SIST EN 15732:2013

(Main)Light weight fill and thermal insulation products for civil engineering applications (CEA) - Expanded clay lightweight aggregate products (LWA)

Light weight fill and thermal insulation products for civil engineering applications (CEA) - Expanded clay lightweight aggregate products (LWA)

This standard describes the product characteristics and includes procedures for testing, marking and labelling.

This European Standard specifies the requirements for loose-fill expanded clay lightweight aggregate (expanded clay LWA) products for Civil Engineering Applications excluding the use as thermal insulation in and under buildings which are covered by EN 14063-1. The standard covers the use of expanded clay LWA as lightweight fill and insulation materials in embankments for roads, railways and other trafficked areas and as lightweight backfill for structures.

This standard does not specify the required level of a given property to be achieved by a product to demonstrate fitness for purpose in a particular application. The levels required for a given application are to be found in regulations or non-conflicting standards.

Leichte Schütt- und Wärmedämmstoffe für bautechnische Anwendungen (CEA) - Produkte aus Blähton-Leichtzuschlagstoffen (LWA)

Diese Europäische Norm beschreibt die Produkteigenschaften und die Verfahren zur Prüfung, Kennzeichnung und Etikettierung. Diese Europäische Norm legt Anforderungen an Schüttdämmstoffe aus Blähton-Leichtzuschlagstoffen (Blähton-LWA) für bautechnische Zwecke fest. Ausgenommen sind Anwendungen als Wärmedämmung in und unter Gebäuden, die in EN 14063-1 erfasst werden. In der vorliegenden Norm wird die Anwendung von Blähton-Leichtzuschlagstoffen als leichte Schütt- und Dämmstoffe an Straßendämmen, Schienenwegen und anderen befahrbaren Bereichen sowie ihre Anwendung als leichte Hinterfüllung für Bauwerke beschrieben. Diese Norm legt keine Anforderungsstufen für eine bestimmte Eigenschaft fest, die ein Produkt erreichen muss, um für einen bestimmten Anwendungszweck gebrauchstauglich zu sein. Die erforderlichen Stufen sind den gesetzlichen Bestimmungen oder nicht entgegenstehenden Normen zu entnehmen.

Matériaux de remplissage légers et produits isolants thermiques pour les applications du génie civil - Produits à base de granulats légers d'argile expansée

La présente Norme européenne décrit les caractéristiques des produits et contient des modes opératoires d'essai, de marquage et d'étiquetage.

La présente norme spécifie les exigences concernant les produits en vrac à base de granulats légers d'argile expansée pour les applications en génie civil, à l'exclusion de l'utilisation comme isolant thermique dans et sous les bâtiments qui est traitée par l’EN 14063-1. La norme traite de l'utilisation de granulats légers d'argile expansée comme matériau de remplissage léger et matériau isolant dans les remblais pour les chaussées, les voies ferrées et d'autres zones de circulation et comme remblai léger pour les structures.

La présente norme ne spécifie pas le niveau requis d'une propriété donnée devant être atteint par un produit pour en démontrer l'aptitude à l'emploi dans une application particulière. Les niveaux requis pour une application particulière figurent dans les réglementations ou dans des normes non contradictoires.

Toplotnoizolacijski in lahki polnilni proizvodi za inženirske objekte (CEA) - Proizvodi iz ekspandiranega glinenega agregatnega proizvoda (LWA)

Ta evropski standard opisuje lastnosti proizvodov ter zajema postopke za preskušanje, označevanje in etiketiranje. Ta standard določa zahteve za lahke polnilne proizvode iz ekspandiranega glinenega agregatnega (ekspandirana glina LWA) proizvoda za inženirske objekte, razen za uporabo z namenom toplotne izolacije in pod stavbami, ki so zajete v standardu EN 14063-1. Standard zajema uporabo ekspandirane gline LWA kot lahkega polnila in izolacijskega materiala v nasipih za ceste, železnice in druga prometna območja ter kot lahkega zasipa za zgradbe. Ta standard ne določa zahtevanih ravni določene lastnosti, ki jo mora proizvod doseči, da se dokaže njegova primernost namenu za posamezno vrsto uporabe. Zahtevane ravni za posamezno uporabo so določene v uredbah ali standardih, ki niso v nasprotju s tem standardom.

