SIST EN 10289:2003

(Main)Steel tubes and fittings for onshore and offshore pipelines - External liquid applied epoxy and epoxy-modified coatings

Steel tubes and fittings for onshore and offshore pipelines - External liquid applied epoxy and epoxy-modified coatings

The standard defines the reqiurements of liquid applied external coating, epoxy (EP) and epoxy-modified (EP-MOD), for the corrosion protection of tubes and pipeline fittings.

The coating in this standard can be applied to longitudinally or spirally welded and to seamless steel tubes and fittings used for the construction of pipelines for conveying liquids or gases.

If the component has to be cold bent the coating shall be applied after bending unless otherwise approved by the purchaser.

The coating shall consist normally of one layer of liquid product, applied by brush or by spray airless technique. Other application methods can be recommended by the product manufacturer, in accordance with the kind of product.

This coating can be used for the protection of buried or submerged steel tubes for service at the following temperatures and with three thickness classes A (400 *m), B (800 *m) and C(1500 *m) based on the following combination:

- type 1 : - 20 °C to 40 °C, thickness class A or B or C

- type 2 : - 20 °C to 60 °C, thickness class B or C

- type 3 : - 20 °C to 80 °C, thickness class C

Other temperatures can be agreed ; in this case, tests shall be carried out at the required temperature.

In this standard the word components is used for tubes and fittings.

Frequencies of tests on fittings shall be agreed by the parties at the ordering stage.

Components coated with these types of coatings may be further protected by means of cathodic protection.

Stahlrohre und Formstücke für On- und Offschoreverlegte Rohrleitungen - Umhüllung (Außenbeschichtung) mit Epoxi- und epoxi-modifizierten Materialien

Diese Norm definiert den Anwendungsbereich für die Außenmhüllung von Flüssigkunststoffen aus Epoxi (EP) und epoximodifiziertem Material (EP-MOD) für den Korrosionsschutz von Rohren und Formteilen. Nach dieser Norm kann die Beschichtung zur Umhüllung von längs- oder spiralgeschweißten sowie auf nahtlose Stahlrohre und Formteile zum Bau von Rohrleitungen für die Beförderung von Flüssigkeiten oder Gasen aufgebracht werden. Bei der Kaltbiegung von Stahlteilen muß die Beschichtung nach dem Biegevorgang aufgebracht werden, wenn vom Besteller nicht anders vorgegeben.

Tubes et raccords en acier pour canalisations enterrées et immergées - Revetements externes en résine époxyde ou époxyde modifiée appliquée a l'état liquide

La présente Norme européenne spécifie les prescriptions relatives aux revêtements externes à base de résine époxyde (EP) ou époxyde modifiée (EP-MOD), appliqués à l'état liquide, pour la protection anti-corrosion des tubes et raccords de canalisations en acier.

Le revêtement défini dans la présente norme peut être appliqué à des tubes en acier soudés en long ou en hélice ou sans soudure et aux raccords utilisés pour la construction de canalisations de transport de fluides liquides ou gazeux.

Si l'élément est cintré à froid, le revêtement doit être appliqué après cintrage sauf accord contraire de l'acheteur.

Le revêtement doit normalement comprendre une couche de produit liquide appliquée à la brosse ou au pistolet à air comprimé. Selon le type de produit, d'autres méthodes d'application peuvent être recommandées par le fabricant du produit.

Ce revêtement peut être utilisé pour la protection de tubes en acier enterrés ou immergés, employés aux températures suivantes et avec trois classes d'épaisseur A (400 mm), B (800 mm) et C (1 500 mm) sur la base des combinaisons suivantes :

¾ type 1 : - 20 °C à 40 °C, classe d'épaisseur A, B ou C ;

¾ type 2 : - 20 °C à 60 °C, classe d'épaisseur B ou C ;

¾ type 3 : - 20 °C à 80 °C, classe d'épaisseur C.

D'autres températures peuvent être convenues ; dans ce cas, les essais doivent être effectués à la température requise.

Dans la présente norme, le terme « éléments » s'applique aux tubes et raccords.

Les fréquences d'essais sur les raccords doivent faire l'objet d'un accord entre les parties au moment de la commande.

Les éléments revêtus avec ces types de revêtement peuvent être protégés ultérieurement par protection cathodique.

