SIST EN 10242:2026

(Main)Threaded pipe fitting in malleable cast iron

Threaded pipe fitting in malleable cast iron

This document specifies the requirements for the design and performance of threaded pipe fittings in malleable cast iron with black or hot dip galvanized surface.

These fittings are for general purposes for the transmission of fluids and gases up to the limits of operating pressure and operating temperature specified in this document. They are intended for the connection of elements threaded with sizes 1/8 to 6 (DN 6 to DN 150).

Fittings with alternative permanent coatings or permanent coatings on top of hot dip galvanizing do not fall under the scope of this document.

NOTE One main use is for the connection of non-alloy steel tubes according to EN 10255 and with support of the thread joint by using sealing materials according to the EN 751 series.

Gewindefittings aus Temperguss

Dieses Dokument legt die Anforderungen an die Konstruktion und Gebrauchseigenschaften von Gewindefittings in Temperguss mit unverzinkten oder schmelztauchverzinkten Oberflächen fest.

Diese Fittings dienen allgemein der Übertragung von Fluiden und Gasen bis zu den in diesem Dokument festgelegten Betriebsdruck- und Betriebstemperaturgrenzen. Sie sind bestimmt für die Verbindung von Teilen mit Gewinden in den Größen 1/8 bis 6 (DN 6 bis DN 150).

Fittings mit alternativen dauerhaften Beschichtungen oder dauerhaften Beschichtungen über der Schmelztauchverzinkung fallen nicht in den Anwendungsbereich dieses Dokumentes.

ANMERKUNG Eine wesentliche Anwendung ist die Verbindung unlegierter Stahlrohre nach EN 10255 und mit Unterstützung des Gewindeanschlusses durch Verwendung von Dichtungswerkstoffen nach EN 751 (alle Teile).

Raccords de tuyauterie filetés en fonte malléable

Le présent document spécifie les exigences de conception et de performance des raccords de tuyauterie filetés en fonte malléable avec une surface noire ou galvanisée à chaud.

Ces raccords, d'usage général, servent au transport de fluides et de gaz dans les limites de pression de service et de température de service spécifiées dans le présent document. Ils sont prévus pour le raccordement d'éléments filetés de diamètre ⅛ à 6 (DN 6 à DN 150).

Les raccords présentant des revêtements permanents alternatifs ou des revêtements permanents appliqués sur la galvanisation à chaud ne relèvent pas du domaine d'application du présent document.

NOTE Une des principales utilisations est le raccordement de tubes en acier non allié conformes à l'EN 10255 et le maintien de la jonction filetée à l’aide de matériaux d'étanchéité conformes à l'EN 751 (toutes les parties).

Fitingi z navojem iz temprane litine

General Information

- Status

- Published

- Public Enquiry End Date

- 12-Jul-2022

- Publication Date

- 22-Dec-2025

- Technical Committee

- IFEK - Ferrous metals

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 18-Dec-2025

- Due Date

- 22-Feb-2026

- Completion Date

- 23-Dec-2025

Relations

- Effective Date

- 17-Dec-2025

- Effective Date

- 17-Dec-2025

- Effective Date

- 17-Dec-2025

- Effective Date

- 18-Jan-2023

Overview

EN 10242:2025 - Threaded pipe fittings in malleable cast iron is a CEN European Standard that specifies design, performance and inspection requirements for threaded pipe fittings made from malleable cast iron with either black or hot dip galvanized surfaces. The standard covers fittings intended for the transmission of fluids and gases and for connecting elements with thread sizes 1/8 to 6 (DN 6 to DN 150). Fittings with alternative permanent coatings or coatings applied on top of galvanizing are excluded.

Key topics and technical requirements

- Material requirements: Defines accepted malleable cast iron grades and allows some other ferrous materials where specified.

- Corrosion protection: Requirements for hot dip galvanizing (chemical composition, coating mass and thickness, surface condition) and rules for black-finished fittings. Includes provisions on dangerous substances and despatch conditions.

- Design and dimensions: Design characteristic, dimensions, tolerances, lengths of engagement and widths across flats for spanner use. A new subclause on reaction to fire is included.

- Threads: Specifies acceptable jointing threads (EN 10226-1 / EN 10226-2) and fastening threads (EN ISO 228-1), thread alignment, chamfering and inspection criteria.

- Performance and testing: Leak tightness tests, hydrostatic pressure tests for higher performance classes, tensile testing references, coating thickness measurement and polycyclic aromatic hydrocarbons (PAH) analysis where applicable.

- Manufacture, inspection and documentation: Manufacturing controls, inspection sampling (ISO 2859-1), traceability, quality and product documentation, and marking/designation rules for ordering.

Practical applications

EN 10242:2025 is intended for general-purpose piping systems where robust, threaded connections are required:

- Domestic and commercial plumbing and water distribution

- Gas installations and low-pressure fluid transmission

- Industrial piping where malleable cast iron fittings are preferred for mechanical strength

- Connections to non-alloy steel tubes (EN 10255) using EN 751-series sealing materials

The standard ensures compatibility, safety and repeatable performance of threaded malleable cast iron fittings across European markets.