General Information

- Status

- Published

- Public Enquiry End Date

- 29-Jun-2012

- Publication Date

- 14-Jan-2013

- Technical Committee

- TOP - Thermal insulation

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 05-Nov-2012

- Due Date

- 10-Jan-2013

- Completion Date

- 15-Jan-2013

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 06-May-2015

- Effective Date

- 18-Jan-2023

Overview

EN 15732:2012 is the CEN European Standard for loose-fill expanded clay lightweight aggregate (expanded clay LWA) products intended for civil engineering applications (CEA). It defines product characteristics and specifies procedures for sampling, testing, marking, labelling and conformity assessment for expanded clay LWA used as lightweight fill and insulation in embankments, road and rail substructures, trafficked areas and as lightweight backfill for structures. The standard excludes in‑and‑under‑building thermal insulation (covered by EN 14063‑1). EN 15732 is a harmonised document supporting CE marking under the relevant EU construction products directive.

Key topics and technical requirements

- Product scope and definitions - terminology for expanded clay LWA, compressibility, compressive strength CS(10), compressive creep (CC), declared levels and classes.

- Sampling and conditioning - procedures for representative sampling and laboratory sample reduction (references to EN 932‑1 / EN 932‑2).

- Test methods and annexes - normative annexes describe specific laboratory tests, including:

- Annex A: static triaxial compression test (shear strength properties)

- Annex B: resistance to cyclic compressive loading

- Annex C: compressive creep determination

- Annex D: factory production control (FPC) requirements

- Annex E: tabulated λ10,dry-values for lightweight fill applications

- Mechanical and physical properties - requirements for loose bulk density, aggregate size, particle density, water content and related characteristics (references to EN 1097 series).

- Designation, conformity and FPC - designation code, initial type testing (ITT), ongoing factory production control and procedures for evaluating conformity (EN 13172 referenced for conformity evaluation).

- Marking and labelling - required product information to support traceability and correct application.

- Limitations - the standard does not set mandatory performance levels for specific applications; required performance is determined by project regulations or complementary standards.

Applications and users

Practical uses:

- Lightweight fill for embankments on roads, railways and other trafficked areas

- Lightweight backfill behind retaining structures and bridge abutments

- Loose‑fill insulation layers in civil engineering contexts (non‑building)

Primary users:

- Manufacturers of expanded clay LWA

- Civil and geotechnical engineers and specifiers

- Contractors and installers for road/rail works

- Testing laboratories and certification bodies

- Regulatory authorities evaluating fitness for purpose

Related standards

- EN 14063‑1 (in‑situ formed expanded clay LWA for buildings)

- EN 13172 (evaluation of conformity for thermal insulation products)

- EN 1097 series, EN 932 series (aggregate tests and sampling)

- EN 13501‑1 (reaction to fire classification)

- EN ISO 10456 / EN ISO 9229 (thermal/hygrothermal terminology)

EN 15732 helps ensure consistent specification, testing and labelling of expanded clay LWA in civil engineering projects - enabling reliable material selection, QA/QC and regulatory compliance.

Frequently Asked Questions

SIST EN 15732:2013 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Light weight fill and thermal insulation products for civil engineering applications (CEA) - Expanded clay lightweight aggregate products (LWA)". This standard covers: This standard describes the product characteristics and includes procedures for testing, marking and labelling. This European Standard specifies the requirements for loose-fill expanded clay lightweight aggregate (expanded clay LWA) products for Civil Engineering Applications excluding the use as thermal insulation in and under buildings which are covered by EN 14063-1. The standard covers the use of expanded clay LWA as lightweight fill and insulation materials in embankments for roads, railways and other trafficked areas and as lightweight backfill for structures. This standard does not specify the required level of a given property to be achieved by a product to demonstrate fitness for purpose in a particular application. The levels required for a given application are to be found in regulations or non-conflicting standards.

This standard describes the product characteristics and includes procedures for testing, marking and labelling. This European Standard specifies the requirements for loose-fill expanded clay lightweight aggregate (expanded clay LWA) products for Civil Engineering Applications excluding the use as thermal insulation in and under buildings which are covered by EN 14063-1. The standard covers the use of expanded clay LWA as lightweight fill and insulation materials in embankments for roads, railways and other trafficked areas and as lightweight backfill for structures. This standard does not specify the required level of a given property to be achieved by a product to demonstrate fitness for purpose in a particular application. The levels required for a given application are to be found in regulations or non-conflicting standards.

