oSIST prEN 3197:2023

(Main)Aerospace series - Design and installation of aircraft electrical and optical interconnection systems

Aerospace series - Design and installation of aircraft electrical and optical interconnection systems

This document provides instructions on the methods to be used when designing, selecting, manufacturing, installing, repairing or modifying the aerospace vehicles electrical and optical interconnection networks, now called Electrical Wiring Interconnection System (EWIS), and Optical Fibre Interconnection Systems (OFIS), subject to the limitations defined in Clause 4 of this document. Aerospace Vehicles include manned and unmanned aeroplanes, helicopters, lighter-than- air vehicles, missiles and external pods.

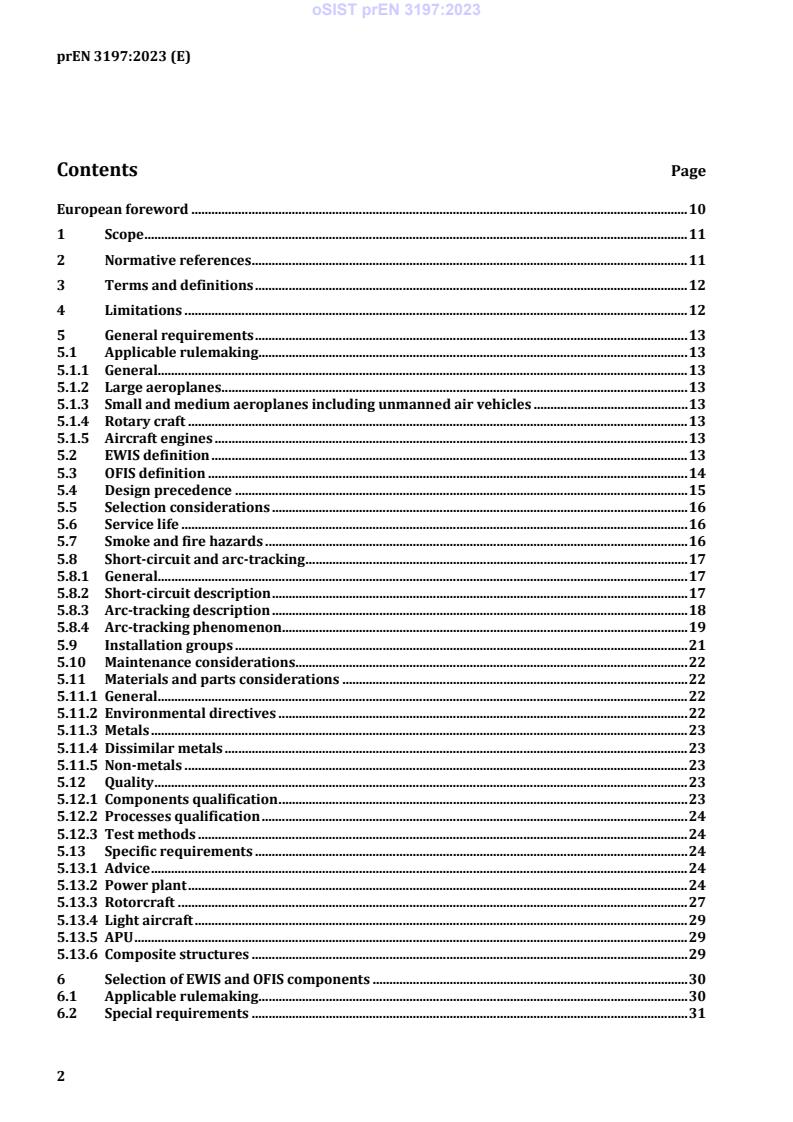

The general content of this document is described in page 2.

A detailed content of this document is given in Annex A.

This document lists all the relevant European standards related to EWIS and OFIS in Annex B.

Luft- und Raumfahrt - Konstruktion und Installation elektrischer und optischer Verkabelung in Luftfahrzeugen

Série aérospatiale - Conception et installation de systèmes d'interconnexion électrique et optique d'aéronefs

Le présent document fournit des instructions sur les méthodes à utiliser lors de la conception, de la sélection, de la fabrication, de l'installation, de la réparation ou de la modification des organes de raccordements électriques et à fibres optiques des véhicules aérospatiaux, qui s'appellent maintenant « système d'interconnexion du câblage électrique » [Electrical Wiring Interconnection System (EWIS)] et « système d'interconnexion des fibres optiques » [Optical Fibre Interconnection System (OFIS)], soumises aux restrictions définies dans l'Article 4 du présent document. Les véhicules aérospatiaux comprennent les aéronefs avec ou sans équipage à bord, les hélicoptères, les véhicules plus légers que l'air, les missiles et les capsules externes.

