) categories: 65.080 - Fertilizers. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1482-1:2025 has the following relationships with other standards: It is inter standard links to SIST EN 1482-1:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1482-1:2025 is associated with the following European legislation: EU Directives/Regulations: 2019/1009; Standardization Mandates: M/564, M/564 AMD 1, M/564 AMD 2. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1482-1:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2025

Nadomešča:

SIST EN 1482-1:2007

Gnojila, sredstva za apnjenje in inhibitorji - Vzorčenje in priprava vzorcev - 1. del:

Splošne zahteve za vzorčenje

Fertilizers, liming materials and inhibitors - Sampling and sample preparation - Part 1:

General sampling provisions

Düngemittel, Kalkdünger und Hemmstoffe - Probenahme und Probenvorbereitung - Teil

1: Allgemeine Festlegungen zur Probenahme

Engrais, amendements minéraux basiques et inhibiteurs - Échantillonnage et préparation

de l’échantillon - Partie 1 : Dispositions générales pour l’échantillonnage

Ta slovenski standard je istoveten z: EN 1482-1:2024

ICS:

65.080 Gnojila Fertilizers

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1482-1

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2024

EUROPÄISCHE NORM

ICS 65.080 Supersedes EN 1482-1:2007

English Version

Fertilizers, liming materials and inhibitors - Sampling and

sample preparation - Part 1: General sampling provisions

Engrais, amendements minéraux basiques et Düngemittel, Kalkdünger und Hemmstoffe -

inhibiteurs - Échantillonnage et préparation de Probenahme und Probenvorbereitung - Teil 1:

l'échantillon - Partie 1 : Dispositions générales pour Allgemeine Festlegungen zur Probenahme

l'échantillonnage

This European Standard was approved by CEN on 25 November 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1482-1:2024 E

worldwide for CEN national Members.

