SIST EN 17476:2021+A1:2022

(Main)Specifications for dedicated liquefied petroleum gas appliances - LPG vapour pressure appliances incorporating a horizontal cartridge in the chassis

Specifications for dedicated liquefied petroleum gas appliances - LPG vapour pressure appliances incorporating a horizontal cartridge in the chassis

This document specifies the construction characteristics, performances and marking related to safety and the rational use of energy of portable, flat gas appliances directly supplied at the LPG vapour pressure, incorporating a gas cartridge complying with EN 417:2012, inserted horizontally in the chassis.

NOTE 1 These appliances are referred to in the body of the text as “appliances”.

This document covers appliances for outdoor or in well ventilated areas uses only.

This document does not cover appliances supplied by an external gas source.

For example, the following types of appliances are covered:

a) cooking appliances (stoves, barbecues);

b) heating appliances.

This document specifies the requirements applicable to these appliances or their functional sections whether or not the latter are independent or incorporated into an assembly.

Appliances covered by this document are not connected to a flue for the discharge of products of combustion and are not connected to the mains electricity supply.

This document covers neither appliances supplied with LPG in the liquid phase nor appliance with fixed integral container which could be refilled by the user.

This document does not cover appliances of direct pressure propane category.

Requirements for rational use of energy have been considered for stove burners.

NOTE 2 However, such requirements have not been considered for the other types of appliances because:

- for barbecues, this type of cooking varies according to the type of food and region where the appliance is used;

- for heating appliances, all the heat produced is discharged into the environment.

Festlegungen für Flüssiggasgeräte - Mit Dampfdruck betriebene Flüssiggasgeräte, die eine waagerechte Kartusche im Gehäuse enthalten

Dieses Dokument legt die Konstruktionsmerkmale, Funktionen und Markierungen in Zusammenhang mit der Sicherheit und der wirtschaftlichen Verwendung von Energie von tragbaren, flachen Gasgeräten fest, die direkt mit LPG-Dampfdruck versorgt werden und über eine integrierte Gaskartusche in Übereinstimmung mit EN 417:2012 verfügen, die horizontal in das Gehäuse eingebaut ist.

ANMERKUNG 1 Diese Geräte werden im gesamten Text als „Geräte“ bezeichnet.

Dieses Dokument ist nur für Geräte anzuwenden, die für die Verwendung im Freien oder in gut belüfteten Bereichen bestimmt sind.

Dieses Dokument ist nicht für Geräte anzuwenden, die von einer externen Gasquelle versorgt werden.

Abgedeckt sind beispielsweise folgende Arten von Geräten:

a) Kochgeräte (Kocher, Grills);

b) Heizgeräte.

Dieses Dokument legt die Anforderungen an diese Geräte bzw. deren funktionswichtige Bauteile fest, unabhängig davon, ob letztere separat oder in eine Baugruppe integriert sind.

Durch dieses Dokument sind Geräte abgedeckt, die nicht an Abgasleitungen zur Abführung der Verbrennungsprodukte und nicht an das elektrische Netz angeschlossen sind.

Dieses Dokument bezieht sich weder auf Geräte, die mit Flüssiggas (LPG, en: liquefied petroleum gas) in flüssiger Phase versorgt werden, noch auf Geräte mit fest eingebautem, durch den Anwender nachfüllbarem Gasbehälter.

Dieses Dokument bezieht sich nicht auf Geräte der Kategorie mit unmittelbarem Propandruck.

Die Anforderungen an die wirtschaftliche Nutzung der Energie wurden in Hinblick auf die Brenner der Kocher berücksichtigt.

ANMERKUNG 2 Dagegen wurden derartige Anforderungen nicht für die anderen Gerätearten festgelegt, denn:

— für Grills ist das Kochergebnis je nach Art der Nahrung und der Region, in der das Gerät eingesetzt wird, unterschiedlich;

— für Heizgeräte wird die gesamte Wärme auf die Umgebung übertragen.

Spécifications pour les appareils fonctionnant exclusivement aux gaz de pétrole liquéfiés - Appareils GPL à pression de vapeur incorporant une cartouche horizontale dans leur châssis

Le présent document spécifie les caractéristiques de construction, les performances et le marquage relatifs à la sécurité et à l'utilisation rationnelle de l'énergie des appareils plats à gaz portatifs directement alimentés à la pression de vapeur des GPL, comprenant une cartouche de gaz conforme à l'EN 417:2012, insérée horizontalement dans le châssis.

NOTE 1 Ces appareils sont désignés dans l'ensemble du texte par « appareils ».

Le présent document couvre les appareils pour utilisation en plein air ou dans des espaces bien aérés uniquement.

Le présent document ne couvre pas les appareils alimentés par une source de gaz externe.

