SIST EN 13172:2012

(Main)Thermal insulation products - Evaluation of conformity

Thermal insulation products - Evaluation of conformity

This European Standard specifies the procedures and the criteria for the evaluation of the conformity of a thermal insulating product with the relevant European product specification.

This European Standard applies to factory made products for buildings, factory made products for building equipment and industrial installations, in-situ products for buildings, in-situ products for building equipment and industrial installations and to external thermal insulation composite systems.

Wärmedämmstoffe - Konformitätsbewertung

Diese Europäische Norm legt die Verfahren und die Kriterien für die Bewertung der Konformität eines Wärmedämmstoffes mit der entsprechenden europäischen Produktnorm fest. Diese Europäische Norm gilt für werkmäßig hergestellte Wärmedämmstoffe für Gebäude, für werkmäßig hergestellte Wärmedämmstoffe für die technische Gebäudeausrüstung und betriebstechnische Anlagen, für in-situ-Dämmstoffe für Gebäude, für in-situ-Dämmstoffe für die technische Gebäudeausrüstung und betriebstechnische Anlagen und für Wärmedämm-Verbundsysteme.

Produits isolants thermiques - Évaluation de la conformité

La présente Norme européenne spécifie les procédures et les critères pour l’évaluation de la conformité d’un

produit isolant thermique aux spécifications européennes du produit correspondant.

La présente Norme européenne s’applique aux produits manufacturés pour le bâtiment, aux produits

manufacturés pour l’équipement du bâtiment et les installations industrielles, aux produits mis en oeuvre in

situ pour le bâtiment, aux produits mis en oeuvre in situ pour l’équipement du bâtiment et les installations

industrielles et aux systèmes composites pour l’isolation thermique par l’extérieur.

Toplotnoizolacijski proizvodi - Vrednotenje skladnosti

Ta evropski standard določa postopke in merila za vrednotenje skladnosti toplotnoizolacijskega proizvoda z ustrezno evropsko specifikacijo proizvoda. Ta evropski standard se uporablja za tovarniško izdelane proizvode za stavbe, tovarniško izdelane proizvode za gradbeno opremo in industrijsko napeljavo, proizvode za stavbe, izdelane na kraju samem, proizvode za gradbeno opremo in industrijsko napeljavo, izdelane na kraju samem, ter za toplotnoizolacijske sestavljene sisteme.

General Information

- Status

- Withdrawn

- Public Enquiry End Date

- 29-Jun-2010

- Publication Date

- 02-May-2012

- Withdrawal Date

- 11-Nov-2024

- Technical Committee

- TOP - Thermal insulation

- Current Stage

- 9900 - Withdrawal (Adopted Project)

- Start Date

- 11-Nov-2024

- Due Date

- 04-Dec-2024

- Completion Date

- 12-Nov-2024

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 01-Jun-2012

- Effective Date

- 01-Jan-2025

Frequently Asked Questions

SIST EN 13172:2012 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Thermal insulation products - Evaluation of conformity". This standard covers: This European Standard specifies the procedures and the criteria for the evaluation of the conformity of a thermal insulating product with the relevant European product specification. This European Standard applies to factory made products for buildings, factory made products for building equipment and industrial installations, in-situ products for buildings, in-situ products for building equipment and industrial installations and to external thermal insulation composite systems.

This European Standard specifies the procedures and the criteria for the evaluation of the conformity of a thermal insulating product with the relevant European product specification. This European Standard applies to factory made products for buildings, factory made products for building equipment and industrial installations, in-situ products for buildings, in-situ products for building equipment and industrial installations and to external thermal insulation composite systems.

SIST EN 13172:2012 is classified under the following ICS (International Classification for Standards) categories: 91.100.60 - Thermal and sound insulating materials. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13172:2012 has the following relationships with other standards: It is inter standard links to SIST EN 13172:2008, SIST EN 13172:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13172:2012 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/103. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase SIST EN 13172:2012 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Toplotnoizolacijski proizvodi - Vrednotenje skladnostiWärmedämmstoffe - KonformitätsbewertungProduits isolants thermiques - Évaluation de la conformitéThermal insulation products - Evaluation of conformity91.100.60Thermal and sound insulating materialsICS:Ta slovenski standard je istoveten z:EN 13172:2012SIST EN 13172:2012en,fr,de01-junij-2012SIST EN 13172:2012SLOVENSKI

