SIST EN 10296-1:2003

(Main)Welded circular steel tubes for mechanical and general engineering purposes - Technical delivery conditions - Part 1: Non-alloy and alloy steel tubes

Welded circular steel tubes for mechanical and general engineering purposes - Technical delivery conditions - Part 1: Non-alloy and alloy steel tubes

This part of EN 10296 specifies the technical delivery conditions for electric welded, laser beam welded and submerged arc welded tubes of circular cross section made of non-alloy and alloy steels for mechanical and general engineering purposes.

Geschweißte kreisförmige Stahlrohre für den Maschinenbau und allgemeine technische Anwendungen - Technische Lieferbedingungen - Teil 1: Rohre aus unlegierten und legierten Stählen

Dieser Teil der EN 10296 enthält die technischen Lieferbedingungen für elektrisch geschweißte, laserstrahl-geschweißte und unterpulvergeschweißte Rohre mit kreisförmigem Querschnitt aus unlegierten und legierten Stählen, die für die Anwendung im Maschinenbau und für allgemeine technische Anwendungen bestimmt sind.

Tubes ronds soudés en acier pour utilisation en mécanique générale et en construction mécanique - Conditions techniques de livraison - Partie 1 : Tubes en acier non allié et allié

La présente partie de l'EN 10296 spécifie les conditions techniques de livraison des tubes à section circulaire en acier non allié et allié soudés électriquement, par laser et à l'arc immergé sous flux en poudre, pour utilisation en mécanique générale et en construction mécanique.

Okrogle varjene jeklene cevi za strojništvo in splošno uporabo v tehniki – Tehnični dobavni pogoji – 1. del: Cevi iz nelegiranih in legiranih jekel

General Information

- Status

- Published

- Publication Date

- 31-Oct-2003

- Technical Committee

- IFEK - Ferrous metals

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Nov-2003

- Due Date

- 01-Nov-2003

- Completion Date

- 01-Nov-2003

Overview

EN 10296-1:2003 specifies the technical delivery conditions for welded circular steel tubes used in mechanical and general engineering. It covers electric welded (EW), laser beam welded and submerged arc welded tubes of circular cross section made from non-alloy and alloy steels. The standard defines what manufacturers must deliver and what purchasers must specify when ordering engineering tubes.

Key topics and technical requirements

- Scope of materials and processes: electric welded, laser beam welded and submerged arc welded circular tubes made from non-alloy and alloy steels; includes steelmaking and deoxidation process considerations.

- Designation and classification: steel names use the “E” prefix (engineering steels), specified minimum yield strength (Re) for T ≤ 16 mm, K2 suffix for steels with specified impact energy of 40 J at −20 °C, and M for thermomechanical rolling delivery condition.

- Delivery conditions: normalizing (+N), thermomechanical rolling (M), annealing (+A) and other supplier-specified conditions.

- Dimensions and tolerances: outside diameter, wall thickness, masses per unit length and sectional properties (reference to EN 10220 and Annexes).

- Mechanical and chemical requirements: chemical composition limits, tensile and yield properties, impact requirements where applicable.

- Inspection and testing: comprehensive testing regime including tensile tests (parent material and transverse weld), flattening, drift expanding, bend (full section and weld bend), impact, leak tightness, dimensional inspection, visual examination and non‑destructive testing (NDT) of welds (automatic ultrasonic, eddy-current, magnetic flux leakage, radiography as referenced).

- Marking, documentation and protection: inspection documents per EN 10204, marking and delivery protection requirements.

Applications and who uses it

- Practical uses: specifying welded circular steel tubes for shafts, machine frames, axles, hydraulic cylinders, structural elements and general mechanical components where consistent mechanical and delivery conditions are required.

- Primary users: tube manufacturers, purchasing engineers, mechanical and design engineers, quality and inspection teams, fabricators and project specifiers who need harmonized delivery and testing criteria across Europe.

Purchasing information & options

Purchasers must supply: quantity (mass, length or number), the term “tube”, dimensions (OD and wall thickness) and steel designation. Optional choices include tube manufacture process, delivery condition, descaling/pickling, NDT level of weld, leak tightness testing and length tolerances.

Related standards

- EN 10296-2 (stainless steel tubes), EN 10297 (seamless tubes), EN 10246 series (NDT methods), EN 10220 (dimensions & masses), EN 10204 (inspection documents).

