SIST EN 415-8:2008

(Main)Safety of packaging machines - Part 8: Strapping machines

Safety of packaging machines - Part 8: Strapping machines

This European Standard applies to the following groups of machines:

- powered hand strapping tools;

- semi-automatic strapping machines;

- automatic strapping machines;

- horizontal pallet strapping machines;

- vertical pallet strapping machines.

The individual machines are described in 3.3.

This European Standard deals with safety requirements for machine design, construction, installation, commissioning, operation, adjustment, maintenance and cleaning of strapping machines.

The extent to which hazards, hazardous situations and events are covered, are indicated in Clause 4.

Exclusions

This European Standard is not applicable to the following machines:

- strapping tools that are powered exclusively by manual effort;

- strapping machines that were manufactured before the date of publication of this document by CEN.

This European Standard does not consider the following hazards:

- the use of strapping machines in potentially explosive atmospheres;

- the health, safety or hygiene hazards associated with the products that may be handled by the machines, but does include general advice on this subject;

- hazards that can be associated with electromagnetic emissions from strapping machines;

- hazards that can be associated with decommissioning strapping machines.

Sicherheit von Verkpackungsmaschinen - Teil 8: Umreifungs-Verschließmaschinen

Diese Europäische Norm behandelt folgende Maschinengruppen:

Angetriebene Handumreifungsgeräte;

Halbautomatische Umreifungsmaschinen;

Automatische Umreifungsmaschinen;

Horizontale Palettenumreifungsmaschinen;

Vertikale Palettenumreifungsmaschinen.

Die einzelnen Maschinenarten werden in Abschnitt 3.3 dieser Norm beschrieben.

Diese Europäische Norm beschreibt Sicherheitsanforderungen für Gestaltung, Bau, Installation, Inbetrieb¬nahme, Betrieb, Einstellung, Instandhaltung und Reinigung von Umreifungsmaschinen.

Der Umfang der behandelten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse sind in Abschnitt 4 angegeben.

Ausnahmen

Diese Norm ist nicht anwendbar auf folgende Maschinen:

Umreifungsgeräte, deren ausschließliche Energiequelle die menschliche Kraft ist;

Umreifungsmaschinen, die vor der Veröffentlichung dieses Dokuments durch CEN hergestellt wurden.

Diese Norm berücksichtigt folgende Gefährdungen nicht:

Den Einsatz von Umreifungsmaschinen in explosionsgefährdeten Bereichen;

Gefährdungen für Gesundheit, Sicherheit oder Hygiene, die sich durch die Produkte ergeben, die von den Maschinen verarbeitet werden. Jedoch werden allgemeine Hinweise zu diesem Thema gegeben;

Gefährdungen durch elektromagnetische Emissionen von Umreifungsmaschinen;

Gefährdungen, die sich bei der Außerbetriebnahme von Umreifungsmaschinen ergeben können.

Sécurité des machines d'emballage - Partie 8: Cercleuses

Diese Europäische Norm behandelt folgende Maschinengruppen:

Angetriebene Handumreifungsgeräte;

Halbautomatische Umreifungsmaschinen;

Automatische Umreifungsmaschinen;

Horizontale Palettenumreifungsmaschinen;

Vertikale Palettenumreifungsmaschinen.

Die einzelnen Maschinenarten werden in Abschnitt 3.3 dieser Norm beschrieben.

Diese Europäische Norm beschreibt Sicherheitsanforderungen für Gestaltung, Bau, Installation, Inbetrieb¬nahme, Betrieb, Einstellung, Instandhaltung und Reinigung von Umreifungsmaschinen.

Der Umfang der behandelten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse sind in Abschnitt 4 angegeben.

Ausnahmen

Diese Norm ist nicht anwendbar auf folgende Maschinen:

Umreifungsgeräte, deren ausschließliche Energiequelle die menschliche Kraft ist;

Umreifungsmaschinen, die vor der Veröffentlichung dieses Dokuments durch CEN hergestellt wurden.