Le sommaire général du présent document est donné à la page 2.

Un sommaire détaillé du présent document est donné à l'Annexe A.

Le présent document répertorie toutes les normes européennes pertinentes relatives aux systèmes EWIS et OFIS à l'Annexe B.

Aeronavtika - Načrtovanje in vgradnja letalskih električnih in optičnih sistemov za medsebojno povezovanje

General Information

- Status

- Not Published

- Public Enquiry End Date

- 25-Jul-2023

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 98 - Abandoned project (Adopted Project)

- Start Date

- 21-May-2024

- Due Date

- 26-May-2024

- Completion Date

- 21-May-2024

Relations

- Effective Date

- 19-Jan-2023

Overview

prEN 3197 is a CEN draft European standard for the design and installation of aircraft electrical and optical interconnection systems. It covers Electrical Wiring Interconnection Systems (EWIS) and Optical Fibre Interconnection Systems (OFIS) for manned and unmanned aeroplanes, helicopters, lighter-than-air vehicles, missiles and external pods. The document provides instructions for designing, selecting, manufacturing, installing, repairing and modifying interconnection networks and includes detailed content in Annex A and a list of related European standards in Annex B. Clause 4 defines the limitations and applicability for specific vehicle types and installations.

Practical value: the standard helps engineers, manufacturers and maintenance organisations achieve robust, maintainable and certifiable EWIS/OFIS installations that address safety, reliability and maintainability concerns.

Key Topics

- Scope and applicability - types of aerospace vehicles covered and Clause 4 limitations

- Terms and definitions - EWIS, OFIS and related terminology to ensure consistent interpretation

- General requirements - design precedence, selection considerations and service life expectations

- Hazard management - smoke, fire hazards, short-circuit and arc-tracking phenomena

- Installation groups and maintenance - grouping criteria and maintenance considerations to support airworthiness

- Materials and parts - selection guidance for metals, non-metals and treatment of dissimilar materials

- Quality and qualification - component and process qualification, test methods

- Component selection - cable (electrical and fibre), connectors, terminal lugs, splices and protective devices

- Systems elements - circuit protection, switching devices and terminal junction systems

Applications

The standard is applicable across design, production and in-service phases:

- Systems design: guiding EWIS/OFIS architecture choices, cable routing and connector selection for new aircraft programs

- Manufacturing: informing material selection, component qualification and assembly practices

- Installation & retrofit: best practices for installing or modifying wiring and fibre networks in airframes and external pods

- Maintenance & repair: inspection, repair and modification criteria to preserve airworthiness and reduce in-service failures

Key practical benefits include improved electrical safety (mitigating short-circuit and arc-tracking risks), reduced fire and smoke hazards, consistent component selection strategies, and clearer maintenance requirements that support reliability and lifecycle cost control.

Related Standards

prEN 3197 references a consolidated set of European standards for EWIS and OFIS (listed in Annex B). Practitioners should cross-reference:

- National and international airworthiness rulemaking applicable to the vehicle type

- Industry specifications for cables, connectors, circuit protection and fibre-optic components

- Test and qualification standards cited in Annex B for component and process validation

For full implementation, consult the complete prEN 3197 draft text, Annex A detailed content and Annex B normative references to align design, production and maintenance practices with the published European standard.

Frequently Asked Questions

oSIST prEN 3197:2023 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Aerospace series - Design and installation of aircraft electrical and optical interconnection systems". This standard covers: This document provides instructions on the methods to be used when designing, selecting, manufacturing, installing, repairing or modifying the aerospace vehicles electrical and optical interconnection networks, now called Electrical Wiring Interconnection System (EWIS), and Optical Fibre Interconnection Systems (OFIS), subject to the limitations defined in Clause 4 of this document. Aerospace Vehicles include manned and unmanned aeroplanes, helicopters, lighter-than- air vehicles, missiles and external pods. The general content of this document is described in page 2. A detailed content of this document is given in Annex A. This document lists all the relevant European standards related to EWIS and OFIS in Annex B.

