SIST EN 1857:2010

(Main)Chimneys - Components - Concrete flue liners

Chimneys - Components - Concrete flue liners

This European Standard specifies the material, dimensional and performance requirements, including methods of test, for precast concrete flue liners and fittings with or without insulation for the construction of multi-wall chimneys.

This document does not cover:

- high positive pressure (H) designated products;

- products designated wet (W) in conjunction with corrosion class 3.

This document also applies to storey-height and flue liners reinforced only for handling.

NOTE 1 Any reference to the term flue liners implies both flue liners and their fittings, except where otherwise indicated.

NOTE 2 The pressure classes and corrosion classes are defined in EN 1443.

Abgasanlagen - Bauteile - Betoninnenrohre

Diese Europäische Norm legt die Anforderungen an den Werkstoff, die Maße sowie die Leistungsanforderungen einschließlich Prüfverfahren für Innenrohre und Formstücke aus Fertigbeton mit und ohne Dämmung zum Bau von mehrschaligen Abgasanlagen fest.

Folgende Produkte sind nicht Gegenstand dieser Norm:

- mit hohem Überdruck (H) gekennzeichnete Produkte;

- Produkte, die mit „feucht“ (W) gekennzeichnet sind, in Verbindung mit Korrosionsbeständigkeitsklasse 3.

Diese Norm gilt außerdem für geschosshohe und nur mit Transportbewehrung versehene Innenrohre.

ANMERKUNG 1 Sämtliche Verweise auf den Begriff „Innenrohre“ bedeuten „Innenrohre und ihre Formstücke“, außer wenn es anders angegeben ist.

ANMERKUNG 2 Die Druck und die Korrosionswiderstandsklassen sind in EN 1443 definiert.

Conduits de fumée - Composants - Conduits intérieurs en béton

La présente Norme européenne spécifie les exigences relatives aux matériaux, aux dimensions et aux

performances, ainsi que les méthodes d'essai, pour les conduits de fumée intérieurs et les accessoires

préfabriqués en béton avec ou sans isolation destinés à la réalisation de conduits de fumée multiparois.

Le présent document ne couvre pas :

les produits désignés pour fonctionnement à haute pression positive (H) ;

les produits désignés pour fonctionnement en conditions humides (W) conjointement à la classe de

corrosion 3.

Le présent document couvre également les conduits intérieurs hauteur d'étage et les conduits intérieurs

armés pour la manutention.

NOTE 1 Toute référence au terme conduit intérieur implique l’ensemble des conduits intérieurs et leurs accessoires,

sauf si indication différente.

NOTE 2 Les classes de pression et les classes de corrosion sont définies dans la norme EN 1443.

Dimniki - Sestavni deli - Betonske tuljave

Ta evropski standard določa material, dimenzije in zahteve za zmogljivost, vključno z metodami preskusa, za montažne betonske tuljave in vodila z ali brez izolacije za izgradnjo več-stenskih dimnikov. Ta dokument ne zajema: - proizvodov, označenih za visok pozitiven pritisk (H); - mokre(W) označene proizvode skupaj s korozijskim razredom 3. Ta dokument prav tako velja za etažno višino in tuljave, ojačane le za rokovanje.

General Information

- Status

- Published

- Public Enquiry End Date

- 14-Jan-2009

- Publication Date

- 04-May-2010

- Technical Committee

- POZ - Požarna varnost

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 23-Apr-2010

- Due Date

- 28-Jun-2010

- Completion Date

- 05-May-2010

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 01-Jun-2010

Overview

EN 1857:2010 - "Chimneys - Components - Concrete flue liners" (CEN) specifies material, dimensional and performance requirements, including test methods, for precast concrete flue liners and fittings used in the construction of multi‑wall chimneys. The standard covers liners with or without insulation and includes storey‑height liners and liners reinforced only for handling. It excludes products designated high positive pressure (H) and products designated wet (W) when combined with corrosion class 3. Pressure and corrosion class definitions are referenced to EN 1443.

Key Topics

EN 1857:2010 defines the technical framework for design, manufacture, testing and marking of concrete flue liners. Major topics include:

- Materials and reaction to fire requirements for precast concrete components.

- Dimensional tolerances, straightness and squareness of ends.

- Reinforcement rules limited to handling-only reinforcement for certain liners.

