SIST EN 15313:2024

(Main)Railway applications - In-service wheelset operation requirements - In-service and off-vehicle wheelset maintenance

Railway applications - In-service wheelset operation requirements - In-service and off-vehicle wheelset maintenance

To ensure safety and interoperability, this document gives:

- the limits for in-service and off-vehicle wheelsets;

- the operations to be carried out for which the specific values (and/or criteria) remain to be defined in the maintenance plan.

This document applies to wheelsets and axleboxes complying with the following European standards:

- EN 13103-1:2017+A1:2022;

- EN 13260:2020, EN 13261:2020, EN 13262:2020;

- EN 13979-1:2023;

- EN 13715:2020;

- EN 13749:2021+A1:2023;

that comprise:

- the axle fitted with wheels of diameters greater than or equal to 330 mm;

- axleboxes with bearings and grease.

This document is also applicable to wheelsets:

- fitted with brake discs, final drive, transmission or noise-damping systems, as appropriate;

- not complying with the above European standards, but complying with the international requirements in force, for example in UIC leaflets, before the approval of these standards;

- with tyred wheels;

- with resilient wheels.

For equipment not covered by Directive (EU) 2016/797, this European Standard can be applied, noting that different values can be used.

All dimensions in this document are in millimetres (mm).

It is necessary to describe in a specific document the tasks to be performed in order to maintain wheelsets within the limits defined therein.

NOTE The specific values and criteria are defined in an appropriate maintenance plan.

Bahnanwendungen - Radsätze und Drehgestelle - Radsatzinstandhaltung

Um Sicherheit und Interoperabilität sicherzustellen, legt dieses Dokument Folgendes fest:

die Grenzwerte für eingebaute und ausgebaute Radsätze;

die durchzuführenden Maßnahmen, für welche besondere Werte (und/oder Kriterien) im Instandhaltungsplan festzulegen sind.

Dieses Dokument ist anwendbar für Radsätze und Radsatzlager, die die folgenden Europäischen Normen erfüllen:

EN 13103 1:2017+A1:2022;

EN 13260:2020, EN 13261:2020, EN 13262:2020;

EN 13979 1:2023;

EN 13715:2020;

EN 13749:2021+A1:2023.

die Folgendes einschließen:

Radsätze mit Raddurchmessern größer oder gleich 330 mm;

Radsatzlager mit Wälzlagern und Schmierfett.

Dieses Dokument ist auch auf Radsätze anwendbar, die:

gegebenenfalls mit Bremsscheiben, Achsantrieb, Getriebe oder Schallabsorber ausgerüstet sind;

nicht die oben genannten Europäischen Normen erfüllen, jedoch die geltenden internationalen Anforderungen, z. B. der UIC-Merkblätter, vor Inkrafttreten dieser Normen erfüllen;

mit bereiften Rädern ausgestattet sind;

mit elastomergefederten Rädern ausgestattet sind.

Diese Europäische Norm kann auch für Fahrzeuge angewendet werden, die nicht der Richtlinie (EU) 2016/797 unterliegen, wobei auf die Anwendung eventuell abweichender Werte hingewiesen wird.

Alle Maße in diesem Dokument werden in Millimetern (mm) angegeben.

Es ist notwendig, die durchzuführenden Maßnahmen zum Einhalten der definierten Grenzwerte für Radsätze in einem besonderen Dokument zu beschreiben.

ANMERKUNG Die Werte und besonderen Kriterien sind im entsprechenden Instandhaltungsplan festgelegt.

Applications ferroviaires - Exploitation des essieux en service - Maintenance des essieux en exploitation ou déposés

Pour assurer la sécurité et l'interopérabilité, le présent document donne :

- les valeurs limites pour les essieux en exploitation ou déposés ;

- les opérations à réaliser pour lesquelles les valeurs (et/ou critères) spécifiques restent à fixer dans le plan de maintenance.

Le présent document s'applique aux essieux et aux boîtes d'essieux conformes aux normes européennes suivantes :

- EN 13103-1:2017+A1:2022 ;

- EN 13260:2020, EN 13261:2020, EN 13262:2020 ;

- EN 13979-1:2023 ;

- EN 13715:2020 ;

- EN 13749:2021+A1:2023 ;

et qui comprennent :

- l'essieu-axe équipé de roues de diamètre supérieur ou égal à 330 mm ;

- des boîtes d'essieux avec des roulements et de la graisse.

Le présent document s'applique également aux essieux :

- éventuellement équipés de disques de frein, d'un pont moteur, d'une transmission ou de dispositifs d'insonorisation ;

- non conformes aux normes européennes citées ci-dessus, mais qui satisfont aux exigences internationales en vigueur, par exemple aux exigences des fiches de l'UIC, avant l'approbation de ces normes ;

- avec des roues bandagées ;

- avec des roues résilientes.

Pour les équipements non couverts par la Directive (EU) 2016/797, la présente Norme européenne peut être utilisée, tout en sachant que des valeurs différentes peuvent être utilisées.

Toutes les dimensions indiquées dans le présent document sont exprimées en millimètres (mm).