Jeklene cevi in fitingi za cevovode v zemlji in pod vodo - Zunanja prevleka, izdelana iz tekoče epoksidne in modificirane epoksidne smole

General Information

- Status

- Published

- Publication Date

- 31-Mar-2003

- Technical Committee

- IFEK - Ferrous metals

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Apr-2003

- Due Date

- 01-Apr-2003

- Completion Date

- 01-Apr-2003

Relations

- Effective Date

- 22-Dec-2008

Overview

EN 10289:2002 (CEN) specifies requirements for external liquid-applied epoxy (EP) and epoxy-modified (EP‑MOD) coatings used for the corrosion protection of steel tubes and pipeline fittings for onshore and offshore pipelines. The standard covers application to longitudinally or spirally welded and seamless steel tubes and fittings, use on buried or submerged pipelines, and coordination with mechanical processes such as cold bending.

Key Topics and Requirements

- Coating types: Liquid-applied epoxy (EP) and epoxy-modified (EP‑MOD) systems, normally applied as a single layer.

- Application methods: Brush or airless spray; other manufacturer‑recommended methods permitted depending on product.

- Cold bending: Coating shall normally be applied after cold bending unless the purchaser approves otherwise.

- Service temperature / thickness classes: The standard defines three thickness classes - A (400), B (800) and C (1500) - and three temperature/coverage combinations (type 1: −20 °C to 40 °C; type 2: −20 °C to 60 °C; type 3: −20 °C to 80 °C). Other temperatures and thicknesses can be agreed with testing at the required temperature.

- Testing and inspection: Detailed normative test methods and acceptance criteria are specified, including:

- Dry film thickness measurement

- Holiday (continuity) detection

- Impact resistance

- Adhesion (resistance to removal and pull‑off)

- Cathodic disbondment

- Specific electrical insulation resistance

- Immersion/aging tests (thermal ageing, adhesion after immersion)

- Indentation resistance and infrared scanning

- Quality assurance and documentation: Packaging, manufacturer specifications, inspection documents and frequencies (fittings test frequencies to be agreed at ordering) are addressed.

- Additional protection: Components may be further protected using cathodic protection systems.

Applications and Who Uses This Standard

EN 10289 is used by:

- Pipeline engineers and designers specifying pipeline coatings for onshore and offshore projects

- Manufacturers of steel tubes and fittings and coating system suppliers

- Procurement and quality assurance teams preparing purchase orders and inspection plans

- Inspection bodies and testing laboratories performing coatings evaluation per the standard

- Asset owners/operators requiring compliant corrosion protection for buried or submerged pipelines

Practical applications include corrosion protection of transmission pipelines for liquids and gases, pre‑coated pipes for trench or subsea installation, and coated fittings where environmental and service temperature requirements align with EN 10289.

Related Standards

Refer to the normative references listed in EN 10289 for related CEN and national standards on steel tubes, pipeline fittings and coating testing procedures. For project specifications, coordinate EN 10289 requirements with other pipeline design and cathodic protection standards.

Frequently Asked Questions

SIST EN 10289:2003 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Steel tubes and fittings for onshore and offshore pipelines - External liquid applied epoxy and epoxy-modified coatings". This standard covers: The standard defines the reqiurements of liquid applied external coating, epoxy (EP) and epoxy-modified (EP-MOD), for the corrosion protection of tubes and pipeline fittings. The coating in this standard can be applied to longitudinally or spirally welded and to seamless steel tubes and fittings used for the construction of pipelines for conveying liquids or gases. If the component has to be cold bent the coating shall be applied after bending unless otherwise approved by the purchaser. The coating shall consist normally of one layer of liquid product, applied by brush or by spray airless technique. Other application methods can be recommended by the product manufacturer, in accordance with the kind of product. This coating can be used for the protection of buried or submerged steel tubes for service at the following temperatures and with three thickness classes A (400 *m), B (800 *m) and C(1500 *m) based on the following combination: - type 1 : - 20 °C to 40 °C, thickness class A or B or C - type 2 : - 20 °C to 60 °C, thickness class B or C - type 3 : - 20 °C to 80 °C, thickness class C Other temperatures can be agreed ; in this case, tests shall be carried out at the required temperature. In this standard the word components is used for tubes and fittings. Frequencies of tests on fittings shall be agreed by the parties at the ordering stage. Components coated with these types of coatings may be further protected by means of cathodic protection.