Diese Norm berücksichtigt folgende Gefährdungen nicht:

Den Einsatz von Umreifungsmaschinen in explosionsgefährdeten Bereichen;

Gefährdungen für Gesundheit, Sicherheit oder Hygiene, die sich durch die Produkte ergeben, die von den Maschinen verarbeitet werden. Jedoch werden allgemeine Hinweise zu diesem Thema gege¬ben;

Gefährdungen durch elektromagnetische Emissionen von Umreifungsmaschinen;

Gefährdungen, die sich bei der Außerbetriebnahme von Umreifungsmaschinen ergeben können.

Varnost pakirnih strojev - 8. del: Stroji za pakiranje s trakovi

General Information

- Status

- Withdrawn

- Publication Date

- 04-Mar-2008

- Withdrawal Date

- 07-Apr-2025

- Technical Committee

- DTN - Lift and transport appliances

- Current Stage

- 9900 - Withdrawal (Adopted Project)

- Start Date

- 08-Apr-2025

- Due Date

- 01-May-2025

- Completion Date

- 08-Apr-2025

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 21-Feb-2018

Frequently Asked Questions

SIST EN 415-8:2008 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Safety of packaging machines - Part 8: Strapping machines". This standard covers: This European Standard applies to the following groups of machines: - powered hand strapping tools; - semi-automatic strapping machines; - automatic strapping machines; - horizontal pallet strapping machines; - vertical pallet strapping machines. The individual machines are described in 3.3. This European Standard deals with safety requirements for machine design, construction, installation, commissioning, operation, adjustment, maintenance and cleaning of strapping machines. The extent to which hazards, hazardous situations and events are covered, are indicated in Clause 4. Exclusions This European Standard is not applicable to the following machines: - strapping tools that are powered exclusively by manual effort; - strapping machines that were manufactured before the date of publication of this document by CEN. This European Standard does not consider the following hazards: - the use of strapping machines in potentially explosive atmospheres; - the health, safety or hygiene hazards associated with the products that may be handled by the machines, but does include general advice on this subject; - hazards that can be associated with electromagnetic emissions from strapping machines; - hazards that can be associated with decommissioning strapping machines.

This European Standard applies to the following groups of machines: - powered hand strapping tools; - semi-automatic strapping machines; - automatic strapping machines; - horizontal pallet strapping machines; - vertical pallet strapping machines. The individual machines are described in 3.3. This European Standard deals with safety requirements for machine design, construction, installation, commissioning, operation, adjustment, maintenance and cleaning of strapping machines. The extent to which hazards, hazardous situations and events are covered, are indicated in Clause 4. Exclusions This European Standard is not applicable to the following machines: - strapping tools that are powered exclusively by manual effort; - strapping machines that were manufactured before the date of publication of this document by CEN. This European Standard does not consider the following hazards: - the use of strapping machines in potentially explosive atmospheres; - the health, safety or hygiene hazards associated with the products that may be handled by the machines, but does include general advice on this subject; - hazards that can be associated with electromagnetic emissions from strapping machines; - hazards that can be associated with decommissioning strapping machines.

SIST EN 415-8:2008 is classified under the following ICS (International Classification for Standards) categories: 55.200 - Packaging machinery. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 415-8:2008 has the following relationships with other standards: It is inter standard links to SIST EN 415-8:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 415-8:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC, EUR-PUB; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 415-8:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Safety of packaging machines - Part 8: Strapping machinesVarnost pakirnih strojev - 8. del: Stroji za pakiranje s trakoviSécurité des machines d'emballage - Partie 8: CercleusesSicherheit von Verkpackungsmaschinen - Teil 8: Umreifungs-VerschließmaschinenTa slovenski standard je istoveten z:EN 415-8:2008SIST EN 415-8:2008en,fr55.200ICS:SLOVENSKI

