SIST EN 817:2009

(Main)Sanitary tapware - Mechanical mixers (PN 10) - General technical specifications

Sanitary tapware - Mechanical mixers (PN 10) - General technical specifications

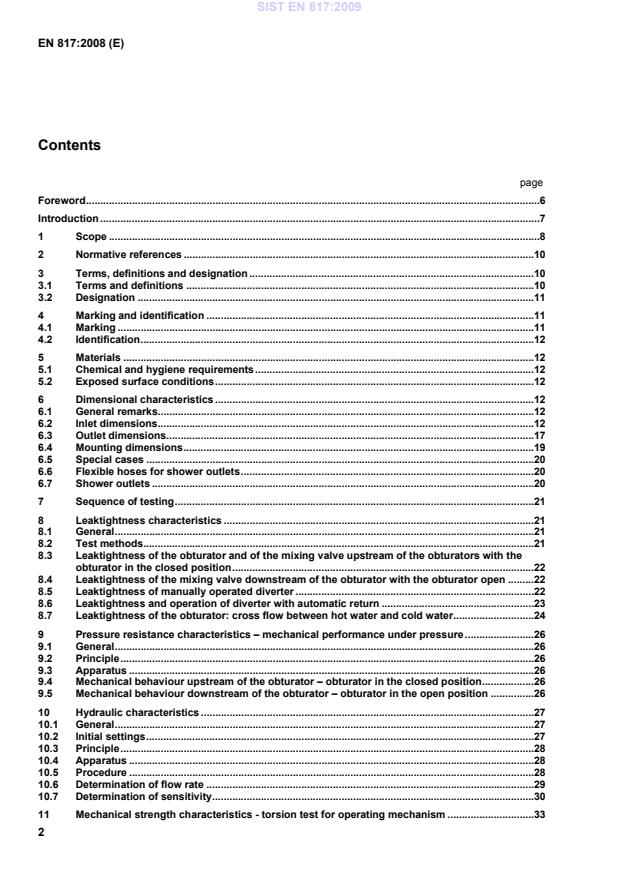

This European Standard specifies:

the dimensional, leaktightness, pressure resistance, hydraulic performance, mechanical strength, endurance and acoustic characteristics with which mechanical mixing valves need to comply;

test methods to verify the characteristics;

the tests described in this European Standard are type tests (laboratory tests) and not quality control tests carried out during manufacture.

This European Standard applies to PN 10 mechanical mixing valves for use with sanitary appliances installed in rooms used for bodily hygiene (cloakrooms, bathrooms, etc.) and in kitchens, i.e. for use with baths, wash basins, bidets, showers and sinks.

The conditions of use and classifications are given in Table 1.

Table 1 - Conditions of use/classifications

Sanitärarmaturen - Mechanisch einstellbare Mischer (PN 10) - Allgemeine technische Spezifikation

Diese Europäische Norm legt Folgendes fest:

die Maße, die Dichtheit, die Druckbeständigkeit, die hydraulische Leistung, die mechanische Festigkeit, die Dauerfestigkeit sowie das Geräuschverhalten, die mechanische einstellbare Mischer erfüllen müssen;

die Prüfverfahren, um diese Anforderungen nachzuweisen;

die in dieser Europäischen Norm beschriebenen Prüfungen sind Typ Anerkennungsprüfungen (Laborprüfungen) und keine Qualitätskontrollprüfungen, die während der Herstellung durchgeführt werden.

Diese Europäische Norm gilt für mechanisch einstellbare Mischer (PN 10) für die Ausrüstung von Sanitär¬ausstattungsgegenständen, die in den der Körperhygiene dienenden Räumen (Toiletten, Bäder usw.) und in Küchen installiert werden, d. h. für Badewannen, Waschbecken, Bidets, Brausen und Spülbecken.

Die Anwendungsbedingungen und Klassifizierungen sind in Tabelle 1 dargestellt.