- Surface treatment and insulation options.

- Performance requirements and associated test methods for:

- Heat stress and heat shock resistance

- Gas tightness

- Abrasion and compressive strength

- Corrosion and condensate resistance

- Bulk density and thermal resistance

- Freeze/thaw durability

- Flow resistance (liners and fittings)

- Designation, marking and product information requirements to ensure traceability and appropriate use.

- Evaluation of conformity: initial type testing, factory production control and sampling plans (ISO 2859‑1 based).

The standard includes normative annexes with detailed test methods, thermal resistance calculations and sampling/inspection procedures.

Applications and Who Uses It

EN 1857:2010 is essential for professionals involved in the specification, production and certification of chimney systems:

- Manufacturers of precast concrete flue liners and fittings - to design products to recognized performance classes and to perform required tests.

- Chimney system designers and installers - to select appropriate liner types for fuel, temperature and corrosion environments.

- Test laboratories and certification bodies - for conducting compliance tests and factory production control.

- Specifiers, architects and building regulators - to reference compliance in technical specifications and approvals. Practical applications include multi‑wall chimney systems for residential, commercial and industrial heating appliances where durable, gas‑tight and thermally appropriate concrete liners are required.

Related Standards

- EN 1443 - defines pressure classes and corrosion classes referenced by EN 1857.

- Annex ZA of EN 1857 addresses alignment with the EU Construction Products Directive for regulatory and conformity considerations.

Keywords: EN 1857:2010, concrete flue liners, chimneys, CEN, precast, thermal resistance, gas tightness, corrosion resistance, compressive strength, chimney components.

Frequently Asked Questions

SIST EN 1857:2010 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Chimneys - Components - Concrete flue liners". This standard covers: This European Standard specifies the material, dimensional and performance requirements, including methods of test, for precast concrete flue liners and fittings with or without insulation for the construction of multi-wall chimneys. This document does not cover: - high positive pressure (H) designated products; - products designated wet (W) in conjunction with corrosion class 3. This document also applies to storey-height and flue liners reinforced only for handling. NOTE 1 Any reference to the term flue liners implies both flue liners and their fittings, except where otherwise indicated. NOTE 2 The pressure classes and corrosion classes are defined in EN 1443.

This European Standard specifies the material, dimensional and performance requirements, including methods of test, for precast concrete flue liners and fittings with or without insulation for the construction of multi-wall chimneys. This document does not cover: - high positive pressure (H) designated products; - products designated wet (W) in conjunction with corrosion class 3. This document also applies to storey-height and flue liners reinforced only for handling. NOTE 1 Any reference to the term flue liners implies both flue liners and their fittings, except where otherwise indicated. NOTE 2 The pressure classes and corrosion classes are defined in EN 1443.

SIST EN 1857:2010 is classified under the following ICS (International Classification for Standards) categories: 91.060.40 - Chimneys, shafts, ducts; 91.100.30 - Concrete and concrete products. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1857:2010 has the following relationships with other standards: It is inter standard links to SIST EN 1857:2003+A1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1857:2010 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/105. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1857:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Dimniki - Sestavni deli - Betonske tuljaveAbgasanlagen - Bauteile - BetoninnenrohreConduits de fumée - Composants - Conduits intérieurs en bétonChimneys - Components - Concrete flue liners91.100.30Beton in betonski izdelkiConcrete and concrete products91.060.40Dimniki, jaški, kanaliChimneys, shafts, ductsICS:Ta slovenski standard je istoveten z:EN 1857:2010SIST EN 1857:2010en,de01-junij-2010SIST EN 1857:2010SLOVENSKI

STANDARDSIST EN 1857:2003+A1:20081DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1857

April 2010 ICS 91.060.40 Supersedes EN 1857:2003+A1:2008English Version

Chimneys - Components - Concrete flue liners

Conduits de fumée - Composants - Conduits intérieurs en béton

Abgasanlagen - Bauteile - Betoninnenrohre This European Standard was approved by CEN on 20 February 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1857:2010: ESIST EN 1857:2010