Il est nécessaire de décrire dans un document spécifique les opérations à réaliser pour maintenir les essieux dans les limites définies dans le présent document.

NOTE Les valeurs et critères spécifiques sont définis dans un plan de maintenance approprié.

Železniške naprave - Zahteve za kolesne dvojice med vožnjo - Vzdrževanje kolesnih dvojic v vgrajenem in razstavljenem stanju

Za zagotavljanje varnosti in medsebojne uporabnosti ta dokument določa:

– omejitve za kolesne dvojice v vgrajenem in razstavljenem stanju;

– potrebne postopke, za katere je treba v načrtu vzdrževanja opredeliti specifične vrednosti (in/ali kriterije).

Ta dokument se uporablja za kolesne dvojice in pestnice, ki so v skladu z naslednjimi evropskimi standardi:

– EN 13103-1:2017;

– EN 13260:2020, EN 13261:2020, EN 13262:2020;

– EN 13979-1:2020;

– EN 13715:2020;

– EN 13749:2021;

ki zajemajo:

– osi s premerom koles, večjim ali enakim 330 mm;

– pestnice z ležaji in mastjo.

Ta dokument se uporablja tudi za kolesne dvojice:

– opremljene z zavornimi diski, končno prestavo, menjalnikom ali sistemi za dušenje hrupa, kot je ustrezno;

– ki niso skladne z zgoraj navedenimi evropskimi standardi, vendar so v skladu z mednarodnimi zahtevami, ki so bile v veljavi pred odobritvijo teh standardov;

– s kolesi s pnevmatiko;

– z odpornimi kolesi.

Standard se lahko uporablja za opremo, ki ni zajeta v Direktivi 2016/797/ES, pri čemer se lahko vrednosti razlikujejo.

Vse mere v tem dokumentu so podane v milimetrih (mm).

V posebnem dokumentu je treba opisati naloge, ki jih je treba izvesti za vzdrževanje kolesnih dvojic znotraj opredeljenih omejitev.

OPOMBA: Specifične vrednosti in merila so opredeljeni v ustreznem načrtu vzdrževanja.

General Information

- Status

- Published

- Public Enquiry End Date

- 30-Jun-2022

- Publication Date

- 17-Oct-2024

- Technical Committee

- IŽNP - Reilway applications

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 16-Oct-2024

- Due Date

- 21-Dec-2024

- Completion Date

- 18-Oct-2024

Relations

- Effective Date

- 01-Dec-2024

Overview

EN 15313:2024 - Railway applications - In-service wheelset operation requirements - In-service and off-vehicle wheelset maintenance (CEN) defines safety and interoperability requirements for the maintenance of wheelsets and axleboxes. The standard sets the limits for in-service and off-vehicle wheelsets, specifies required operations, and requires that specific values and decision criteria be defined in a maintenance plan. All dimensions are given in millimetres (mm).

Key topics and requirements

- Scope and applicability

- Applies to axle/wheel combinations with wheel diameters ≥ 330 mm and axleboxes with bearings and grease.

- Also applicable to wheelsets with brake discs, final drives, transmissions, noise-damping systems, tyre wheels and resilient wheels, and to equipment complying with relevant international requirements (e.g., UIC) prior to standard approval.

- Can be used for equipment outside Directive (EU) 2016/797, noting values may differ.

- Maintenance framework

- Requirement for a maintenance organization plan and a vehicle/wheelset-specific maintenance plan where the specific limit values and criteria are recorded.

- Staff competence, certification and qualification of maintenance undertakings.

- Traceability, storage and transportation rules; annexes define minimum database content for freight and passenger/locomotive wheelsets.

- Inspection and operations

- Limits for in-service dimensions and positions; reprofiling operations and post-reprofiling dimensional limits (e.g., front-to-front, diameter differences, run-out).

- Detection and assessment methods for tread, flange, hub, web and axle defects, including non-destructive testing (NDT) intervals and procedures.

- Damage acceptance limits for axles and criteria for axleboxes and whole wheelsets.

- Incident response

- Prescribed actions after incidents: hot axlebox detection, derailment, short-circuit exposure, overheating, overload, lubricant loss and other irregularities.

Applications

- Used to develop and document wheelset maintenance plans, inspection regimes and repair acceptance criteria.

- Guides day-to-day in-service wheelset monitoring, depot/off-vehicle maintenance, reprofiling and NDT scheduling.

- Supports vehicle manufacturers, maintainers, fleet operators, infrastructure managers and safety assessors in ensuring safe, interoperable wheelset operation.

Who should use this standard

- Rolling stock maintenance organizations and workshops

- Railway operators and fleet managers

- Component manufacturers (wheels, axles, axleboxes)

- Infrastructure managers and safety/regulatory authorities

- Consultants developing maintenance plans or compliance documentation

Related standards

- EN 13103-1:2017+A1:2022; EN 13260:2020; EN 13261:2020; EN 13262:2020; EN 13979-1:2023; EN 13715:2020; EN 13749:2021+A1:2023 - referenced in EN 15313:2024 for component requirements.