STANDARDSIST EN 13172:20081DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13172

January 2012 ICS 91.100.60 Supersedes EN 13172:2008English Version

Thermal insulation products - Evaluation of conformity

Produits isolants thermiques - Évaluation de la conformité Wärmedämmstoffe - Konformitätsbewertung This European Standard was approved by CEN on 9 December 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13172:2012: ESIST EN 13172:2012

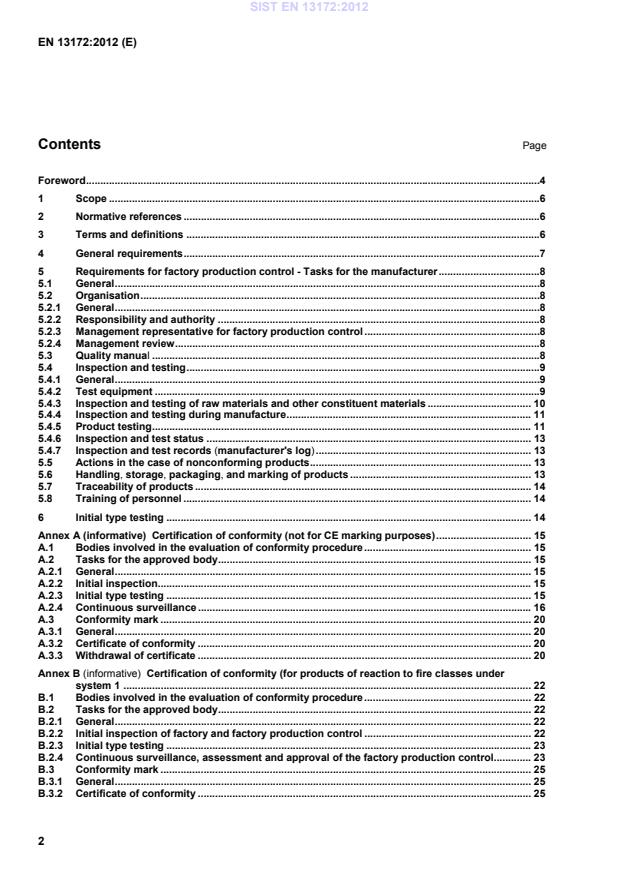

Certification of conformity (not for CE marking purposes) . 15A.1 Bodies involved in the evaluation of conformity procedure . 15A.2 Tasks for the approved body . 15A.2.1 General . 15A.2.2 Initial inspection. 15A.2.3 Initial type testing . 15A.2.4 Continuous surveillance . 16A.3 Conformity mark . 20A.3.1 General . 20A.3.2 Certificate of conformity . 20A.3.3 Withdrawal of certificate . 20Annex B (informative)

Certification of conformity (for products of reaction to fire classes under system 1

.............................................................................................................................................. 22B.1 Bodies involved in the evaluation of conformity procedure .......................................................... 22B.2 Tasks for the approved body ............................................................................................................. 22B.2.1 General ................................................................................................................................................. 22B.2.2 Initial inspection of factory and factory production control .......................................................... 22B.2.3 Initial type testing ............................................................................................................................... 23B.2.4 Continuous surveillance, assessment and approval of the factory production control ............. 23B.3 Conformity mark ................................................................................................................................. 25B.3.1 General ................................................................................................................................................. 25B.3.2 Certificate of conformity .................................................................................................................... 25SIST EN 13172:2012

Declaration of conformity by the manufacturer (for the performance requirements under system 3 ) . 26C.1 Bodies involved in the evaluation of conformity procedure. 26C.2 Tasks for the approved body . 26C.2.1 General . 26C.2.2 Initial type testing . 26C.3 Conformity mark . 27C.3.1 General . 27C.3.2 Declaration of conformity . 27Annex D (informative)

Declaration of conformity by the manufacturer (for products of reaction to fire classes under system 4 ) . 28D.1 Conformity mark . 28Annex E (informative)

Guidance on the use of annex(es) . 29E.1 CE marking . 29E.2 Voluntary product certification . 30E.3 Overview of the elements of the evaluation of conformity systems . 30Annex F (informative)

Criteria for assessing non-conformity – Procedures in case of a complaint . 31F.1 Complaint on the product declaration . 31F.1.1 General . 31F.1.2 Complaint on the declared thermal resistance or thermal conductivity . 31F.1.3 Complaint on other characteristics . 32F.2 Complaint on a lot . 32Bibliography . 33 SIST EN 13172:2012