Who should use this standard

- Manufacturers and foundries producing malleable cast iron fittings

- Product designers and piping engineers specifying components for fluid and gas systems

- Quality inspectors, test houses and certification bodies performing compliance checks

- Procurement and compliance teams requiring standardized product designation and documentation

Related standards

Key normative references include:

- EN 1562 (malleable cast irons)

- EN 10226-1 / EN 10226-2 (pipe threads for pressure-tight joints)

- EN ISO 228-1 (non-pressure-tight threads)

- EN 10255 (non-alloy steel tubes)

- EN ISO 1460, EN ISO 2178 (coating measurement)

- EN ISO 6892-1 (tensile testing)

- ISO 2859-1 (sampling procedures)

By following EN 10242:2025, stakeholders gain clear technical requirements for safe, interoperable and inspected threaded malleable cast iron fittings.

Frequently Asked Questions

SIST EN 10242:2026 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Threaded pipe fitting in malleable cast iron". This standard covers: This document specifies the requirements for the design and performance of threaded pipe fittings in malleable cast iron with black or hot dip galvanized surface. These fittings are for general purposes for the transmission of fluids and gases up to the limits of operating pressure and operating temperature specified in this document. They are intended for the connection of elements threaded with sizes 1/8 to 6 (DN 6 to DN 150). Fittings with alternative permanent coatings or permanent coatings on top of hot dip galvanizing do not fall under the scope of this document. NOTE One main use is for the connection of non-alloy steel tubes according to EN 10255 and with support of the thread joint by using sealing materials according to the EN 751 series.

This document specifies the requirements for the design and performance of threaded pipe fittings in malleable cast iron with black or hot dip galvanized surface. These fittings are for general purposes for the transmission of fluids and gases up to the limits of operating pressure and operating temperature specified in this document. They are intended for the connection of elements threaded with sizes 1/8 to 6 (DN 6 to DN 150). Fittings with alternative permanent coatings or permanent coatings on top of hot dip galvanizing do not fall under the scope of this document. NOTE One main use is for the connection of non-alloy steel tubes according to EN 10255 and with support of the thread joint by using sealing materials according to the EN 751 series.

SIST EN 10242:2026 is classified under the following ICS (International Classification for Standards) categories: 23.040.40 - Metal fittings. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 10242:2026 has the following relationships with other standards: It is inter standard links to SIST EN 10242:1997/A1:2000/AC:2000, SIST EN 10242:1997/A1:2000, SIST EN 10242:1997/A2:2003, SIST EN 10242:1997. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 10242:2026 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2026

Nadomešča:

SIST EN 10242:1997/A1:2000

SIST EN 10242:1997/A1:2000/AC:2000

SIST EN 10242:1997/A2:2003

Fitingi z navojem iz temprane litine

Threaded pipe fitting in malleable cast iron

Gewindefittings aus Temperguss

Raccords de tuyauterie filetés en fonte malléable

Ta slovenski standard je istoveten z: EN 10242:2025

ICS:

23.040.40 Kovinski fitingi Metal fittings

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 10242

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2025

EUROPÄISCHE NORM

ICS 23.040.40 Supersedes EN 10242:1994

English Version

Threaded pipe fittings in malleable cast iron

Raccords de tuyauterie filetés en fonte malléable Gewindefittings aus Temperguss

This European Standard was approved by CEN on 17 November 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 10242:2025 E

worldwide for CEN national Members.