Keywords: EN 15313:2024, wheelset maintenance, in-service wheelset, off-vehicle maintenance, railway standards, axlebox, wheel inspection, reprofiling, NDT, CEN.

Frequently Asked Questions

SIST EN 15313:2024 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Railway applications - In-service wheelset operation requirements - In-service and off-vehicle wheelset maintenance". This standard covers: To ensure safety and interoperability, this document gives: - the limits for in-service and off-vehicle wheelsets; - the operations to be carried out for which the specific values (and/or criteria) remain to be defined in the maintenance plan. This document applies to wheelsets and axleboxes complying with the following European standards: - EN 13103-1:2017+A1:2022; - EN 13260:2020, EN 13261:2020, EN 13262:2020; - EN 13979-1:2023; - EN 13715:2020; - EN 13749:2021+A1:2023; that comprise: - the axle fitted with wheels of diameters greater than or equal to 330 mm; - axleboxes with bearings and grease. This document is also applicable to wheelsets: - fitted with brake discs, final drive, transmission or noise-damping systems, as appropriate; - not complying with the above European standards, but complying with the international requirements in force, for example in UIC leaflets, before the approval of these standards; - with tyred wheels; - with resilient wheels. For equipment not covered by Directive (EU) 2016/797, this European Standard can be applied, noting that different values can be used. All dimensions in this document are in millimetres (mm). It is necessary to describe in a specific document the tasks to be performed in order to maintain wheelsets within the limits defined therein. NOTE The specific values and criteria are defined in an appropriate maintenance plan.

To ensure safety and interoperability, this document gives: - the limits for in-service and off-vehicle wheelsets; - the operations to be carried out for which the specific values (and/or criteria) remain to be defined in the maintenance plan. This document applies to wheelsets and axleboxes complying with the following European standards: - EN 13103-1:2017+A1:2022; - EN 13260:2020, EN 13261:2020, EN 13262:2020; - EN 13979-1:2023; - EN 13715:2020; - EN 13749:2021+A1:2023; that comprise: - the axle fitted with wheels of diameters greater than or equal to 330 mm; - axleboxes with bearings and grease. This document is also applicable to wheelsets: - fitted with brake discs, final drive, transmission or noise-damping systems, as appropriate; - not complying with the above European standards, but complying with the international requirements in force, for example in UIC leaflets, before the approval of these standards; - with tyred wheels; - with resilient wheels. For equipment not covered by Directive (EU) 2016/797, this European Standard can be applied, noting that different values can be used. All dimensions in this document are in millimetres (mm). It is necessary to describe in a specific document the tasks to be performed in order to maintain wheelsets within the limits defined therein. NOTE The specific values and criteria are defined in an appropriate maintenance plan.

SIST EN 15313:2024 is classified under the following ICS (International Classification for Standards) categories: 45.040 - Materials and components for railway engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15313:2024 has the following relationships with other standards: It is inter standard links to SIST EN 15313:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 15313:2024 is associated with the following European legislation: EU Directives/Regulations: 2016/631, 2016/797/EU; Standardization Mandates: M/483, M/591. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 15313:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2024

Železniške naprave - Zahteve za kolesne dvojice med vožnjo - Vzdrževanje

kolesnih dvojic v vgrajenem in razstavljenem stanju

Railway applications - In-service wheelset operation requirements - In-service and off-

vehicle wheelset maintenance

Bahnanwendungen - Radsätze und Drehgestelle - Radsatzinstandhaltung

Applications ferroviaires - Exploitation des essieux en service - Maintenance des essieux

en exploitation ou déposés

Ta slovenski standard je istoveten z: EN 15313:2024

ICS:

45.040 Materiali in deli za železniško Materials and components

tehniko for railway engineering

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 15313

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2024

EUROPÄISCHE NORM

ICS 45.040 Supersedes EN 15313:2016

English Version

Railway applications - In-service wheelset operation

requirements - In-service and off-vehicle wheelset

maintenance

Applications ferroviaires - Exploitation des essieux en Bahnanwendungen - Radsätze und Drehgestelle -

service - Maintenance des essieux en exploitation ou Radsatzinstandhaltung

déposés

This European Standard was approved by CEN on 12 August 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15313:2024 E

worldwide for CEN national Members.

