SIST EN 12446:2011

(Main)Chimneys - Components - Concrete outer wall elements

Chimneys - Components - Concrete outer wall elements

This European Standard specifies the material, dimensional and performance requirements for factory made precast concrete outer wall elements for chimneys including outer wall fittings.

This European Standard covers elements having up to four passages designated to accommodate a combination of flue liners and/or ventilation passages.

This European Standard also relates to storey-height and reinforced outer wall elements.

This European Standard does not apply to structurally independent (freestanding or self-supporting) chimneys constructed using these outer wall elements.

NOTE Any reference to the term "outer wall element" implies both the outer wall elements and their fittings, except where otherwise indicated.

Abgasanlagen - Bauteile - Außenschalen aus Beton

Diese Europäische Norm legt die Werkstoffe, Maße und Leistungsanforderungen für werkseitig hergestellte Außenschalen aus Fertigbeton für Abgasanlagen, einschließlich Außenschalenformstücken fest.

Diese Europäische Norm beschreibt Außenschalen mit bis zu vier Durchgängen, die eine Kombination aus Innenrohren und/oder Lüftungsdurchgängen aufnehmen können.

Diese Europäische Norm gilt auch für geschosshohe und bewehrte Außenschalen.

Diese Europäische Norm gilt nicht für strukturell unabhängige (freistehende oder freitragende) Abgasanlagen, die unter Verwendung dieser Außenschalen errichtet wurden.

ANMERKUNG Der Begriff „Außenschalen“ bedeutet in dieser Norm immer „Außenschalen und deren Formstücke“, es sei denn, er ist ausdrücklich anders bezeichnet.

Conduits de fumée - Composants - Enveloppes externes en béton

La présente Norme européenne spécifie les exigences relatives aux matériaux, aux dimensions et aux

performances, pour les enveloppes externes de conduits en béton préfabriquées en usine, y compris les

accessoires des enveloppes externes.

Cette Norme européenne s’applique aux éléments ayant jusqu’à quatre canaux conçus pour s’adapter aux

combinaisons de conduits intérieurs et/ou de passages de ventilation.

Cette Norme européenne s’applique également aux enveloppes externes hauteur d'étage et aux enveloppes

externes armées.

La présente norme ne s'applique pas aux conduits de fumée structurellement indépendants (autostables ou

auto-portants) construits à l'aide de ces enveloppes externes.

NOTE Toute référence au terme « enveloppe externe » implique l’ensemble des enveloppes externes et leurs

accessoires, sauf indication contraire.

Dimniki - Sestavni deli - Betonski elementi plašča dimnika

Ta evropski standard določa zahteve glede materiala, mer in zmogljivosti za tovarniško narejene montažne betonske elemente plašča dimnika za dimnike, vključno z vodili na zunanji steni. Ta evropski standard zajema elemente, ki imajo do štiri prehode za namestitev kombinacije oblog za dimne cevi in/ali prehodov za prezračevanje. Ta evropski standard je prav tako povezan z višino nadstropja in ojačanih zunanjih zidnih elementov.

General Information

- Status

- Published

- Public Enquiry End Date

- 19-May-2010

- Publication Date

- 18-Sep-2011

- Technical Committee

- POZ - Požarna varnost

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 06-Jul-2011

- Due Date

- 10-Sep-2011

- Completion Date

- 19-Sep-2011

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 01-Oct-2010

Overview

EN 12446:2011 - Chimneys: Concrete outer wall elements is a CEN European Standard that specifies material, dimensional and performance requirements for factory-made precast concrete outer wall elements and their fittings for chimneys. The standard covers elements with up to four passages to accommodate flue liners and/or ventilation passages, including storey-height and reinforced outer wall elements. It does not apply to structurally independent (freestanding) chimneys built from these elements. EN 12446:2011 also includes provisions for conformity assessment and links to CE marking under the Construction Products Directive.

Key Topics

- Scope and definitions: Precise definitions for outer wall elements (hollow, solid, straight, storey-height) and manufacturer-declared dimensions.

- Materials and durability: Requirements for precast concrete composition, reaction to fire, surface treatments and reinforcement for handling.

- Form, dimensions and tolerances: Geometric criteria, tolerances and squareness of ends to ensure fit and assembly.

- Performance requirements and tests:

- Heat stress resistance and heat shock resistance (thermal performance)

- Thermal resistance and heat flow considerations (including high-pressure applications)

- Compressive strength and bulk density

- Freeze–thaw resistance

- Flexural strength under wind loading (new in 2011 revision)

- Gas tightness of passages used for combustion air

- Resistance to fire from external sources and soot fire resistance

- Release of dangerous substances

- Designation and marking: Temperature classes, pressure classes, distance to combustible materials, manufacturer’s information and labelling.

