SIST EN 1976:2014

(Main)Copper and copper alloys - Cast unwrought copper products

Copper and copper alloys - Cast unwrought copper products

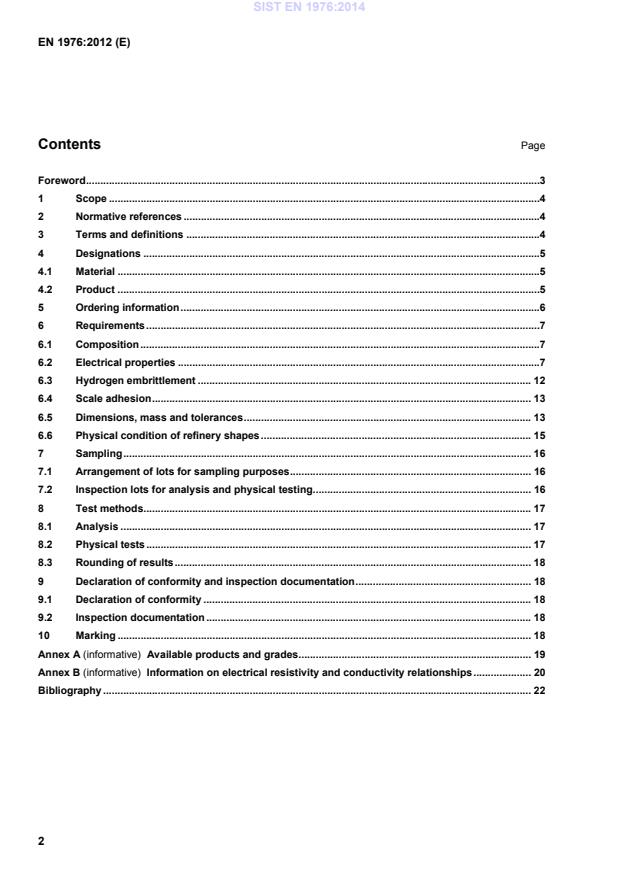

This European Standard specifies the composition and physical properties of cast unwrought copper products (refinery shapes) in thirteen grades of copper and nine silver-bearing copper grades. The refinery shapes included are horizontally, vertically and continuously cast wire bars, cakes, billets and ingots. Wire bars, cakes and billets are intended for fabricating into wrought products; ingots are intended for alloying in wrought and cast copper alloys.

A table indicating the refinery shapes in which each copper grade is normally available is given in Annex A. Annex B gives information on the relationships between electrical resistivity and conductivity of copper.

Kupfer und Kupferlegierungen - Gegossene Rohformen aus Kupfer

Diese Europäische Norm legt die Zusammensetzung und die physikalischen Eigenschaften von gegossenen Rohformen aus Kupfer (Gussformate) für dreizehn Kupfersorten und neun silberhaltige Kupfersorten fest. Die Gussformate umfassen horizontal, vertikal und kontinuierlich gegossene Drahtbarren, Walzplatten, Rund-blöcke und Blockmetalle. Drahtbarren, Walzplatten und Rundblöcke sind zur Herstellung von Knetprodukten, Blockmetalle zum Legieren von Kupfer-Knetlegierungen und Kupfer-Gusslegierungen, vorgesehen.

Eine Tabelle in Anhang A gibt die Gussformate wieder, in denen die jeweilige Kupfersorte üb¬licherweise erhältlich ist. Anhang B beschreibt die Beziehung zwischen spezifischem elektrischen Widerstand und spezifischer elektrischer Leitfähigkeit von Kupfer.

Cuivre et alliages de cuivre - Formes brutes de coulée en cuivre

La présente Norme européenne spécifie la composition et les propriétés physiques des formes brutes de coulée en cuivre en treize nuances de cuivre et neuf nuances de cuivre à l’argent. Les formes brutes de coulée considérées sont des barres à fil, plateaux, billettes et lingots moulés par coulée continue horizontalement ou verticalement. Les barres à fil, plateaux et billettes sont destinés à être transformés en produits corroyés ; les lingots sont destinés à être transformés en alliages de cuivre corroyés et moulés.

Un tableau indiquant les formes brutes de coulée sous lesquelles chaque nuance de cuivre est normalement disponible est donné en Annexe A. L’Annexe B donne des informations sur les relations entre la résistivité électrique et la conductivité du cuivre.

Baker in bakrove zlitine - Uliti negneteni polizdelki iz bakra

Ta evropski standard določa sestavo in fizične lastnosti ulitih negnetenih izdelkov iz bakra (rafinirane oblike) v trinajstih razredih bakra in devetih razredih bakra s srebrom. Vključene rafinirane oblike so vodoravno, navpično in kontinuirno lite žične palice, plošče, kovinske palice in ingoti. Žične palice, plošče in kovinske palice so namenjene izdelovanju gnetenih izdelkov, ingoti pa so namenjeni legiranju v gnetenih in ulitih bakrovih zlitinah. Tabela, ki označuje rafinirane oblike, v katerih je običajno razpoložljiv posamezni razred bakra, je podana v dodatku A. Dodatek B navaja informacije o razmerju med električno upornostjo in prevodnostjo bakra.