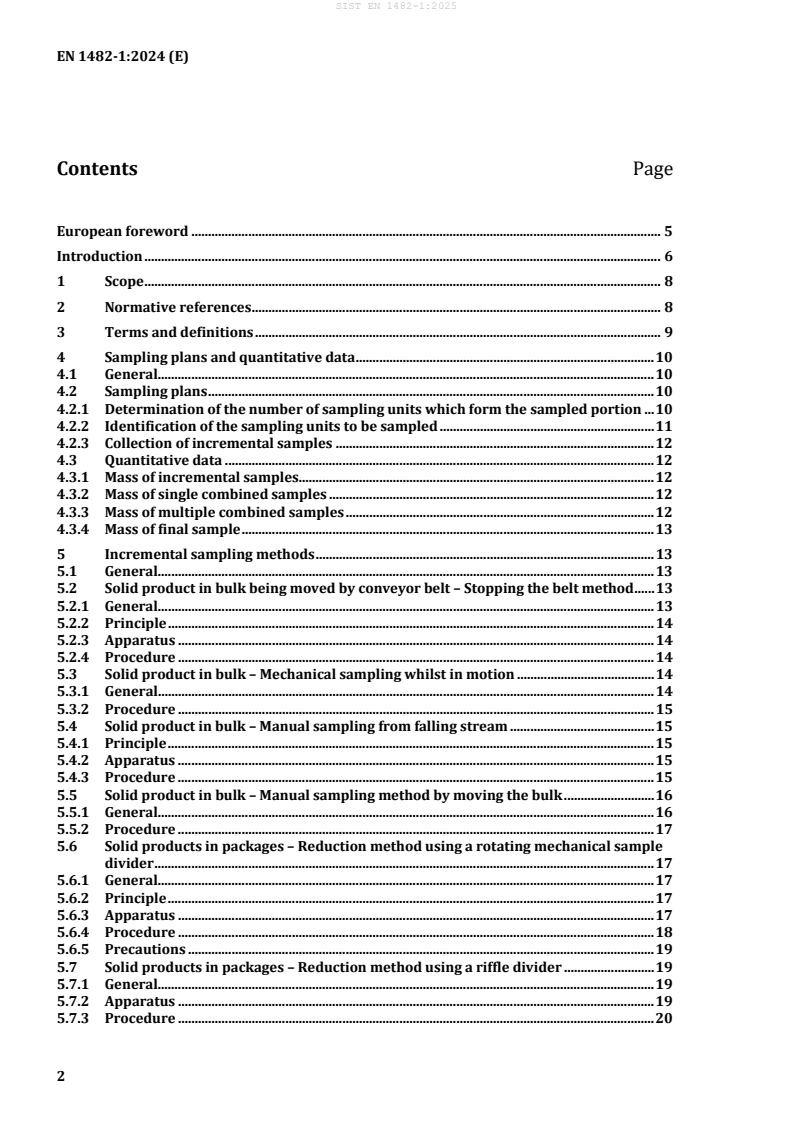

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 9

4 Sampling plans and quantitative data . 10

4.1 General. 10

4.2 Sampling plans . 10

4.2.1 Determination of the number of sampling units which form the sampled portion . 10

4.2.2 Identification of the sampling units to be sampled . 11

4.2.3 Collection of incremental samples . 12

4.3 Quantitative data . 12

4.3.1 Mass of incremental samples. 12

4.3.2 Mass of single combined samples . 12

4.3.3 Mass of multiple combined samples . 12

4.3.4 Mass of final sample . 13

5 Incremental sampling methods . 13

5.1 General. 13

5.2 Solid product in bulk being moved by conveyor belt – Stopping the belt method . 13

5.2.1 General. 13

5.2.2 Principle . 14

5.2.3 Apparatus . 14

5.2.4 Procedure . 14

5.3 Solid product in bulk – Mechanical sampling whilst in motion . 14

5.3.1 General. 14

5.3.2 Procedure . 15

5.4 Solid product in bulk – Manual sampling from falling stream . 15

5.4.1 Principle . 15

5.4.2 Apparatus . 15

5.4.3 Procedure . 15

5.5 Solid product in bulk – Manual sampling method by moving the bulk . 16

5.5.1 General. 16

5.5.2 Procedure . 17

5.6 Solid products in packages – Reduction method using a rotating mechanical sample

divider . 17

5.6.1 General. 17

5.6.2 Principle . 17

5.6.3 Apparatus . 17

5.6.4 Procedure . 18

5.6.5 Precautions . 19

5.7 Solid products in packages – Reduction method using a riffle divider . 19

5.7.1 General. 19

5.7.2 Apparatus . 19

5.7.3 Procedure . 20

5.8 Sampling of solid products in packages – Manual method . 21

5.9 Sampling from intermediate bulk containers (IBCs) by controlled flow . 22

5.9.1 General . 22

5.9.2 Principle . 22

5.9.3 Safety . 23

5.9.4 Apparatus . 23

5.9.5 Obtaining incremental samples . 25

5.9.6 Precautions . 26

5.10 Sampling from intermediate bulk containers (IBCs) – Manual method . 26

5.10.1 Principle . 26

5.10.2 Procedure . 26

5.11 Sampling of liquid products . 27

5.11.1 General . 27

5.11.2 Apparatus . 27

5.11.3 Procedure . 27

6 Reduction of combined sample . 30

6.1 General . 30

6.2 Solid products . 30

6.2.1 General . 30

6.2.2 Procedure . 30

6.3 Liquid products . 31

6.3.1 Apparatus . 31

6.3.2 Procedure . 31

7 Division into final samples . 31

8 Practical arrangements for final samples . 31

8.1 Containers . 31

8.2 Sealing of containers . 31

8.3 Labelling of final samples . 31

8.4 Dispatch of the final sample . 32

8.5 Storage of final samples . 32

9 Sampling report . 32

9.1 General . 32

9.2 Essential information . 32

9.3 Additional information . 33

Annex A (normative) Test for bias in mechanical samplers . 34

A.1 Principle . 34

A.2 Apparatus . 34

A.3 Test conditions . 34

A.4 Procedure . 34

A.4.1 Collection of incremental samples . 34

A.4.2 Preparation of samples . 35

A.4.3 Analysis of samples . 35

A.5 Expression of results . 35

A.5.1 General case where the incremental samples taken by the two methods do not

correspond exactly to each other . 35

A.5.2 Special case where the incremental samples taken by the two methods correspond