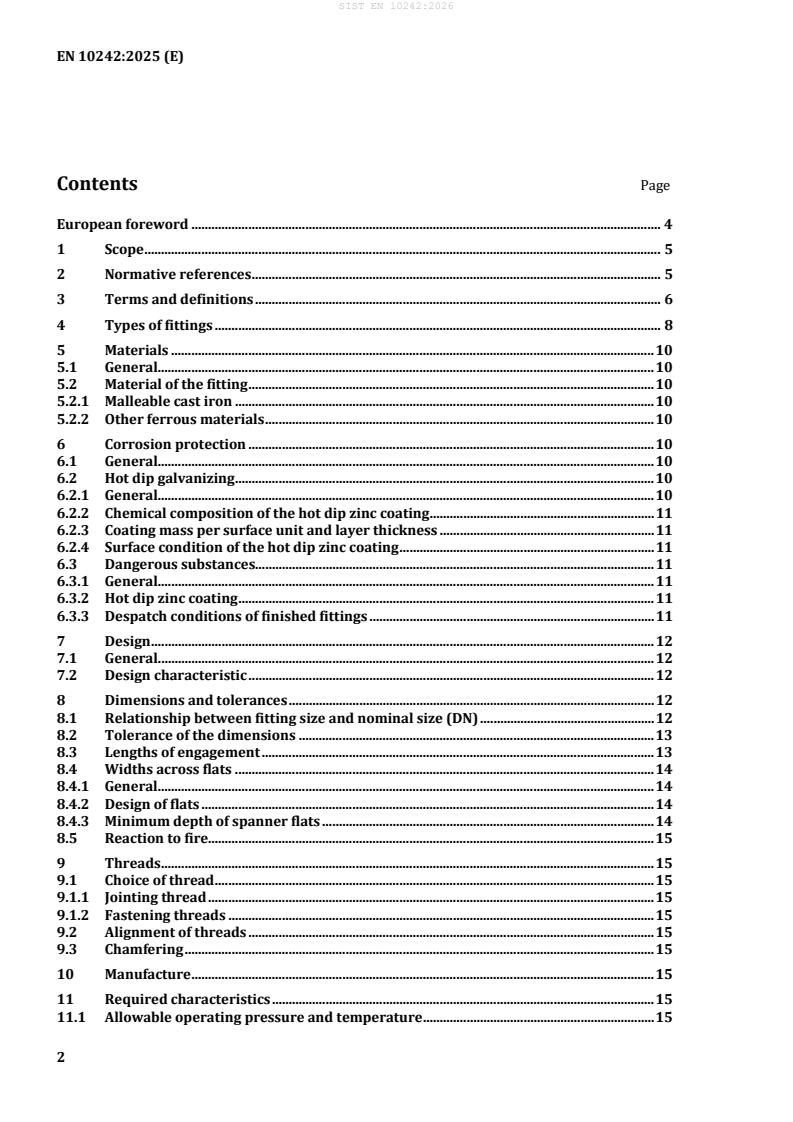

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Types of fittings . 8

5 Materials . 10

5.1 General. 10

5.2 Material of the fitting . 10

5.2.1 Malleable cast iron . 10

5.2.2 Other ferrous materials . 10

6 Corrosion protection . 10

6.1 General. 10

6.2 Hot dip galvanizing . 10

6.2.1 General. 10

6.2.2 Chemical composition of the hot dip zinc coating . 11

6.2.3 Coating mass per surface unit and layer thickness . 11

6.2.4 Surface condition of the hot dip zinc coating . 11

6.3 Dangerous substances. 11

6.3.1 General. 11

6.3.2 Hot dip zinc coating . 11

6.3.3 Despatch conditions of finished fittings . 11

7 Design . 12

7.1 General. 12

7.2 Design characteristic . 12

8 Dimensions and tolerances . 12

8.1 Relationship between fitting size and nominal size (DN) . 12

8.2 Tolerance of the dimensions . 13

8.3 Lengths of engagement . 13

8.4 Widths across flats . 14

8.4.1 General. 14

8.4.2 Design of flats . 14

8.4.3 Minimum depth of spanner flats . 14

8.5 Reaction to fire. 15

9 Threads . 15

9.1 Choice of thread . 15

9.1.1 Jointing thread . 15

9.1.2 Fastening threads . 15

9.2 Alignment of threads . 15

9.3 Chamfering . 15

10 Manufacture . 15

11 Required characteristics . 15

11.1 Allowable operating pressure and temperature . 15

11.2 Design strength . 16

11.3 Assembly . 16

12 Testing and inspection. 17

12.1 Malleable cast iron . 17

12.2 Hot dip zinc coating. 17

12.3 Threads . 17

12.3.1 Jointing threads . 17

12.3.2 Fastening threads . 17

12.3.3 Alignment . 17

12.4 Leak tightness test . 17

12.5 Final visual inspection . 18

12.6 Acceptance tests for higher performances . 18

12.6.1 General . 18

12.6.2 Hydrostatic pressure tests . 18

12.7 Analysis of polycyclic aromatic hydrocarbons . 18

12.8 Inspection documents . 18

12.8.1 Quality documentation . 18

12.8.2 Product documentation . 18

13 Designation of fittings . 18

13.1 Elements of the designation for ordering . 18

13.2 Additional notes on designation of size . 18

13.3 Example of designation . 19

14 Marking . 20

15 Tables with dimensions . 21

Bibliography . 49

European foreword

This document (EN 10242:2025) has been prepared by Technical Committee CEN/TC 459 “ECISS -

European Committee for Iron and Steel Standardization” , the Secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2026 and conflicting national standards shall be

withdrawn at the latest by June 2026.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 10242:1994.

This document includes the following significant technical changes with respect to EN 10242:1994:

— normative references have been updated;

— additional fittings types used in UK have been introduced in Table 1;

— terms and definitions under Clause 3 have been revised;

— requirements for hot dip galvanizing under 6.2.1 have been changed, and the chemical

composition with regard to dangerous substances under 6.2.2 has been adjusted;

— malleable cast iron grades in 5.2.1 have been reduced and therefore the number of Design

Symbols in Table 2 has been reduced;

— new subclause 8.5 “Reaction to fire” has been added;

— change from ISO to EN requirements in 12.3 has been made;

— Method B for designation has been moved to a note under 13.2;

— Clause 12 has become subclause 12.8.1 and has been updated;

— additional types and sizes used in UK have been introduced in the tables in Clause 15.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Through its sub-committee CEN/TC 459/SC 10 “Steel tubes, and iron and steel fittings” (secretariat: UNI).

1 Scope

This document specifies the requirements for the design and performance of threaded pipe fittings in

malleable cast iron with black or hot dip galvanized surface.

These fittings are for general purposes for the transmission of fluids and gases up to the limits of

operating pressure and operating temperature specified in this document. They are intended for the

connection of elements threaded with sizes 1/8 to 6 (DN 6 to DN 150).

Fittings with alternative permanent coatings or permanent coatings on top of hot dip galvanizing do not

fall under the scope of this document.