This document provides instructions on the methods to be used when designing, selecting, manufacturing, installing, repairing or modifying the aerospace vehicles electrical and optical interconnection networks, now called Electrical Wiring Interconnection System (EWIS), and Optical Fibre Interconnection Systems (OFIS), subject to the limitations defined in Clause 4 of this document. Aerospace Vehicles include manned and unmanned aeroplanes, helicopters, lighter-than- air vehicles, missiles and external pods. The general content of this document is described in page 2. A detailed content of this document is given in Annex A. This document lists all the relevant European standards related to EWIS and OFIS in Annex B.

oSIST prEN 3197:2023 is classified under the following ICS (International Classification for Standards) categories: 49.060 - Aerospace electric equipment and systems; 49.090 - On-board equipment and instruments. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN 3197:2023 has the following relationships with other standards: It is inter standard links to SIST EN 3197:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

oSIST prEN 3197:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2023

Aeronavtika - Načrtovanje in vgradnja letalskih električnih in optičnih sistemov za

medsebojno povezovanje

Aerospace series - Design and installation of aircraft electrical and optical

interconnection systems

Luft- und Raumfahrt - Konstruktion und Installation elektrischer und optischer

Verkabelung in Luftfahrzeugen

Série aérospatiale - Conception et installation de systèmes d'interconnexion électrique et

optique d'aéronefs

Ta slovenski standard je istoveten z: prEN 3197

ICS:

49.060 Letalska in vesoljska Aerospace electric

električna oprema in sistemi equipment and systems

49.090 Oprema in instrumenti v On-board equipment and

zračnih in vesoljskih plovilih instruments

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

April 2023

ICS 49.060; 49.090 Will supersede EN 3197:2010

English Version

Aerospace series - Design and installation of aircraft

electrical and optical interconnection systems

Série aérospatiale - Conception et installation de Luft- und Raumfahrt - Konstruktion und Installation

systèmes d'interconnexion électrique et optique elektrischer und optischer Verkabelung in

d'aéronefs Luftfahrzeugen

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee ASD-

STAN.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 3197:2023 E

worldwide for CEN national Members.