exactly to each other . 36

A.6 Interpretation of the results . 36

Annex B (informative) Examples of rotating sample dividers . 37

Annex C (normative) Test for bias in a rotary divider . 40

Annex D (informative) Examples of apparatus for sampling liquid products . 41

Annex E (normative) Methods of mixing for liquid products . 49

E.1 General. 49

E.2 Small containers . 49

E.2.1 Hand shaking . 49

E.2.2 Rocking . 49

E.3 Drums and casks (up to about 1,8 m deep) . 49

E.3.1 Rocking in a see-saw fashion . 49

E.3.2 Rolling to and from . 49

E.3.3 Mechanically driven drum shaker or roller . 49

E.3.4 Mechanical mixing . 49

E.3.5 Hand mixing . 51

E.3.6 Compressed gas . 52

E.4 Shallow tanks . 52

E.5 Deep tanks . 53

E.5.1 General. 53

E.5.2 Pumped circulation . 53

E.5.3 Compressed gas . 53

E.6 Precautions for sampling multi-phase liquids, including slurries . 53

E.7 Precautions for sampling liquids with significant vapour pressure . 54

E.7.1 Introduction . 54

E.7.2 General precautions . 54

E.7.3 Gases liquefied by pressure at ambient temperatures . 54

E.8 Precautions against static electricity. 54

E.8.1 Generation of static electricity . 54

E.8.2 Discharge of static electricity . 55

Bibliography . 56

European foreword

This document (EN 1482-1:2024) has been prepared by Technical Committee CEN/TC 260 “Fertilizers

and liming materials”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2025, and conflicting national standards shall be

withdrawn at the latest by June 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 1482-1:2007.

EN 1482-1 includes the following significant technical changes with respect to EN 1482-1:2007:

— Title, Introduction, Scope, Normative References, Terms and definitions have been updated;

— Requirements on sampling for detonation testing, oil retention and other tests added to 4.3.2;

— The mass of the final sample in 4.3.4 has been specified;

— 5.11 has been modified to improve sampling procedures.

EN 1482, Fertilizers, liming materials and inhibitors — Sampling and sample preparation consists of four

parts:

— Part 1: General sampling provisions;

— Part 2: General sample preparation provisions;

— Part 3: Sampling of static heaps;

— Part 4: Sampling for microbiological presence in fertilizers.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document covers the following aspects of sampling, derived from the International Standards and

documents indicated but presented in a simplified and condensed form. The titles of the International

Standards are given in the Bibliography.

— Sampling plans and quantitative data: ISO 8634, ISO/TR 5307, ISO/TR 7553 and Regulation (EU)

2019/1009;

— Sampling methods: ISO 3963;

— Reduction: ISO 7410, ISO 7742, ISO 8358;

— Sampling reports: ISO 5306.

EN 1482-2 covers the general methods for the reduction and preparation of samples of fertilizers, liming

materials and inhibitors for analysis. EN 1482-3 covers the sampling of specified products when stored

in a static heap. EN 1482-4 covers the sampling of specified fertilizers to be tested for the presence of

regulated microbes.

Figure 1 gives a schematic diagram of the sampling and sample preparation process for solids.

The fundamental principle of representative sampling is that every particle has an equal chance of being

selected or rejected. In some circumstances this principle cannot easily be complied with, particularly in

the case of bulk heaps of solid products not specified in EN 1482-3, or large storage tanks of liquid

products as the majority of the product cannot be reached by any sampling device. The fertilizers, liming

materials or inhibitors in these cases are sampled during transfer, during the building up of the heap,

during the filling of the storage tank, during dispatch or where it is being moved solely for sampling

purposes.

Figure 1 — Schematic diagram of sampling process for solids for chemical and physical testing

1 Scope

This document specifies sampling plans and methods of representative sampling of fertilizers, liming

materials and inhibitors, in liquid and solid form, for physical and chemical analysis. This document

covers sampling of products in bulk only while in motion and from packages and containers up to and

including 1 000 kg of product in solid form and 1 000 l of product in liquid form.

NOTE 1 The sampling of bulk heaps of specified types of fertilizers and liming materials is covered in EN 1482-3.

Sampling for detection of microbial presence is covered by EN 1482-4.

NOTE 2 The term product is used throughout the body of this document and is understood to include fertilizers,

liming materials and inhibitors unless otherwise indicated.

It is applicable to the sampling of batches of fertilizers, liming materials and inhibitors supplied or ready

for supply to third parties, as such, or in smaller batches, each of which would be subject to local, national

or regional legislation.

This document does not cover complete, statistical sampling plans.