NOTE One main use is for the connection of non-alloy steel tubes according to EN 10255 and with support of

the thread joint by using sealing materials according to the EN 751 series.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1562, Founding — Malleable cast irons

EN 10204, Metallic products — Types of inspection documents

EN 10216-1, Seamless steel tubes for pressure purposes — Technical delivery conditions — Part 1: Non-

alloy steel tubes with specified room temperature properties

EN 10216-2, Seamless steel tubes for pressure purposes — Technical delivery conditions — Part 2: Non-

alloy and alloy steel tubes with specified elevated temperature properties

EN 10217-1, Welded steel tubes for pressure purposes — Technical delivery conditions — Part 1: Electric

welded and submerged arc welded non-alloy steel tubes with specified room temperature properties

EN 10217-2, Welded steel tubes for pressure purposes — Technical delivery conditions — Part 2: Electric

welded non-alloy and alloy steel tubes with specified elevated temperature properties

EN 10226-1, Pipe threads where pressure tight joints are made on the threads — Part 1: Taper external

threads and parallel internal threads — Dimensions, tolerances and designation

EN 10226-2, Pipe threads where pressure tight joints are made on the threads — Part 2: Taper external

threads and taper internal threads — Dimensions, tolerances and designation

EN 10255, Non-Alloy steel tubes suitable for welding and threading — Technical delivery conditions

EN ISO 228-1, Pipe threads where pressure-tight joints are not made on the threads — Part 1: Dimensions,

tolerances and designation (ISO 228-1)

EN ISO 1460, Metallic coatings — Hot dip galvanized coatings on ferrous materials — Gravimetric

determination of the mass per unit area (ISO 1460)

EN ISO 2178, Non-magnetic coatings on magnetic substrates — Measurement of coating thickness —

Magnetic method (ISO 2178)

EN ISO 6892-1, Metallic materials — Tensile testing — Part 1: Method of test at room temperature

(ISO 6892-1)

ISO 2859-1, Sampling procedures for inspection by attributes — Part 1: Sampling schemes indexed by

acceptance quality limit (AQL) for lot-by-lot inspection

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

fitting

connecting piece for pipes and other piping accessories, consisting of one or more parts

3.2

jointing thread

thread complying with EN 10226-1 or EN 10226-2

3.3

fastening thread

thread complying with EN ISO 228-1

3.4

fitting size

nominal size of the connecting (steel) pipe(s)

Note 1 to entry: See also 8.1.

3.5

designation of thread size

size designation of the thread in inch according to EN 10226-1 or EN 10226-2

3.6

nominal size

DN

alphanumeric designation of size for components of a pipework system, which is used for reference

purposes

Note 1 to entry: See EN ISO 6708.

Note 2 to entry: It comprises the letters DN followed by a dimensionless whole number which is indirectly related

to the physical size, in millimetres, of the bore or outside diameter of the end connections.

Note 3 to entry: Nominal size (DN) should not be used for the designation of fitting size.

Note 4 to entry: The relationship between fitting size and nominal size (DN) is given in Table 3 for information.

3.7

reinforcement

additional material on the outside diameter of an internally threaded fitting

EXAMPLE Examples for reinforcements are shown in Figure 1.

a) Bead b) Band

Figure 1 — Forms of reinforcement

3.8

rib

local and axially aligned additional material on the outside or inside of a fitting for assistance in assembly

or manufacturing

3.9

outlet

end of a fitting for the purpose of connection with a pipe or other piping accessories

3.10

run

two principal axially aligned outlets of a tee or cross

3.11

branch

side outlet(s) of a tee or cross

3.12

chamfer

removal of a conical portion at the entrance of a thread to assist assembly and prevent damage to the

start of the thread

3.13

face-to-face dimension

distance between the two parallel faces of axially aligned outlets of a fitting

3.14

face-to-centre dimension

distance between the face of an outlet and the central axis of an angularly disposed outlet

3.15

laying length

average distance from the assembled pipe end to the axis of the fitting, or between the ends of two

assembled pipes

Note 1 to entry: See also 8.3.

4 Types of fittings

Table 1 gives an index to the fitting types, patterns and symbols. The symbols allow the identification of

fittings and shall be used for designation (see 13.1).

Table 1 — Index of fitting types, symbols and index to tables and patterns

Types Patterns

Symbols A1 A1/45° A4 A4/45°

A

Elbows

Table 9 Table 10 Table 11 Table 9 Table 10 Table 11

Symbols B1 B4

B

Tees

Table 9 Table 12 Table 12 Table 13 Table 13 Table 9

Symbols C1

C

Crosses

Table 9 Table 14

Symbols D1 D4 D8

D

Short

bends

Table 15 Table 15 Table 15

Symbols E1 E2

E

Pitcher

tees

Twin

elbows

Table 15 Table 16 Table 16 Table 16 Table 15 Table 17

Symbols G1 G1/45° G4 G4/45° G8

G

Long

sweep

bends

Table 18 Table 19 Table 18 Table 19 Table 18

Types Patterns

Symbols M2 M4 M3

M

Sockets

Table 20 Table 20 Table 21 Table 21 Table 20

Symbols N4 N8

N

Bushings

Hexagon

nipples

Table 22 Table 22 Table 22 Table 23 Table 23

Symbols P4

P

Backnut

Table 24

Symbols T1 T8 T9 T11

T

Caps

Plugs

Table 25 Table 25 Table 25 Table 25

Symbols U1 U2 U11 U12

U

Unions

Table 26 Table 26 Table 26 Table 26

Symbols UA1 UA2 UA11 UA12

UA

Union

elbows

Table 27 Table 27 Table 27 Table 27

Symbols Za1 Za2

Za

Side

outlet

elbows

Table 9 Table 9

and tees

5 Materials

5.1 General

All materials of fitting body and components shall be resistant against the medium of the respective

application.

