oSIST prEN 13477-1:2026

(Main)Non-destructive testing - Acoustic emission testing - Equipment characterization - Part 1: Equipment description

Non-destructive testing - Acoustic emission testing - Equipment characterization - Part 1: Equipment description

This document describes the main components that constitute an acoustic emission testing system on the basis of the utilization of piezoelectric sensors. Each component is assigned to one of the following list items:

a) piezoelectric sensor;

b) signal conditioning;

c) signal acquisition;

d) analysis and output of results.

Zerstörungsfreie Prüfung - Schallemissionsprüfung - Gerätecharakterisierung - Teil 1: Gerätebeschreibung

Dieses Dokuments beschreibt die Hauptbestandteile, aus denen ein System zur Schallemissionsprüfung, das auf dem Einsatz piezoelektrischer Sensoren beruht, besteht. Jeder Bestandteil ist einem der folgenden Listenpunkte zugeordnet:

a) piezoelektrischer Sensor;

b) Signalaufbereitung;

c) Signalerfassung;

d) Analyse und Ausgabe von Ergebnissen.

Essais non destructifs - Essais d'émission acoustique - Caractérisation de l'équipement - Partie 1: Description de l'équipement

Le présent document décrit les principaux composants d’un système de contrôle par émission acoustique basé sur l’emploi de capteurs piézoélectriques. Chaque composant est associé à l’un des éléments suivants :

a) capteur piézoélectrique ;

b) conditionnement des signaux ;

c) acquisition des signaux ;

d) analyse et sortie des résultats.

Neporušitvene preiskave - Preskušanje z akustično emisijo - Karakterizacija opreme - 1. del: Opis opreme

General Information

- Status

- Not Published

- Public Enquiry End Date

- 27-Feb-2026

- Technical Committee

- PKG - Testing of metallic materials

- Current Stage

- 4020 - Public enquire (PE) (Adopted Project)

- Start Date

- 18-Dec-2025

- Due Date

- 07-May-2026

Relations

- Effective Date

- 12-Feb-2025

Overview

The oSIST prEN 13477-1:2026:2026 standard by CEN presents a comprehensive description of the main components that constitute an acoustic emission (AE) testing system based on piezoelectric sensor technology. Acoustic emission testing is a crucial non-destructive testing (NDT) method employed widely in industrial applications to monitor the integrity of materials and structures by detecting transient elastic waves generated from sources such as crack formation or material deformation.

This standard serves as Part 1 of the series focused on equipment characterization. It offers a detailed overview of each system component involved in AE testing, defining their roles within the acoustic emission measurement chain. The components covered include:

- Piezoelectric sensors

- Signal conditioning modules

- Signal acquisition systems

- Data analysis and output processes

By standardizing the equipment description, oSIST prEN 13477-1:2026 enhances the reliability, repeatability, and comparability of AE testing results across different industries and applications.

Key Topics

Piezoelectric Sensor

- Piezoelectric sensors form the heart of AE testing, converting mechanical elastic waves into electrical signals.

- Typically constructed with lead zirconate titanate (PZT) ceramics, they operate efficiently in the frequency range of 20 kHz to 1 MHz.

- Sensors detect various wave types, including compressional, shear, surface (Rayleigh), and plate (Lamb) waves.

- The sensor’s design enables it to capture both burst emissions (discrete events) and continuous emissions (complex overlapped signals).

Signal Conditioning

- Signal conditioning prepares the raw electrical signals from the piezoelectric sensor for acquisition.

- Includes impedance-matched preamplifiers that amplify the weak AE signals.

- Frequency filtering and post-amplification refine the signal, ensuring minimal distortion and noise reduction.

- Coaxial cables transmit the conditioned signals over distances without significant loss.

Signal Acquisition

- Converts analog signals to digital format via analogue-to-digital converters (ADC) for processing.

- Enables detection of burst signals by applying threshold criteria to identify key events or hits.

- Facilitates digital filtering (e.g., low-pass, high-pass, notch filters) to remove irrelevant frequency components.

- Supports storing waveform data for detailed off-line analysis or real-time monitoring.