Annex E describes how to use the annexes together with the main body of this standard to fulfil the requirements to the certification and/or declaration of conformity for a product. SIST EN 13172:2012

thermal insulation product produced under conditions which are presumed uniform to a given specification and placed on the market 3.2 factory production control permanent, internal control of production exercised either by the manufacturer or by his agent on the responsibility of the manufacturer himself NOTE Factory production control comprises operational techniques and all measures necessary to regulate and maintain the conformity of the product to the requirements of the relevant product standard. 3.3 production line assemblage of equipment that produces products using a continuous process 3.4 production unit assemblage of equipment that produces products using a discontinuous process 3.5 production plant/factory all the production equipment on the same site including all production lines and units 3.6 third party approved organisation or body which is able to provide independent verification or approval 3.7 witness testing test performed by the manufacturer at his own facilities monitored by the representative of the third party SIST EN 13172:2012

NOTE 1 Annex A is included for the purposes of voluntary product certification. NOTE 2 Annex F is included for the purposes of describing how to handle the case of a complaint (outside the scope of a voluntary certification, in which case the annex A rules apply). The content of Clause 5 will also be met by supplementing the provisions of EN ISO 9001 with requirements of this standard. For ITT and FPC, each production line is considered separately.

For ITT and FPC, production units using the same process in one factory are considered together (as if one production line). Products may be collected into product groups for declaration and testing purposes subject to the following conditions: • They shall have the same type of production process and shall be derived from the same family of raw material; a distinction is made between glass wool and rock wool and between foams with different blowing agents.

• They shall differ only in aspects that do not influence the properties required in the relevant product standard. • They shall be covered by a single thermal insulation standard, e.g. from the series EN 13162 to EN 13171. • Products which differ only with regard to some properties may be grouped together by their common properties. • Products which are identical except the facing and for which the different facings have been shown to have the same effect on the declared characteristics (e.g. regarding thermal properties, the gas tight facings of some PU products), may be grouped. Products covered by more than one European Standard may be grouped for testing purposes only providing that, • They have a common production specification and that they are from the same type of production process and the same family of raw material, e.g. cellular glass for the EN 13167 and EN 14305.

The properties outside this (these) common group(s) shall be tested product by product. Products which are outside the scope of a product standard cannot be grouped for declaration purposes with products declared under the scope of that standard. Providing that a product within the group meets the requirements of the product standard then all products within the same group shall be deemed to comply with the product standard for the properties concerned. If the same product fails to comply with the product standard then the whole group shall be assumed to have failed to comply with the product standard. SIST EN 13172:2012

a) initiate action to prevent the occurrence of product non-conformity; b) identify and record any product quality problems. 5.2.3 Management representative for factory production control At every place of production, a representative, with the appropriate knowledge and production experience, shall be appointed by the manufacturer and given responsibility for managing and supervising factory production control procedures and for ensuring that the requirements of this standard are implemented and maintained.

5.2.4 Management review Management shall review at appropriate intervals the factory production control system to ensure its continuing suitability and effectiveness. Records of such reviews shall be maintained. 5.3 Quality manual The manufacturer's documentation and procedures shall be relevant to the production and process control used during manufacture of the product, and shall provide the following details in a quality manual: a) the quality aims and the organizational structure, responsibilities and authority of the management with regard to product conformity; b) the procedures for specifying and verifying the raw materials and other constituent materials; c) the manufacturer's production control and other techniques, processes and systematic actions that will be used; d) the inspections and tests to be carried out before, during and after manufacture, together with their frequency (see 5.4) and possible retest procedures (see 5.5); e) the procedures for handling, storage, packaging, marking and labelling the product (see 5.6); f) the procedures for all personnel to receive training in the activities affecting quality (see 5.8). SIST EN 13172:2012

The test equipment (including software) shall be capable of achieving the accuracy required by the test methods referred to in the product standard. 5.4.2.2 Calibration The accuracy of the test equipment shall be ensured by periodic calibration. All calibrations shall be traceable to relevant internationally or, failing that, nationally recognised reference test specimens (standards). Where no such reference test specimens exist, the basis used for calibration shall be documented. The manufacturer shall define compliance criteria for each piece of equipment. The equipment shall be calibrated before being placed into service; periodically at a frequency described by the manufacturer respecting the minimum frequencies specified in Table 1; after any repair (see 5.4.2.4); to verify the test results obtained before being taken out of service. If internal checks are sufficient (e.g. Heat Flow Meter (HFM) equipment) then this calibration is not needed. Equipment not listed in Table 1 shall be calibrated in accordance with the manufacturer's documented procedures.