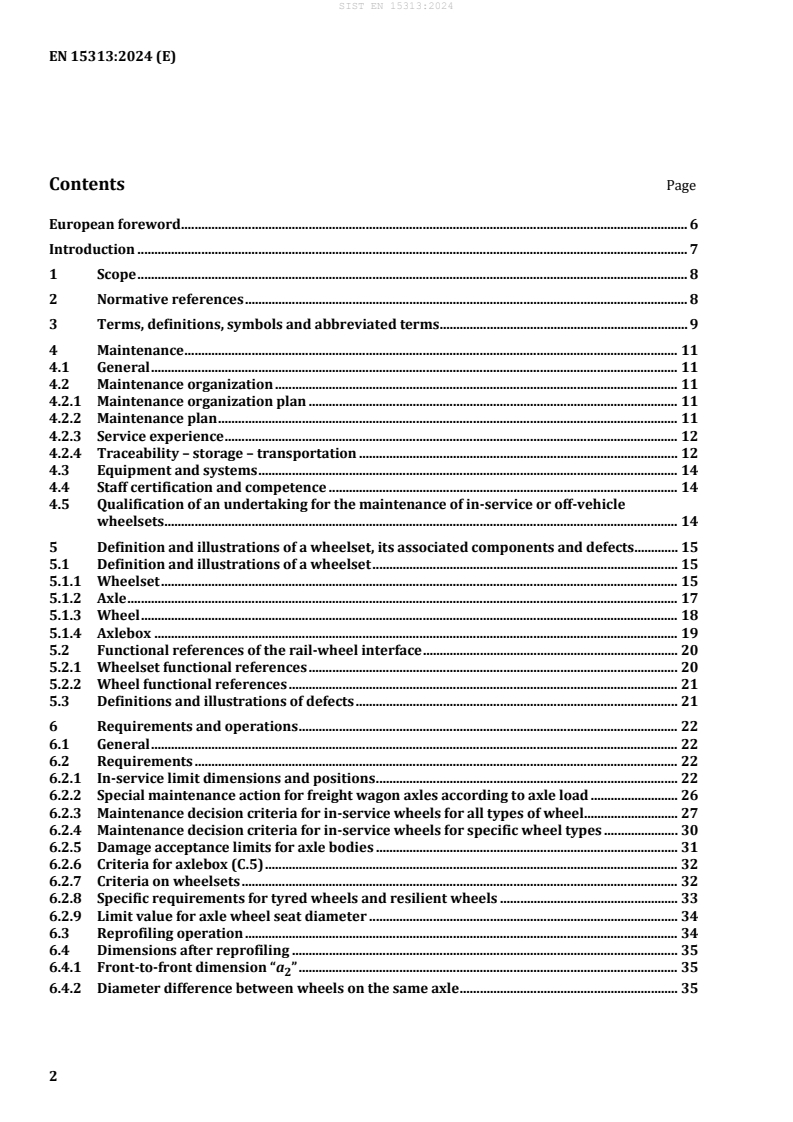

Contents Page

European foreword . 6

Introduction . 7

1 Scope . 8

2 Normative references . 8

3 Terms, definitions, symbols and abbreviated terms . 9

4 Maintenance . 11

4.1 General . 11

4.2 Maintenance organization . 11

4.2.1 Maintenance organization plan . 11

4.2.2 Maintenance plan . 11

4.2.3 Service experience . 12

4.2.4 Traceability – storage – transportation . 12

4.3 Equipment and systems . 14

4.4 Staff certification and competence . 14

4.5 Qualification of an undertaking for the maintenance of in-service or off-vehicle

wheelsets . 14

5 Definition and illustrations of a wheelset, its associated components and defects . 15

5.1 Definition and illustrations of a wheelset . 15

5.1.1 Wheelset . 15

5.1.2 Axle . 17

5.1.3 Wheel . 18

5.1.4 Axlebox . 19

5.2 Functional references of the rail-wheel interface . 20

5.2.1 Wheelset functional references . 20

5.2.2 Wheel functional references . 21

5.3 Definitions and illustrations of defects . 21

6 Requirements and operations . 22

6.1 General . 22

6.2 Requirements . 22

6.2.1 In-service limit dimensions and positions . 22

6.2.2 Special maintenance action for freight wagon axles according to axle load . 26

6.2.3 Maintenance decision criteria for in-service wheels for all types of wheel . 27

6.2.4 Maintenance decision criteria for in-service wheels for specific wheel types . 30

6.2.5 Damage acceptance limits for axle bodies . 31

6.2.6 Criteria for axlebox (C.5) . 32

6.2.7 Criteria on wheelsets . 32

6.2.8 Specific requirements for tyred wheels and resilient wheels . 33

6.2.9 Limit value for axle wheel seat diameter . 34

6.3 Reprofiling operation . 34

6.4 Dimensions after reprofiling . 35

6.4.1 Front-to-front dimension “a ” . 35

6.4.2 Diameter difference between wheels on the same axle . 35

6.4.3 Limit values of radial run-out as a function of the maximum operating speed

authorized for the vehicle . 35

6.4.4 Wheel axial run-out as a function of the maximum operating speed authorized for

the vehicle . 35

6.4.5 Parts of the tread that are not re-profiled . 35

6.4.6 Radial marks and radial defects on the internal side of the rim . 36

6.5 Maintenance operations, examinations and inspections . 36

6.5.1 General . 36

6.5.2 Detection of tread defects . 36

6.5.3 Detection of thermal damage on the wheel rim or tyre . 36

6.5.4 Detection of wheel tread roll-over . 37

6.5.5 Detection of damage to chamfered corner and flange . 37

6.5.6 Detection of damage resulting from identification markings . 37

6.5.7 Detection of defects on the external and internal face of the rim . 37

6.5.8 Verification of web integrity . 37

6.5.9 Verification of hub integrity . 37

6.5.10 Verification of rim integrity - Detection of deep sub-surface tread defects . 38

6.5.11 Detection of thermal defects on the web of a wheel used as a braking surface . 38

6.5.12 Detection of overheating affecting the wheel rim-web transition on monobloc

wheels . 38

6.5.13 Verification of axle surface integrity . 38

6.5.14 Detection of damage caused by corrosion . 41

6.5.15 Detection of circumferential defects around the whole circumference . 41

6.5.16 Detection of circumferential defects in a singular section of the circumference . 41

6.5.17 Detection of notches and impact damage . 41

6.5.18 Detection of longitudinal defects on axles . 41

6.5.19 Detection of damage in interference fit zones . 41

6.5.20 Verification after rectification . 41

6.5.21 Verification of residual magnetism . 41

6.5.22 Lubrication operation . 41

6.5.23 Checking for axlebox defects . 42

6.5.24 Verification of wheelset electrical resistance after heavy maintenance of wheelsets . 42

6.6 Requirements for additional maintenance equipment and operations . 42