Sont par exemple visés les types d'appareils suivants :

a) appareils de cuisson (réchauds, barbecues) ;

b) appareils de chauffage.

Le present document précise les exigences applicables à tous ces appareils ou éléments fonctionnels, que ces derniers soient indépendants ou incorporés dans un ensemble.

Les appareils couverts par le présent document ne sont pas raccordés à un conduit d'évacuation des produits de la combustion et n'ont pas de raccordement au réseau électrique.

Le présent document ne s'applique ni aux appareils alimentés aux GPL en phase liquide ni à ceux avec réservoir fixe incorporé remplissable par l'utilisateur.

Le présent document ne s'applique pas aux appareils de la catégorie pression directe propane.

Des exigences concernant l'utilisation rationnelle de l'énergie ont été prises en compte pour les brûleurs de réchauds.

NOTE 2 En revanche, de telles exigences n'ont pas été prises en compte pour les autres types d'appareils car :

- pour les barbecues, ce type de cuisson varie en fonction du type d'aliment et des régions où l'appareil est utilisé ;

- pour les appareils de chauffage, toute la chaleur produite est transmise dans l'environnement.

Specifikacije za plinske aparate na utekočinjeni naftni plin (UNP) - Aparati na UNP, ki delujejo s parnim tlakom in vsebujejo vodoravno kartušo v ohišju (vključuje dopolnilo A1)

General Information

- Status

- Published

- Publication Date

- 14-Nov-2022

- Technical Committee

- PLN - Gas appliances for domestic use

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 26-Oct-2022

- Due Date

- 31-Dec-2022

- Completion Date

- 15-Nov-2022

Relations

- Effective Date

- 01-Dec-2022

Overview

EN 17476:2021+A1:2022 is a CEN European standard that specifies construction characteristics, performance and marking for portable, flat liquefied petroleum gas (LPG) appliances operating at LPG vapour pressure and incorporating a horizontal gas cartridge (compliant with EN 417:2012) inserted in the chassis. The standard applies only to appliances for outdoor or well-ventilated area use, such as cooking appliances (stoves, barbecues) and heating appliances, and excludes externally supplied gas, liquid-phase LPG appliances, refillable fixed integral containers and direct-pressure propane category appliances. Appliances covered are not connected to a flue or mains electricity.

Key Topics

EN 17476:2021+A1:2022 addresses both safety and energy-use considerations. Major technical topics and requirements include:

- Safety requirements: general safety principles, materials, assembly, cleaning and maintenance, strength and stability.

- Gas circuit integrity: soundness and leak testing of gas circuits and burner assemblies.

- Controls and user interfaces: taps, control handles, pressure-sensitive safety devices and marking requirements.

- Ignition and flame control: ignition devices, flame supervision devices, ignition/crosslighting and flame stability tests.

- Burner and heat performance: burner design, injectors, radiant elements, verification and calculation of heat input.

- Thermal protection: resistance to overheating, temperatures of appliance parts and cartridge, and panel temperature limits for floors/walls.

- Combustion and emissions: tests for combustion quality, analysis of combustion products and accumulation of un-burnt gas.

- Durability and markings: endurance testing and durability of safety markings and instructions.

- Rational use of energy: specific requirements and test methods for stove burners to promote energy-efficient operation.

- Test methods: specified test gases, test conditions, and detailed procedures for verification (soundness, strength, combustion, temperature, etc.).

Applications and Users

Who uses EN 17476:2021+A1:2022:

- Manufacturers and designers of portable LPG vapour pressure appliances (stoves, barbecues, portable heaters) to design compliant products.

- Test laboratories and certification bodies conducting type testing and conformity assessment.

- Regulators and market surveillance authorities verifying product safety and marking for outdoor/well‑ventilated use.

- Distributors and retailers evaluating product compliance before market placement. Practical applications include product specification, safety documentation, conformity testing and guidance for safe user instructions and labelling.

Related Standards

- EN 417:2012 - Specification for non-refillable metallic gas cartridges (referenced for cartridge compatibility and safety).

- CEN delivery and national standardization rules apply for national adoption and translations of EN 17476:2021+A1:2022.

Keywords: EN 17476:2021+A1:2022, LPG vapour pressure appliances, horizontal cartridge, EN 417:2012, portable gas appliances, safety requirements, rational use of energy, CEN.