The manufacturer shall assess the calibration results and document the results of such assessments. The calibration records shall be maintained for a period of 10 years. SIST EN 13172:2012

Equipment not listed in Table 1 shall be checked in accordance with the manufacturer's documented procedures. Records of internal checks shall be maintained for a period of 10 years.

Table 1 — Minimum frequencies of checks and calibrations of test equipment Properties

Internal checks Calibration of

test equipment Thickness Once per montha

Prior to first use of equipment and thereafter annually Mass Once per montha Mechanical properties

- Thermal properties b :

- heat flow meter

- guarded hot plate

Once per two weeks Once per year a A lower frequency of once every 3 months may be used when stability has been verified for a period of at least one year. If any single measurement indicates significant variation, the frequency reverts to once a month. b For thermal properties a part of the calibration shall be to compare test results obtained by the manufacturer with those obtained by an approved body on the same sample. The reference test specimen to be used is the IRMM 440 defining the European thermal conductivity level.

5.4.2.4 Defective equipment Equipment that has been subjected to abuse or mishandling, which gives suspect results or has been shown to be defective or outside specified limits, shall be taken out of service immediately and marked as defective.

The manufacturer shall examine whether or not defective equipment gives cause for concern regarding the conformity of the products tested using the defective equipment. This examination shall be documented. In case of any doubt regarding conformity of products, 5.5 applies. After any repair, calibration shall be repeated before the equipment is placed into use. 5.4.3 Inspection and testing of raw materials and other constituent materials The manufacturer shall ensure that raw materials and other constituent materials conform to his specified requirements. In determining the checks necessary consideration shall be given to the control exercised by the supplier and the documented evidence of conformity supplied (often referred to as supplier certified components or certified raw materials). The manufacturer shall ensure that incoming raw materials and other constituent materials are used or processed only after they have been verified as conforming to the specified requirements. Where incoming material is released for urgent production purposes prior to verification it shall be identified and recorded in order to permit immediate recall in the event of non-conformity. SIST EN 13172:2012

Reduced testing frequencies for direct testing may be used for well established production lines/units for properties other than reaction to fire and thermal resistance/conductivity: • in the case of a given characteristic where a well controlled production process can be demonstrated, the testing frequency may be reduced as described below following the relevant statistical rule. • the frequency for direct testing cannot be reduced to less than 10 % of the minimum frequency given in the relevant product standard. In no case may the frequency be less than once a year. • the risk of failure in a test shall not exceed 1,0 %. For dimensional tolerances the confidence level shall be at least 99 %, for other characteristics the confidence level shall be at least 50 %. Three situations arise: I) for characteristics with declared classes – tolerance interval, T (one-sided interval for dimensional characteristics where only a plus or a minus tolerance interval is declared and two-sided interval for e.g. dimensional characteristics where a plus-minus tolerance interval is declared).

If the Gaussian distribution can be assumed for the test results, then Equation 1 applies.

T2 ≥ (k99/99 x s)2

(1) where T is the tolerance interval for the test results obtained over a period not exceeding 3 years; s is the estimate of the standard deviation of the test results obtained over a period not exceeding 3 years; k is a factor corresponding to the number of test results, n, available over a period not exceeding 3 years at the reduced testing frequency. SIST EN 13172:2012

If the Gaussian distribution can be assumed for the test results, the equation 2 or 3 applies.

skxxD⋅≥−50/90 for minimum values (2) skxxD⋅≥−50/90 for maximum values (3) where x is the mean of the measured values; xD is the declared value; s is the estimate of the standard deviation of the test results obtained over a period not exceeding 3 years; k is a factor corresponding to the number of test results, n, available over a period not exceeding 3 years at the reduced testing frequency. Table 2 gives the k factors corresponding to a 90 % tolerance interval with a confidence level of 50 % (90/50). Table 2 — k factors for estimated standard deviations Number of test results n k factors k99,99 k90,50 One-sided interval a Two-sided interval b One-sided interval c 10 5,074 5,611 2,411 20 3,932 4,175 2,366 50 3,125 3,390 2,342 100 2,850 3,098 2,334 200 2,679 2,922 2,330 a Applicable for a plus or a minus-tolerance. b Applicable for plus-minus-tolerances. c Applicable for limit values. For other numbers of test results see ISO 16269-6, Statistical interpretation of data – Determination of

statistical tolerance intervals.