NOTE In case of potable water, national hygienic requirements apply.

No component of the fitting shall show any signs of damage, pitting, bubbles, sand, blisters, inclusions or

cracks to an extent that would prevent compliance with this document. They shall not be treated to cover

such defects. The sealing surfaces shall be free of all scratches, blisters or cracks that might affect the leak

tightness of the assembled joint.

5.2 Material of the fitting

5.2.1 Malleable cast iron

The material used shall be malleable cast iron conforming to EN 1562. The grade of material used shall

be selected from the following grades (see Clause 7):

— grade EN-GJMW-400-5 for fittings in whiteheart malleable cast iron;

— grade EN-GJMB-350-10 for fittings in blackheart malleable cast iron.

5.2.2 Other ferrous materials

Despite this requirement, any other ferrous materials which give mechanical properties at least

equivalent to those malleable cast irons specified in EN 1562, shall be considered in compliance with this

document for straight fittings not larger than 3/8, but excluding unions.

6 Corrosion protection

6.1 General

In applications where materials can be exposed to corrosion, the components shall be adequately

protected as specified in 6.2.

6.2 Hot dip galvanizing

6.2.1 General

Where a protection by zinc coating is required, the zinc coating shall be applied by the hot dip galvanizing

process and shall meet the following requirements.

Fittings with alternative permanent coatings or permanent coatings on top of hot dip galvanizing don't

fall under the scope of this document.

For fittings supplied in other ferrous materials (such as carbon steel, see 5.2.2), an alternative zinc coating

may be provided by agreement with the purchaser.

6.2.2 Chemical composition of the hot dip zinc coating

The content by mass of the accompanying elements in the finished zinc coating shall not exceed the

following maximum values:

antimony (Sb) 0,01 %

arsenic (As) 0,02 %

bismuth (Bi) 0,01 %

cadmium (Cd) 0,01 %

lead (Pb) 0,1 %

NOTE The chemical composition is restricted with regard to the limitation of dangerous substances also in

respect to potable water applications. When fittings are used in potable water applications, relevant national

hygienic regulations apply.

6.2.3 Coating mass per surface unit and layer thickness

The surface related mass of the zinc coating shall not be less than 500 g/m , which equals to a layer

thickness of 70 μm. These limits refer to the average of 5 fittings with 10 measurements each, statistically

distributed across the fitting. The layer mass/thickness measured on an individual sample shall not be

less than 450 g/m (63 μm).

s

The medium layer thickness of the zinc coating in μm shall be calculated by using the approximation

formula

m

A

s=

72,

where

m is the surface related mass of the zinc coating in g/m .

A

6.2.4 Surface condition of the hot dip zinc coating

The internal zinc coating shall be continuous, with the exception of the machined black surfaces, and free

from zinc blisters, zinc burrs or non-metallic additions. In the case of larger diameter items, iron-zinc

alloy phases, leading to a dull grey finish, may be present, but this will not affect the degree of protection

provided.

6.3 Dangerous substances

6.3.1 General

For the use of fittings produced in accordance with this document, national regulations with regard to

dangerous substances can apply.

6.3.2 Hot dip zinc coating

The chemical composition of the hot dip zinc coating shall not exceed the limits given in 6.2.2.

6.3.3 Despatch conditions of finished fittings

The surfaces of the fittings shall be free of polycyclic aromatic hydrocarbons.

7 Design

7.1 General

The fittings are compatible with tubes according to EN 10255, EN 10216-1, EN 10216-2, EN 10217-1 and

EN 10217-2.

The minimum wall thickness of the tube for thread cutting, given by EN 10255 shall be considered.

7.2 Design characteristic

Fittings shall be identified by the design symbol according to the selected material (see 5.2.1), the choice

of thread (see 9.1.1) and the type of reinforcement, if applicable, as given in Table 2.

Table 2 — Design symbol

Design Thread type Material grade Reinforcement of internally

symbol threaded ends

external internal

EN-GJMW-400-5 or

A R Rp Bead, see Figure 1a)

EN-GJMB-350-10

EN-GJMW-400-5 or

C R Rc Band, see Figure 1b)

EN-GJMB-350-10

NOTE Design symbols B and D have been removed during the latest revision.

The drawings in Table 9 to Table 27 are schematic, without prejudice to the manufactured form.

Dimensionally standardized types and fitting sizes are shown in Table 9 to Table 27.

The dimensions of the gaskets for flat seat unions are specified in Table 28.

Fittings shall be reinforced at the internally threaded ends, except where they are polygonal in shape to

allow for spanner flats, or where fittings have side outlets (type Za1 and Za2).

Manufacturers may incorporate ribs at their discretion. Ribs shall not project higher than the

reinforcement.

Backnuts may be plain or recessed and one face may be machined.

Table 26 and Table 27 show two typical types of seats of unions and their designation. Other types of seat

design and seat material shall be considered as complying with this document, if they meet the

dimensions specified in Table 26 and Table 27 and the requirements of this document. Such unions do

not have a specific designation according to this document.