Contents Page

European foreword . 10

1 Scope . 11

2 Normative references . 11

3 Terms and definitions . 12

4 Limitations . 12

5 General requirements . 13

5.1 Applicable rulemaking . 13

5.1.1 General. 13

5.1.2 Large aeroplanes . 13

5.1.3 Small and medium aeroplanes including unmanned air vehicles . 13

5.1.4 Rotary craft . 13

5.1.5 Aircraft engines . 13

5.2 EWIS definition . 13

5.3 OFIS definition . 14

5.4 Design precedence . 15

5.5 Selection considerations . 16

5.6 Service life . 16

5.7 Smoke and fire hazards . 16

5.8 Short-circuit and arc-tracking . 17

5.8.1 General. 17

5.8.2 Short-circuit description . 17

5.8.3 Arc-tracking description . 18

5.8.4 Arc-tracking phenomenon. 19

5.9 Installation groups . 21

5.10 Maintenance considerations . 22

5.11 Materials and parts considerations . 22

5.11.1 General. 22

5.11.2 Environmental directives . 22

5.11.3 Metals . 23

5.11.4 Dissimilar metals . 23

5.11.5 Non-metals . 23

5.12 Quality . 23

5.12.1 Components qualification . 23

5.12.2 Processes qualification . 24

5.12.3 Test methods . 24

5.13 Specific requirements . 24

5.13.1 Advice . 24

5.13.2 Power plant . 24

5.13.3 Rotorcraft . 27

5.13.4 Light aircraft . 29

5.13.5 APU . 29

5.13.6 Composite structures . 29

6 Selection of EWIS and OFIS components . 30

6.1 Applicable rulemaking . 30

6.2 Special requirements . 31

6.2.1 Commonality . 31

6.2.2 Maintenance, repair or modification. 31

6.2.3 Materials . 31

6.3 Electrical and fibre optic cable selection . 31

6.3.1 Environment . 31

6.3.2 Type of cable . 32

6.3.3 Electrical cables . 32

6.3.4 Voltage and current ratings . 34

6.3.5 Equipment cable . 34

6.3.6 Airframe cable . 34

6.3.7 Fireproof and fire-resistant cable . 34

6.3.8 Coaxial cable . 35

6.3.9 Data bus cable . 35

6.3.10 Thermocouple or extension cable . 35

6.3.11 Fibre optic cables . 35

6.3.12 Special cable types . 37

6.4 Connector selection . 38

6.4.1 Environment . 38

6.4.2 Types of connectors . 38

6.4.3 Construction . 39

6.4.4 Electrical contacts . 40

6.4.5 Fibre optic termini . 41

6.4.6 Cable outlet accessories . 41

6.4.7 Connector voltage ratings . 41

6.5 Circuit protective devices selection . 42

6.5.1 Type of protective devices . 42

6.5.2 Electrical protection . 42

6.5.3 Circuit Breaker . 45

6.5.4 Arc Fault Circuit Interrupter . 46

6.5.5 Arc Fault Circuit Breaker . 46

6.5.6 Remote Control Circuit Breaker . 46

6.5.7 Solid State Circuit Breaker . 46

6.5.8 Residual Current Device (RCD) . 46

6.5.9 Fuse . 46

6.6 Switching devices selection . 47

6.6.1 Type of switching devices . 47

6.6.2 Electrical switching . 47

6.6.3 Interrupter . 48

6.6.4 Switch . 48

6.6.5 Push-button . 48

6.6.6 Relays and micro-contactors . 48

6.6.7 Contactor . 50

6.6.8 Switching High Voltage DC Circuits . 50

6.7 Terminal junction systems . 50

6.7.1 Definition and requirements . 50

6.7.2 Environmental . 51

6.7.3 Design . 51

6.7.4 Mounting frames . 52

6.7.5 Other types of modules . 52

6.8 Terminal lugs selection . 53

6.8.1 Definition and requirements . 53

6.8.2 Selection criteria . 53

6.8.3 Inspection . 53

6.9 Splices selection . 54

6.9.2 Definition and requirements . 55

6.9.3 Installation constraints . 56

6.9.4 General notes on splices . 56

6.9.5 Screened cable splices . 56

6.9.6 Quick disconnect splices . 56

6.9.7 Closed end splices . 57

6.9.8 Splices for fibre optic cables . 57

6.9.9 Inspection . 57

6.10 Solder sleeves selection . 57

6.10.1 Description . 57

6.10.2 Solder and flux . 57

6.10.3 Solder sleeve selection . 57

6.10.4 Selection criteria . 58

6.11 Feedthrough Selection (Pressure Bung housing assemblies) . 58

6.11.1 General. 58

6.11.2 Selection criteria . 58

6.11.3 Design . 58

6.12 Clamp selection . 58

6.12.1 General. 58

6.12.2 Selection of “P” clamps . 59

6.12.3 Selection of “Ω” clips . 59

6.13 Protective parts selection . 59

6.13.1 General. 59

6.13.2 Selection criteria . 59

6.14 Identification parts selection . 60

6.14.1 General. 60

6.14.2 Selection criteria . 60

6.15 Installation components selection . 60

6.15.1 Selection of cable ties . 60

6.15.2 Tapes . 62

6.15.3 Raceways and cable tray . 62

6.16 Junction boxes . 63

6.16.1 General. 63

6.16.2 Construction . 63

6.16.3 Inside wiring . 64

6.16.4 Identification . 64

7 Components Identification . 64

7.1 Applicable rulemaking . 64

7.2 General. 64

7.3 Component manufacturer marking – Part number . 65

7.3.1 Component manufacturer identification . 65

7.3.2 Alternate manufacturer identification . 65

7.3.3 Identification intervals . 65