Analysis and Output

- Extracts burst signal features such as arrival time, peak amplitude, duration, and energy.

- Allows integration of additional parameters (temperature, pressure) synchronized with AE data for contextual interpretation.

- Automates data processing, reporting, and supervision to streamline industrial workflow.

- Provides options for on-line and off-line analysis, enabling proactive maintenance and failure prevention.

Applications

The equipment characterization defined in oSIST prEN 13477-1:2026 is vital for numerous industrial sectors where non-destructive testing assures the safety and longevity of critical assets. Typical applications include:

- Structural Health Monitoring: Detecting stress, cracks, and fatigue in bridges, aircraft, pipelines, and pressure vessels.

- Manufacturing Quality Control: Monitoring weld integrity, composite material defects, and component reliability.

- Power Generation: Evaluating turbine blades, generators, and nuclear reactor components to prevent catastrophic failures.

- Automotive and Aerospace: Ensuring material durability and detecting early-stage damages in high-performance vehicles and aircraft.

- Research and Development: Analyzing material behaviors and failure mechanisms under different stress conditions.

By precisely characterizing AE equipment, the standard enhances detection sensitivity and data accuracy, leading to more reliable NDT results and improved safety management.

Related Standards

oSIST prEN 13477-1:2026 is part of a broader framework governing acoustic emission testing and non-destructive evaluation:

- prEN 13477-2: Verification of operating characteristics - focuses on performance verification and calibration of AE equipment.

- EN 1330 series: Terminology standards for non-destructive testing, including terms common to AE testing.

- ISO 18436-6: Condition monitoring and diagnostics of machines - Acoustic emission testing methodology.

- ASTM E673: Standard practice for describing and measuring acoustic emission from failures in materials.

These related standards complement oSIST prEN 13477-1:2026 by ensuring consistent terminology, equipment validation, and testing protocols, fostering harmonized AE testing approaches worldwide.

Keywords: Acoustic emission testing, non-destructive testing, AE equipment characterization, piezoelectric sensors, signal conditioning, signal acquisition, burst signal detection, waveform analysis, industrial NDT standards, oSIST prEN 13477-1:2026.

Frequently Asked Questions

oSIST prEN 13477-1:2026 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Non-destructive testing - Acoustic emission testing - Equipment characterization - Part 1: Equipment description". This standard covers: This document describes the main components that constitute an acoustic emission testing system on the basis of the utilization of piezoelectric sensors. Each component is assigned to one of the following list items: a) piezoelectric sensor; b) signal conditioning; c) signal acquisition; d) analysis and output of results.

This document describes the main components that constitute an acoustic emission testing system on the basis of the utilization of piezoelectric sensors. Each component is assigned to one of the following list items: a) piezoelectric sensor; b) signal conditioning; c) signal acquisition; d) analysis and output of results.

oSIST prEN 13477-1:2026 is classified under the following ICS (International Classification for Standards) categories: 19.100 - Non-destructive testing. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN 13477-1:2026 has the following relationships with other standards: It is inter standard links to SIST EN 13477-1:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

oSIST prEN 13477-1:2026 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2026

Neporušitvene preiskave - Preskušanje z akustično emisijo - Karakterizacija

opreme - 1. del: Opis opreme

Non-destructive testing - Acoustic emission testing - Equipment characterization - Part 1:

Equipment description

Zerstörungsfreie Prüfung - Schallemissionsprüfung - Gerätecharakterisierung - Teil 1:

Gerätebeschreibung

Essais non destructifs - Essais d'émission acoustique - Caractérisation de l'équipement -

Partie 1: Description de l'équipement

Ta slovenski standard je istoveten z: prEN 13477-1

ICS:

19.100 Neporušitveno preskušanje Non-destructive testing

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

January 2026

ICS 19.100 Will supersede EN 13477-1:2001

English Version

Non-destructive testing - Acoustic emission testing -

Equipment characterization - Part 1: Equipment

description

Essais non destructifs - Essais d'émission acoustique - Zerstörungsfreie Prüfung - Schallemissionsprüfung -

Caractérisation de l'équipement - Partie 1: Description Gerätecharakterisierung - Teil 1: Gerätebeschreibung

de l'équipement

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 138.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2026 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 13477-1:2026 E

worldwide for CEN national Members.