SIST EN 15732:2013 is classified under the following ICS (International Classification for Standards) categories: 91.100.60 - Thermal and sound insulating materials. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15732:2013 has the following relationships with other standards: It is inter standard links to oSIST prEN 15732:2019, oSIST prEN 15732:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 15732:2013 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/103. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 15732:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Toplotnoizolacijski in lahki polnilni proizvodi za inženirske objekte (CEA) - Proizvodi iz ekspandiranega glinenega agregatnega proizvoda (LWA)Leichte Schütt- und Wärmedämmstoffe für bautechnische Anwendungen (CEA) - Produkte aus Blähton-Leichtzuschlagstoffen (LWA)Matériaux de remplissage légers et produits isolants thermiques pour les applications du génie civil - Produits à base de granulats légers d'argile expanséeLight weight fill and thermal insulation products for civil engineering applications (CEA) - Expanded clay lightweight aggregate products (LWA)91.100.60Thermal and sound insulating materialsICS:Ta slovenski standard je istoveten z:EN 15732:2012SIST EN 15732:2013en,fr,de01-februar-2013SIST EN 15732:2013SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15732

October 2012 ICS 91.100.60 English Version

Light weight fill and thermal insulation products for civil engineering applications (CEA) - Expanded clay lightweight aggregate products (LWA)

Matériaux de remplissage légers et produits isolants thermiques pour les applications du génie civil - Produits à base de granulats légers d'argile expansée

Leichte Schütt- und Wärmedämmstoffe für bautechnische Anwendungen (CEA) - Produkte aus Blähton-Leichtzuschlagstoffen (LWA) This European Standard was approved by CEN on 9 September 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15732:2012: ESIST EN 15732:2013

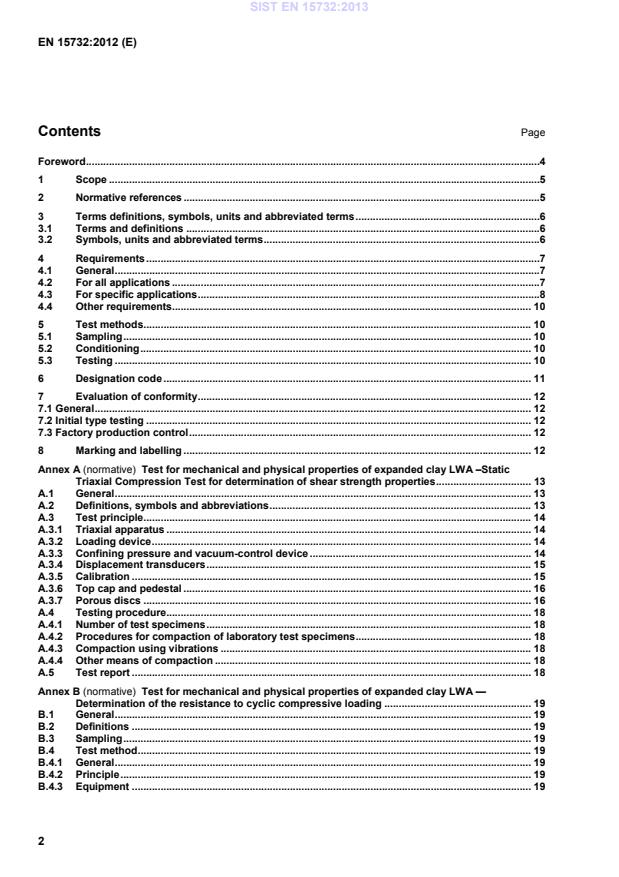

Test for mechanical and physical properties of expanded clay LWA –Static Triaxial Compression Test for determination of shear strength properties . 13A.1General . 13A.2Definitions, symbols and abbreviations . 13A.3Test principle . 14A.3.1Triaxial apparatus . 14A.3.2Loading device . 14A.3.3Confining pressure and vacuum-control device . 14A.3.4Displacement transducers . 15A.3.5Calibration . 15A.3.6Top cap and pedestal . 16A.3.7Porous discs . 16A.4Testing procedure. 18A.4.1Number of test specimens . 18A.4.2Procedures for compaction of laboratory test specimens . 18A.4.3Compaction using vibrations . 18A.4.4Other means of compaction . 18A.5Test report . 18Annex B (normative)

Test for mechanical and physical properties of expanded clay LWA — Determination of the resistance to cyclic compressive loading . 19B.1General . 19B.2Definitions . 19B.3Sampling . 19B.4Test method . 19B.4.1General . 19B.4.2Principle . 19B.4.3Equipment . 19SIST EN 15732:2013

Test for mechanical and physical properties of expanded clay LWA — Determination of the compressive creep . 25C.1General . 25C.2Principles. 25C.3Equipment . 25C.4Preparation of test specimens . 27C.5Testing . 27C.5.1Test procedure . 27C.5.2Calculations . 28C.5.3Expression of results . 28C.6Report . 28Annex D (normative)

Factory production control. 30Annex E (informative)

Tabulated λλλλ10,dry-values of expanded clay LWA in lightweight fill applications . 31Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive . 32 SIST EN 15732:2013