STANDARDSIST EN 415-8:200801-maj-2008

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 415-8January 2008ICS 55.200 English VersionSafety of packaging machines - Part 8: Strapping machinesSécurité des machines d'emballage - Partie 8: CercleusesSicherheit von Verpackungsmaschinen - Teil 8:UmreifungsmaschinenThis European Standard was approved by CEN on 14 December 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 415-8:2008: E

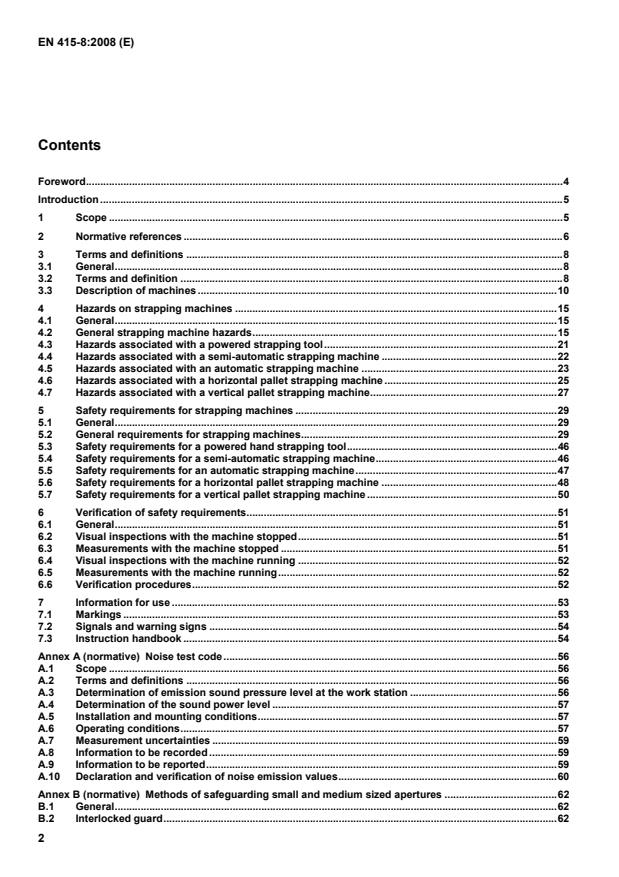

Noise test code.56 A.1 Scope.56 A.2 Terms and definitions.56 A.3 Determination of emission sound pressure level at the work station.56 A.4 Determination of the sound power level.57 A.5 Installation and mounting conditions.57 A.6 Operating conditions.57 A.7 Measurement uncertainties.59 A.8 Information to be recorded.59 A.9 Information to be reported.59 A.10 Declaration and verification of noise emission values.60 Annex B (normative)

Methods of safeguarding small and medium sized apertures.62 B.1 General.62 B.2 Interlocked guard.62

Methods of safeguarding large apertures.67 C.1 General.67 C.2 ESPE in a vertical plane.67 C.3 Dynamic cell positioning of ESPE.68 C.4 Positioning of ESPE.69 Annex D (normative)

ESPE Muting.71 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC.73 Annex ZB (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC.74 Bibliography.75

(IEC 60204-1:2005, modified) EN 60529:1991, Degrees of protection provided by enclosures (IP code) (IEC 60529:1989) EN 61310-1:1995, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for visual, auditory and tactile signals (ISO 61310-1:1995) EN 61310-3:1999, Safety of machinery — Indication marking and actuation — Part 3: Requirements for the location and operation of actuators (ISO 61310-3:1999) EN 61496-1:2004, Safety of machinery — Electro-sensitive protective equipment — Part 1: General requirements and tests (ISO 61496-1:2004, modified) CLC/TS 61496-3:2003, Safety of machinery — Electro-sensitive protective equipment — Part 3: Particular requirements for Active Opto-electronic Protective Devices responsive to Diffuse Reflection (AOPDDR) (IEC 61496-3:2001) EN 61508-1:2001, Functional safety of electrical/electronic/programmable electronic safety-related systems —