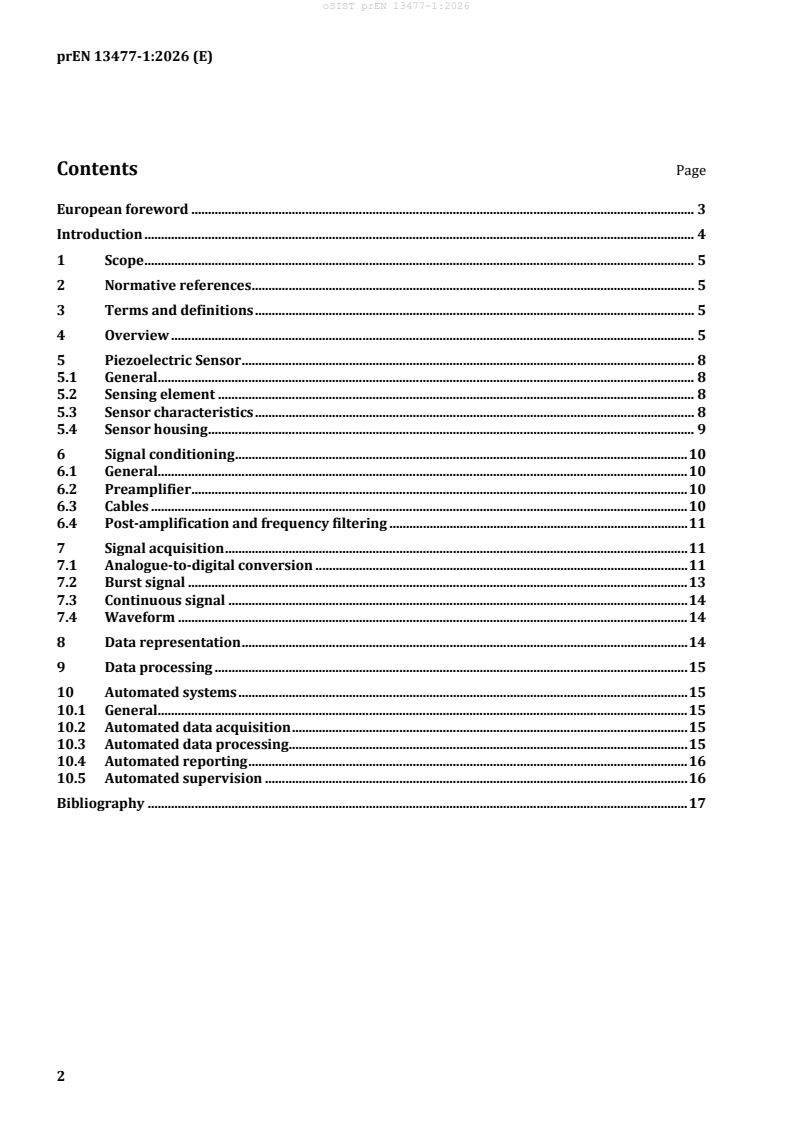

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Overview . 5

5 Piezoelectric Sensor . 8

5.1 General. 8

5.2 Sensing element . 8

5.3 Sensor characteristics . 8

5.4 Sensor housing . 9

6 Signal conditioning . 10

6.1 General. 10

6.2 Preamplifier . 10

6.3 Cables . 10

6.4 Post-amplification and frequency filtering . 11

7 Signal acquisition . 11

7.1 Analogue-to-digital conversion . 11

7.2 Burst signal . 13

7.3 Continuous signal . 14

7.4 Waveform . 14

8 Data representation . 14

9 Data processing . 15

10 Automated systems . 15

10.1 General. 15

10.2 Automated data acquisition . 15

10.3 Automated data processing. 15

10.4 Automated reporting . 16

10.5 Automated supervision . 16

Bibliography . 17

European foreword

This document (prEN 13477-1:2026) has been prepared by Technical Committee CEN/TC 138

“Non-destructive testing”, the secretariat of which is held by AFNOR.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 13477-1:2001.