Frequently Asked Questions

SIST EN 17476:2021+A1:2022 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Specifications for dedicated liquefied petroleum gas appliances - LPG vapour pressure appliances incorporating a horizontal cartridge in the chassis". This standard covers: This document specifies the construction characteristics, performances and marking related to safety and the rational use of energy of portable, flat gas appliances directly supplied at the LPG vapour pressure, incorporating a gas cartridge complying with EN 417:2012, inserted horizontally in the chassis. NOTE 1 These appliances are referred to in the body of the text as “appliances”. This document covers appliances for outdoor or in well ventilated areas uses only. This document does not cover appliances supplied by an external gas source. For example, the following types of appliances are covered: a) cooking appliances (stoves, barbecues); b) heating appliances. This document specifies the requirements applicable to these appliances or their functional sections whether or not the latter are independent or incorporated into an assembly. Appliances covered by this document are not connected to a flue for the discharge of products of combustion and are not connected to the mains electricity supply. This document covers neither appliances supplied with LPG in the liquid phase nor appliance with fixed integral container which could be refilled by the user. This document does not cover appliances of direct pressure propane category. Requirements for rational use of energy have been considered for stove burners. NOTE 2 However, such requirements have not been considered for the other types of appliances because: - for barbecues, this type of cooking varies according to the type of food and region where the appliance is used; - for heating appliances, all the heat produced is discharged into the environment.

This document specifies the construction characteristics, performances and marking related to safety and the rational use of energy of portable, flat gas appliances directly supplied at the LPG vapour pressure, incorporating a gas cartridge complying with EN 417:2012, inserted horizontally in the chassis. NOTE 1 These appliances are referred to in the body of the text as “appliances”. This document covers appliances for outdoor or in well ventilated areas uses only. This document does not cover appliances supplied by an external gas source. For example, the following types of appliances are covered: a) cooking appliances (stoves, barbecues); b) heating appliances. This document specifies the requirements applicable to these appliances or their functional sections whether or not the latter are independent or incorporated into an assembly. Appliances covered by this document are not connected to a flue for the discharge of products of combustion and are not connected to the mains electricity supply. This document covers neither appliances supplied with LPG in the liquid phase nor appliance with fixed integral container which could be refilled by the user. This document does not cover appliances of direct pressure propane category. Requirements for rational use of energy have been considered for stove burners. NOTE 2 However, such requirements have not been considered for the other types of appliances because: - for barbecues, this type of cooking varies according to the type of food and region where the appliance is used; - for heating appliances, all the heat produced is discharged into the environment.

SIST EN 17476:2021+A1:2022 is classified under the following ICS (International Classification for Standards) categories: 23.020.35 - Gas cylinders. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 17476:2021+A1:2022 has the following relationships with other standards: It is inter standard links to SIST EN 17476:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 17476:2021+A1:2022 is associated with the following European legislation: EU Directives/Regulations: 2016/426; Standardization Mandates: M/BC/CEN/89/6. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 17476:2021+A1:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2022

Nadomešča:

SIST EN 17476:2021

Specifikacije za plinske aparate na utekočinjeni naftni plin (UNP) - Aparati na UNP,

ki delujejo s parnim tlakom in vsebujejo vodoravno kartušo v ohišju (vključuje

dopolnilo A1)

Specifications for dedicated liquefied petroleum gas appliances - LPG vapour pressure

appliances incorporating a horizontal cartridge in the chassis

Festlegungen für Flüssiggasgeräte - Mit Dampfdruck betriebene Flüssiggasgeräte, die

eine waagerechte Kartusche im Gehäuse enthalten

Spécifications pour les appareils fonctionnant exclusivement aux gaz de pétrole liquéfiés

- Appareils GPL à pression de vapeur incorporant une cartouche horizontale dans leur

châssis

Ta slovenski standard je istoveten z: EN 17476:2021+A1:2022

ICS:

23.020.35 Plinske jeklenke Gas cylinders

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17476:2021+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

February 2022

EUROPÄISCHE NORM

ICS 23.020.35 Supersedes EN 17476:2021

English Version

Specifications for dedicated liquefied petroleum gas

appliances - LPG vapour pressure appliances

incorporating a horizontal cartridge in the chassis

Spécifications pour les appareils fonctionnant Festlegungen für Flüssiggasgeräte - Mit Dampfdruck

exclusivement aux gaz de pétrole liquéfiés - Appareils betriebene Flüssiggasgeräte, die eine waagerechte

GPL à pression de vapeur incorporant une cartouche Kartusche im Gehäuse enthalten

horizontale dans leur châssis

This European Standard was approved by CEN on 12 March 2021 and includes Amendment 1 approved by CEN on 10 November

2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17476:2021+A1:2022 E

worldwide for CEN national Members.