General Information

- Status

- Published

- Public Enquiry End Date

- 14-May-2011

- Publication Date

- 25-May-2014

- Technical Committee

- INEK - Nonferrous metals

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 14-May-2014

- Due Date

- 19-Jul-2014

- Completion Date

- 26-May-2014

Relations

- Effective Date

- 01-Jul-2014

Overview

EN 1976:2012 - published by CEN - is the European standard that defines the composition and physical properties of cast unwrought copper products (refinery shapes). It covers thirteen unalloyed copper grades and nine silver-bearing copper grades in commonly produced refinery shapes: horizontally, vertically and continuously cast wire bars, cakes, billets and ingots. Wire bars, cakes and billets are intended for fabrication into wrought products; ingots are intended primarily for remelting and alloying.

Key topics and technical requirements

- Material grades and designation: The standard specifies material symbol and number designations (based on ISO/EN systems) so suppliers and purchasers can unambiguously identify grades.

- Composition limits: Elemental composition requirements are defined for each grade (including Ag‑bearing variants). Annexed tables indicate permitted impurities and maximum totals for specific element groups.

- Electrical properties: Maximum mass resistivity at 20 °C (and related conductivity information) are specified for grades where electrical performance is critical; Annex B explains resistivity–conductivity relationships.

- Hydrogen embrittlement and scale adhesion: Requirements and referenced test methods (e.g., EN ISO 2626 for hydrogen embrittlement, ISO 4746 for scale adhesion) ensure mechanical integrity and surface quality during downstream processing.

- Dimensions, mass and tolerances: Nominal dimensions, unit mass and tolerances for refinery shapes (wire bars, cakes, billets, ingots) are addressed to support interchangeability and downstream manufacturing.

- Sampling, testing and inspection: Procedures for lot arrangement, sampling for chemical and physical testing, and rounding of results are included. Test methods reference internationally recognised standards (IEC, ISO).

- Ordering, marking and documentation: The standard sets out the information purchasers should provide (grade, shape, dimensions, tests required), requirements for declarations of conformity and inspection documents, and marking practices.

Applications and who uses this standard

EN 1976:2012 is used by:

- Refineries and foundries producing cast copper refinery shapes.

- Procurement and specification engineers in electrical, electronics, plumbing, and HVAC industries specifying base copper for further processing.

- Rolling mills, wire‑drawing and forging shops that convert wire bars, cakes and billets into wrought products.

- Quality assurance and metallurgical laboratories performing composition, resistivity and embrittlement testing.

- Designers and manufacturers of copper alloys who use ingots for remelting and alloying.

Practical benefits include consistent raw‑material quality, controlled electrical performance for conductive applications, and reduced risk of processing defects due to hydrogen embrittlement or scale adhesion.

Related standards (normative/informative)

- EN 1977 (Copper drawing stock), EN 1978 (Copper cathodes)

- EN 1655, EN 10204, EN ISO 2626, IEC 60468, ISO 4746

- ISO 1190-1 (designation system) and EN 1412 (material numbering)

Keywords: EN 1976:2012, cast unwrought copper products, refinery shapes, wire bars, cakes, billets, ingots, copper grades, electrical resistivity, hydrogen embrittlement, CEN.

Frequently Asked Questions

SIST EN 1976:2014 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Copper and copper alloys - Cast unwrought copper products". This standard covers: This European Standard specifies the composition and physical properties of cast unwrought copper products (refinery shapes) in thirteen grades of copper and nine silver-bearing copper grades. The refinery shapes included are horizontally, vertically and continuously cast wire bars, cakes, billets and ingots. Wire bars, cakes and billets are intended for fabricating into wrought products; ingots are intended for alloying in wrought and cast copper alloys. A table indicating the refinery shapes in which each copper grade is normally available is given in Annex A. Annex B gives information on the relationships between electrical resistivity and conductivity of copper.

This European Standard specifies the composition and physical properties of cast unwrought copper products (refinery shapes) in thirteen grades of copper and nine silver-bearing copper grades. The refinery shapes included are horizontally, vertically and continuously cast wire bars, cakes, billets and ingots. Wire bars, cakes and billets are intended for fabricating into wrought products; ingots are intended for alloying in wrought and cast copper alloys. A table indicating the refinery shapes in which each copper grade is normally available is given in Annex A. Annex B gives information on the relationships between electrical resistivity and conductivity of copper.