- Conformity & certification: Initial type testing, factory production control, sampling plans per ISO 2859-1 and Annex ZA guidance for CE marking and Declaration of Conformity.

Applications

EN 12446:2011 is essential for:

- Manufacturers of precast concrete chimney outer wall elements to design, test and declare product performance.

- Chimney system designers and specifiers ensuring components meet thermal, mechanical and fire-safety requirements.

- Installers and contractors selecting compliant elements for multi-pass chimney stacks in residential, commercial and industrial buildings.

- Test laboratories and certification bodies conducting initial type testing, factory production control and conformity assessment.

- Regulatory authorities and clients verifying CE marking and product documentation.

Keywords for search: EN 12446:2011, concrete outer wall elements, chimney components, precast concrete chimneys, thermal resistance, gas tightness, freeze-thaw resistance, CE marking.

Related Standards

- EN 1443 - Chimneys: General requirements

- EN 1857 - Chimneys: Concrete flue liners

- EN 1858 - Chimneys: Concrete flue blocks

- EN 14297 - Freeze–thaw test method for chimney products

- ISO 2859-1 - Sampling procedures for inspection by attributes

EN 12446:2011 is part of the coordinated European suite of chimney standards and supports harmonized design, testing and safe installation of concrete chimney systems.

Frequently Asked Questions

SIST EN 12446:2011 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Chimneys - Components - Concrete outer wall elements". This standard covers: This European Standard specifies the material, dimensional and performance requirements for factory made precast concrete outer wall elements for chimneys including outer wall fittings. This European Standard covers elements having up to four passages designated to accommodate a combination of flue liners and/or ventilation passages. This European Standard also relates to storey-height and reinforced outer wall elements. This European Standard does not apply to structurally independent (freestanding or self-supporting) chimneys constructed using these outer wall elements. NOTE Any reference to the term "outer wall element" implies both the outer wall elements and their fittings, except where otherwise indicated.

This European Standard specifies the material, dimensional and performance requirements for factory made precast concrete outer wall elements for chimneys including outer wall fittings. This European Standard covers elements having up to four passages designated to accommodate a combination of flue liners and/or ventilation passages. This European Standard also relates to storey-height and reinforced outer wall elements. This European Standard does not apply to structurally independent (freestanding or self-supporting) chimneys constructed using these outer wall elements. NOTE Any reference to the term "outer wall element" implies both the outer wall elements and their fittings, except where otherwise indicated.

SIST EN 12446:2011 is classified under the following ICS (International Classification for Standards) categories: 91.060.40 - Chimneys, shafts, ducts; 91.100.30 - Concrete and concrete products. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 12446:2011 has the following relationships with other standards: It is inter standard links to SIST EN 12446:2003, SIST EN 12446:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 12446:2011 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/105. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 12446:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Abgasanlagen - Bauteile - Außenschalen aus BetonConduits de fumée - Composants - Enveloppes externes en bétonChimneys - Components - Concrete outer wall elements91.100.30Beton in betonski izdelkiConcrete and concrete products91.060.40Dimniki, jaški, kanaliChimneys, shafts, ductsICS:Ta slovenski standard je istoveten z:EN 12446:2011SIST EN 12446:2011en,fr,de01-oktober-2011SIST EN 12446:2011SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12446

June 2011 ICS 91.060.40 Supersedes EN 12446:2003English Version

Chimneys - Components - Concrete outer wall elements

Conduits de fumée - Composants - Enveloppes externes en béton

Abgasanlagen - Bauteile - Außenschalen aus Beton This European Standard was approved by CEN on 25 May 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12446:2011: ESIST EN 12446:2011