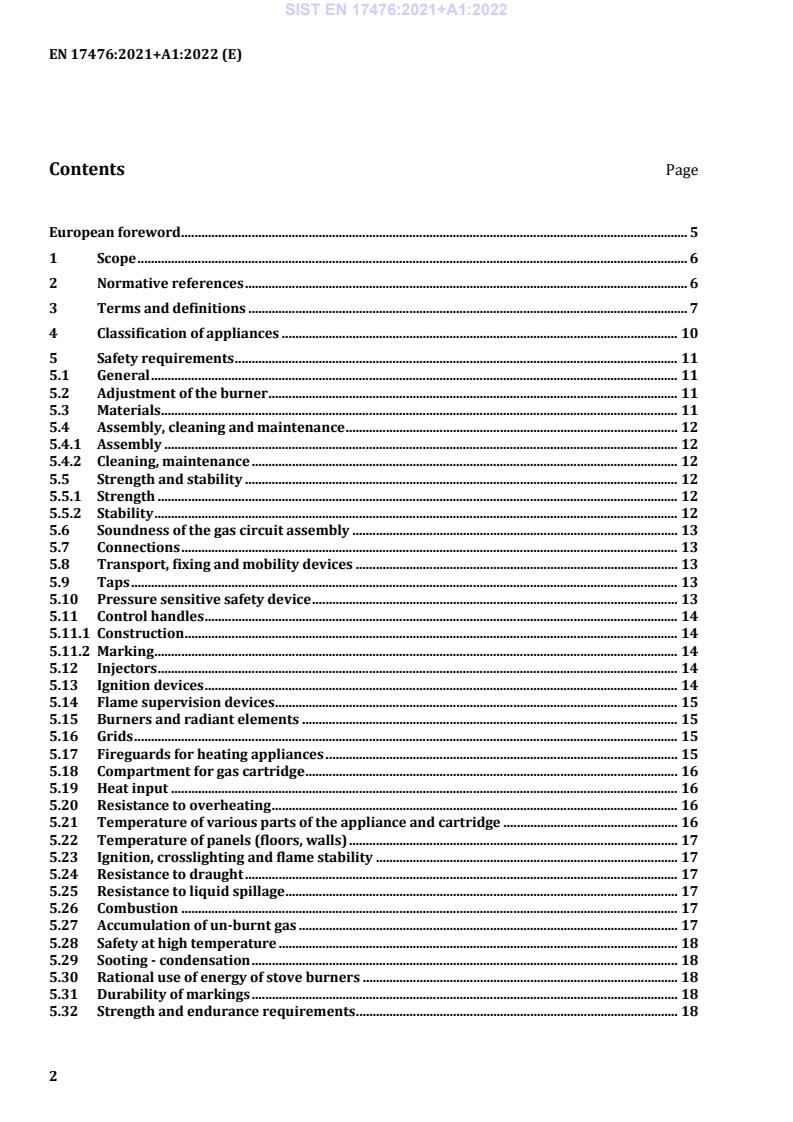

Contents Page

European foreword . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Classification of appliances . 10