SIST EN 1976:2014 is classified under the following ICS (International Classification for Standards) categories: 77.150.30 - Copper products. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1976:2014 has the following relationships with other standards: It is inter standard links to SIST EN 1976:1999. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1976:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Baker in bakrove zlitine - Uliti negneteni polizdelki iz bakraKupfer und Kupferlegierungen - Gegossene Rohformen aus KupferCuivre et alliages de cuivre - Formes brutes de coulée en cuivreCopper and copper alloys - Cast unwrought copper products77.150.30Bakreni izdelkiCopper productsICS:Ta slovenski standard je istoveten z:EN 1976:2012SIST EN 1976:2014en,fr,de01-julij-2014SIST EN 1976:2014SLOVENSKI

STANDARDSIST EN 1976:19991DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1976

October 2012 ICS 77.150.30 Supersedes EN 1976:1998English Version

Copper and copper alloys - Cast unwrought copper products

Cuivre et alliages de cuivre - Formes brutes de coulée en cuivre

Kupfer und Kupferlegierungen - Gegossene Rohformen aus Kupfer This European Standard was approved by CEN on 18 August 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1976:2012: ESIST EN 1976:2014

Available products and grades . 19Annex B (informative)

Information on electrical resistivity and conductivity relationships . 20Bibliography . 22 SIST EN 1976:2014

Other products are specified as follows: EN 1977, Copper and copper alloys — Copper drawing stock (wire rod); EN 1978, Copper and copper alloys — Copper cathodes. In comparison with the first edition of EN 1976:1998, the following significant changes were made: a) Clause 3, Terms and definitions for the various refinery shapes have been added from ISO 197-2; b) Table 2, Cu-FRHC, Other elements – content has been modified and a new footnote "d" has been added. Within its programme of work, Technical Committee CEN/TC 133 requested CEN/TC 133/WG 1 "Unwrought copper products" to revise the following standard: EN 1976:1998, Copper and copper alloys — Cast unwrought copper products. According to the CEN/CENELEC Internal Regulations, the national standards organisations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom.

Billet EN 1976 — Cu-ETP — RND 250 × 1 000

or

Billet EN 1976 — CR004A — RND 250 × 1 000 Denomination

Number of this European Standard

Material designation

Cross-sectional shape and nominal dimensions in millimetres

5 Ordering information In order to facilitate the enquiry, order and confirmation of order procedures between the purchaser and the supplier, the purchaser shall state on his enquiry and order the following information: a) quantity of product required (mass); b) denomination (Billet, Wire bar, Cake or Ingot); c) number of this European Standard (EN 1976); d) material designation (see Tables 1 to 4); e) cross-sectional shape required; f) nominal dimensions (i.e. diameter, or width × thickness, and length) and nominal mass, where appro-priate (see Table 7 for wire bar dimensions). It is recommended that the product designation, as described in 4.2, is used for items b) to f). In addition, the purchaser shall also state on the enquiry and order any of the following, if required: g) for Cu-ETP and Cu-FRHC only: if oxygen content is higher than 0,040 % (see Table 2, Footnote b); h) for Cu-FRHC only: if the total impurities content is higher than 0,06 % (see Table 2, Footnote d); i) for ingots only: whether they are to be marked with a furnace charge mark; j) the tests, if any, which the purchaser requires to be carried out by the manufacturer on the product, selected from the tests appropriate to each copper grade given in Table 6; k) whether a declaration of conformity is required (see 9.1); l) whether an inspection document is required, and if so, which type (see 9.2). SIST EN 1976:2014

— — — — — — — — — — max.— 0,002 5 0,000 5 0,000 200,000 1—— 0,001 00,000 50,001 0—d 0,006

0,000 50,001 50,000 40,000 20— 0,000 20,000 20 0,000 1— — a (As + Cd + Cr + Mn + P + Sb) maximum 0,001 5 %. b (Bi + Se + Te) maximum 0,000 3 %, of which (Se + Te) maximum 0,000 30 %. c (Co + Fe + Ni + Si + Sn + Zn) maximum 0,002 0 %. d The oxygen content shall be controlled by the manufacturer so that the material conforms to the hydrogen embrittlement requirements.

0,005 0,03

Cu-FRHC CR005A min. 99,90 — — — — Ag, O max. — — 0,040b — 0,06d

Cu-FRTP CR006A min. 99,90 — — — — Ag, Ni, O max. — — 0,100

— 0,05

Cu-OF CR008A min. 99,95 — — — — Ag max. — 0,000 5 —c 0,005 0,03

NOTE The total of other elements (than copper) is defined as the sum of Ag, As, Bi, Cd, Co, Cr, Fe, Mn, Ni, O, P, Pb, S, Sb, Se, Si, Sn, Te and Zn, subject to the exclusion of any individual elements indicated. a Including silver, up to a maximum of 0,015 %. b Oxygen content up to 0,060 % is permitted, subject to agreement between the purchaser and the supplier. c The oxygen content shall be controlled by the manufacturer so that the material conforms to the hydrogen

embrittlement requirements.

d Higher total impurities content is permitted, subject to agreement between the purchaser and the supplier.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...