7 In-service wheelset maintenance . 42

7.1 Maintenance plan . 42

7.2 Wheelset protection during vehicle and bogie cleaning . 42

8 Off-vehicle wheelset maintenance . 43

8.1 Maintenance plan . 43

8.2 Key operations for off-vehicle wheelset maintenance . 43

8.3 Off-vehicle wheelset cleaning . 44

8.4 NDT Interval . 44

9 Action to be taken on any wheelset after an incident in service or when not covered

by the maintenance plan . 44

9.1 Wheelset bearings subject to water ingress . 44

9.2 Wheelsets having been subjected to a short circuit current (e.g. from falling

overhead line equipment, etc.) . 44

9.3 Detection of a wheel circularity defect by a trackside facility or an onboard

monitoring system . 44

9.4 Wheelsets loaded over the allowed limit . 44

9.5 Hot axlebox detection . 45

9.5.1 General . 45

9.5.2 Technical procedure . 45

9.6 Derailment . 45

9.7 Head-on collision . 46

9.8 Lubricant leakage or loss from the axlebox . 46

9.9 Thermal overloaded wheels, brake incident (detection of seized brake or

discoloration) . 46

9.10 Reporting after detection of a wheelset irregularity outside the maintenance plan . 46

10 Equipment not subject to Directive (EU) 2016/797 . 46

11 Summary table of requirements of this document . 46

Annex A (normative) Minimum database content for freight wagon wheelset traceability . 47

A.1 Data categories for storage time . 47

A.2 Minimum data to be collected . 47

A.3 Measures to be applied resulting from lack of traceability . 52

Annex B (informative) Database content for the traceability of wheelsets of vehicles in the

scope of TSI “Rolling stock - Locomotive and passenger rated vehicles” (TSI Loc and

Pas) . 54

B.1 Data categories for storage time . 54

B.2 Minimum data to be collected . 54

B.3 Measures to be applied resulting from lack of traceability . 59

Annex C (normative) Definition and illustration of defects . 61

C.1 General . 61

C.2 Defects for all types of wheel . 61

C.3 Defects specific to wheel types . 83

C.4 Axle defects. 87

C.5 Axlebox defects . 92

C.6 Wheelset defects . 93

Annex D (normative) Freight stock . 96

Annex E (informative) Rim size without roll-over for equipment not subject to

Directive (EU) 2016/797 . 97

Annex F (normative) Definitions of Type A and B axles . 98

Annex G (informative) Permissible circularity defects . 101

Annex H (informative) Tyred wheels and resilient wheels . 102

H.1 General . 102

H.2 Marking of tyred wheels and resilient wheels . 102

H.3 Tyre thickness of tyred wheels . 103

H.4 Defects specific to tyred wheels . 104

H.5 Verification of the electrical resistance during medium and heavy maintenance . 104

Annex I (normative) Reference images for axle surface condition limits for off-vehicle

wheelset maintenance . 105

I.1 General . 105

I.2 Local and severe defect . 105

I.3 Large and heavily corroded areas, strongly and uniformly pitted surface . 106

I.4 Corrosion defects in abutment area and transition radii . 106

Annex J (informative) NDT interval . 108

J.1 General . 108

J.2 Axle . 108

J.3 Wheel . 108

Annex K (informative) Summary of the requirements of this standard for in-service boxed

wheelsets . 109

Annex L (informative) Characteristics of narrow gauge wheelsets . 111

Annex M (informative) Characteristics of Spanish and Portuguese gauge wheelsets . 112

Annex N (informative) Characteristics of Finnish and Baltic country gauge wheelsets . 113

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive (EU) 2016/797 aimed to be covered . 114

Bibliography . 116

European foreword

This document (EN 15313:2024) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2025, and conflicting national standards shall be

withdrawn at the latest by April 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 15313:2016.