Robinetterie sanitaire - Mitigeurs mécaniques (PN 10) - Spécifications techniques générales

La présente Norme européenne prescrit :

les caractéristiques dimensionnelles, d’étanchéité, de résistance à la pression, hydrauliques, de résistance mécanique, d’endurance et acoustiques auxquelles doivent répondre les mitigeurs mécaniques ;

les méthodes d’essai visant à vérifier les caractéristiques.

Les essais décrits dans la présente Norme européenne sont des essais de type (essais en laboratoire) et non des essais de contrôle qualité réalisés en cours de fabrication.

La présente Norme européenne s’applique aux mitigeurs mécaniques PN 10 destinés à l’équipement des appareils sanitaires installés dans les locaux d’hygiène corporelle (toilettes, salles de bains, etc.) et dans les cuisines, en vue d’équiper des baignoires, lavabos, bidets, douches et éviers.

Les conditions d’utilisation et les classifications sont données dans le Tableau 1.

Sanitarne armature - Mehansko nastavljiva mešalna armatura (PN 10) - Splošne tehnične zahteve

General Information

- Status

- Withdrawn

- Publication Date

- 20-Nov-2008

- Withdrawal Date

- 10-Oct-2024

- Technical Committee

- IOVO - Water supply and waste water engineering

- Current Stage

- 9900 - Withdrawal (Adopted Project)

- Start Date

- 10-Oct-2024

- Due Date

- 02-Nov-2024

- Completion Date

- 11-Oct-2024

- Directive

- 89/106/EEC - Construction products

Relations

- Replaces

SIST EN 817:1997 - Sanitary tapware - Mechanical mixers (PN 10) - General technical specifications - Effective Date

- 01-Jan-2009

- Effective Date

- 28-Jan-2023

Frequently Asked Questions

SIST EN 817:2009 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Sanitary tapware - Mechanical mixers (PN 10) - General technical specifications". This standard covers: This European Standard specifies: the dimensional, leaktightness, pressure resistance, hydraulic performance, mechanical strength, endurance and acoustic characteristics with which mechanical mixing valves need to comply; test methods to verify the characteristics; the tests described in this European Standard are type tests (laboratory tests) and not quality control tests carried out during manufacture. This European Standard applies to PN 10 mechanical mixing valves for use with sanitary appliances installed in rooms used for bodily hygiene (cloakrooms, bathrooms, etc.) and in kitchens, i.e. for use with baths, wash basins, bidets, showers and sinks. The conditions of use and classifications are given in Table 1. Table 1 - Conditions of use/classifications

This European Standard specifies: the dimensional, leaktightness, pressure resistance, hydraulic performance, mechanical strength, endurance and acoustic characteristics with which mechanical mixing valves need to comply; test methods to verify the characteristics; the tests described in this European Standard are type tests (laboratory tests) and not quality control tests carried out during manufacture. This European Standard applies to PN 10 mechanical mixing valves for use with sanitary appliances installed in rooms used for bodily hygiene (cloakrooms, bathrooms, etc.) and in kitchens, i.e. for use with baths, wash basins, bidets, showers and sinks. The conditions of use and classifications are given in Table 1. Table 1 - Conditions of use/classifications

SIST EN 817:2009 is classified under the following ICS (International Classification for Standards) categories: 91.140.70 - Sanitary installations. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 817:2009 has the following relationships with other standards: It is inter standard links to SIST EN 817:1997, SIST EN 817:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 817:2009 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 817:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sanitärarmaturen - Mechanisch einstellbare Mischer (PN 10) - Allgemeine technische SpezifikationRobinetterie sanitaire - Mitigeurs mécaniques (PN 10) - Spécifications techniques généralesSanitary tapware - Mechanical mixers (PN 10) - General technical specifications91.140.70Sanitarne napraveSanitary installationsICS:Ta slovenski standard je istoveten z:EN 817:2008SIST EN 817:2009en,fr,de01-januar-2009SIST EN 817:2009SLOVENSKI