Part 1: General requirements (IEC 61508-1:1998 + Corrigendum 1999) EN 61508-2:2001, Functional safety of electrical/electronic/programmable electronic safety-related systems —

Part 2: Requirements for electrical/electronic/programmable electronic safety-related systems (IEC 61508-2:2000) EN 61508-3:2001, Functional safety of electrical/electronic/programmable electronic safety-related systems —

Part 3: Software requirements (IEC 61508-3:1998 + Corrigendum 1999) EN 62061:2005 Safety of machinery — Functional safety of safety-related electrical, electronic and programmable electronic control systems (IEC 62061:2005) ISO 7000:1989, Graphical symbols for use on equipment — Index and synopsis IEC 60417:2002, Graphical symbols for use on equipment 3 Terms and definitions 3.1 General For the purposes of this document, the terms and definitions given in Clause 3 of EN ISO 12100-1:2003,

EN 415-1:2000 and the following apply. 3.2 Terms and definition 3.2.1 bayonet; lance; sword section of strap chute that moves under power, typically to feed strap through a pallet 3.2.2 change parts machine parts designed to handle a specific product, packaging material or pack size, that need to be changed when the machine is set up to handle a different product, packaging material or pack size

Figure 1 — Powered hand strapping tool

3.3.3 semi-automatic strapping machine strapping machine that tensions and seals a strap around a product or a group of products, once an operator has placed the strap around the product and inserted the strap back into the machine manually. The strap will typically be made from plastic or paper. The characteristic features are: strap dispenser; strap feeding mechanism; strap gripping device; strap retraction mechanism; strap tension mechanism; strap cutting device; strap sealing mechanism; compression device (optional)

Figure 2 — Semi-automatic strapping machine

3.3.4 automatic strapping machine strapping machine that applies a strap automatically around a product or a group of products. The product may be positioned under the arch either manually or automatically. The strap will typically be made from plastic, metal or paper. The characteristic features are: strap dispenser; strap feeding mechanism; strap arch or strap chute; strap accumulator; strap gripping device; strap retraction mechanism; strap tension mechanism; strap cutting device; strap sealing mechanism; compression device (optional); product feeding, discharging or positioning devices (optional); turntable to rotate the product (optional)

Figure 3 — Automatic strapping machine

3.3.5 horizontal pallet strapping machine strapping machine that applies one or more straps horizontally around a pallet load. Machines of this type will typically be fully automatic. The strap will typically be made from plastic or metal. The characteristic features are: strap dispenser; strapping head; strap accumulator; mechanism to move the strapping head towards and away from the product; horizontal strap arch or strap chute; mechanism to raise and lower the strap arch or strap chute; product positioning device; compression device (optional); product conveying mechanism (optional)

Figure 4 — Horizontal strapping machine

3.3.6 vertical pallet strapping machine strapping machine that applies one or more straps vertically around a pallet load. The strap will typically be made from plastic or metal. Machines of this type will typically be fully automatic. The strapping head may be located above or to the side of the product being strapped. The characteristic features are: strap dispenser; strapping head; strap accumulator; mechanism to move the strapping head and bayonet towards and away from the product; vertical strap arch or strap chute; mechanism to move the strap arch or strap chute together with the strapping head from side to side (optional); compression device (optional); product conveying mechanism (optional); turntable to rotate the product (optional); product positioning devices (optional)

Figure 5 — Vertical strapping machine

Hazards on strapping machines 4.1 General This clause lists all the significant hazards, hazardous situations and events that can be found on typical strapping machines. Before using this European Standard, the manufacturer shall establish that the hazards on his machine correspond to the hazards described in this European Standard. If the manufacturer identifies hazards that are not listed in this clause, he shall assess these hazards by using the principles detailed in EN 1050. The hazards on a specific strapping machine can vary depending on its working principle; the type, size and mass of the product; the packaging material; auxiliary equipment attached to the machine and the environment in which the machine is used. The hazards that occur on most strapping machines are listed in 4.2 and the hazards that are specific to particular types of strapping machine are listed in 4.3 to 4.7. 4.2 General strapping machine hazards 4.2.1 General The following hazards occur on most strapping machines. 4.2.2 Mechanical hazards 4.2.2.1 Moving parts Strapping machines incorporate moving parts which present a variety of mechanical hazards including crushing, shearing, cutting, entanglement, friction and drawing-in. Stored energy can cause some of these hazards to persist after the power supply has been cut off.