This document is applicable to the fertilizing products blends where a blend is a mix of at least two of the

following components: fertilizers, liming materials, soil improvers, growing media, inhibitors and plant

biostimulants and where the following category organic fertilizers, organo-mineral fertilizers, inorganic

fertilizers, liming materials or inhibitors is the highest % in the fertilizing product blend by mass or

volume, or in the case of liquid form by dry mass. If the category (organic fertilizers, organo-mineral

fertilizers, inorganic fertilizers, liming materials or inhibitors) is not the highest % in the fertilizing

product blend, the European Standard for the highest % of the fertilizing product blend applies. In case a

fertilizing product blend is composed of components in equal quantity, the user decides which standard

to apply. Special care is needed to ensure that the fertilizing product blend is and stays homogeneous and

well mixed when sampled.

NOTE 3 It is the responsibility of manufacturers, importers and sellers, however, to ensure they supply a product

that complies with its label declaration at the moment of delivery and fulfils the expectations of the end user at the

moment of application.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1235, Solid fertilizers — Test sieving (ISO 8397:1988 modified)

EN 12944-1, Fertilizers and liming materials — Vocabulary — Part 1: General terms

ISO 2602, Statistical interpretation of test results — Estimation of the mean — Confidence interval

ISO 3310-1, Test sieves — Technical requirements and testing — Part 1: Test sieves of metal wire cloth

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 12944-1 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

batch

total quantity of product present assumed to have the same characteristics

Note 1 to entry: A batch is produced by the same process at the same time, under the same conditions and labelled

in the same manner, and assumed to have the same characteristics to be sampled using a particular sampling plan.

3.2

sampled portion

quantity of product from the same batch from which one

representative combined sample is taken

Note 1 to entry: In some instances, the batch and the sampled portion will be the same.

3.3

sampling unit

defined quantity of product having a boundary, which can be physical or hypothetical

Note 1 to entry: An example of a physical boundary is a container. An example of a hypothetical boundary is a time

interval for a flow of product.

3.4

incremental sample

quantity of product taken from a sampling point

3.5

combined sample

combination of all incremental samples taken from one sampled portion

3.6

reduction

process of producing a representative smaller mass of product from a larger mass, with the remainder

being discarded

3.7

reduced sample

representative part of the combined sample obtained by a process of reduction in such a manner that the

mass is at least the mass of the required final samples

3.8

division

process of producing a number of representative smaller portions, approximately equal in mass to each

other, from a larger mass

3.9

final sample

representative part of the combined sample taken from the sampled

portion obtained, where necessary, by a process of reduction

3.10

delivery

quantity of product transferred at one time

3.11

laboratory sample

final sample intended for laboratory testing

3.12

ammonium nitrate fertilizer of high nitrogen content

straight or compound solid inorganic macronutrient fertilizer, which is ammonium nitrate-based and

contains 28 % or more by mass of nitrogen (N) as a result of ammonium nitrate

4 Sampling plans and quantitative data

4.1 General

Correct sampling is a difficult operation which requires great care. The need to obtain a fully

representative sample for both the chemical and physical testing of products cannot be stressed too

much. Sampling plans have been produced to cover a range of quantities of product and these form the

basis of International Standards (see Bibliography).

The sampling plans given in this document are not based on strict statistical principles but samples

obtained by following the procedures described in this clause shall be considered to be representative of

the original batch or sampled portion.

This clause specifies sampling plans for the evaluation of deliveries of products as well as statutory

control plans which shall be followed in certain circumstances.

For the commercial evaluation of a large delivery which is supplied for resale in smaller batches a number

of samples representing parts of the delivery are required in order to assess the variability of the batch.

For example, a delivery of 5 000 t shall be treated as at least five deliveries of 1 000 t each and a separate

final sample shall be collected and prepared from each. The determination in this document is based on

a simple relationship between the amount to be sampled and the minimum number of incremental

samples to be taken.

The methods of sampling to be used are described in Clause 5.

4.2 Sampling plans

4.2.1 Determination of the number of sampling units which form the sampled portion

4.2.1.1 General

The number of sampling units from which incremental samples shall be taken depends on the size of the

batch.

4.2.1.2 Product in packages or containers

In the case of product in packages or containers, the sampling unit is a package. The minimum number of

individual packages from which incremental samples shall be taken is given in Table 1. In this context a

package is normally taken to hold no more than 50 kg – larger containers such as Intermediate Bulk

Containers (IBCs) are treated according to the procedure in 5.9 or 5.10. For packages weighing less than

1 kg each, it might be necessary to increase the number of packages to ensure a sufficiently large

combined sample.

Table 1 — Minimum number of individual packages (sampling units) from which incremental

samples shall be taken

Batch size Minimum number of sampling units

4 or fewer packages All packages

More than 4 and up to 10 packages 4

The nearest whole number above the square root of the

More than 10 and up to 400 packages

number of packages present.