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 15732:2013

This standard does not specify the required level of a given property to be achieved by a product to demonstrate fitness for purpose in a particular application. The levels required for a given application are to be found in regulations or non-conflicting standards. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 932-1, Tests for general properties of aggregates — Part 1: Methods for sampling EN 932-2, Tests for general properties of aggregates — Part 2: Method for reducing laboratory samples EN 933-1, Tests for geometrical properties of aggregates — Part 1: Determination of particle size distribution — Sieving method EN 1097-3, Tests for mechanical and physical properties of aggregates — Part 3: Determination of loose bulk density and voids EN 1097-5, Tests for mechanical and physical properties of aggregates — Part 5: Determination of the water content by drying in a ventilated oven EN 1097-6:2000, Tests for mechanical and physical properties of aggregates — Part 6: Determination of particle density and water absorption EN 13055-1:2002, Lightweight aggregates — Part 1: Lightweight aggregates for concrete, mortar and grout EN 13055-2:2004, Lightweight aggregates — Part 2: Lightweight aggregates for bituminous mixtures and surface treatments and for unbound and bound applications EN 13172:2012, Thermal Insulation products — Evaluation of conformity EN 13286-4, Unbound and hydraulically bound mixtures — Part 4: Test methods for laboratory reference density and water content — Vibrating hammer EN 13286-5, Unbound and hydraulically bound mixtures — Part 5: Test methods for laboratory reference density and water content — Vibrating table EN 13286-7, Unbound and hydraulically bound mixtures — Part 7: Cyclic load triaxial test for unbound mixtures

EN 13501-1, Fire classification of construction products and building elements — Part 1: Classification using data from reaction to fire test EN 13820, Thermal insulating materials for building applications — Determination of organic content SIST EN 15732:2013

For the purposes of this document, the terms and definitions given in EN ISO 9229:2007, and the following apply. 3.1.1 expanded clay lightweight aggregate insulation material or product composed of lightweight granular material having a cellular structure formed by expanding clay minerals by heat 3.1.2 compressibility

deformation at a certain load of a vibrated specimen, given as a load-deformation curve 3.1.3 compressive strength, CS(10) the load where the deformation of a vibrated specimen is 10 % 3.1.4 stiffness modulus is given as the tangent to the load-deformation curve and is related to the level of deformation 3.1.5 compressive creep (CC) the deformation at a constant load in a specified time 3.1.6 compaction mechanical compression (e.g. by vibrator) of the installed insulation layer, expressed as a percentage of the initial untreated layer thickness 3.1.7 level given value, which is the upper or lower limit of a requirement. The level is given by the declared value of the characteristic concerned 3.1.8 class combination of two levels of the same property, between which the performance falls, where the levels are given by the declared value of the characteristic concerned 3.2 Symbols, units and abbreviated terms Symbols and units used in this standard: LD

is the symbol of the declared level for loose bulk density PS

is the symbol of the declared level for aggregate size (mm) SIST EN 15732:2013

is the symbol of the declared level for compressive creep Abbreviated terms used in this standard:

LWA is Lightweight Aggregate

ITT

is Initial Type Test

CEA

is Civil Engineering Applications 4 Requirements 4.1 General Product properties shall be assessed in accordance with Clause 5. To conform with this standard, products shall meet the requirements of 4.2 and the requirements of 4.3 as appropriate.

Sampling of expanded clay LWA shall be performed according to EN 932-1 and splitting of samples according to EN 932-2. One test result on a product property is the average of the measured values on the number of test specimens given in Table 1. 4.2 For all applications 4.2.1 Loose bulk density Loose bulk density shall be declared and determined in accordance with EN 1097-3. The dry loose bulk density shall be declared by the manufacturer in steps of 5 kg/m3 up to a density of 400 kg/m3 and thereafter in steps of 10 kg/m3. It shall be in the range of ± 15 % of the manufacturers declared value with a maximum of

± 100 kg /m3 .The value shall be expressed in kg/m3. NOTE The value of the density used for design purposes will be influenced by compaction and water content. 4.2.2 Particle size distribution 4.2.2.1 General Particle size distribution shall be measured in accordance with EN 933-1, without washing, and shall be declared in % by mass.

4.2.2.2

Aggregate size The pair of sieve sizes between which the main proportion of the particles lies shall designate the size and any undersize or oversize shall comply with 4.2.2.3 and 4.2.2.4. The sieve sizes in mm shall be selected from the specifications in EN 13055-2. NOTE

Normally the aggregate size for expanded clay LWA products will be in the range 0 mm - 32 mm.

4.2.2.3 Undersize The content of undersize material shall not exceed 15 % by mass. SIST EN 15732:2013

NOTE The product is a clay mineral product thermo-processed to form a stable structure. 4.2.4.2 Durability of reaction to fire against ageing/degradation The reaction to fire performance of expanded clay LWA does not change with time.