5 Safety requirements . 11

5.1 General . 11

5.2 Adjustment of the burner . 11

5.3 Materials . 11

5.4 Assembly, cleaning and maintenance . 12

5.4.1 Assembly . 12

5.4.2 Cleaning, maintenance . 12

5.5 Strength and stability . 12

5.5.1 Strength . 12

5.5.2 Stability . 12

5.6 Soundness of the gas circuit assembly . 13

5.7 Connections . 13

5.8 Transport, fixing and mobility devices . 13

5.9 Taps . 13

5.10 Pressure sensitive safety device . 13

5.11 Control handles . 14

5.11.1 Construction . 14

5.11.2 Marking . 14

5.12 Injectors . 14

5.13 Ignition devices . 14

5.14 Flame supervision devices . 15

5.15 Burners and radiant elements . 15

5.16 Grids . 15

5.17 Fireguards for heating appliances . 15

5.18 Compartment for gas cartridge . 16

5.19 Heat input . 16

5.20 Resistance to overheating . 16

5.21 Temperature of various parts of the appliance and cartridge . 16

5.22 Temperature of panels (floors, walls) . 17

5.23 Ignition, crosslighting and flame stability . 17

5.24 Resistance to draught . 17

5.25 Resistance to liquid spillage . 17

5.26 Combustion . 17

5.27 Accumulation of un-burnt gas . 17

5.28 Safety at high temperature . 18

5.29 Sooting - condensation . 18

5.30 Rational use of energy of stove burners . 18

5.31 Durability of markings . 18

5.32 Strength and endurance requirements . 18

5.33 Atmosphere sensing device . 18

6 Test methods . 19

6.1 General . 19

6.1.1 Test gases . 19

6.1.2 Test conditions . 19

6.1.3 Test gases and pressures . 19

6.1.4 Test vessel . 20

6.2 Adjustment of the burner . 20

6.3 Materials . 20

6.4 Assembly, cleaning and maintenance . 20

6.5 Strength and stability . 21

6.5.1 Strength . 21

6.5.2 Stability . 21

6.6 Soundness of the gas circuit assembly . 22

6.6.1 Soundness of the appliance . 22

6.6.2 Soundness of burner assemblies. 22

6.7 Connections . 22

6.8 Transport, fixing and mobility devices . 22

6.9 Taps . 22

6.10 Pressure sensitive safety device design and test . 22

6.11 Control handles . 23

6.12 Injectors . 23

6.13 Ignition devices . 23

6.14 Flame supervision devices . 23

6.14.1 General . 23

6.14.2 Ignition delay time . 23

6.14.3 Extinction delay time . 23

6.15 Burners and radiant elements . 23

6.16 Grids . 23

6.17 Fireguards for heating appliances . 24

6.17.1 Strength of fireguards . 24

6.17.2 Dimensions . 24

6.18 Compartments for gas cartridge . 24

6.19 Verification of heat inputs . 24

6.19.1 Test . 24

6.19.2 Calculation of heat inputs . 25

6.20 Resistance to overheating . 25

6.21 Temperatures of the various parts of the appliance and cartridge . 26

6.21.1 Test installation . 26

6.21.2 Test method . 26

6.22 Temperature of panels (floor, wall) . 27

6.23 Ignition, crosslighting and flame stability . 27

6.23.1 Test conditions . 27

6.23.2 Test on individual burners, others being extinguished . 27

6.23.3 Test on individual burners, others being lit . 27

6.24 Resistance to draught . 28

6.25 Resistance to liquid spillage . 28

6.26 Combustion . 28

6.26.1 General conditions . 28

6.26.2 Stove burners . 29

6.26.3 Analysis of the products of combustion. 29

6.27 Accumulation of un-burnt gases . 29

6.28 Safety at high temperature . 29

6.29 Sooting - condensation . 30

6.30 Rational use of energy of stove burners . 30

6.31 Durability of the markings . 31

6.32 Strength and endurance test . 32

6.33 Atmosphere sensing devices . 32

7 Markings . 32

7.1 Appliance marking . 32

7.2 Packaging marking . 33

8 Instructions for use, maintenance and assembly . 33

8.1 General . 33

8.2 Instruction contents . 33

Annex A (normative) Characteristics of test vessels (see 6.5.2.3) . 42

Annex B (normative) Tests on taps . 43

B.1 Resistance to temperature . 43

B.2 Endurance . 43

Annex C (normative) Vitiation room . 44

C.1 Dimension . 44

C.2 Sealing requirement . 44

C.3 Construction . 44

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Regulation (EU) 2016/426/EC . 46

Bibliography . 49

European foreword

This document (EN 17476:2021+A1:2022) has been prepared by Technical Committee CEN/TC 181 “Appliances

and leisure vehicle installations using liquefied petroleum gas and appliances using natural gas for outdoor use”,

the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an identical text

or by endorsement, at the latest by August 2022, and conflicting national standards shall be withdrawn at the

latest by August 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1 approved by CEN on 10 November 2021.

This document supersedes !EN 17476:2021".

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

This document has been prepared under a mandate given to CEN by the European Commission and the European

Free Trade Association, and supports essential requirements of EU Regulation (EU) 2016/426 of the European

Parliament and of the Council of 9 March 2016 on appliances burning gaseous fuels and repealing Directive

2009/142/EC.

For relationship with EU Regulation (EU) 2016/426, see informative Annex ZA, which is an integral part of this

document.

Appliances covered by this document differ from the ones covered by EN 521:2019+AC:2019 by the fact that the

gas cartridge is incorporated inside the appliance body in a position which can create particular situations which

need different approach than these used in EN 521:2019+AC:2019.

Any feedback and questions on this document should be directed to the users’ national standards body. A

complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the following

countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech

Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North Macedonia, Romania, Serbia,

Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom.

1 Scope

This document specifies the construction characteristics, performances and marking related to safety and the

rational use of energy of portable, flat gas appliances directly supplied at the LPG vapour pressure, incorporating

a gas cartridge complying with EN 417:2012, inserted horizontally in the chassis.

NOTE 1 These appliances are referred to in the body of the text as “appliances”.

This document covers appliances for outdoor or in well ventilated areas uses only.

This document does not cover appliances supplied by an external gas source.

For example, the following types of appliances are covered:

a) cooking appliances (stoves, barbecues);

b) heating appliances.

This document specifies the requirements applicable to these appliances or their functional sections whether or

not the latter are independent or incorporated into an assembly.

Appliances covered by this document are not connected to a flue for the discharge of products of combustion and

are not connected to the mains electricity supply.