NOTE Linear interpolation is acceptable.

III) For characteristics where test results are expressed in terms of pass/fail, a binominal distribution can be assumed. To lower the frequency it is required that the test shall be performed on at least 100 different samples from different production days and 99 % shall pass. Satisfaction of the conditions for reduced testing frequencies (I, II or III), shall be verified in the event of failure and at least once a year. SIST EN 13172:2012

Products, which have not met the value intended to be declared by the manufacturer for a given property shall be permitted to qualify for a less stringent value of that property and shall be labelled accordingly. 5.6 Handling, storage, packaging, and marking of products In accordance with the quality manual (see 5.3) the manufacturer shall:

1) provide methods of handling that prevent damage or deterioration; SIST EN 13172:2012

Certification of conformity (not for CE marking purposes) NOTE This annex supports the standards for thermal insulation products. When used in the evaluation of conformity of these products its use is mandatory. For this reason the text of the annex, where appropriate, is written in the imperative form. A.1 Bodies involved in the evaluation of conformity procedure The following external bodies may be involved in the evaluation of conformity of products with this standard: 1) certification body which provides conformity certification; 2) inspection body, which performs assessments, makes recommendations on the acceptability of manufacturer's factory production control, performs subsequent audits and which selects samples of products for testing; 3) testing laboratory, which measures, examines, tests or otherwise determines the characteristics or performance of materials or products and which calibrates equipment. NOTE The functions of these three bodies may be performed by the certification body or by different bodies. If different bodies are involved, the inspection body and/or the testing laboratory carry out their functions on behalf of the certification body. In this annex these bodies are referred to by the term "approved body". A.2 Tasks for the approved body A.2.1 General A.2 specifies the tasks for the approved body in the evaluation of conformity procedure and also the manufacturer's duties arising in connection with them. If a quality system certified to a quality system standard, such as EN ISO 9001, is used, this certification shall be taken into account by the product certification body for those elements that are common to both systems. A.2.2 Initial inspection The initial inspection shall determine whether the prerequisites for staff and equipment, for continuous and orderly manufacture and for the corresponding factory production control, are in accordance with Clause 5. The results and recommendations from the initial inspection shall be documented in an assessment report. This shall include evidence that all the requirements of Clause 5 have been assessed. A.2.3 Initial type testing Each product, which is submitted for assessment, shall be tested by the approved body in accordance with the product standard. SIST EN 13172:2012

NOTE 2 For new production lines/units the normal evaluation of conformity procedures apply. For the manufacturer starting a line/unit, identical in terms of product performance to an existing line/unit, and for existing products/product groups, a special agreement may be made to handle the practical start of production and the performance of ITT ensuring that all evaluation of conformity requirements are finalised within a period of less than 6 months. In any case the manufacturer has the full responsibility for the declared values. A.2.4 Continuous surveillance A.2.4.1 General Production shall be subjected to continuous surveillance by an approved inspection body, consisting of routine inspections (see A.2.4.2), audit testing (see A.2.4.3), actions in the case of non-conformity (see A.2.4.4) and extraordinary inspections (see A.2.4.5). SIST EN 13172:2012

The manufacturer shall inform the certification body of changes in the quality system that are (or might be) directly connected to the conformity of the products. A.2.4.2 Routine Inspections Routine inspections shall be performed to assess the continued conformity of the manufacturer's factory production control system to the requirements of Clause 5. Reference shall be made to the records of the initial inspection and/or previous routine inspections to ensure changes to the manufacturer's factory production control system are assessed. Records of inspections shall include details of the status of the factory production control system as it exists on the date of the inspection. During each routine inspection, the following shall be specifically examined: 1) results of the manufacturer's own testing to check:

a)

whether tests have been performed at the specified frequency and

b)

that only products that have conformed to the product standard have been released; 2) that proper corrective actions have been taken when required; 3) the calibration and maintenance of test equipment; 4) the marking and labelling of products. The results of the routine inspections shall be documented in a record of the inspection. The routine inspections shall be performed twice a year, unless additional extraordinary insp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...