The standard defines the reqiurements of liquid applied external coating, epoxy (EP) and epoxy-modified (EP-MOD), for the corrosion protection of tubes and pipeline fittings. The coating in this standard can be applied to longitudinally or spirally welded and to seamless steel tubes and fittings used for the construction of pipelines for conveying liquids or gases. If the component has to be cold bent the coating shall be applied after bending unless otherwise approved by the purchaser. The coating shall consist normally of one layer of liquid product, applied by brush or by spray airless technique. Other application methods can be recommended by the product manufacturer, in accordance with the kind of product. This coating can be used for the protection of buried or submerged steel tubes for service at the following temperatures and with three thickness classes A (400 *m), B (800 *m) and C(1500 *m) based on the following combination: - type 1 : - 20 °C to 40 °C, thickness class A or B or C - type 2 : - 20 °C to 60 °C, thickness class B or C - type 3 : - 20 °C to 80 °C, thickness class C Other temperatures can be agreed ; in this case, tests shall be carried out at the required temperature. In this standard the word components is used for tubes and fittings. Frequencies of tests on fittings shall be agreed by the parties at the ordering stage. Components coated with these types of coatings may be further protected by means of cathodic protection.

SIST EN 10289:2003 is classified under the following ICS (International Classification for Standards) categories: 25.220.60 - Organic coatings; 77.140.75 - Steel pipes and tubes for specific use. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 10289:2003 has the following relationships with other standards: It is excused to SIST EN 10290:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 10289:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stahlrohre und Formstücke für On- und Offschoreverlegte Rohrleitungen - Umhüllung (Außenbeschichtung) mit Epoxi- und epoxi-modifizierten MaterialienTubes et raccords en acier pour canalisations enterrées et immergées - Revetements externes en résine époxyde ou époxyde modifiée appliquée a l'état liquideSteel tubes and fittings for onshore and offshore pipelines - External liquid applied epoxy and epoxy-modified coatings77.140.75Jeklene cevi in cevni profili za posebne nameneSteel pipes and tubes for specific use25.220.60Organske prevlekeOrganic coatingsICS:Ta slovenski standard je istoveten z:EN 10289:2002SIST EN 10289:2003en01-april-2003SIST EN 10289:2003SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 10289August 2002ICS 23.040.99; 25.220.60English versionSteel tubes and fittings for onshore and offshore pipelines -External liquid applied epoxy and epoxy-modified coatingsTubes et raccords en acier pour canalisations enterrées etimmergées - Revêtements externes en résine époxyde ouépoxyde modifiée appliquée à l'état liquideStahlrohre und Formstücke für On- und OffschoreverlegteRohrleitungen - Umhüllung (Außenbeschichtung) mit Epoxi-und epoxi-modifizierten MaterialienThis European Standard was approved by CEN on 11 April 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2002 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 10289:2002 ESIST EN 10289:2003

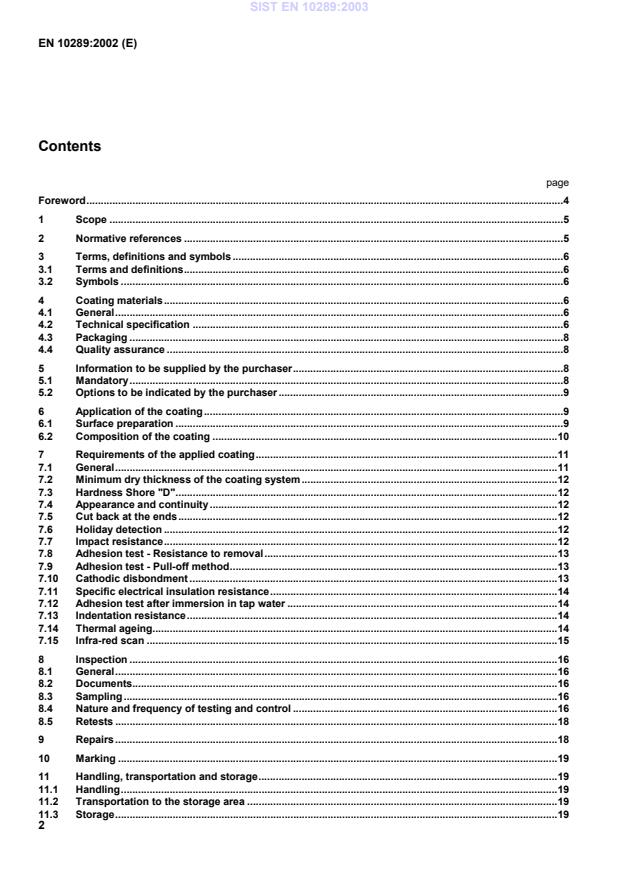

Dry thickness of the coating system.20A.1General.20A.2Apparatus.20A.3Procedure.20A.4Results.20Annex B (normative)