4.2.4.3 Durability of thermal resistance against ageing/degradation The thermal conductivity (4.3.2) of the product does not change with time.

4.2.4.4 Durability of compressive strength against ageing/degradation The compressive strength of expanded clay does not change with time.

4.2.4.5 Durability of resistance to dynamic loads against ageing/degradation The resistance to dynamic loads does not change with time.

4.2.4.6 Durability against chemicals and biological attack

The expanded clay LWA is a ceramic material and is durable against chemicals and biological attack.

4.3 For specific applications 4.3.1 General If there is no requirement for a property, described in 4.3.2 – 4.3.16, for a product in use, then the property need not to be determined and declared by the manufacturer. 4.3.2 Thermal resistance and thermal conductivity The thermal conductivity and thermal resistance shall be determined in accordance with EN 14063-1.

NOTE For light weight fill applications without specific thermal insulation requirements tabulated thermal values in accordance with Annex E may be used. 4.3.3 Specific heat capacity Specific heat capacity shall be determined in accordance with EN ISO 10456.

NOTE In accordance with EN ISO 10456:2007, Table 4, a typical value for specific heat capacity of 1000J/(kg K) can be used. SIST EN 15732:2013

NOTE EN 1097-6:2000, Annex C is only applicable to aggregate particles larger than 4 mm. 4.3.5 Water content The water content shall be determined in accordance with EN 1097-5.

4.3.6 Water absorption The water absorption after an immersion time of 28 days shall be determined in accordance with

EN 1097-6:2000, Annex C.

NOTE EN 1097-6:2000, Annex C is only applicable to aggregate particles larger than 4 mm. 4.3.7 Compressibility and confined compressive strength The compressibility, in terms of load-deformation curve, stiffness modulus, and the compressive strength CS(10) shall be determined in accordance with EN 13055-2:2004, Annex A. The stiffness modulus shall be given as the tangent to the stress-strain relationship curve and related to the level of deformation.

NOTE The compressive strength at 10 % strain is not a design value, it is used as a reference value for material characterisation only. For characterisation of material properties the stiffness modulus and the load at a strain level at maximum 2 % is more relevant. 4.3.8 Compressive creep The compressive creep, in terms of deformation in % of the height of a vibrated sample, shall be determined in accordance with Annex C. The load shall be applied in load steps corresponding to stress levels of

50 N/mm2 from 50 N/mm2 and upwards.

4.3.9 Shear strength – static loading The shear strength properties shall be determined in accordance with Annex A.

4.3.10 Cyclic compression The cyclic compression shall be determined in accordance with Annex B. The cyclic load shall be applied in load steps corresponding to stress levels of 50 N/mm2 from 50 N/mm2 and upwards. The results shall be given as deformation in % related to the stress level. 4.3.11 Shear strength – cyclic loading The resilient modulus (elastic stiffness) and resistance to permanent deformations shall be determined by cyclic triaxial tests. Cyclic triaxial testing shall be performed in accordance with EN 13286-7. The multistage loading procedure (low stress level) shall be followed.

NOTE The development of permanent deformations is highly dependent on the stress history. This should be taken into consideration when the results from the test are used. 4.3.12 Water permeability The property is not measured because the open structure of the final product itself offers no substantial resistance to the free movement of water. NOTE Based on experience; the typical graded expanded clay LWA has a permeability greater than 10-3 m/s. SIST EN 15732:2013

NOTE According to EN ISO 10456, a typical water vapour resistance factor is 2. 4.3.14 Chemical content The chemical content of the expanded clay LWA shall be determined in accordance with EN 13055-2. 4.3.15 Freezing and thawing resistance The freezing and thawing resistance of expanded clay LWA shall be determined in accordance with EN 13055-2:2004, Annex B. 4.3.16 Release of dangerous substances Expanded Clay LWA shall not release any dangerous substances in excess of the maximum permitted levels specified in a relevant European Standard for the material or permitted in the national regulations of the member state of destination. 4.4 Other requirements 4.4.1 Crushing resistance The crushing resistance shall be measured in accordance with EN 13055-1:2002, Annex A. NOTE The crushing resistance is entirely to be used for quality documentation and factory production control. There is no correlation between the crushing resistance and relevant properties for the end use conditions. 5 Test methods 5.1 Sampling Sampling shall be carried out according to the procedures given in EN 932-1. 5.2 Conditioning If not otherwise prescribed in the test method, the test specimens shall be dried to constant mass according to EN 1097-5 (at 110 ± 5 ºC). 5.3 Testing 5.3.1 General