Keywords: EN 10296-1:2003, welded circular steel tubes, electric welded, laser beam welded, submerged arc welded, non-alloy and alloy steel tubes, technical delivery conditions, mechanical engineering, NDT.

Frequently Asked Questions

SIST EN 10296-1:2003 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Welded circular steel tubes for mechanical and general engineering purposes - Technical delivery conditions - Part 1: Non-alloy and alloy steel tubes". This standard covers: This part of EN 10296 specifies the technical delivery conditions for electric welded, laser beam welded and submerged arc welded tubes of circular cross section made of non-alloy and alloy steels for mechanical and general engineering purposes.

This part of EN 10296 specifies the technical delivery conditions for electric welded, laser beam welded and submerged arc welded tubes of circular cross section made of non-alloy and alloy steels for mechanical and general engineering purposes.

SIST EN 10296-1:2003 is classified under the following ICS (International Classification for Standards) categories: 77.140.75 - Steel pipes and tubes for specific use. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 10296-1:2003 is associated with the following European legislation: Standardization Mandates: M/005. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 10296-1:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Geschweißte kreisförmige Stahlrohre für den Maschinenbau und allgemeine technische Anwendungen - Technische Lieferbedingungen - Teil 1: Rohre aus unlegierten und legierten StählenTubes ronds soudés en acier pour utilisation en mécanique générale et en construction mécanique - Conditions techniques de livraison - Partie 1 : Tubes en acier non allié et alliéWelded circular steel tubes for mechanical and general engineering purposes - Technical delivery conditions - Part 1: Non-alloy and alloy steel tubes77.140.75Jeklene cevi in cevni profili za posebne nameneSteel pipes and tubes for specific useICS:Ta slovenski standard je istoveten z:EN 10296-1:2003SIST EN 10296-1:2003en01-november-2003SIST EN 10296-1:2003SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 10296-1June 2003ICS 77.140.75English versionWelded circular steel tubes for mechanical and generalengineering purposes - Technical delivery conditions - Part 1:Non-alloy and alloy steel tubesTubes ronds soudés en acier pour utilisation en mécaniquegénérale et en construction mécanique - Conditionstechniques de livraison - Partie 1: Tubes en acier non alliéet alliéGeschweißte kreisförmige Stahlrohre für denMaschinenbau und allgemeine technische Anwendungen -Technische Lieferbedingungen - Teil 1: Rohre ausunlegierten und legierten StählenThis European Standard was approved by CEN on 20 February 2003.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Spain, Sweden, Switzerland and UnitedKingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2003 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 10296-1:2003 ESIST EN 10296-1:2003

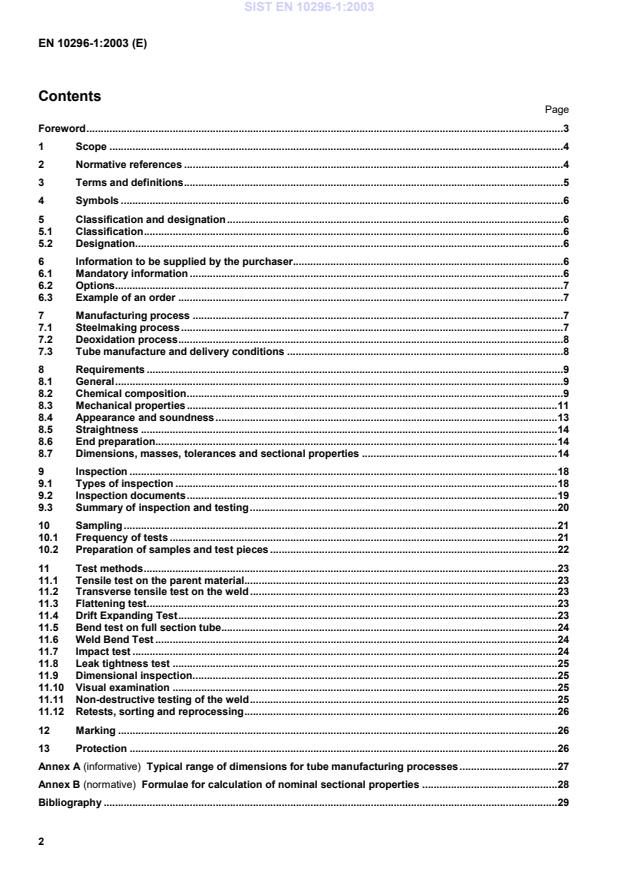

Typical range of dimensions for tube manufacturing processes.27Annex B (normative)