This document covers neither appliances supplied with LPG in the liquid phase nor appliance with fixed integral

container which could be refilled by the user.

This document does not cover appliances of direct pressure propane category.

Requirements for rational use of energy have been considered for stove burners.

NOTE 2 However, such requirements have not been considered for the other types of appliances because:

— for barbecues, this type of cooking varies according to the type of food and region where the appliance is used;

— for heating appliances, all the heat produced is discharged into the environment.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references, the

latest edition of the referenced document (including any amendments) applies.

EN 30-1-1:2008+A3:2013, Domestic cooking appliances burning gas - Part 1-1: Safety - General

EN 125:2010+A1:2015, Flame supervision devices for gas burning appliances - Thermoelectric flame supervision

devices

EN 437:2018, Test gases — Test pressures — Appliance categories

EN 549:2019, Rubber materials for seals and diaphragms for gas appliances and gas equipment

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

stove

cooking appliance incorporating one or several burners and a pan support(s) designed in such a way that it(they)

can support the vessels containing the food

3.2

flat portable gas appliance

flat appliance operating with a gas cartridge horizontally placed in the chassis

3.2.1

flat portable gas stove

flat portable gas appliance for which the length and/or width is bigger than its height

Note 1 to entry: Figure 1 gives an example of flat portable gas stoves (single and double burners).

3.2.2

flat portable gas heater

flat portable gas appliance intended to heat environment

Note 1 to entry: Figure 2 gives an example of flat portable gas heater.

3.2.3

barbecue

flat portable gas appliance the main function of which is to roast and/or grill food

Note 1 to entry: Cooking is carried out by radiant heat and, possibly, by convection and conduction.

Note 2 to entry: Figure 4 gives an example of barbecue covered by this document.

3.3

vapour pressure appliance

appliance for which the pressure at the gas inlet is equal to the pressure in the gas cartridge

Note 1 to entry: A pressure reducing device may be incorporated in the gas circuit, between the gas inlet and the injector.

3.4

gas cartridge

non-refillable container with a maximum capacity of 1 000 ml filled with gas or a gas mixture

Note 1 to entry: An example of gas cartridges to be horizontally inserted in appliances is given in Figure 3.

Note 2 to entry: Gas cartridges are not fittings.

3.5

cooking device

device supplied with the appliance designed to hold or receive the food to be cooked

3.6

useful part of a cooking device

part of the device in contact with food during cooking

3.7

grid

cooking device part of a barbecue holding the food to be cooked designed in such a way that most part of the food

is directly heated by the flames

3.8

griddle

part of a barbecue consisting of the plate placed above a burner, that allows the cooking of food by direct contact

with the surface of the plate which is brought to a high temperature

3.9

pan support

support placed above an open stove burner and designed to support the pan to be heated

3.10 safety device

3.10.1

flame supervision device

device which, due to the presence of a flame on the sensing element, keeps open the gas flow to the burner and

any pilot and which cuts off the gas supply to the burner and possibly a pilot in the event of extinction of the

supervised flame

3.10.2

pressure sensitive safety device

device which automatically shuts off the gas supply to the burner in the event of overpressure in the cartridge

3.11

ignition delay time

time between the ignition of the supervised flame and the moment when the effect of this flame is sufficient to

keep the closing device open

3.12

extinction delay time

time between the extinction of the supervised flame and the closure of the gas supply to the burner and possibly

a pilot

3.13

tap

controlling device, part of the appliance, designed to isolate a burner from the internal gas pipework and possibly

to adjust its rate during use

3.14

control handle

component designed to be operated manually so as to operate a control of the burner

3.15

gripping area

outside part of the appliance designed to be handled during use

3.16

burner

component that allows the gas to burn

3.17

injector

component part that admits the gas into a burner

Note 1 to entry: An injector is said to be calibrated when the section of the outlet orifice is fixed.

3.18

ignition device

device to ignite one or more burners directly or indirectly

3.19

means of sealing

static or dynamic device designed to ensure leak tightness

EXAMPLE Flat-faced joints, O-ring or conical joints, diaphragms, grease, pastes, putties, etc.

3.20

detachable

possible to dismantle without using a tool

3.21

removable

removal only possible with a tool

3.22

soft solder

solder for which the lowest temperature of the melting range, after application, is less than 450 °C

3.23

flame stability

flames are stable at the burner ports when the phenomena of flame lift or light back do not occur

3.24

flame lift

phenomenon characterized by the partial or total movement of the base of the flame away from the burner port

3.25

light back

phenomenon characterized by the return of the flame inside the body of the burner

3.26

calorific value

quantity of heat produced by the complete combustion, at a constant pressure equal to 1 013,25 mbar, of a unit

volume or mass of gas, the constituents of the combustible mixture being taken at reference conditions and the

products of combustion being brought back to the same conditions

Note 1 to entry: A distinction is made between:

— the gross calorific value Hs: the water produced by combustion is assumed to be condensed;

— the net calorific value Hi: the water produced by combustion is assumed to be in the vapour state.