STANDARDSIST EN 817:19971DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 817June 2008ICS 91.140.70Supersedes EN 817:1997

English VersionSanitary tapware - Mechanical mixing valves (PN 10) - Generaltechnical specificationsRobinetterie sanitaire - Mitigeurs mécaniques (PN 10) -Spécifications techniques généralesSanitärarmaturen - Mechanisch einstellbare Mischer (PN10) - Allgemeine technische SpezifikationThis European Standard was approved by CEN on 29 May 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 817:2008: ESIST EN 817:2009

Apparatus.43 Annex B (informative)

Pressure take-off tee.47 Bibliography.50 SIST EN 817:2009

See Clause 4Pressure Dynamic pressure > 0,05 MPa (0,5 bar) Static pressure ≤ 1,0 MPa (10,0 bar) Dynamic pressure (0,1 to 0,5) MPa [(1,0 to 5,0) bar] Z ≤ 0,15 l/s A ≤ 0,25 l/s S ≤ 0,33 l/s B ≤ 0,42 l/s C ≤ 0,50 l/s D ≤ 0,63 l/s

Group I -

Group II –

unclassified

for example IA IIC / B

I /- a II /- a Temperature ≤ 90 °C ≤ 65 °C

a Without flow rate class: mechanical mixing valves without interchangeable outlet accessories are tested with the original outlet accessories of the manufacturer and are not marked with a flow rate class.

NOTE Mechanical mixing valves for use at pressures lower than those in Table 1 are covered by EN 1286. SIST EN 817:2009

Key 1 cold water 2 hot water 3 mains supply pipe (supply pressures up to 10 bar) 4 water heater Figure 1 — Supply system with a pressure range of (0,05 to 1,0) MPa [(0,5 to 10) bar] SIST EN 817:2009

(ISO 3822-2:1995) EN ISO 3822-4:1997, Acoustics — Laboratory tests on noise emission from appliances and equipment used in water supply installations — Part 4: Mounting and operating conditions for special appliances (ISO 3822-4:1997) 3 Terms, definitions and designation 3.1 Terms and definitions For the purpose of this document, the following term and definition applies. mechanical mixing valve valve which mixes hot and cold water and which, by means of a control device, allows the user to adjust between ‘all cold water’ and ’all hot water’, which implies the flow rate of the mixture obtained may be adjusted between ‘no flow’ and ‘maximum flow’ using either the same control device or another separate control device SIST EN 817:2009

Connecting centres

G a 150 + 1 Supply connection, Straight unions G 1 140 to 160 2 – hole wall mounted - with eccentric unions (extension of this range is permitted) Inlet connections N 1 12,3 + 0,2 N 2 5 min Type A

N 1 15,2 + 0,05 N 2 13 min Type B

30° chamfer/flat 0,3 N 1 14,7 + 0,3 N 2 6,4 min Type C N 1 19,9 + 0,3 N 2 6,4 min Type C

T

Plain end ∅ 10 or 12 or 15 or G ½ or G 3/8 male or female

Copper tube(s) or flexible hose(s) U 350 min

Tube(s) or flexible hose(s)

Flexible hoses in accordance with prEN 13618-1 and/or prEN 13618-2 a

Other dimensions are permissible (for replacement) when market tradition requires it, provided the manufacturer specifies the actual dimension in literature to avoid confusion with the standard dimension – which can be achieved using an excentric connection.