Formulae for calculation of nominal sectional properties.28Bibliography.29SIST EN 10296-1:2003

products - Types of inspection documents.EN 10220, Seamless and welded steel tubes – Dimensions and masses per unit length.EN 10232, Metallic materials - Tube (in full section) - Bend test.EN 10233, Metallic materials - Tube - Flattening test.EN 10234, Metallic materials - Tube - Drift expanding test.EN 10246-1, Non-destructive testing of steel tubes - Part 1: Automatic electromagnetic testing of seamless andwelded (except submerged arc-welded) ferromagnetic steel tubes for verification of hydraulic leak-tightness.EN 10246-3, Non-destructive testing of steel tubes - Part 3: Automatic eddy current testing of seamless and welded(except submerged arc-welded) steel tubes for the detection of imperfections.EN 10246-5, Non-destructive testing of steel tubes - Part 5: Automatic full peripheral magnetic transducer/fluxleakage testing of seamless and welded (except submerged arc-welded) ferromagnetic steel tubes for the detectionof longitudinal imperfections.EN 10246-7, Non-destructive testing of steel tubes - Part 7: Automatic full peripheral ultrasonic testing of seamlessand welded (except submerged arc-welded) steel tubes for the detection of longitudinal imperfections.

1)In preparation; until this document is published as a European Standard, a corresponding national standard should be agreed at the time ofenquiry and order.SIST EN 10296-1:2003

2 non-destructivetesting personnel.CR 10260, Designation systems for steel - Additional symbols.prEN 102662), Steel tubes, fittings and structural hollow sections – Symbols and definitions of terms for use inproduct standards.EN ISO 377, Steel and steel products - Location and preparation of samples and test pieces for mechanical testing(ISO 377:1997).EN ISO 643 , Steels - Micrographic determination of the apparent grain size (ISO/DIS 643:2003).EN ISO 2566-1, Steel – Conversion of elongation values - Part 1: Carbon and low alloy steels (ISO 2566-1:1984).3 Terms and definitionsFor the purposes of this Part of EN 10296, the terms and definitions given in EN 10020, EN 10021, EN 10052 andprEN 10266 and the following apply.3.1fine grain steelsteel having an austenitic/ferritic grain size equal to or finer than 6 when measured in accordance with EN ISO 643.3.2normalizing rollingrolling process in which the final deformation is carried out in a certain temperature range leading to a materialcondition equivalent to that obtained after normalizing so that the specified values of the mechanical properties areretained even after normalizing (+N)3.3thermomechanical rollingrolling process in which the final deformation is carried out in a certain temperature range leading to a materialcondition with certain properties which cannot be achieved or repeated by heat treatment aloneNOTE 1The abbreviated form of this delivery condition is M.NOTE 2Subsequent heating above 580°C may lower the strength values. If temperatures above 580°C are neededreference should be made to the supplier.NOTE 3 Thermomechanical rolling leading to the delivery condition M can include processes with an increasing cooling ratewith or without tempering including self-tempering but excluding direct quenching and tempering.3.4hot reducingprocess in which the outside diameter of a tube is reduced by a rolling and/or stretching process after heating intothe austenitic region (i.e. above Ac3)

2)In preparation; until this document is published as a European Standard, a corresponding national standard should be agreed at the time ofenquiry and order.SIST EN 10296-1:2003

In theevent that the purchaser does not indicate his wish to implement any of these options at the time of enquiry andorder the tube shall be supplied in accordance with the basic specification (see 6.1).1) Process of tube manufacture (see 7.3.1);2) delivery condition of EW (see 7.3.2);3) tube shall be supplied descaled (see 7.3.2);4) EW tubes shall be produced from pickled strip (see 7.3.2);5) non-destructive testing of the weld (see 8.4.2);6) a leak tightness test (see 8.4.2);7) random lengths (see 8.7.2);8) exact lengths (see 8.7.2);9) restriction of the residual height of the internal weld bead of EW tube (see 8.7.3.1);10) specific inspection and testing for tube made of non-alloy quality steel (see 5.1 and 9.1);11) inspection document type 2.2 (see 9.2.1);12) inspection document type 3.1.A, 3.1.C or 3.2 (see 9.2.1);13) flattening test or drift expanding or