7.3.4 Types of wire manufacturer markings . 65

7.4 Airframer component function marking – Function identification number . 65

7.4.1 Airframe manufacturer identification . 65

7.4.2 Identification intervals . 66

7.4.3 Types of airframe manufacturer markings . 66

7.5 Identification of EWIS and OFIS bundles – Airframer identification – Routing. 66

7.5.1 Routing identification . 66

7.5.2 Types of routing identification . 67

7.5.3 Visible identification of critical design configuration limitations . 67

7.6 Identification of equipments . 67

7.7 Identification of user EWIS and OFIS modification or repair – Operators

identification coding . 68

8 Separation and principles to apply . 68

8.1 Applicable rulemaking . 68

8.2 General requirements . 68

8.2.1 General . 68

8.2.2 Segregation of functions . 69

8.2.3 Separation of different high voltage systems . 69

8.2.4 General . 69

8.2.5 Separation by physical distances versus separation by barrier . 69

8.2.6 Determination of separation . 70

8.2.7 Separation from personnel and cargo . 70

8.2.8 Electromagnetic interference (EMI) . 71

8.2.9 Separation from flammable fluids . 71

8.2.10 Separation from water waste . 71

8.2.11 Separation from flight controls . 71

8.2.12 Separation from high temperature equipment . 71

8.2.13 Redundant system separation . 72

8.3 Electrical requirements. 72

8.3.1 Voltage drop . 72

8.3.2 Coaxial and bus cable attenuation . 72

8.3.3 Ground electrical return . 72

8.3.4 Electromagnetic Compatibility (EMC) . 73

8.3.5 Grounding of screened cables . 73

8.3.6 Compass deviation . 73

8.3.7 Corona effect prevention . 73

8.3.8 High voltage AC. and DC. networks . 75

8.4 Ignition . 75

8.4.1 Magneto type . 75

8.4.2 Ignition High Energy/High Voltage (HE/HV) . 75

8.5 Mechanical requirements . 76

8.5.1 Cable handling . 76

8.5.2 Cable on engines (see 5.13.2 “Power plant” for further details) . 76

8.6 Environmental requirements . 76

8.6.1 Ambient temperature of installed harnesses . 76

8.6.2 Cable in undercarriage bays . 76

8.6.3 SWAMP areas . 76

8.7 Fuel tanks requirements . 76

8.7.1 Rational . 76

8.7.2 Cables inside fuel tanks . 77

8.7.3 Wiring segregation . 77

8.7.4 Harness installation . 77

8.7.5 Cable routing through fuel tanks . 77

8.8 Fire zone . 78

8.9 Attachment requirements . 78

8.10 Fibre optic cable requirements . 79

8.10.1 Installation . 79

8.10.2 Attenuation . 79

8.11 Size requirements . 79

8.12 EWIS and OFIS installation . 79

8.12.1 Zone categories . 79

8.12.2 General rules . 80

8.12.3 Protection against specific hazards . 80

8.12.4 Separation between route categories and codes . 80

8.12.5 Panels and boxes . 81

8.12.6 Cabin related harnesses . 81

9 Installation and manufacturing principles . 81

9.1 Applicable Rulemaking . 81

9.2 Security against high voltage . 81

9.3 General principles of cable routing . 82

9.3.1 Arrangement of cables . 82

9.3.2 Dead endings . 82

9.3.3 Drip loop and slack in cabling . 82

9.4 Arrangement and installation of power routes . 83

9.4.1 Feeder route . 83

9.4.2 Power route . 83

9.4.3 Power supply of equipment . 83

9.5 Minimum bending radius requirements . 83

9.5.1 General. 83

9.5.2 Method . 84

9.5.3 Bend radius for a standard wire or cable used alone . 84

9.5.4 Bend radius for an electrical transmission cable used alone . 85

9.5.5 Bend radius for fibre optic cables . 86

9.5.6 Bend radius for bundles or harnesses . 86

9.5.7 Bend radius for bundles or harnesses in hinge area . 87

9.5.8 Service loop for equipment removing (“blind” mounting) . 87

9.6 Cable preparation . 87

9.6.1 Marking . 87

9.6.2 Cutting to length . 87

9.6.3 Stripping . 88

9.7 Supports . 88

9.7.1 Cabling support . 88

9.7.2 Support at connectors . 88

9.7.3 Cable supports . 89

9.7.4 Installation of “P” clamps . 89

9.7.5 Adhesive clamps . 89

9.7.6 Installation of Omega clips . 90

9.8 Connectors and accessories . 90

9.8.1 Installation . 90

9.8.2 Precautions to ensure correct connector mating . 91

9.8.3 Terminals . 92

9.8.4 User control tests for terminals and splices (electrical) . 94

9.8.5 Fibre optic connectors . 95

9.9 Splices . 96

9.9.1 In-line splices . 96

9.9.2 Step-down splices . 96

9.9.3 Insulated splices . 96

9.9.4 Low air density splices . 96

9.9.5 Location of splices . 96

9.9.6 Support of splices . 97

9.9.7 Post-insulation of splices . 97

9.9.8 Recording procedure for splices . 97

9.10 Solder sleeve termination . 97

9.10.1 Installation . 97

9.10.2 Inspection .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...