1 2 Key 1 flexible hose 2 plain tube Figure 2 — Flexible hoses and plain tube SIST EN 817:2009

Figure 3 — Multi-hole mechanical mixing valve

Figure 4 — Supply connections for mechanical mixing valve and remote outlets SIST EN 817:2009

Nozzle outlets not in accordance with EN 246 are covered by 6.5

Figure 5 — Remote outlet Figure 6 — Single hole mechanical mixing valve

Figure 7 — Two hole mechanical mixing valve

6.4 Mounting dimensions Mounting dimensions shall be as specified in Table 5, 0 and 0. Table 5 — Mounting dimensions (outlets, single- and multi-hole mechanical mixing valve) Dimensions (mm) Comments Shank diameter

H 1 24 max Two hole mechanical mixing valve size ½ Adjustable centres H 2 29 max Side spray Adjustable centres H 3 33,5 max Single hole

Base or flange

J 1 42 min Side spray J 2 45 min Bath, bath/shower, basin, bidet, sink Dimension of base or flange J 3 50 max Single and multi hole mechanical mixing valve Diameter of clamping washer V 32 max Basin, bidet, sink Flange projection to rear

V 1 35 max Bath – two hole mechanical mixing valve

L Dimension which allows taps and outlets to be fitted on to supports of thickness between 1 mm and 18 mm. Minimum range (mm) of supports, which allows the installation of the mixing valves.

1 2 Key 1 basin – bidet – sink 2 remote spray attachment Figure 8 — Single hole mechanical mixing valve SIST EN 817:2009

Figure 9 — Two hole mechanical mixing valve 6.5 Special cases Mechanical mixing valves intended for special applications, e.g. for installation on sanitary appliances not conforming with European Standards, or where dimensional interchangeability is not a requirement can incorporate dimensional deviations provided that: all other requirements of this standard are satisfied; secure fixing to the mounting surface is provided with all fixing holes covered; thread connections to the supply pipes comply with EN ISO 228-1; the air gap dimension E ≥ 25 mm or a backflow prevention device is provided in accordance with EN 1717. the D 1 dimension is coordinated with the sanitary appliance. The manufacturer's literature including the installation instructions supplied with the tapware shall indicate clearly that the tapware is for special application. 6.6 Flexible hoses for shower outlets Requirements for flexible hoses for shower outlets shall be as specified in EN 1113. 6.7 Shower outlets Requirements for shower outlets shall be as specified in EN 1112. SIST EN 817:2009

dimensions 2 leaktightness

(Clause 8) flow rate/sensitivity

(Clause 10) 3 endurance

(Clause 12) mechanical strength

(Clause 11) 4 leaktightness

(Clause 8) leaktightness

(Clause 8) 5

pressure resistance

(Clause 9)

NOTE Acoustic testing will require three samples which can be different from the two mentioned above. 8 Leaktightness characteristics 8.1 General This clause describes the test methods that shall be carried out to verify the leaktightness of the mechanical mixing valve and specifies the corresponding requirements (see 0). 8.2 Test methods 8.2.1 Principle The principle of the test consists of checking under cold water pressure the leaktightness of: the obturator (see 8.3); the complete mixing valve (see 8.4); the bath/shower diverter (either manual or with automatic return) (see 8.5 and 8.6). In the case of a diverter with automatic return being considered to provide backflow prevention, it shall comply with the requirements of EN 14506. 8.2.2 Apparatus A hydraulic test circuit capable of gradually supplying the required static and dynamic pressures and of maintaining them throughout the duration of the test(s). SIST EN 817:2009

Table 7 — Summary of leaktightness tests Cold water test Test conditions Pressure Duration Leaktightness of: Mixing valve, Diverters Position of obturator(s) or diverter Condition of outlet orifice(s) (MPa) (s) Requirement: No leakage Upstream of obturator

Obturator closed Open 1,6 ± 0,05 60 ± 5 - past obturator or through walls upstream of obturator 0,4 ± 0,02 Mixing valve assembly Downstream of obturator Obturator open Closed 0,02 ± 0,002 60 ± 5 - past any seal Obturator open, diverter in flow-to-bath mode Artificially closed outlet to bath, outlet to shower open - at outlet to shower Diverter- manually operated Obturator open, diverter in flow-to-shower mode Artificially closed outlet to shower, outlet to bath open 0,4 ± 0,02 0,02 ± 0,002 60 ± 5 - at outlet to bath Obturator open, diverter in flow-to-bath mode 0,4 ± 0,02 0,02 ± 0,002 60 ± 5 - at hose attachment point Obturator open, diverter in flow-to-shower mode