bend test (whole tube) (see 9.3);14) selection of leak tightness test method for EW tube (see 11.8.1);15) special coating for transit and storage (see clause 13).6.3 Example of an orderFifteen tonnes of tube with specified outside diameter of 60,3 mm and a specified wall thickness of 3,6 mm made ofsteel in accordance with EN 10296-1 grade E275 supplied with specific inspection and testing.15 tTube60,3 x 3,6 EN 10296-1 E275Option 107 Manufacturing process7.1 Steelmaking processThe steelmaking process is at the discretion of the manufacturer.Elements not included in Tables 2, 3 or 4 for the relevant grade shall not be intentionally added to the steel withoutthe agreement of the purchaser, except for elements which may be added for finishing the cast. All appropriateSIST EN 10296-1:2003

The process is at the discretion of the manufacturer unless option 1 is specified.Option 1:The process of tube manufacture is specified by the purchaser from those mentioned in the aboveparagraph.A Table of typical dimension ranges for the different manufacturing processes is given for information in annex A.EW tubes shall not include welds used for joining lengths of the strip prior to forming the tube.Laser beam welded and submerged arc welded tubes may be longitudinally or helically welded.

Strip used for themanufacture of helically, laser beam welded (LBWH) or submerged arc-welded (SAWH) tubes shall have a width ofnot less than 0,8 times or more than 3,0 times the outside diameter of the tube.

Longitudinal welded LBW or SAWtubes shall not include welds used for joining together lengths of the strip prior to forming.

LBWH or SAWH tubesmay include the weld joining together lengths of the strip prior to forming, provided this weld is subject to the sameinspection and testing as the helical weld.SAWL tubes may be cold sized by cold expanding (see Table 1).7.3.2Tubes shall be delivered in one of the delivery conditions shown in Table 1.The delivery condition of EW tube including heat treatment is at the discretion of the manufacturer unless option 2is specified.Option 2 :The delivery condition of EW tube is specified by the purchaser from those shown in Table 1.When option 3 is specified tube shall be supplied descaled . The amount of scale shall be agreed at the time ofenquiry and order.

The method is at the discretion of the manufacturer.Option 3:Tubes shall be supplied descaled.The starting material for tubes is at the discretion of the manufacturer unless option 4 is specified.Option 4:EW tubes shall be produced from pickled strip.7.3.3All NDT activities shall be carried out by qualified and competent level 1, 2 and/or 3 personnel authorisedto operate by the employer.The qualification shall be in accordance with EN 10256 or at least an equivalent to it.It is recommended that the level 3 personnel be certified in accordance with EN 473 or at least an equivalent to it.The operating authorisation issued by the employer shall be in accordance with a written procedure.NDT operations shall be authorised by a level 3 NDT individual approved by the employer.NOTE The definition of level 1, 2 and 3 can be found in appropriate Standards, e.g. EN 473 and EN 10256.SIST EN 10296-1:2003

ornormalized rolledstrip/plateCold formedorhot formedAs welded c f+UThermomechanicallyrolled strip/plate eCold formed aAs weldedNoneSubmerged arc-welded- longitudinal (SAWL)or- helical (SAWH) seamHot rolled strip/plateor normalized rolledstrip/plateCold formedorHot formedAs welded c f+UThermomechanicallyrolled strip/plate eCold formed aAs weldedNoneaIncludes cold sized/cold finished at manufacturers discretion.bAn appropriate heat treatment of the weld zone is permitted.cAn as welded product from which the +N properties can be achieved after heat treatment.dAn as welded product from which the +N properties may not be achieved after heat treatment.eOnly available in conjunction with steels from Table 4.fTubes may be supplied hot sized or cold sized (with or without heat treatment) at the discretion of themanufacturer.8 Requirements8.1 GeneralThe tubes, when supplied in a delivery condition indicated in Tables 6, 7, 8 and 9 and inspected in accordance withclause 9 shall conform to the requirements of this Part of EN10296.

In addition, the general technical deliveryrequirements specified in EN 10021 apply.8.2 Chemical compositionThe cast analysis reported by the steel producer shall apply and shall conform to the requirements of Table 2, 3and 4.SIST EN 10296-1:2003

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...