EN 13477-1:2001:

— Clause 4 “Overview” added.

EN 13477, Non-destructive testing — Acoustic emission testing — Equipment characterization, consists

of the following parts:

— Part 1: Equipment description;

— Part 2: Verification of operating characteristics.

Part 1 of this document describes the main components of an acoustic emission testing system.

Part 2 of this document gives methods and acceptance criteria for verifying routinely the electronic

performance of an acoustic emission testing system composed of one or more acoustic emission

channels during its lifetime.

Introduction

Most of the acoustic emission testing systems for industrial applications are based on the utilization of

piezoelectric sensors. This sensor technology usually offers high sensitivity as well as reliability and is

sufficiently robust at the same time. Piezoelectric sensors have been used successfully for decades in

the field of acoustic emission testing and thus a wide range of different piezoelectric sensor types and

models produced by various equipment manufacturers are available.

Therefore, this document describes the equipment used for utilizing piezoelectric sensors as this

technology is the most widespread one.

1 Scope

This document describes the main components that constitute an acoustic emission testing system on

the basis of the utilization of piezoelectric sensors. Each component is assigned to one of the following

list items:

a) piezoelectric sensor;

b) signal conditioning;

c) signal acquisition;

d) analysis and output of results.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1330-1:2014, Non-destructive testing — Terminology — Part 1: List of general terms

EN 1330-2:1998, Non-destructive testing — Terminology — Part 2: Terms common to the non-destructive

testing methods

EN 1330-9:2017, Non-destructive testing — Terminology — Part 9: Terms used in acoustic emission

testing

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 1330-1:2014, EN 1330-2:1998

and EN 1330-9:2017 apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

4 Overview

The measurement chain employed in acoustic emission testing (AT) is based predominately on

piezoelectric sensors and can be divided into three sections: the piezoelectric sensor is designated as

section 1, the signal conditioning as section 2 and the signal acquisition as section 3.

The piezoelectric sensor is usually mounted directly onto the surface of the test object and constitutes

section 1 of each measurement chain for the detection of acoustic emission (AE) released in the course

of the test. Generally, the output signal of the sensor shall represent the characteristic response to the

surface displacement caused by the elastic wave arriving at the sensor's sensitive face. In case of burst

emission, the output signal of the sensor can be separated in time into single AE signals. In case of

continuous emission, a high number of burst emissions superpose so that no clear separation into

single burst emissions is possible anymore. However, the output signal due to continuous emission shall

be characteristic of the excitation at the sensor’s sensitive face as well.

The excitation at the sensitive face of such an AE sensor may be described by the normal component of

the surface displacement u at the sensor position x as a function of time t. Figure 1 a) shows an

XD

example in terms of the output signal voltage s in time t of a broadband capacitive sensor

C

(displacement sensor) in response to a single burst emission due to the breakage of a glass capillary at

the surface of a steel test block. The glass capillary is positioned in close vicinity to the capacitive sensor

and at the midway point to a resonant AE sensor so that the time of excitation by the surface pulse due

to the breakage of the glass capillary is equal for both sensors. The measurement setup as well as the

results are described in References [1], [2] and discussed further in Reference [3]. Figure 1 b) holds the

representation of the AE sensor response by the output signal voltage s in time t. The excitation of the

AE sensor is characterized by a rather distinct pulse-like shape, whereas the response of the AE sensor

to the excitation is an oscillating electrical signal with a rather sharp rise till to the maximum amplitude

followed by a less sharp decline. The comparison of both graphs, Figure 1 a) and Figure 1 b), underline

that the excitation of the sensor by a mechanical stimulus (i.e. the surface displacement) differs in

general from its response (i.e. the electrical signal). Only in the exceptional case of a displacement

sensor, the shape of the excitation and the respective response would be similar.