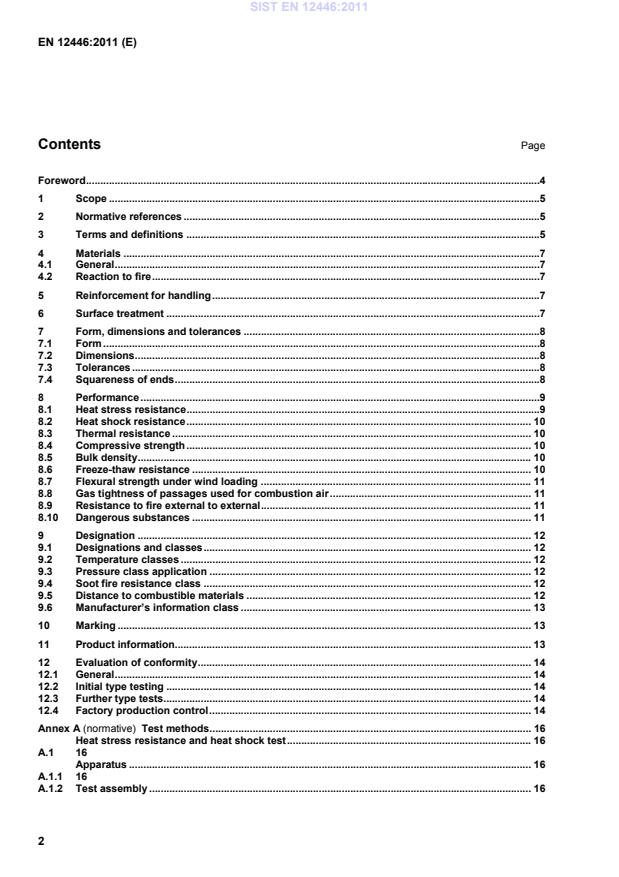

Test methods . 16 Heat stress resistance and heat shock test . 16A.1 16 Apparatus . 16A.1.1 16A.1.2 Test assembly . 16SIST EN 12446:2011

Requirements of sampling plan according to ISO 2859-1 at an Acceptable Quality Level (AQL) and inspection level S2 Inspection Procedure . 24B.1 Acceptability determination . 24B.1.1 General . 24B.1.2 Single sampling . 24B.1.3 Double sampling . 24B.2 Normal inspection . 24B.3 Reduced Inspection . 26B.4 Reduced to normal inspection . 26B.5 Tightened inspection . 26B.6 Tightened to normal inspection . 27B.7 Discontinuation of inspection . 27Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive . 28ZA.1 Scope and relevant characteristics . 28ZA.2 Procedure of attestation of conformity of concrete outer wall elements . 29ZA.2.1 System of attestation of conformity . 29ZA.2.2 EC Certificate and Declaration of conformity . 31ZA.3 CE Marking and labelling . 31Bibliography . 34 SIST EN 12446:2011

Key H Internal height Figure 1 — Internal height 3.7 manufacturer's declared structural height maximum safe constructional height of the outer wall elements as declared by the manufacturer 3.8 manufacturer's declared overall wall thickness dimensions at its thinnest point, between the inside face and the outside face of the outer wall element, not measured at any joint feature, e.g. spigot/socket end 3.9 outer wall element with handling reinforcement outer wall element having steel reinforcement to assist handling and transportation 3.10 solid wall outer wall element outer wall element without cavities in the thickness of its walls SIST EN 12446:2011

concrete that is cast in a place other than its final location of use [EN 1858:2008] 4 Materials

4.1 General Outer wall elements shall be made of pre-cast concrete. Materials shall be identified for factory production control purposes. NOTE Additions can include glass or steel fibres. 4.2 Reaction to fire Attention is drawn to the Commission Decision 96/603/EC, as amended, in which non-combustible masonry units containing not more than 1 % by mass or volume (whichever is the more onerous) of homogeneously distributed organic materials are classified as reaction to fire class A1 without testing. 5 Reinforcement for handling Where an outer wall element is reinforced for handling, the reinforcement shall have a maximum diameter of 8 mm and a minimum concrete cover of 15 mm on all sides for temperature classes up to and including T 250 and 20 mm on all sides for all other temperature classes. In outer wall elements having a bulk density of less than 2 000 kg/m3, when measured according to A.10 of EN 1857:2010, any reinforcement shall be protected against corrosion by one of the following means: a) use of stainless steel conforming to the requirements of EN 10088-2; b) by completely covering any mild steel reinforcement conforming to the requirements of EN 10218-2 with a coating (e.g. Portland cement CEM I or CEM II mixed with water to form a slurry, or epoxy resin). 6 Surface treatment Any surface treatment of the outer wall element, e.g. render, coating, shall be applied as described by the product manufacturer, prior to testing. SIST EN 12446:2011

a) Declared internal transverse dimensions below 300 mm: ± 3 mm 300 mm and above:

± 1,5 % b) Declared height below 300 mm ± 5 mm 300 mm to 700 mm: ± 7 mm above 700 mm: ± 10 mm c) Declared overall wall thickness below 10 mm: 21+− mm 10 mm to 40 mm : 51,5+− mm above 40 mm: 125+− % 7.4 Squareness of ends When tested in accordance with either procedure described in A.3 of EN 1857:2010, the permissible deviation from squareness of ends of concrete outer wall elements shall not be greater than 10 mm at 'G' for the first procedure. With the second procedure the deviation shall not be more than 5 mm at 'G' for elements up to 400 mm and 8 mm at 'G' for elements greater than 400 mm in height. SIST EN 12446:2011