Table 1 gives the minimum number of measurements required to get one test result and any specific conditions, which are necessary. SIST EN 15732:2013

No. Title Test method Minimum number of test specimens to get one test result Specific conditions 4.2.1 Loose bulk density EN 1097-3 3

4.2.2 Particle size distribution EN 933-1 1

4.2.3 Reaction to fire (organic content) EN 13820 See Annex ZA, reaction to fire class A1 without testing 4.3.2 Thermal conductivity In accordance with EN 14063-1 4.3.4 Particle density EN 1097-6:2000, Annex C 2

4.3.5 Water content EN 1097-5 3 Not applicable for ITT 4.3.6 Water absorption EN 1097-6:2000, Annex C 2

4.3.7 Compressibility and confined compressive strength Compressibility and confined compressive strength (EN13055-2:2004, Annex A) 3

4.3.8 Compressive creep Annex C 3

0 Shear strength –static loading

Annex A 3

0 Cyclic compression Annex B 2

0 Shear strength –cyclic loading EN 13286-7

4.3.14 Chemical content EN 13055-2 1

4.3.15 Freezing and thawing resistance EN 13055-2:2004, Annex B 3

4.3.16 Release of dangerous substances Test method not yet available -

4.4.1 Crushing resistance EN 13055-1:2002, Annex A 3

6 Designation code A designation code for the product shall be given by the manufacturer. The following shall be included except when there is no requirement for a property described in 4.3:

Abbreviated term

– Expanded clay LWA

Exp. clay LWA

– This EN standard number EN 15732

– Loose bulk density LD “i”

– Particle size

PS “i”

7 Evaluation of conformity 7.1 General The compliance of the expanded clay LWA with the requirements of this standard and with the stated values (including classes) shall be demonstrated by: initial type testing, factory production control by the manufacturer, including product assessment

The evaluation of conformity shall be carried out in accordance with EN 13172. 7.2 Initial type testing ITT shall be carried out in accordance with EN 13172 for all characteristics declared. 7.3 Factory production control FPC shall be made for the characteristics listed in Annex D.

If a manufacturer decides to group his products it shall be done in accordance with EN 13172. The minimum frequencies of tests in the factory production control shall be in accordance with Table D.1. When indirect testing is used, the correlation to direct testing shall be established in accordance with

EN 13172.

The manufacturer or the authorized representative shall make available, in response to a request, a certificate or declaration of conformity as appropriate.

8 Marking and labelling Products conforming with this standard shall be clearly marked on the label on the packaging or on an accompanying document, with the following information: – product name or other identifying characteristic; – name or identifying mark and address of the manufacturer or his authorised representative; – date of delivery, manufacturing plant and/or traceability code; – reaction to fire class; – designation code as given in Clause 6; – quantity of material, in m3. NOTE For CE marking and labelling see ZA.3.

Test for mechanical and physical properties of expanded clay LWA –Static Triaxial Compression Test for determination of shear strength properties A.1 General This test description specifies a triaxial test method for determination of strength and deformation properties of expanded clay LWA.In a drained triaxial test an axial deviator stress and a static confining cell pressure are imposed on a cylindrical specimen. The test procedure shall simulate relevant conditions and stress states for these materials.

This method is applicable to specimens prepared by compaction in the laboratory, where various compaction methods may be used to obtain the wanted porosity/density. This method applies to materials, in which all particles have a maximum size of 1/5 of the specimen diameter.

The test results are used to interpret the strength properties (friction angle φ and cohesion c) of the expanded clay LWA aggregate. The method could be used to investigate a variety of test conditions, such as different moisture and stress states. The properties determined with this procedure can be used with classical procedures of limit state soil mechanic to establish the stability or bearing capacity of the structure. NOTE A European Standard on triaxial testing is currently under preparation based on CEN ISO/TS 17892-9. A.2 Definitions, symbols and abbreviations

For the purposes of this test description, the following definitions and symbols in Table A.1 apply.

Table A.1 — Symbols and definitions Symbol DefinitionExplanation and equations Unitσ Normal stress

N/mm2 σ£ and σ£‘ Major total and effective stress, respectively

N/mm2 σ3 = σ2 and σ3‘=σ2‘ Minor total and effective radial stress respectively i.e. the applied confining pressure in the triaxial chamber or the vacuum inside the specimen when no triaxial chamber is used

N/mm2 σd Deviatoric stress i.e. difference between total major and minor stress N/mm2 P Mean normal stress p = (σ1 + 2 * σ3)/3 N/mm2 ε Engineering strain

∆h / H0, H0 = initial total height or the gage length % ε1p Permanent axial strain

% ε3p = ε2p Permanent radial strain

% dε1 Change in linear strain

% Dt Change in time

s φ Friction angle

c Apparent cohesion

kN/m2 ρd Dry density

kg/m3

The drained triaxial test is used to determine the stress-strain relationship and effective stress path of expanded clay LWA prepared in the form of cylindrical specimen under isotropic or anisotropic stress in drained conditions. The specimen has to be tested at known density and moisture condition. The axial load is increased monotonically until failure takes place in the specimen. If no clear failure is observed the test is interrupted when 10 % axial strain level is reached.