Key

s (t) output signal voltage (arbitrary units) of the broadband capacitive sensor as a function of time t

C

s(t) output signal voltage (arbitrary units) of the resonant AE sensor as a function of time t

Figure 1 — Excitation and response of a piezoelectric sensor in case of a surface pulse according

to reference [2], a) the output signal of the broadband capacitive sensor representing the

excitation and b) the output signal of a resonant AE sensor representing the response

Section 1 of the measurement chain, the AE sensor, provides the mechanical-to-electrical conversion for

burst emission detection and burst signal acquisition as depicted schematically in Figure 2.

Section 2 of the measurement chain, the signal conditioning, commences where the analogue electrical

signal at the sensor output is connected to the input of the impedance adapted preamplifier. The output

signal voltage of the AE sensor is amplified by the preamplifier gain between the lower and the upper

roll-off frequency of the built-in bandpass filter. The output of the preamplifier is capable to drive the

amplified AE signal over some 100 m to the input of the measurement board of the AE instrument

without significant distortion. Section 2 of the measurement chain is concluded when the signal has

passed the analogue filter of the measurement board (including a low-pass anti-aliasing filter).

Section 3 of the measurement chain, the signal acquisition, starts with the analogue-to-digital

conversion, where the analogue signal is converted at a given rate into a sequence of discrete samples.

The sampled signal is then sent to the digital signal processing unit (i.e. digital signal filtering), where

non-relevant frequency contents can be removed in a convenient way by selecting suited low-pass,

high-pass or notch filters when setting up the acquisition process. The main step of section 3 is the

conversion from the digital signal to the burst signal features.

Key

XD piezoelectric sensor, section 1 of the measurement chain

SC signal conditioning, section 2 of the measurement chain

SA signal acquisition, section 3 of the measurement chain

EW elastic wave arriving at the sensitive face of the sensor mounted onto the surface of the test object

ES electrical signal at the sensor output in response to the excitation at the input side

G(f) gain with respect to the frequency f within the bandwidth of the preamplifier

l length of the coaxial cable from the preamplifier output to the measurement board input

T(f) transmission of the high-pass and the low-pass (anti-aliasing) filter with respect to the frequency f

AS analogue signal at the input of the analogue-to-digital conversion

DS digital signal as the result of the analogue-to-digital conversion

s[i] digital signal voltage of sample i measured at time t[i]

DSP digital signal processing utilizing algorithms for low-pass, high-pass and notch filtering

BSF burst signal features as the result of a hit

WF burst signal waveform as the result of a hit

AED acoustic emission data

WFD waveform data

Figure 2 — Principle of the measurement chain for burst signal acquisition

A burst signal is detected when the measured signal voltage exceeds the first time the selected detection

threshold after a defined period without threshold crossings. The event of burst signal detection

constitutes a hit and triggers the determination of burst signal features (e.g. arrival time, measurement

channel number, maximum amplitude, rise time, duration, energy) as well as the registration of

additional information related to continuous signal features (e.g. background noise level). Further

information characteristic of the given conditions at the time of burst signal detection, for instance time

synchronized slow-varying parameter data (e.g. reading of a pressure gauge) acquired at a sampling

rate appropriate for the application and digitized by the AE instrument itself or by a separate measuring

instrument, should be added to the AE data set.

In the course of the data acquisition process for detection and characterization of burst signals, a

stream of AE data sets is generated and stored to the AE data. Optionally, the samples of the burst signal

can be stored as digitized representation for further analysis, what is called waveform recording. In this

case two separate but interrelated data bases are provided as the result of the acquisition process. At

the end of the section 3 of the measurement chain, AE data and waveform data are available for analysis

and output of results, on-line as well as off-line.

5 Piezoelectric Sensor

5.1 General

A piezoelectric sensor is the most commonly used device for detecting acoustic emission (AE). It

provides the most effective conversion of elastic waves into an electrical signal in the frequency range

most commonly used for AE detection, 20 kHz – 1 MHz. Usually, it consists of a piezoelectric ceramic

element mounted in a protective housing. The piezoelectric element is sensitive to different wave types

arriving from any direction at the sensor’s face: compressional, shear, surface (Rayleigh) and plate

(Lamb) waves.

5.2 Sensing element

The sensing material affects the conversion efficiency and operating temperature range. Lead zirconate

titanate (PZT), a ceramic, is the most commonly used materia

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...