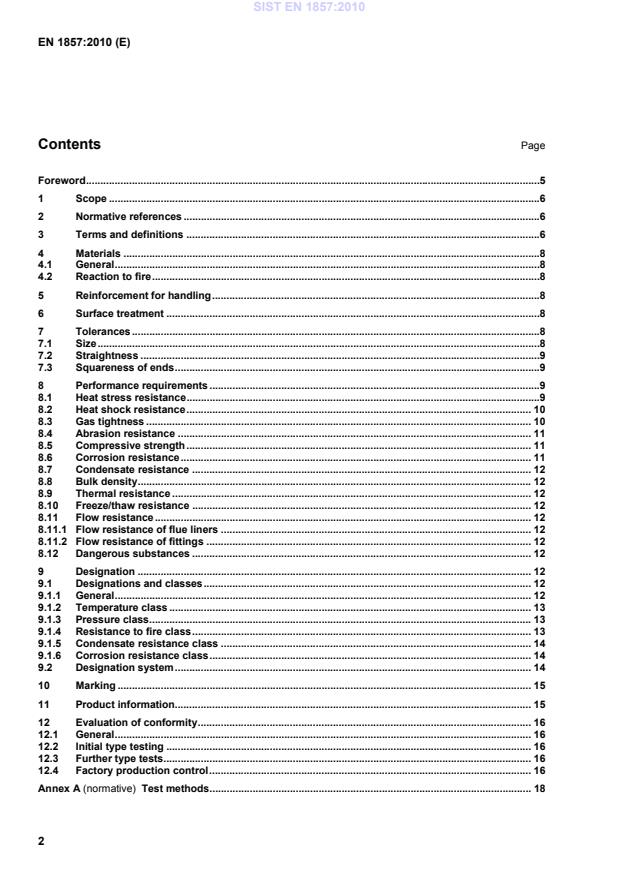

Test methods . 18SIST EN 1857:2010

Illustration of joint types . 35Annex C (normative)

Thermal resistance calculation . 36C.1 Thermal resistance of the individual element . 36C.2 Thermal resistance of the flue liner . 36Annex D (normative)

Requirements of sampling plan in accordance with ISO 2859-1 at an Acceptable Quality Level (AQL) and inspection level S2 Inspection procedure . 38SIST EN 1857:2010

Recommended test sequence . 42Annex F (informative)

Abbreviated designations for common types of concrete flue liners . 43Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive . 44ZA.1 Scope and relevant characteristics . 44ZA.2 Procedure of attestation of conformity of concrete flue liners . 45ZA.2.1 System of attestation of conformity . 45ZA.2.2 EC Certificate and Declaration of conformity . 46ZA.3 CE Marking and labelling . 47Bibliography . 49 SIST EN 1857:2010

The co-ordinated package of standards is further divided by material of construction and this European Standard is one of a series of specifications and installation documents dealing with design and installation of concrete chimney products and systems.

The standards in this series for concrete chimney products are:

EN 1857, Chimneys — Components — Concrete flue liners EN 1858, Chimneys — Components — Concrete flue blocks EN 12446, Chimneys — Components — Concrete outer wall elements In this European Standard, Annexes A, C and D are normative and Annexes B, E, F and ZA are informative. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom.

3 Terms and definitions For the purposes of this document, the terms and definitions given in EN 1443:2003 and the following apply. SIST EN 1857:2010

[EN 206-1:2000] 3.2 flue liner bend flue liner that changes the direction of the flue 3.3 manufacturer's declared internal transverse dimensions

internal dimensions of the flue liner measured perpendicular to the longitudinal axis 3.4 manufacturer's declared height internal height of the flue liner

NOTE Examples of measurement are shown in Figure 1. HH

a) With rebate b) With plain end Key H

internal height Figure 1 — Manufacturer's declared height 3.5 manufacturer's declared structural height

maximum height of construction of the flue liners as declared by the manufacturer 3.6 precast concrete

concrete that is cast in a place other than its final location of use 3.7 reinforced flue liner

flue liner having reinforcement to assist handling

NOTE The reinforcement is not for structural stability. 3.8 storey-height liner

flue liner having manufacturer's declared height relating to the floor to floor height of a building SIST EN 1857:2010

a) use of stainless steel conforming to the requirements of EN 10088-2; or b) by completely covering any mild steel reinforcement conforming to EN 10218-2 with a coating (e.g. typically Portland cement CEM I or CEM II mixed with water to form a slurry or epoxy resin). 6 Surface treatment Any surface treatment of the flue liner, e.g. coatings, shall be factory applied before the product is tested.