30 min ± 1 min, the element shall subsequently meet the requirements of 8.4. When an outer wall element has multiple passages with an equal wall thickness, the heat shock test shall be carried out on the passage with the highest temperature designation. NOTE The test described in A.1.4 is the method used to assess the sootfire resistance. 8.2.2 Bends or fittings, made of the same material mix and by the same method of manufacture as the tested straight outer wall element, shall be deemed to conform to 8.2.1. 8.2.3 Outer wall elements, made of a different material mix or using a different method of manufacture from those described in 8.2.2, shall be checked for heat shock resistance by testing a special straight test sample in accordance with 8.2.1. This straight test sample shall be made using the same material mix and manufacturing method as the outer wall elements. 8.2.4 The maximum temperature measured on the surface of adjacent combustible materials shall not exceed 100 °C when related to an ambient temperature of 20 °C, when test assembly is tested at the test temperature of 1 000 °C over a period of 30 min. The manufacturer shall declare the distance to the combustible partition and whether the gap between the outer wall element and the adjacent combustible partition is opened or closed. This distance shall not exceed the distance determined as described in 8.1.5. 8.3 Thermal resistance Thermal resistance shall be measured according to the method given in A.4 of EN 1858:2008 (reference method) or calculated according to the method given in Annex C of EN 1858:2008 and the value obtained declared. 8.4 Compressive strength 8.4.1 When tested as described in A.8 of EN 1857:2010, straight outer wall elements shall withstand an intensity of loading equivalent to 4 times the manufacturer's declared structural height before subjecting the element to the thermal performance test(s) and three times the manufacturer's declared structural height after subjecting the element to the thermal performance test(s). 8.4.2 Outer wall element bends and fittings made of the same material mix and by the same method of manufacture as the tested straight elements shall be deemed to conform to 8.4.1. 8.4.3 Outer wall elements made from a different material mix, or using a different method of manufacture from those described in 8.4.2, shall be checked for compressive strength by testing a special straight test sample in accordance with 8.4.1. This special straight test sample shall be made using the same material mix and manufacturing method as the bend or fitting. 8.5 Bulk density When outer wall elements are tested as described in A.10 of EN 1857:2010, the lowest and highest bulk density value shall be within a tolerance of ± 10 % of the manufacturers declared bulk density for the outer wall element. 8.6 Freeze-thaw resistance Where national regulations require freeze/thaw resistance of wall elements, they shall be tested in accordance with EN 14297. The product shall not present any damage of type 7, 8, 9 and 10 in accordance with EN 14297:2004, Table 1. SIST EN 12446:2011

Key 1 top of chimney excluding any terminal or chimney pot 2 last point of support Figure 2 — Explanation of last point of support Alternatively, the free standing part of the outer wall element above the last lateral support shall withstand a wind load of 1,5 kN/m2 (or a value according to national regulations) when tested in accordance with A.2. 8.8 Gas tightness of passages used for combustion air The gas tightness of the passage of an outer wall element, which is to be used for the air supply duct of a room sealed chimney application, shall be at least N2 (as defined in EN 1857) when measured after thermal testing. The gas tightness test shall be carried out in accordance with A.3. 8.9 Resistance to fire external to external Where national regulations require resistance to fire external to external (see EN 1443) of outer wall elements, they shall be evaluated and declared in accordance with those regulations. 8.10 Dangerous substances Materials used in products shall not release any dangerous substances in excess of the maximum permitted levels specified in a relevant European Standard for the material, or permitted in the national regulations of the member state of destination. SIST EN 12446:2011

NOTE An example of a designation system is given in Figure 3.

EN 12446

- T 120 (P)

- O(20)

-

Mi The number of this standard Flue gas temperature class (see 9.2) Pressure class application (see 9.3) Resistance to fire class G or O (see 9.4) followed by a distance to combustible material (xx) (see 9.5) Manufacturer’s information class Mi or Mn (see 9.6) Figure 3 — Example of a designation system 9.2 Temperature classes The temperature class shall be as specified in EN 1443. 9.3 Pressure class application The pressure class signifies the heat flow used for thermal testing of the outer wall element, i.e: N for negative pressure conditions; P for positive pressure conditions; H for high positive pressure conditions. 9.4 Soot fire resistance class The soot fire resistance class, which shall conform to EN 1443, shall be as follows: O for outer wall components tested without soot fire conditions; G for outer wall components tested with soot fire conditions. 9.5 Distance to combustible materials The distance to combustible materials shall be as specified in EN 1443. The designation of the distance of the outer surface of the wall components shall be given as xx, where xx is the distance in mm for the tested temperature class and sootfire conditions. SIST EN 12446:2011

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...