In comparison with the previous edition, the following technical modifications have been made:

— a clearer definition of the signs to identify thermal overload of wheels and associated pictures;

— the maintenance requirements to be followed when thermal overloading of a wheel is identified.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

The objectives of this amendment to EN 15313:2016 are to:

— incorporate the appropriate results of the ERA Joint Network Secretariat “broken wheels” and Joint

Sector Group task force.

1 Scope

To ensure safety and interoperability, this document gives:

— the limits for in-service and off-vehicle wheelsets;

— the operations to be carried out for which the specific values (and/or criteria) remain to be defined

in the maintenance plan.

This document applies to wheelsets and axleboxes complying with the following European standards:

— EN 13103-1:2017+A1:2022;

— EN 13260:2020, EN 13261:2020, EN 13262:2020;

— EN 13979-1:2023;

— EN 13715:2020;

— EN 13749:2021+A1:2023;

that comprise:

— the axle fitted with wheels of diameters greater than or equal to 330 mm;

— axleboxes with bearings and grease.

This document is also applicable to wheelsets:

— fitted with brake discs, final drive, transmission or noise-damping systems, as appropriate;

— not complying with the above European standards, but complying with the international

requirements in force, for example in UIC leaflets, before the approval of these standards;

— with tyred wheels;

— with resilient wheels.

For equipment not covered by Directive (EU) 2016/797, this European Standard can be applied, noting

that different values can be used.

All dimensions in this document are in millimetres (mm).

It is necessary to describe in a specific document the tasks to be performed in order to maintain wheelsets

within the limits defined therein.

NOTE The specific values and criteria are defined in an appropriate maintenance plan.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 13260:2020, Railway applications — Wheelsets and bogies — Wheelsets — Product requirements

EN 13261:2020, Railway applications — Wheelsets and bogies — Axles — Product requirements

EN 13262:2020, Railway applications — Wheelsets and bogies — Wheels — Product requirements

EN 13715:2020, Railway applications — Wheelsets and bogies — Wheels — Tread profile

EN 13979-1:2023, Railway applications — Wheelsets and bogies — Monobloc wheels — Technical

approval procedure — Part 1: Forged and rolled wheels

EN 15085-2:2020+A1:2023, Railway applications — Welding of railway vehicles and components —

Part 2: Requirements for welding manufacturer

EN ISO 9712:2022, Non-destructive testing — Qualification and certification of NDT personnel

(ISO 9712:2021)

EN ISO 9934-1:2016, Non-destructive testing — Magnetic particle testing — Part 1: General principles

(ISO 9934-1:2016)

EN ISO 9934-2:2015, Non-destructive testing — Magnetic particle testing — Part 2: Detection media

(ISO 9934-2:2015)

EN ISO 9934-3:2015, Non-destructive testing — Magnetic particle testing — Part 3: Equipment (ISO 9934-

3:2015)

3 Terms, definitions, symbols and abbreviated terms

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

• ISO Online browsing platform: available at https://www.iso.org/obp

• IEC Electropedia: available at https://www.electropedia.org/

3.1

technical expert

person(s) competent in the maintenance of wheelsets

3.2

ECM

Entity in Charge of Maintenance

3.3

wheelset maintenance levels

maintenance of wheelsets is divided into 3 maintenance levels:

— reprofiling;

— medium wheelset maintenance;

— heavy wheelset maintenance

Note 1 to entry: Reprofiling is a maintenance level that corresponds to reprofiling of wheels (in-service or off-

vehicle) and depends mainly on the wear of the wheel or the tread defects.

Note 2 to entry: Medium wheelset maintenance corresponds to off-vehicle overhaul of wheelset (revision of

bearing and reprofiling of wheels).

Note 3 to entry: Heavy wheelset maintenance corresponds to the off-vehicle replacement of the wheels. This

maintenance level is in principle defined by the wear limit of the wheel.

3.4

maintenance plan

structured and documented set of tasks comprising the activities, instructions, resources and the length

of time necessary in order to perform the maintenance (see also definitions in EN 13306:2017;

Maintenance — Maintenance terminology and EN 17018:2019; Railway applications — Rolling stock

maintenance — Terms and definitions)

3.5

in-service wheelset maintenance

maintenance of in-service wheelsets comprises all of the operations which are performed on wheelsets

between medium and/or heavy maintenance levels

3.6

NDT

non-destructive testing

3.7

MT

magnetic particle testing

3.8

UT

ultrasonic testing

3.9

VT

visual testing

3.10

resilient wheels

wheels that contain rubber elements between the tyre and the web

3.11

witness mark

area of unmachined material which can remain after reprofiling to demonstrate that the minimum of

material has been removed

3.12

wagon overhaul

planned heavy maintenance operation on a wagon

4 Maintenance

4.1 General

Maintenance involves:

— maintenance of in-service wheelsets/axleboxes;

— maintenance of off-vehicle wheelsets/axleboxes;

— special maintenance attention after in-service incidents (e.g. overloads, hot axlebox detection,

wheelset bearings subject to water ingress, etc.).

An in-service wheelset shall be maintained by a maintenance undertaking qualified in this type of

wheelset.