Parts of the machine e.g. sealing mechanisms and drive motors, which have high surface temperatures, can cause burning hazards. See EN ISO 13732-1 for details of the burn thresholds for different materials and contact times. The burning hazard will usually continue to exist for a period of time after power has been disconnected. 4.2.5 Noise Noise generated by strapping machines can result in: a) permanent hearing loss; b) tinnitus; c) tiredness, stress etc.; d) other effects such as loss of balance, loss of awareness; e) interference with speech communication; f) inability to hear acoustic warning signals. 4.2.6 Hazards from products and materials 4.2.6.1 Hazards generated by products Strapping machines are used to pack a wide range of products, some of which can be potentially hazardous to persons operating or in the vicinity of the strapping machine during normal operation or if a package containing a hazardous substance is damaged in the strapping machine. Hazards generated by the product can include: a) ingestion of harmful substances e.g. insecticides, aggressive or harmful chemicals, pharmaceuticals; b) fire or explosion e.g. flammable liquids, explosives, dusty products; c) biological hazards e.g. vaccines; d) impact by ejected packaging materials or products e.g. broken glass. 4.2.6.2 Strapping materials Strap will typically be made from plastic, metal or paper. These materials present the following hazards: a) burning hazards from hot plastic or plastic strap; b) inhalation of harmful substances from heated or burning plastic e.g. polyester strap (PET); c) cuts from strap edges or ends; d) cuts from metal clips. 4.2.7 Hazards due to neglecting ergonomic principles Hazards to safety and health can occur when people are carrying out the following activities on strapping machines:

Key A dispenser flanges B dispenser flange nut C dispenser brake arm D strap wheels or pulleys Figure 6 — Typical components on a strap dispenser

4.2.11.2 Strap feeding mechanism The strap feeding mechanism, which on most machines will be contained within the strapping head, pulls strap from the accumulator if fitted, or directly from the strap dispenser. The strap feeding mechanism presents crushing, drawing-in and entanglement hazards.

Key A sealing and crimping jaws B strap cutter C tension wheel / assembly D handle E suspension bow Figure 7 — Typical components on a powered strapping tool

Powered strapping tools will incorporate most of the mechanisms described in 4.2.11.1 to 4.2.11.8 however some of these mechanisms will be powered by hand or require manual intervention. Where mechanisms are powered, there is the potential for crushing, shearing, drawing-in, entanglement, cutting and burning hazards. In addition there is the risk of transmitting vibration to the operator’s hand and an impact hazard if the operator drops or loses control of the tool. Muscular skeletal injuries can occur if ergonomic design principles are neglected e.g. if the mass of the tool is too great or the work requires repetitive movements or awkward postures.

Key A strap dispenser B strap feeding mechanism C product support table D strapping head

Figure 8 — Typical components on a semi-automatic strapping machine

4.4.2 Strap dispenser On semi-automatic strapping machines the strap dispenser may be positioned underneath or to one side of the machine, In addition to the hazards described in 4.2.11.1. Back strain or other muscular skeletal problems can occur if the manufacturer does not take into account ergonomic design principles when positioning the coil holder.

Key A strap dispenser B product support table C strap arch or chute Figure 9 — Typical components on an automatic strapping machine 4.5.2 Strap dispenser On automatic strapping machines the strap dispenser may be positioned underneath or to one side of the machine, In addition to the hazards

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...