This method applies in principle to all unbound mixtures in which the specimen diameter is at least five times maximum particle size and height from 1,85 to 2,25 times the diameter.

Apparatus

A.3.1 Triaxial apparatus The triaxial apparatus capable for testing of expanded clay LWA are similar to most standard triaxial apparatus, except that they are somewhat larger to facilitate larger samples. An example of a triaxial test apparatus and the corresponding terminology is given in Figure A1. Figure A2 shows an apparatus using internal partial vacuum to provide the confining pressure. Air, water or silicon oil may be used as the chamber fluid. Water is suitable only if the electrical cables and connections of the instrumentation are fully sealed.

The chamber pressure may alternatively be replaced using a partial vacuum applied inside the specimen.

NOTE For vacuum systems the practical limit for confining pressure is about 80 N/mm2 dependent on the equipment. A.3.2 Loading device

The external loading device may be any device capable of providing monotonic increasing loads up to the failure load of the specimen. These devices range from simple mechanical motor driven devices to closed-loop electro-hydraulic or electro-pneumatic systems. The loading is done under strain control at constant strain rate. The axial strain rate is defined as the ratio between the axial strain and the corresponding time increment (dε1/dt). When the press is set to advance at a certain strain rate, the actual rate should not deviate more than ±10 % from the required value. The movement of the press shall be smooth without fluctuations and vibrations. The load is measured with an electronic load cell or similar between the specimen top cap and the loading piston. The device for measurement of the piston load shall be sufficiently accurate to permit the load to be known within ± 3 % or 1 N.

Internal load cells shall be insensitive to horizontal forces, eccentricities in axial load and uninfluenced by the magnitude of the total cell pressure.

For specimen sizes up to 150 mm in diameter, the loading device should be capable of providing axial loads up to 20 kN -25 kN. For 300 mm specimens, the load needed may reach 100 kN. A.3.3 Confining pressure and vacuum-control device

The confining pressure regulator shall be capable of applying and controlling cell pressures constant within ± 2 %. The vacuum-control device shall be capable of applying and controlling partial vacuums to within

± 2 %. Pressures below 25 N/mm2 shall be kept constant within an accuracy of ± 0,5 N/mm2. SIST EN 15732:2013

A.3.4.1 General Axial deformations are measured with one to three displacement transducers

If the radial deformation is measured two to three displacement transducers should be used (optional). The axial displacement of the specimen is usually determined by the distance the piston travels during the test. This distance shall be measured with accuracy better than ± 0,02 % of the initial specimen height. Possible false displacement due to changes in cell pressure shall be accounted for.

A.3.4.2 Lateral transducers (optional) The lateral displacement transducers measure either the distance between the specimen surface to the ring or the opening of a hinged ring during the loading. This distance shall be measured with accuracy better than ± 0,02 % of the initial specimen diameter. The fixing method must allow relatively large deformations to occur during compression both in axial and radial direction without leading to errors in the measured deformation.

Figure A.1 — Triaxial apparatus with possibility of both constant and variable confining pressure A.3.5 Calibration

In order to minimise errors in the stress and strain, the system should be calibrated periodically.

A new calibration may be carried out every third month or after 100 tests, depending on what comes first. In addition, the transducers should be checked if they are loaded up to or beyond their maximum capacity.

Key

1 load frame

radial displacement transducer (LVDT)

2 pneumatic jack

drainage tubes 3 pressure sensor 9

axial displacement transducer (LVDT)

4 triaxial cell

10 air (max. 10 bar) 5 load transducer 11 data acquisition and computer unit

6 rubber membrane

12 specimen

The specimen top cap and pedestal shall be designed to provide drainage from both ends of the specimen. They shall be constructed of a rigid, non-corrosive, impermeable material, and each shall, except for the drainage provision, have a circular plane surface in contact with the porous discs of circular cross section.

The diameter of the top cap and pedestal shall be equal to or larger than the initial diameter of the specimen. The specimen base shall be connected to the triaxial compression chamber or load frame (if no chamber is used) to prevent lateral motion or tilting. The top cap and the pedestal, and the connection between the top cap and the piston, shall be designed so that their deformations are negligible compared to the deformations of the soil specimen.