More than 400 packages 20

4.2.1.3 Product in bulk

In the case of product in bulk, the minimum number of sampling units from which incremental samples

shall be taken depends on the total mass present. The minimum number of sampling units to be sampled

shall be in accordance with Table 2.

Table 2 — Minimum number of sampling units from which incremental samples shall be taken

Batch size Minimum number of sampling units

25 t or less 10

The nearest whole number above the square root of 4 times the

More than 25 t and up to 400 t

number of tonnes present.

More than 400 t 40

4.2.2 Identification of the sampling units to be sampled

4.2.2.1 Solid and liquid product in packages or containers

Identify the packages in the batch or sampled portion consecutively and, by using a source of random

numbers, select the packages from which incremental samples shall be taken and mark them.

4.2.2.2 Solid and liquid product in bulk during movement

Where the movement relates to loading or unloading using grabbing equipment such as a crane or

automatic shovel loader, the sampling unit is the quantity of product corresponding to one grab. If the

movement is a continuous operation such as on a conveyor belt or through a pipe, each sampling unit is

made up of a mass of no more than 5 t.

Calculate the number of sampling units present from the total mass and, by using a source of random

numbers, select the sampling units from which incremental samples shall be taken during the movement.

Number the sampling units in chronological order of their formation.

Estimate the time taken for the product to pass the sampling place. Divide this time into equal time

intervals such that the number of intervals is at least twice the minimum number of sampling units to be

sampled in accordance with Table 2 and each sampling unit is not more than 5 t. The time intervals are

the sampling units. From these sampling units randomly select the number from which incremental

samples shall be taken. Within each of the selected sampling units randomly select a time at which the

incremental sample is to be taken.

As there will be some variation in the speed of the belt or the flow in the pipe and the quantity at any one

point, it is recommended that the number of sampling units selected is at least 10 % more than the

minimum in Table 2.

Automatic mechanical samplers normally work at fixed time intervals. In this case the incremental

samples are collected over the whole timescale and cannot be regarded as having been taken randomly.

For formal sampling purposes the mechanical sampler shall be operated at the selected random times.

4.2.3 Collection of incremental samples

4.2.3.1 General

All incremental samples shall be of approximately the same mass or the same volume.

4.2.3.2 Solid product in packages or containers up to and including 50 kg

Take one incremental sample from each of the selected packages (sampling units 4.2.2.1), by the use of a

divider (5.6 or 5.7) or by the manual method described in 5.8.

4.2.3.3 Product in intermediate bulk containers

Collect the relevant number of incremental samples by using the method described in 5.9 and/or 5.10.

4.2.3.4 Solid product in bulk

Collect the relevant number of incremental samples by using one of the methods described in 5.2 to 5.5.

4.2.3.5 Liquid products

Follow the appropriate procedure described in 5.11.

4.3 Quantitative data

4.3.1 Mass of incremental samples

Incremental samples shall be of at least 250 g each. For blended fertilizers and for liming materials

coarser than 80 % passing 0,315 mm the minimum mass of each incremental sample shall be 500 g. For

packages weighing 4 kg or less, the entire contents are taken as the incremental sample.

4.3.2 Mass of single combined samples

Combine and mix all the collected incremental samples. When necessary, reduce the combined sample as

described in Clause 6, so that the final mass for chemical testing is at least 2 kg and for physical testing at

least 4 times the maximum amount required for the physical test method.

When sampling ammonium nitrate fertilizers of high nitrogen content for testing for detonation

resistance, the minimum quantity shall be 75 kg.

When sampling ammonium nitrate fertilizers of high nitrogen content for oil retention and other tests,

the minimum quantity shall be 4 kg.

4.3.3 Mass of multiple combined samples

Combine and mix all the collected incremental samples for one sample before reduction to final samples.

Each final sample shall have at least a mass equal to 4 times the maximum amount required for testing.

Repeat this procedure for each final sample.

4.3.4 Mass of final sample

The mass of each final sample for chemical analysis shall be at least 500 g. For physical testing the mass

is dependent on the tests to be carried out.

Final samples of ammonium nitrate fertilizers of high nitrogen content for testing shall be as follows:

(a) For chemical analysis to check against declared content: 500 g;

(b) For porosity (oil retention) testing minimum: 1 kg;

(c) For resistance to detonation testing: 25 kg.