- at outlet to bath Obturator open, diverter in flow-to-shower mode 0,05 ± 0,002 or 0,02 ± 0,002

- no reversion of diverter; - no leakage to bath Obturator closed

Diverter reverts to flow to bath mode Diverter- with

automatic return Obturator open, diverter in flow-to-bath mode Both outlets open 0,05 ± 0,002 or 0,02 ± 0,002 60 ± 5 - no leakage at outlet to showerCross flow Obturator closed Open 0.4 ± 0,02 60 ± 5 no leakage at outlet or unconnected inlet

Position of obturator(s) Condition of outlet orifices Pressure (MPa) Duration (s) Requirement Mixing valve assembly

Upstream of obturator

Obturator closed Open (2,5 ± 0,05) MPa [(25,0 ± 0,5) bar] Downstream of obturator mixing valves with flow rate regulator (0,4 ± 0,02) MPa [(4,0 ± 0,2) bar] No permanent deformation Downstream of the obturator without flow rate regulator Obturator open Open Pressure to give 0,4 l/s 60 ± 5 No permanent deformation of parts situated downstream of the obturator 10 Hydraulic characteristics 10.1 General This clause specifies test methods to determine the following characteristics of mechanical mixing valves: flow rate (see 10.6); sensitivity (see 10.7). 10.2 Initial settings When called-up in a specific test procedure, the samples and their supplies shall initially be adjusted as shown in Table 9. Table 9 — Initial settings Inlet Cold Hot Temperature ϑc (°C) Pressure (MPa) [bar] Temperature ϑ h (°C) Pressure (MPa) [bar] (10 to 15) (0,020- 3,0+) [0,20- 3+] (ϑC + 50) ±1 (0,020- 3,0+) [0,20- 3+]

Connect the mechanical mixing valve to the test rig; b)

flexible inlet connections shall be mounted in a straight position; c)

fit the operating device to the mechanical mixing valve's controls: For mixing valves with a flow rate control device which is separate from the temperature control device, set it at the maximum flow position; for single control mixing valve, set the flow rate control device to the position providing maximum flow; d)

pressurize the test rig; e)

adjust the mechanical mixing valve's controls or its outlet pipework to deliver maximum flow; f)

adjust the supply temperatures and pressures in accordance with Table 9; g)

while the test rig remains pressurized, close the applicable flow controls; h)

when these adjustments have been made, return the control device to the off position with the mixing valve remaining under pressure. SIST EN 817:2009

3 MPa

3,00,20-0,020-++ , applied to the hot and cold water supplies, for the full extent of the temperature control range. The measurement is made on a fully open mixing valve, going from cold to hot, then from hot to cold. If the mixing valve has standard accessories (aerators, showers, etc.), the measurement is carried out replacing these with a hydraulic resistance corresponding to the flow rate class marking, as defined in Table 14, see also EN 246 (for example: for marking A, class A resistance will be used during testing). If the mixing valve is equipped with water saving accessories or aerators not complying with the dimensions specified in EN 246 the flow rate test and acoustic test shall be made with the mixing valve as delivered by the manufacturer. 10.6.2 Procedure Open the flow rate control fully and operate the temperature control device for the full extent of its range at a pressure of ()()[]bar

3 MPa

3,00,20-0,020-++. Record the flow rate for at least the five temperatures specified below: full cold position; 34 °C; 38 °C; 44 °C; full hot position. 10.6.3 Requirements The flow rate measured at ()()[]bar

3 MPa

3,00,20-0,020-++ shall, depending on the type of appliance for which the mixing valve is intended, be as specified in Table 10. Table 10 — Flow rates according to application Applicat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...