For maintenance of wheelsets, as a minimum, the following shall be utilized:

— a maintenance plan;

— service experience;

— an organization for component and production management;

— specific wheelset maintenance tools;

— qualified staff for non-destructive testing and welding.

4.2 Maintenance organization

4.2.1 Maintenance organization plan

The general maintenance of the wheelsets is organized as shown in Figure 1.

Figure 1 — General maintenance organization

4.2.2 Maintenance plan

For wheelset maintenance, it is necessary to have a maintenance plan for the wheelsets when in-service

and off-vehicle.

The maintenance plan shall specify:

— the actions to be performed to meet the requirements and mandatory operations listed in this

document;

— the maintenance intervals;

— any specific measures to be implemented.

The maintenance plan shall be written by an organization having recognized experience in the wheelset

maintenance field and approved by the technical expert for the owner undertaking.

4.2.3 Service experience

The maintenance plan shall be reviewed to include:

— the service experience based on the performance of parts in service;

— the corrective actions necessary for dealing with defects;

— remedial actions for criteria detected outside of the limits specified in the maintenance plan;

— corrective actions for limits based on data from in-line monitoring devices.

The principle for revising the maintenance plan based on service experience is presented in Figure 2.

Figure 2 — Service experience

4.2.4 Traceability – storage – transportation

4.2.4.1 Wheelset identification

In order to ensure traceability, in-service wheelsets shall have marks complying with the requirements

of EN 13260:2020, EN 13261:2020 and EN 13262:2020.

It is recommended to have:

— the owner’s mark on the wheel (e.g. on the hub, with the same requirement as for the other marks,

as specified in EN 13262:2020 and/or painted on the web, etc.);

— external identification on wheelset with axleboxes fitted (e.g. tag or metal plate on the axlebox, collar

on the axle, radio frequency identification (RFID), etc.).

None of the external identification marks shall adversely affect the axle or its components.

All the identification marks shall be described in a specific document to support the management of the

wheelsets during their service lives.

The markings are to be applied to the wheelsets when the latter are subject to medium and heavy

maintenance.

It is recommended, where possible, for these markings to be applied retrospectively, even when the

wheelset components were not manufactured in accordance with EN 13261:2020 or EN 13262:2020.

NOTE When transponders are used for identification, the procedures and instructions are given in Chapter 4

“Guideline for MRO identification” of the document “RFID in RAIL – European Guideline for the Identification of

Railway Assets using GS1 Standards”.

4.2.4.2 Traceability of operations and transfers

The traceability shall be ensured throughout the life of the in-service wheelset and its components by

recording its maintenance life history (e.g. various operations and property transfers).

4.2.4.3 Database

4.2.4.3.1 General

The traceability of the original data and maintenance life history shall be recorded in a database.

The contents of the database and process for capturing information shall be described in a specific

procedure.

The consistency of the records shall be checked on a regular basis.

4.2.4.3.2 Freight wagons

For freight wagon wheelsets, the minimum content of the database, the time period to store the data and

the measures resulting from lack of traceability are given in Annex A. The data shall be recorded in an

electronic database.

For new freight wagon wheelsets, the data in Tables A.1 to A.6 shall be collected before the wheelset is

placed in service.

For in-service freight wagon wheelsets, the data shall be collected at the earliest opportunity according

to the maintenance plan (see 7.1).

Collected maintenance data are identified in categories I, II and III in Annex A, according to the minimum

time for retaining the information.

In the event of a change of owner and/or ECM, all available wheelset data shall be transferred to the new

owner and/or ECM.

4.2.4.3.3 Non-freight vehicles

For non-freight vehicles, the content of Annex B may be taken into consideration in ensuring adequate

traceability.

4.2.4.4 Storage

Component parts, equipment, consumables, etc. are to be protected against damage, as well as against

environmental degradation according to manufacturer’s recommendations, if applicable.

For wheelsets stored, the bearings fitted to the wheelsets shall be rotated at a frequency based on service

experience. 24 months maximum is recommended.

4.2.4.5 Handling and transportation conditions for new or maintained wheelsets

The processes and means of handling, transporting and storing shall not be the cause of damage to

wheelsets, their components and their protective covers. The handling, transportation and storage shall

not damage the most stressed areas, such as the wheel seat transitions.

The bearings, journals and other exposed equipment shall be protected against corrosion and mechanical

damage.

Written procedures specifying how these objectives will be reached shall be available.

4.3 Equipment and systems

All railway-specific tools, gauges and systems for wheelset maintenance (e.g. checking for circularity

defect, stresses in the wheel rim, non-destructive testing, etc.) shall be approved to ensure that

requirements of this standard are met.

A reference file shall be created for all railway-specific equipment in order to ensure that it meets the

requirements.

This file shall indicate that the equipment or railway-specific system has the appropriate levels of

sensitivity and repeatability in line with the desired objective. Performance sustainability shall be

demonstrated by means of calibrated reference equipment.

In addition, when new methods are used, it shall be ensured that the results achieved with the new

equipment or system are at least equivalent to those obtained with the former (e.g. differentiation

between parts with or without defects, etc.).