8 Dimensions and tolerances

8.1 Relationship between fitting size and nominal size (DN)

The relationship between designation of the fitting size (equal to thread size) and nominal diameter (DN)

is given in Table 3 for guidance only.

Table 3 — Fitting size and nominal diameter

Designation of

thread size/fitting 1/8 1/4 3/8 1/2 3/4 1 1 1/4 1 1/2 2 2 1/2 3 4 5 6

size

Nominal size, DN 6 8 10 15 20 25 32 40 50 65 80 100 125 150

8.2 Tolerance of the dimensions

Fittings shall have the appropriate dimensions given in Table 9 to Table 27. Where maximum or

minimum dimensions are not specified, the tolerances for the face-to-face and face-to-centre dimensions

shall be as given in Table 4. The face-to-face and face-to-centre dimensions of unions may exceed the

tolerance given due to the compound effect of piece tolerances upon the final assembly.

NOTE 1 Fitting sizes shown in brackets are optional sizes.

NOTE 2 The face-to-face and face-to-centre dimensions of unions can exceed the tolerance given due to the

compound effect of piece tolerances upon the final assembly.

Table 4 — Tolerance on length

Dimensions in millimetres

a

Fitting measurement Tolerance

≤ 30 ±1,5

> 30 ≤ 50 ±2,0

> 50 ≤ 75 ±2,5

> 75 ≤ 100 ±3,0

> 100 ≤ 150 ±3,5

> 150 ≤ 200 ±4,0

> 200 ±5,0

a

Measurements according to Table 9 to Table 27.

8.3 Lengths of engagement

Laying lengths are given for assistance and guidance during installation. Their accuracy is dependent

upon the tolerances given in 8.2 and on the tolerance of the threads specified in 9.1. The dimensions z

given in Table 9 to Table 27 are the average distance from the pipe end to the axis of the fitting (see

Figure 2) or the distance from pipe end to pipe end (see Figure 3).

These laying lengths are calculated by deducting average lengths of engagement from the face-to-face or

face-to-centre dimensions given in the tables. The average lengths of engagement are rounded from the

dimensions of the threads specified in 9.1.1 and are given in Table 5.

Table 5 — Lengths of engagement

Designation of

1/8 1/4 3/8 1/2 3/4 1 1 1/4 1 1/2 2 2 1/2 3 4 5 6

thread size

Length of

engagement,

7 10 10 13 15 17 19 19 24 27 30 36 40 40

mm

Figure 2 — Example of laying lengths z in the case of an angularly disposed fitting

Figure 3 — Example of laying length z in the case of an axially aligned fitting

8.4 Widths across flats

8.4.1 General

The dimensions of widths across flats depend on the design of the fittings and are at the discretion of the

manufacturer.

8.4.2 Design of flats

External flats on plugs shall be square. Flats on other fittings up to and including size 3/4 should be

hexagonal. Flats on other fittings above size 3/4 may be hexagonal or octagonal. Flats on union parts,

excluding the union nut, may be hexagonal, octagonal or decagonal.

8.4.3 Minimum depth of spanner flats

The minimum depth of the flats measured at the corners shall be as given in Table 6. For backnuts any

chamfering shall not reduce the depth of flat below the minimum dimension given in Table 6.

Table 6 — Minimum depth of spanner flats

Designation of

1/8 1/4 3/8 1/2 3/4 1 1 1/4 1 1/2 2 2 1/2 3 4 5 6

thread size

Min. depth of

4 4 5 5 5,5 6 6,5 6,5 7 7 7,5 8 8 8

spanner flats, mm

8.5 Reaction to fire

Malleable cast iron is class A1 in accordance with the Commission Decision 96/603/EEC of

4 October 1996 amended by the Council Decision of 28 September 2000 and therefore does not require

to be tested for reaction to fire.

9 Threads

9.1 Choice of thread

9.1.1 Jointing thread

Fittings shall be threaded in accordance with EN 10226-1 or EN 10226-2. External threads shall be

taper (R), internal threads shall be parallel (Rp) or taper (Rc).

9.1.2 Fastening threads

The threads of backnuts, union nuts and their mating threads shall be in accordance with EN ISO 228-1.

9.2 Alignment of threads

The axes of the screw threads shall be accurate within ±0,5° of the specified angle.

9.3 Chamfering

The jointing threads of the fittings shall have a chamfer.

On internal threads, the chamfer shall have an included angle of 90° to 120°, and the chamfer diameter at

the face shall exceed the major diameter of the thread.

On external threads, the chamfer shall be an included angle between 60° and 90° and the diameter at the

face shall not exceed the minor diameter of the thread at that face.

10 Manufacture

Fittings according to this document shall be produced using a quality management system, e.g. according

to EN ISO 9001 or equivalent.

11 Required characteristics

11.1 Allowable operating pressure and temperature

The fittings of all sizes shall be suitable for the maximum allowable operating pressures within the

operating temperature ranges given in Table 7, set out in Figure 4. Intermediate pressure ratings at

operating temperatures between +120 °C and +300 °C shall be obtained by linear interpolation. For

normal applications the lowest allowable operating temperature for fittings is –20 °C.

For special applications at operating temperatures below –20 °C, the manufacturer should be consulted.