Note 2 to entry: The calorific value is expressed:

— either in megajoules per cubic metre (MJ/m ) of dry gas under the reference conditions;

— or in megajoules per kilogram (MJ/kg) of dry gas.

[SOURCE: EN 437:2018]

3.27

gas supply pressure

difference between the static pressure measured at the gas inlet connection of the appliance and the atmospheric

pressure

Note 1 to entry: It is expressed in bar.

3.28

atmosphere sensing device

device that is designed to shut off the gas supply when the carbon dioxide concentration of the surrounding

atmosphere exceeds a given level

Note 1 to entry: Such a device normally comprises a vitiation sensitive pilot in conjunction with a suitable flame

supervision device.

4 Classification of appliances

For the purpose of this document appliances are classified in two groups according to the gas pressures they are

designed for:

a) Butane appliances:

Appliance using mixture of hydrocarbons containing mainly butanes and butenes having a maximum

pressure of 8 bar gauge at 50 °C; called “category direct pressure – butane”;

b) Butane-propane mixt appliances:

Appliance using mixture of hydrocarbons containing mainly butanes, butenes, propane and propene having

a pressure between 8 bar gauge and 12 bar gauge at 50 °C; called “category direct pressure - butane-propane

mixture”.

5 Safety requirements

5.1 General

The test methods and the means of verification are indicated in Clause 6.

The design shall make it impossible to incorrectly fit or refit any user-removable or replaceable part(s) or

component(s) that can have an adverse effect on combustion or cause CO emissions to exceed limits in 5.26.

5.2 Adjustment of the burner

Not any adjustment of the burner shall be possible.

5.3 Materials

Non-metallic materials used as radiant elements in appliances (for example ceramics) shall resist to all tests of

this documents without alteration.

The quality and thickness of materials used in the construction of appliances shall be such that the constructional

and performance characteristics are not altered in use. In particular all the parts of the appliance shall withstand

mechanical, chemical and thermal actions to which they may be submitted during use. In normal conditions of

operation, of cleaning or of adjustment, they shall not be liable to any alterations which might impair their safety.

Sheet-metal parts, not made of corrosion-resistant material, shall be effectively protected against corrosion. This

requirement does not apply to cooking devices.

Seals and joining compounds shall have characteristics suited to their use.

Rubber based materials shall comply with EN 549:2019 class A2 minimum, and LPG resistant.

Asbestos or asbestos based materials shall not be used.

With the exception of seals, membranes, parts in contact with gas shall be made of metallic materials.

Material intended to be in contact with food shall be:

— corrosion resistant;

— non toxic.

The materials shall:

— not transfer undesirable odours, colours or taint to the food;

— not contribute either to the contamination of food or have any adverse influence on the food.

NOTE For information see EN 1672-2.

5.4 Assembly, cleaning and maintenance

5.4.1 Assembly

The entire appliance gas circuit, including the injector shall be factory assembled. If clamps are used, they shall

be of the machine formed type. Removable clamps are not permitted.

Parts, whose assembly is carried out by the user, shall only be able to be assembled correctly by following the

instructions given in the instructions.

It shall not be possible to dismantle parts which are adjusted at the factory, which are not intended to be

dismantled by the user and whose dismantling would affect safety, without using tools. If dismantling is possible

using an open ended spanner or a screwdriver, direct access to such nuts and screw heads shall not be possible,

unless they are sealed.

For flat portable gas stoves, it shall not be possible to operate the appliance if the pan support is not in the cooking

position.

The appliance design shall prevent any accidental blockage of any safety device by contamination by ground

materials

NOTE Contamination by ground materials could include sand, grass, soil.

5.4.2 Cleaning, maintenance

All parts of the appliance requiring frequent cleaning by the user shall be easily accessible. It shall be possible to

put these parts back correctly.

There shall be no sharp corners and edges on the accessible parts of an appliance which could give rise to injury.

5.5 Strength and stability

5.5.1 Strength

5.5.1.1 General

The construction of an appliance shall be such that, during normal conditions of use:

— any displacement of parts;

— any distortion;

— any deterioration

likely to impair safe operation will not occur.

5.5.1.2 Stove pan supports

The application of a mass as described in 6.5.1.2 on the pan support shall not cause any breakage or permanent

distortion of the pan support exceeding 1 mm.

5.5.2 Stability

If the appliance is fitted with a foldable support, it shall be possible to lock this in the position of use.