4.4 Staff certification and competence

Certification is necessary for staff carrying out:

a) non-destructive testing:

the staff shall be qualified according to EN ISO 9712:2022 (Industrial Sector: Railway Maintenance)

or equivalent and authorized to work on specific processes;

NOTE EN 16910-1 gives guidance for the training of operators.

b) welding operations:

the staff shall be qualified according to EN 15085-2:2020+A1:2023 or equivalent for components

where welding is authorized.

4.5 Qualification of an undertaking for the maintenance of in-service or off-vehicle

wheelsets

The qualification principle shown in Figure 3 applies to each of the following activities:

a) maintenance of in-service wheelsets;

b) maintenance of off-vehicle wheelsets;

c) maintenance activity component (example: reprofiling).

The qualification shall be reviewed before its extension to a new type of wheelset/axlebox.

Figure 3 — Flow chart for qualification of a maintenance undertaking

5 Definition and illustrations of a wheelset, its associated components and

defects

5.1 Definition and illustrations of a wheelset

5.1.1 Wheelset

The various components of a wheelset are shown in Figures 4 a) and 4 b).

Key

1 axle

2 monobloc wheel

3 wheel centre

4 tyre

5 retaining ring

a) Wheelset - principal components

Key

1 bearings

2 brake disc, transmission or final drive

3 wheel-fitted brake disc

4 axlebox with bearings

b) Wheelset - other components

Figure 4 — Wheelset

5.1.2 Axle

The axle for all types of wheelset is shown in Figure 5.

Key

1 journal

2 abutment

3 wheel seat

4 axle body

5 seat for brake disc, transmission or final drive

6 transition zone between seats

7 axle bore

Figure 5 — Axle

NOTE Axles can be solid or hollow.

5.1.3 Wheel

The monobloc wheel is shown in Figure 6.

Key

1 rim

2 web

3 hub

L1 hub lenght

Figure 6 — Monobloc wheel

5.1.4 Axlebox

The basic axlebox is shown in Figure 7.

Key

1 front cover

2 end cap bolt and locking device

3 end cap

4 front cover bolt and locking device

5 axlebox body

6 outer bearing

7 internal spacer

8 lubrication point

9 external spacer

10 inner bearing

11 rear cover

12 rear cover bolt and locking device

13 abutment ring

Components 6 – 7 – 9 and 10 may be replaced by a “cartridge” bearing.

The different types of sealing system are to be added as a function of the type of bearing.

Figure 7 — Basic axlebox

5.2 Functional references of the rail-wheel interface

5.2.1 Wheelset functional references

The essential dimensional references of the interface are defined in Figure 8.

The tread profile is defined in EN 13715:2020.

Dimensions in millimetres

Key

a back-to-back dimension

a front-to-front dimension (a + e + e )

2 1 1 2

D0 location of the wheel tread, 70 mm from its internal face. (1) wheel 1, (2) wheel 2

e , e flange thicknesses

1 2

h flange height

H2 finishing point of the flange, on the internal face of the wheel

L rim nominal width

Z1 internal zone of flange (H – S)

FEJ external face of the rim

FIJ internal face of the rim

S connection at the tip of the flange

d , d wheel diameters

1 2

Figure 8 — Interface dimensions – Wheelset functional references

5.2.2 Wheel functional references

The essential dimensional references of the wheel are defined in Figure 9.

Dimensions in millimetres

Key

d wheel diameter

D0 location of the wheel tread, 70 mm from its internal face

h flange height

L rim nominal width

e flange thickness

qR flange angle dimension between P1 and P2

5 × 45° nominal chamfer

Figure 9 — qR value and wheel functional references

NOTE The terms listed in Figures 8 and 9 conform to EN 13715:2020 (Tread profile) and EN 13260:2020

(Wheelsets).

5.3 Definitions and illustrations of defects

Definitions and illustrations of defects are given in Annex C.

6 Requirements and operations

6.1 General

As indicated in the Introduction, this standard defines:

a) requirements for all owners/undertakings (e.g. maximum and minimum dimensions, rail interface

dimensions, etc.);

b) maintenance to be carried out. The acceptance criteria are to be specified in the maintenance plan on

the basis of service experience.

The requirements defined in 6.2 and 6.4 shall be assessed in accordance with the maintenance plan.

The tread profile and wheel dimensions after reprofiling shall be defined on the basis of:

c) the results of vehicle acceptance testing (e.g. stability verification, etc.);

d) the service experience.

The criteria shall be either as defined in 6.2 and 6.4 (allowable limits for safe operation) or as defined in

the maintenance plan based on service experience.

The detection method for defects shall include:

e) manual;

f) visual; or

g) automatic.

6.2 Requirements

6.2.1 In-service limit dimensions and positions

6.2.1.1 General

The maximum and minimum values are given in Tables 1 to 6. The different interface dimensions are

given in Figure 8.

In the case of wheels where the actual diameter passes from one category to another, it is permissible to

use either of the values. This shall be documented in the maintenance plan.

6.2.1.2 Flange h

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...