Table 7 — Operating pressure/temperature ratings

Allowable operating temperature Maximum allowable operating pressure

a

°C MPa

–20 to +120 2,5

Between +120 and +300 interpolated values

+300 2,0

a 5 2

1 bar = 10 N/m = 0,1 MPa.

Key

p pressure, in MPa

t temperature, in °C

Figure 4 — Operating pressure/temperature ratings

11.2 Design strength

Pressure-containing fittings including the component parts of unions shall be designed to withstand the

design test pressures given in Table 8. Three fittings out of every size group and fitting type shall be type

tested in accordance with Table 8.

Table 8 — Hydrostatic design test pressures

Fitting size Hydrostatic design test pressure

a

Size 1/8 to Size 4 10 MPa

a

Size 5 and Size 6 6,4 MPa

a 5 2

1 bar = 10 N/m = 0,1 MPa.

For unions a leakage at the union joint is permissible below the pressure given in Table 8. The leakage

should not occur at a pressure below or equal to 1,5 × maximum allowable operating pressure at ambient

operating temperature (see 11.1).

11.3 Assembly

The fittings shall be capable of withstanding a force normally used during assembly of threads in

accordance with 9.1.

12 Testing and inspection

12.1 Malleable cast iron

The malleable cast iron shall meet the requirements of EN 1562 for the material grade specified in 5.2.1,

which shall be ensured by testing according to EN ISO 6892-1.

In addition to the test requirements of EN 1562, appropriate tests shall be conducted, after annealing and

before machining, to ensure that all fittings are satisfactorily malleabilised.

12.2 Hot dip zinc coating

Where protection by hot dip zinc coating is given, the chemical composition shall be tested in accordance

with 6.2. The elements specified in 6.2.2 shall be determined using spectroscopic or wet chemical analysis

methods.

The method of determination of the coating mass per surface unit area, see 6.2.3, according to

EN ISO 1460 shall be used. Alternatively, the thickness of the coating, shall be checked by using calibrated

electronic or magnetic instruments, according to EN ISO 2178 or by microscopic examination. The limits

given in 6.2.3 refer to the average of 5 fittings with 10 measurements each, statistically distributed across

the fitting.

Hot dip galvanized fittings shall be visually inspected for continuity of the zinc coating in accordance with

sampling plans given in ISO 2859-1.

12.3 Threads

12.3.1 Jointing threads

The manufacturer shall ensure by adequate control that the jointing threads meet the requirements of

9.1.1.

EN 10226-3 gives a recommended system of gauging but other systems of gauging may be used providing

they ensure equivalent results.

12.3.2 Fastening threads

Fastening threads shall meet the requirements of EN ISO 228-1.

EN ISO 228-2 gives a recommended system of gauging but other systems of gauging may be used

providing they ensure equivalent results.

12.3.3 Alignment

The alignment of the threads shall meet the requirements specified in 9.2.

12.4 Leak tightness test

All pressure containing fittings shall be tested after machining by one of the following methods. Each

fitting, when so tested, shall show no sign of leakage:

a) by the application at ambient temperature of an internal hydrostatic pressure of not less than

2,0 MPa; or

b) by the application of an internal pneumatic pressure of not less than 0,5 MPa, whilst the fitting is

completely immersed in water or light oil; or

c) by other tests which ensure an equivalent quality.

Fittings which do not satisfy the chosen test shall be rejected.

12.5 Final visual inspection

The fittings shall be free from visible casting or machining defects. The verification regarding this shall

be done by adequate visual inspection.

12.6 Acceptance tests for higher performances

12.6.1 General

If the customer requires acceptance tests for higher performances, these shall be stipulated and agreed

at the enquiry or order stage. Acceptance tests should be carried out with suitable equipment and the

manpower of the manufacturer.

12.6.2 Hydrostatic pressure tests

Acceptance tests for operating pressures above 2,5 MPa shall be carried out by hydrostatic pressure

according to the agreement at the order stage. The test pressure shall not exceed the limit beyond which

permanent deformations and changes to the thread dimensions would occur.

12.7 Analysis of polycyclic aromatic hydrocarbons

The verification of this requirement (see 6.2) shall be performed by high performance techniques of

chromatography - mass spectrometry or other relevant techniques of chemical analysis.

12.8 Inspection documents

12.8.1 Quality documentation

If required, details of the quality management system used shall be provided.

12.8.2 Product documentation

When specified, inspection documents in accordance with EN 10204 shall be provided – either a

Declaration of compliance with the order “type 2.1” or a Test report “type 2.2”.

13 Designation of fittings

13.1 Elements of the designation for ordering

For purchasing purposes, the fittings complying with this document shall be designated as follows:

a) the type of fitting, see Table 1;

b) EN 10242;

c) the symbol, see Table 1;

d) fitting size, see 13.2 and Table 9 to Table 27;

e) surface condition whether black (symbol Fe) or hot dip zinc coated (symbol Zn);

f) design symbol, see Clause 7.

13.2 Additional notes on designation of size

Equal fittings, where all outlets are of the same size, are referred to by that one size, irrespective of the

number of outlets.

Reducing fittings having two outlets are specified by their outlets in decreasing order (large outlet-small

outlet).