The stability of an appliance designed to rest on a table or on the ground shall allow safe use on level ground. In

addition, the appliance shall not tilt or fall over when it is placed on a slope of 10° in any configuration.

This requirement shall also be met when the appliance is fitted with any optional parts listed in the instructions.

These requirements shall be met under the test conditions described in 6.5.2.

5.6 Soundness of the gas circuit assembly

Holes for screws, pins, etc. intended for the assembly of components shall not open into the space reserved for

the gas ways leading to the injector.

The soundness of parts and assemblies connected to the gas circuit shall be ensured by means of metal-to-metal

joints or joints with seals (for example, flat-faced joints, O-rings or gaskets), i.e. excluding the use of any product

which ensures soundness in the threads. For parts that do not require to be dismantled during normal

maintenance, for example taps, the use of thread sealing compounds is permitted.

Removable components or the threaded parts of the gas pipework which may be dismantled during maintenance

described in the instructions shall remain sound after five disconnections and re-connections in accordance with

the instructions, if necessary after changing a gasket.

Soft solder shall not be used to ensure the soundness of the gas circuit. However it is permitted for internal

connections within the gas circuit when they do not involve soundness.

Under the test conditions defined in 6.6.1, during each of the tests n 1 and 2, the leak shall not exceed 0,07 l/h

(1 013 mbar, 20 °C). This requirement shall also be met after all the tests on the appliance have been carried out,

but before any dismantling of parts subjected to the soundness tests.

5.7 Connections

When following the instructions, connection of the appliance to the gas cartridge shall be easy without gas

leakage during more than 2 s.

5.8 Transport, fixing and mobility devices

It shall not be possible to place any gas cartridge anywhere other than in the gas cartridge compartment even for

the purposes of transport or storage.

5.9 Taps

Each burner shall be controlled by a tap or device allowing the opening and closing of its supply.

Taps shall incorporate two stops, one on the closed position and one at the end of travel.

Taps shall be so placed in such a way that their strength, their operation, their manipulation and their

accessibility undergo no change from actions to which they are subjected in normal use.

Taps shall be mounted in such a way that no accidental movement relative to fixed gas supply pipework is

possible.

It shall not be possible by unscrewing to remove the closing device from the tap when opening the tap.

Taps shall comply with the requirements given in Annex B.

5.10 Pressure sensitive safety device

Each appliance may be fitted with a pressure sensitive safety device.

If any it shall not be possible to bypass accidentally the pressure sensitive safety device.

After action of the device its reactivation shall only be possible by a specific action (different from normal

installation of the cartridge).

In case of a failure of the pressure sensitive safety device, if any, the appliance shall not operate unless the

appliance is fitted with two independent pressure sensitive safety devices.

Under the test condition of 6.10 the gas supply shall be stopped between 4 and 6 bar.

5.11 Control handles

5.11.1 Construction

It shall be obvious which burner is controlled by each control handle.

They shall be so arranged relative to one another that the movement of one handle does not cause inadvertent

movement of an adjacent one.

Control handles shall be so designed that they neither be fitted in the wrong position nor move by themselves.

If control handles operate by turning, the closing direction shall be clockwise.

5.11.2 Marking

The closed, open and, if applicable, reduced rate positions shall be marked in a visible, legible and durable

fashion.

The closed position shall be marked by a full disc or a circle at least 3 mm in diameter. It shall be the same for all

the taps.

Ignition position, if any shall be marked (e.g. with a stylised star).

The identification of the closed position of each tap shall not give rise to any possibility of confusion with the

identification of an open position.

For other positions, the following symbols may be used:

Full rate position Large flame

Reduced rate position Small flame

Rate range Triangle or

Scale 1 2 3 4 or 4 3 2 1

Other symbols, other than letters, are permitted provided that they give similar information clearly.

Additional markings are permitted provided that they do not create confusion for the appliance user.

The meaning of the symbols used shall be given in the instructions.

5.12 Injectors

The gas rate shall be controlled by an injector of which the outlet orifice is fixed.

Removable injectors shall carry an indelible marking allowing their identification, which shall be given in the

instructions.

5.13 Ignition devices

When an ignition device is fitted, it shall be designed and constructed in such a way that it provides rapid and

safe ignition.

The components of the ignition device shall be designed to avoid damage and displacement during use. The

relative positions of the ignition device and the burner shall be sufficiently well defined to ensure safe operation

of the assembly.

5.14 Flame supervision devices

Any flame supervision device when existing shall comply with EN 125:2010+A1:2015.

Heating appliances shall be fitted with a flame supervision device.

When flame supervision devices are fitted, they shall be designed in such a way that, in the case of the failure of

any of the components indispensable to their performance, the supply of the gas to the burner and to the pilot

controlled by the devic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...