7 Tolerances 7.1 Size Tolerances on manufacturer's declared dimensions, including taper, shall be:

a) Declared internal transverse dimensions: 1) below 300 mm

± 3 mm; 2) 300 mm and above ± 3 % but not more than 10 mm (see A.1.1); b) Declared height:

1) below 300 mm

± 5 mm; 2) 300 mm to 700 mm ± 7 mm; 3) above 700 mm

± 3 % but not more than 10 mm (see A.1.2); SIST EN 1857:2010

1) below 10 mm

21+− mm; 2) 10 mm to 40 mm

51,5+− mm; 3) above 40 mm

125+− %. 7.2 Straightness 7.2.1 When tested as in accordance with A.2 the limit deviation from straightness of a straight concrete flue liner of manufacturer's declared height less than or equal to 1 000 mm shall not be greater than 1 % of the declared height. 7.2.2 When tested as described in A.2 for flue liners having a manufacturer's declared height greater than 1 000 mm the limit deviation shall not be greater than 0,5 % of the manufacturer's declared height.

7.3 Squareness of ends When the deviation of the squareness of ends is tested in accordance with either procedure described in A.3 the flue liner shall not touch the upright for the first procedure and the dimension "G" shall not be greater than 5 mm for the second procedure.

8 Performance requirements 8.1 Heat stress resistance 8.1.1 When a flue liner is tested in accordance with A.4 to the test temperature appropriate to the flue liner designation given in Table 1, the flue liner shall subsequently conform to the requirements of 8.3.

The thermal testing shall be carried out on one size of flue liner for each geometrical configuration, e.g. circular, rectangular, square, also for each material mix, method of manufacture and wall thickness. For circular flue liners the size to be tested shall be (200 ± 50) mm internal transverse dimension. For other geometrical configurations the flue liner shall have an equivalent cross-sectional area. SIST EN 1857:2010

°C T 600 700 500+ T 450 550 500+ T 400 500 500+ T 300 350 350+ T 250 300 300+ T 200 250 250+ T 160 190 190+ T 140 170 170+ T 120 150 150+ T 100 120 120+ T 080 100 100+

8.1.2 Flue liner bends or fittings made of the same material mix and by the same method of manufacture as the tested straight flue liner shall be deemed to conform to the requirement in 8.1.1.

8.1.3 Flue liner bends or fittings made of a different material mix or using a different method of manufacture from those described in 8.1.1, shall be checked for heat stress resistance by testing a straight test sample in accordance with 8.1.1. This straight test sample shall be made using the same material mix and manufacturing method as the bend or fitting.

8.2 Heat shock resistance 8.2.1 Following the heat stress resistance test in 8.1, when a liner designated as sootfire resistant is tested as described in A.4 to a flue gas temperature of 1 000 °C for a period of (30 ± 1) min the flue liner shall subsequently conform to the requirements of 8.3. 8.2.2 Flue liner bends or fittings made of the same material mix and by the same method of manufacture as the tested straight flue liner shall be deemed to conform to the requirement in 8.2.1. 8.2.3 Flue liner bends or fittings made of a different material mix or using a different method of manufacture from those described in 8.2.1, shall be checked for heat shock by testing a straight test sample in accordance with 8.2.1. This straight test sample shall be made using the same material mix and manufacturing method as the bend or fitting.

8.3 Gas tightness When tested in accordance with A.6 the gas tightness, expressed as a leakage rate of the walls of the flue liner, shall not be greater than the values specified in Table 4 for the relevant pressure class. SIST EN 1857:2010

kg/m³ Maximum abrasion of inner surface in kg/m² 1 000 1,000 1 100 1,100 1 200 1,200 1 300 1,300 1 400 1,400 1 500 1,500 1 600 1,600 1 700 1,700 1 850 1,850

8.5 Compressive strength 8.5.1 The manufacturer shall declare the structural height. When tested in accordance with A.8, flue liners and straight fittings shall withstand an intensity of loading equivalent to four times the manufacturer's declared structural height.