Reducing fittings having more than two outlets by not reducing on the run are specified as in the following

examples:

a) tees B1 and E1 with an increasing or reducing outlet on the branch. The size of the run is specified

followed by the size of the branch, for example, 1 × 3/4 (see Table 12 and Table 16);

b) twin elbows reducing E2. The size of the large outlet is specified followed by the size of the

two smaller outlets, for example, 1 1/2 × 1 1/4 (see Table 17);

c) reducing crosses C1. The size of the largest run is specified followed by the size of the two smaller

(but equal) branches, for example, 1 1/4 × 1 (see Table 14).

Reducing fittings having more than two outlets and reducing on the run or with three different outlets

shall be specified as shown in Figure 5.

Figure 5 describes the designation method according to this document. Alternatively, the designation of

reduced tees may be done using the order run-run-branch, if required.

Figure 5 — Sequence of specifying outlets

13.3 Example of designation

a) Equal female elbow size 2, black finish, design symbol A:

elbow EN 10242-A1-2-Fe-A

b) reducing tee with run 2 and branch 1, hot dip zinc coated, design symbol A:

tee EN 10242-B1-2×1-Zn-A

c) reducing tee with run 1 and 3/4 and branch 1/2 black finish, design symbol A:

tee EN 10242-B1-1×1/2×3/4-Fe-A

14 Marking

Unless it is not practicable because of casting method space limitations, fittings shall be marked by casting

at least with:

a) the manufacturer’s name or trademark;

b) the fitting size (as defined in 3.4).

Other markings shall not conflict with the markings detailed in a) and b).

When it is not practicable to mark fittings because of casting method space limitations, it is permissible

to omit either or both of the markings detailed in a) and b), as long as these marking is provided at the

packaging. In this case the fitting shall not be marked with any other marking.

15 Tables with dimensions

Table 9 — Elbows (A1); Male and female elbows (A4); Tees (B1); Male/female tees (B4); Crosses (C1); Side outlet elbows (Za1) and

Side outlet tees (Za2)

Fittings size Dimensions Laying length

mm mm

A1 A4 B1 C1 Za1 Za2 B4 a b c z

1/8 1/8 1/8 — — — — 19 25 — 12

1/4 1/4 1/4 (1/4) — — — 21 28 — 11

3/8 3/8 3/8 3/8 (3/8) (3/8) — 25 32 — 15

1/2 1/2 1/2 1/2 1/2 (1/2) 1/2 28 37 39 15

a

3/4 3/4 3/4 3/4 3/4 (3/4) 3/4 33 43 43(48 ) 18

1 1 1 1 (1) (1) 1 38 52 52 21

1 1/4 1 1/4 1 1/4 1 1/4 (1 1/4) — (1 1/4) 45 60 58 26

1 1/2 1 1/2 1 1/2 1 1/2 (1 1/2) — (1 1/2) 50 65 65 31

2 2 2 2 (2) — (2) 58 74 69 34

2 1/2 2 1/2 2 1/2 (2 1/2) — — — 69 88 — 42

3 3 3 (3) — — — 78 98 — 48

4 4 4 (4) — — — 96 118 — 60

(5) — (5) — — — — 115 — — 75

(6) — (6) — — — — 131 — — 91

Fittings size Dimensions Laying length

mm mm

A1 A4 B1 C1 Za1 Za2 B4 a b c z

A1 A4 Za1 B4 Za2

B1 C1

Dimensions which are not specified are left to the discretion of the manufacturer.

( ): see 8.1.

Tolerances: see Table 4.

Threads: in accordance with 9.1.1.

a

Optional measure c for B4 in brackets.

Table 10 — Elbows, reducing (A1); Male and female elbows, reducing (A4)

Fittings sizes Dimensions Laying lengths

mm mm

A1 A4 a b c z1 z2

(3/8 × 1/4) — 23 23 — 13 13

(1/2 × 1/4) — 25 25 — 12 15

1/2 × 3/8 1/2 × 3/8 26 26 33 13 16

(3/4 × 3/8) — 28 28 — 13 18

3/4 × 1/2 3/4 × 1/2 30 31 40 15 18

1 × 1/2 — 32 34 — 15 21

1 × 3/4 1 × 3/4 35 36 46 18 21

(1 1/4 × — 35 39 — 16 26

1/2)

1 1/4 × 3/4 — 36 41 — 17 26

1 1/4 × 1 1 1/4 × 1 40 42 56 21 25

(1 1/2 × 1) — 42 46 — 23 29

1 1/2 × — 46 48 — 27 29

1 1/4

(2 × 1 1/4) — 48 53 — 24 34

2 × 1 1/2 — 52 55 — 28 36

(2 1/2 × 2) — 61 66 — 34 42

A1 A4

Dimensions which are not specified are left to the discretion of the manufacturer.

( ): see 8.1.

Tolerances: see Table 4.

Threads: in accordance with 9.1.1.

Table 11 — 45° elbows (A1/45°); 45° male and female elbows (A4/45°)

Fitting sizes Dimensions Laying length

mm mm

A1/45° A4/45° a b z

(1/4) — 19 — 9

3/8 3/8 20 25 10

1/2 1/2 22 28 9

3/4 3/4 25 32 10

1 1 28 37 11

1 1/4 1 1/4 33 43 14

1 1/2 1 1/2 36 46 17

2 2 43 55 19

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...