The masses of final samples of ammonium nitrate fertilizers of high nitrogen content shall be kept at a

temperature between 0 °C and 25 °C.

5 Incremental sampling methods

5.1 General

Packages of up to and including 50 kg in mass may be sampled by a process of reduction (see 5.6), starting

with the total contents of the package, or by spear sampling from the selected packages but the latter only

when the product is uniform or a single chemical (such as urea, ammonium nitrate or ammonium

sulphate) and the sampling is only for chemical analysis. Intermediate bulk containers should be sampled

by the method described in 5.9. All packages and IBCs may be sampled by emptying the contents as in the

method described in 5.8.

Mechanical sampling devices, if installed in a transfer system, can be used to collect incremental samples,

provided they have been tested for the absence of bias (see Annex A) and the timing of the incremental

samples can be controlled manually.

The sampling apparatus shall be clean, dry and inert (i.e. fabricated of materials which will not affect the

characteristics of the products to be sampled).

All sampling operations shall be carried out in such a way as to minimize changes to sample properties,

e.g. moisture content.

5.2 Solid product in bulk being moved by conveyor belt – Stopping the belt method

5.2.1 General

The sample is taken from a conveyor by stopping the belt.

Taking a representative sample from a consignment of product by sampling from a conveyor, by stopping

the belt, is time-consuming and interrupts the loading or unloading process considerably. The method

shall, therefore, only be used if no other more convenient method is available.

NOTE This sampling technique is also used as a reference method to assess the accuracy of other techniques

or apparatus.

WARNING — This sampling method involves contact with machinery which is normally in motion. It is

essential that precautions be taken so that there is no possibility of the conveyor starting up while the

incremental samples are being taken. An override start/stop button shall be provided at the point of

sampling.

The sampler shall be able to reach the whole cross-section of the belt without undue physical strain. The

position for sampling shall be made as safe and convenient as possible, for example by using a suitable

platform.

5.2.2 Principle

The belt conveying the product is stopped. Two parallel rigid sheets are inserted into and at right angles

to the stream of product and to the axis of the conveyor belt. The product between the sheets as an

incremental sample is removed.

5.2.3 Apparatus

The apparatus consists of two parallel rigid sheets, shaped to the characteristics of the trough of the belt,

sufficiently long to project beyond the sides of the belt by about 500 mm and sufficiently wide for the

upper edge to be at least 50 mm above the top of the product on the belt. It is recommended that a metal

frame is made to carry the rigid sheets. This frame can then be placed across the belt in a single operation.

If it is not possible to make or use a metal frame, two marks shall be made on the supporting structure on

each side of the belt so that the sheets can be inserted in the same places each time.

5.2.4 Procedure

Stop the belt at the times selected as described in 4.2.2.2. Once the belt has stopped, insert the two parallel

rigid sheets at a sufficient distance apart to give an incremental sample of at least 1 kg as follows:

a) if the conveyor belt is horizontal, insert the sheets vertically downwards into the stream of product;

b) if the conveyor belt is inclined, insert the sheets quickly, at right angles to the stream, so as to avoid

any backflow.

Push any product obstructing the insertion of the sheets as follows:

c) in the case of the downstream sheet, into the sample;

d) in the case of the upstream sheet, out of the sample.

As quickly as possible, completely remove the product between the two parallel rigid sheets into a

suitable closable container.

Remove the sheets and make sure that nothing has been left on the belt which could cause damage further

down. Restart the belt.

Repeat the process for each incremental sample.

5.3 Solid product in bulk – Mechanical sampling whilst in motion

5.3.1 General

Mechanical sampling devices installed in a product handling system are a convenient means of collecting

incremental samples providing the timing of the taking of the incremental samples can be controlled

manually to allow randomness in sampling times. A number of different types are available and this

document does not recommend any particular type over another. All might be suitable provided they

have been shown to be capable of operating without bias. Before any incremental samples are taken by

the device for control purposes, it shall be checked for bias using the procedure described in Annex A.

The Annex A bias check test is applicable to any form of mechanical sampling device installed at some

point in a bulk handling system, providing that either the product passes along a conveyor belt, before or

after the device, or it is subsequently packed in bags in order that a reference collection can be made.

The mechanical sampling device can be used for the collection of samples for chemical analysis as well as

for physical testing.

5.3.2 Procedure

Obtain incremental samples by operating the mechanical sampling device at the times selected as

described in 4.2.2.2.

5.4 Solid product in bulk – Manual sampling from falling

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...