The top cap shall be designed so that the eccentricity of the loading, relative to the vertical axis of the specimen, does not exceed 1 % of the diameter of the specimen, D. The cylindrical surfaces of the pedestal and top cap, that form the contact and sealing surfaces for the membrane, shall be smooth and free of scratches.

A.3.7 Porous discs

A.3.7.1 General The specimen shall be separated from the top cap and pedestal by rigid porous discs, having a diameter equal to or slightly smaller than the diameter of the specimen. The discs shall have plane and smooth surfaces, and their compressibility shall be negligible compared to the compressibility of the specimen. It is also possible to use smaller porous discs integrated in the top cap and pedestal to form an even surface. The discs shall be regularly checked for clogging by passing pressurised air or water through them. If the discs are clogged, new discs should be used to ensure effective drainage of the specimen.

A.3.7.2 Semi-permeable filters or filter papers (optional) These filters/filter papers are used to perform constant moisture tests in which the moisture/suction regime is controlled. Water - proof and air permeable filters (paper) are placed between the specimen and the top cap and pedestal. The diameter of the filters shall be equal to that of the specimen and the mass by unit area should be between 50 g/m2 and 80 g/m2. If semi-permeable filters are not used they must be replaced with filter paper discs. A.3.7.3 Rubber membrane

The specimen shall be confined by a rubber/latex membrane which shall prevent the cell fluid from penetrating into the specimen.

To offer minimum restraint to the specimen, the unstretched membrane diameter shall be the same or slightly smaller than the diameter of the specimen.

It is recommended to use membranes with the following properties: The membrane thickness shall not exceed 1 % of the diameter of the specimen. The unstretched diameter should be between 95 % and 100 % of the specimen diameter. The elastic modulus (in tension) should not exceed 1600 N/mm2.

The membrane shall be sealed to the specimen cap and base with suitable sized rubber O-rings or by other means that will provide a positive seal.

Each membrane should be checked for leakage before being used. SIST EN 15732:2013

Devices used to determine the height and diameter of the specimen shall measure the respective dimensions to an accuracy of 0,1 % of the total dimensions, and shall be designed so that their use will not disturb the specimen.

Key 1

hydraulic actuator

valve

axial displacement transducer (top platten)

vacuum supply

specimen, 300 mm x 600 mm

waveform generator

axial displacement transducer

control system

radial displacement transducer of wheels 11 load transducer

data acquisition system

Figure A.2 — Example of triaxial test apparatus using partial vacuum as confining pressure

A.3.7.5 Balance

The device used for weighing the specimen shall determine the mass of the specimen to an accuracy of 0.1 % or better.

A.3.7.6 Testing environment

The consolidation and shearing parts of the test shall be performed in an environment in which the temperature fluctuations are less than ±4 °C and where there is no direct sunlight.

A.4.1 Number of test specimens

Required number of specimen for one test is given in Table 1. A.4.2 Procedures for compaction of laboratory test specimens

The water content used in the test should be equal to the average service water content in the natural condition. In cases where the material is immersed all or part of the time the test should be carried out with moist specimens After mixing the material with water, the sample shall be placed in a plastic bag and stored in an environment with at least 85 % relative humidity for at least 24 h. A complete sealing of the sample may be obtained by wrapping the sample using two or more impermeable plastic bags.

NOTE It has been shown that different methods of reconstituting specimens to the same density may result in significantly different deformation properties. Hence the preparation method is important. A.4.3 Compaction using vibrations

Compact the specimen at required moisture content close to the optimum moisture content using a vibration process, such as vibrating table in EN 13286-5 or vibrating hammer in EN 13286-4.

A.4.4 Other means of compaction

A.4.4.1 General The specimen can also be compacted with a vibration hammer or manually by stamping the specimen in layers into the mould. These methods are better suited for compaction of specimens reaching very high densities, in which the grains tend to crush and the material gradation changes.

A.4.4.2 Determination of strength properties

The determination of shear strength parameters shall be based on a series of three static compression tests with different cell pressure levels. The following cell pressure levels shall be used in the test series: 20, 40 and 80 N/mm2.

During loading, readings shall be taken on all measuring devices at intervals so that the stress - strain curves and the stress paths can be obtained from the readings. These readings will usually include axial load, confining pressure and axial/radial deformations. The loading stage shall be carried out in strain control at a constant rate of strain. The strain rate shall be adjusted to a correct strain rate of dε1/dt = 1 %/min. Unless otherwise specified, the test may be stopped when the axial strain either reaches 10 % or exceeds, by 5 %, the strain at peak deviatoric stress. A.5 Test report

The results from triaxial testing shall be pr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...