NOTE The manufacturer's declared structural height may be derived from the ultimate compressive strength determined by the method in A.11. 8.5.2 Flue liner bends or other fittings made of the same material mix and by the same method of manufacture as the tested straight flue liner shall be deemed to conform to the requirement in 8.5.1.

8.5.3 Flue liner bends or fittings made of a different material mix or using a different method of manufacture from those described in 8.5.2, shall be checked for compressive strength by testing a special straight test sample in accordance with 8.5.1. This special straight test sample shall be made using the same material mix and manufacturing method as the bend or fitting.

8.6 Corrosion resistance When flue liners designated condensate resistance class W (suitable for use in wet operating conditions) are tested as described in A.9, the weight loss of the pieces shall not be greater than 0,1 %. Flue liners designated condensate resistance class D (dry) and which conform from 8.1 to 8.4 may be assigned corrosion resistance class 3. SIST EN 1857:2010

10+h test period shall not be greater than 0,5 g/h·m2 of the flue liner external surface.

8.8 Bulk density When flue liners are tested as described in A.10 each bulk density value shall be within a limit deviation of ± 10 % of the manufacturer's declared bulk density for the flue liner.

8.9 Thermal resistance Thermal resistance shall be measured in accordance with the method given in A.5 or calculated in accordance with the method given in Annex C and its value declared by the manufacturer. 8.10 Freeze/thaw resistance Where national regulations require freeze/thaw resistance of flue liners, they shall be tested in accordance with EN 14297. The product shall not present any damage of type 7, 8, 9 and 10 in accordance with EN 14297:2004, Table 1. 8.11 Flow resistance 8.11.1 Flow resistance of flue liners The manufacturer shall declare the mean value of roughness for a flue liner determined either: by testing in accordance with EN 13216-1 (which is the reference test method); or from the data obtained in EN 13384-1:2002+A2:2008. 8.11.2 Flow resistance of fittings The manufacturer shall declare the coefficient of flow resistance due to a directional and/or cross sectional and/or mass flow change which shall be determined in accordance with the method given in EN 1859 or obtained from the data in EN 13384-1:2002+A2:2008. 8.12 Dangerous substances Materials used in products shall not release any dangerous substances in excess of the maximum permitted levels specified in a relevant European Standard for the material or permitted in the national regulations of the member state of destination. NOTE

See Note 2 in ZA.1. 9 Designation 9.1 Designations and classes 9.1.1 General Designation classes for flue liners for temperature, pressure, resistance to sootfire, condensate resistance and corrosion resistance shall be in accordance with 9.1.2 to 9.1.6.

Temperature classes in relation to nominal working temperature are given in Table 3. Table 3 — Temperature class Temperature class Nominal working temperature °C T600 ≤ 600 T450 ≤ 450 T400 ≤ 400 T300 ≤ 300 T250 ≤ 250 T200 ≤ 200 T160 ≤ 160 T140 ≤ 140 T120 ≤ 120 T100 ≤ 100 T080 ≤ 80

9.1.3 Pressure class

Pressure classes in relation to test pressure and gas tightness are given in Table 4. The pressure class is assigned a gas tightness level, expressed as a maximum leakage rate at a specified test pressure. For flue liners suitable for negative pressure chimneys the pressure classes are N1 and N2. For flue liners suitable for positive pressure chimneys the pressure classes are P1 and P2. Table 4 — Pressure classes and gas tightness

Pressure class Test pressure Pa Gas tightness – Maximum leakage rate l/s/m2 N1 40 2,0 N2 20 3,0 P1 200 0,006 P2 200 0,120

9.1.4 Resistance to fire class Resistance to fire classes are designated as: SIST EN 1857:2010

Condensate resistance are designated as: W for flue liners for chimneys intended to operate under wet conditions; D for flue liners for chimneys intended to operate under dry conditions. 9.1.6 Corrosion resistance class

Corrosion resistance classes for flue liners for chimneys which convey products of combustion from gas or light oils and natural wood or heavy oils and solid mineral fuels, are given in Table 5. Table 5 — Corrosion resistance classes Fuel types 1 possible fuel types 2 possible fuel types 3 possible fuel types gas gas: sulfur-content