Holiday detection test.21B.1General.21B.2Apparatus.21B.3Procedure.21B.4Results.21Annex C (normative)

Impact test.22C.1General.22C.2Apparatus.22C.3Procedure.22C.4Results.23Annex D (normative)

Adhesion test - Resistance to removal.24D.1General.24D.2Apparatus.24D.3Procedure.24D.4Results.25Annex E (normative)

Cathodic disbondment test.26E.1Principle.26E.2Apparatus.26E.3Sampling.27E.4Procedure.28E.5Investigation procedure.28E.6Results.28Annex F (normative)

Specific electrical insulation resistance test.32F.1Test at ambient temperature ((23 ± 2) °C).32F.2Test at maximum service temperature.33Annex G (normative)

Adhesion test after immersion in tap water.36G.1General.36G.2Apparatus.36G.3Procedure.36G.4Results.36Annex H (normative)

Indentation test.37H.1General.37H.2Apparatus.37H.3Procedure.37H.4Results.37Annex J (normative)

Thermal ageing.38J.1General.38J.2Apparatus.38J.3Sampling.38J.4Procedure.38J.5Results.38Annex K (normative)

Types of inspection documents.39Annex L (informative)

A-Deviation.40Bibliography.41SIST EN 10289:2003

2) °C;¾ 28 days at (23 ± 2) °C.Other testing regimes may be used by agreement.SIST EN 10289:2003

R

RSS ³ 0,8Table 3 : Specific electrical insulation resistanceRs value ( Wm²)after 100 days at (23 ± 2) °CRs value ( Wm²)after 30 days at maximum servicetemperature ± 2 °CClass BClass CClass BClass C106107104104For coating class A, the requirements have to be agreed between the purchaser and product manufacturer.7.12 Adhesion test after immersion in tap waterThis test shall be carried out in accordance with the method defined in annex G.Results shall be given for information.7.13 Indentation resistanceIndentation resistance shall be determined by testing in accordance with the method defined in annex H.The test shall be carried out on a coating thickness in the range of 400 µm to 600 µm for class A , in the range of800 µm to 1 200 µm for class B and in the range of 1 500 to 2 000 for class C.The test shall be carried out at (23 ± 2) °C and at the maximum tube service temperature ± 2 °C.The indentation shall not be more than 0,2 mm at (23 ± 2) °C and 30 % of the initial measured coating thickness atthe maximum service temperature ± 2 °C.7.14 Thermal ageingThermal ageing shall be determined by testing in accordance with the method defined in annex J after exposure tothe following conditions:¾ type 1:100 days at (60 ± 2) °C ;¾ type 2:100 days at (80 ± 2) °C ;¾ type 3:100 days at (100 ± 2) °C.SIST EN 10289:2003

Shore "D"7.3EN ISO8684 per shift3 componentsAppearance and continuity7.4VisualEvery component3 componentsCut back7.5VisualEvery component3 componentsHoliday detection7.6annex BEvery component3 componentsImpact resistance at(-5 ± 3) °C and at (23 ± 2) °C7.7annex C-3 samplesiAdhesion test -Resistance to removal7.8annex DOnce per shift at(23 ± 2) °Conce per week atmax. temperaturec3 componentsAdhesion Test -Pull-off methodf7.9EN 24624g3 panelsCathodic disbondmentf h7.10annex Eg i3 componentsSpecific electrical insulationresistancef h7.11annex Fg i3 tubesAdhesion test after immersion intap waterf h7.12annex Gg3 panelsIndentation resistancef7.13annex Hg i3 tubesThermal ageingf h7.14annex Jg i3 tubesInfra-red scanf7.15-g3 componentsaAll tests detailed shall be undertaken at least every 3 years for the same system, material and significant technical process.The system and applicator approval may be combined with a coating production run.bOption 10Other schemes of qualification may be requested by the purchaser.cIf the process is discontinuous this test shall carried out on every component.dThe test shall be carried out as follows :automatic plant :1 tube every 5, or each fitting ;manual application :3 times per component.eAny component from the beginning to the end of production may be used for this test.fOption to be indicated by the purchaser.gThe test and their frequency shall be defined at the time of the inquiry and order.hThe delivery of tubes can be undertaken prior to the completion of the test.iBy agreement the test can be carried out on panels or samples coated at the same time and in the same way as production.This is permissible if qualification trials have been carried out both on panels and components.SIST EN 10289:2003

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...