≤ 50 mg/m3 natural gas L + H gas natural gas L + H gas natural gas L + H liquid kerosene: sulfur-content ≤ 50 mg/m3 oil: sulfur-content ≤ 0,2 mass % kerosene: sulfur-content > 50 mg/m3 oil: sulfur-content > 0,2 mass % kerosene: sulfur-content > 50 mg/m3 wood

wood in open fire places wood in open fire places wood in closed stoves coal

coal peat

peat

NOTE Table 5 does not categorize process gases or liquids. 9.2 Designation system All concrete flue liners to this standard shall be designated in accordance with 9.1. An example of a designation system is given in Figure 2. SIST EN 1857:2010

EN 1857T 400N1D3G_i The number of this standard Flue gas temperature class Negative/positive pressure class Resistance to condensate Corrosion resistance Resistance to fire (G or O) Tested without insulation Figure 2 — Examples of designation system A shortened designation code is given in Annex F.

10 Marking A minimum of 20 % of flue liners or fittings in each consignment shall be legibly and indelibly marked or labelled with the following information:

name or trademark of the manufacturer; manufacturer's batch or date code; number of this European Standard; class or classes or full designation; an arrow indicating direction of flue gas flow. NOTE For CE marking and labelling, see ZA.3. 11 Product information The manufacturer's printed literature for the product shall include the following: a) manufacturer's product description; b) manufacturer's declared sizes; c) product designation; d) manufacturer's declared structural height; e) detailed installation instructions including method of jointing. SIST EN 1857:2010

12.4 Factory production control To achieve compliance with this standard, the manufacturer shall establish and maintain an effective documented quality system. Factory production control tests are carried out following manufacture to monitor the quality of product (see Table 6). Sampling and testing of any batch shall be completed prior to removal from the works and shall be in accordance with ISO 2859-1 at an AQL of 10 % and inspection level S2. Isolated batches of units shall be assessed in accordance with tightened inspection procedures, with a maximum batch size of 2 500 (see Annex D). SIST EN 1857:2010

Test methods A.1 Measurement of dimensions A.1.1 Transverse dimensions The maximum and minimum internal transverse dimensions of the flue liner shall be those calculated from the manufacturer's declared tolerances and the tolerances specified in 7.1. If direct measurement is to be carried out, two measurements should be taken at the observed maximum and minimum diameters. The test also can be carried out using two gauges whose diameters are set at the minimum and maximum diameters. The minimum gauge should be able to be turned through 360° within the whole length of the flue liner. The maximum gauge should not be able to enter the flue liner when turned through a rotation of 360°. For square and rectangular flue liners, the internal transverse dimensions shall be measured between the mid points of opposite sides of the flue liner. A.1.2 Declared height The maximum and minimum declared heights of a flue liner shall be those calculated from the manufacturer's declared dimensions and the tolerances specified in 7.1. If direct measurement is to be carried out, two measurements should be taken at the observed maximum and minimum internal heights. The test can also be carried out by using two gauges whose heights are set at the minimum and maximum internal heights. The minimum gauge should not be able to fit over the internal height of the flue liner. The maximum gauge should be able to fit over the internal height of the flue liner. A.1.3 Wall thickness The maximum and minimum wall thickness dimensions shall be those calculated from the manufacturer's declared dimensions and the tolerances specified in 7.1 or direct measurement is to be carried out at the observed maximum and minimum thickness. A.2 Straightness test A.2.1 Apparatus

A straightness measuring device, such as a straight edge, having a length 100 mm less than the nominal height of the flue liner under test.

A.2.2 Procedure A.2.2.1 Place the measuring device along the line HT as shown in Figure A.1.

A.2.2.2 Measure the maximum distance from the centre of the straight line created by the apparatus in A.2.1 spanning any concave curve on the outside of the flue liner to the flue liner surface (DS) as shown in Figure A.1.

/2sTNTH

/2TH Key HN nominal length of the flue liner in millimetres DS

deviation from straightness in millimetres HT

test length in millimetres HN - HT = 100 mm Figure A.1 — Straightness test A.3 Squareness of ends test A.3.1 Apparatus A.3.1.1 Level test bench, with a fixed upright at 90°, see Figure A.2a). A.3.1.2 Square, having one arm 300 mm long and the second arm 400 mm long. A.3.2 First procedure Place the flue liner upright on the test bench with the base of the liner touching the collar. Rotate the liner through 360°.

A.3.3 Result of first procedure Record any case

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...