SIST EN 13979-1:2004+A1:2009

(Main)Railway applications - Wheelsets and bogies - Monobloc wheels - Technical approval procedure - Part 1: Forged and rolled wheels

Railway applications - Wheelsets and bogies - Monobloc wheels - Technical approval procedure - Part 1: Forged and rolled wheels

The aim of this European Standard is to define the requirements that a monobloc wheel of a freight of passenger railway vehicle non-powered axle shall meet in order to be able to be used on a European network.

For wheels of powered axles or wheels with noise dampers, the requirements may be amended or supplemented.

For light vehicles and tramways, other standards or documents accepted by the customer and supplier may be used.

This European Standard only applies to wheels of new design.

These requirements are intended to assess the validity of the design choice for the proposed use.

The assessment of these requirements is the technical approval procedure.

This European Standard is applicable to forged and rolled wheels for which the quality requirements are defined in EN 13262.

Bahnanwendungen - Radsätze und Drehgestelle - Vollräder - Technische Zulassungsverfahren - Teil 1: Geschmiedete und gewalzte Räder

Diese Europäische Norm legt Anforderungen fest, denen ein Vollrad für Eisenbahnfahrzeuge genügen muss, bevor es auf dem europäischen Eisenbahnnetz eingesetzt werden kann.

Für Räder von Treibradsätzen oder für Räder mit Schallabsorbern können die Anforderungen geändert werden.

Für Nahverkehrsfahrzeuge und Straßenbahnen können andere Normen oder Dokumente angewendet werden. Diese sind zwischen Kunden und Lieferanten zu vereinbaren.

Diese Norm gilt nur für neue Radkonstruktionen.

Der Zweck der Anforderungen besteht darin, die Wahl der Konstruktion für den betrachteten Anwendungs-bereich zu genehmigen.

Die Bewertung dieser Anforderungen wird technisches Zulassungsverfahren genannt.

Dieser Teil der Norm bezieht sich auf geschmiedete und gewalzte Räder, deren Qualitätsanforderungen in

EN 13262 festgelegt sind.

Applications ferroviaires - Essieux montés et bogies - Roues monobloc - Procédure d'homologation technique - Partie 1: Roues forgées et laminées

Železniške naprave - Kolesne dvojice in podstavni vozički - Monoblok kolesa - Postopek za tehnično odobritev - 1. del: Kovana in valjana kolesa

General Information

- Status

- Withdrawn

- Publication Date

- 06-Apr-2009

- Withdrawal Date

- 28-Mar-2011

- Technical Committee

- IŽNP - Reilway applications

- Current Stage

- 9900 - Withdrawal (Adopted Project)

- Start Date

- 29-Mar-2011

- Due Date

- 21-Apr-2011

- Completion Date

- 29-Mar-2011

Relations

- Effective Date

- 01-May-2009

- Effective Date

- 18-Jan-2023

- Effective Date

- 01-May-2011

- Effective Date

- 12-Jun-2010

Frequently Asked Questions

SIST EN 13979-1:2004+A1:2009 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Railway applications - Wheelsets and bogies - Monobloc wheels - Technical approval procedure - Part 1: Forged and rolled wheels". This standard covers: The aim of this European Standard is to define the requirements that a monobloc wheel of a freight of passenger railway vehicle non-powered axle shall meet in order to be able to be used on a European network. For wheels of powered axles or wheels with noise dampers, the requirements may be amended or supplemented. For light vehicles and tramways, other standards or documents accepted by the customer and supplier may be used. This European Standard only applies to wheels of new design. These requirements are intended to assess the validity of the design choice for the proposed use. The assessment of these requirements is the technical approval procedure. This European Standard is applicable to forged and rolled wheels for which the quality requirements are defined in EN 13262.

The aim of this European Standard is to define the requirements that a monobloc wheel of a freight of passenger railway vehicle non-powered axle shall meet in order to be able to be used on a European network. For wheels of powered axles or wheels with noise dampers, the requirements may be amended or supplemented. For light vehicles and tramways, other standards or documents accepted by the customer and supplier may be used. This European Standard only applies to wheels of new design. These requirements are intended to assess the validity of the design choice for the proposed use. The assessment of these requirements is the technical approval procedure. This European Standard is applicable to forged and rolled wheels for which the quality requirements are defined in EN 13262.

SIST EN 13979-1:2004+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 45.040 - Materials and components for railway engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13979-1:2004+A1:2009 has the following relationships with other standards: It is inter standard links to SIST EN 13979-1:2004, SIST EN 13979-1:2004, SIST EN 13979-1:2004+A2:2011, SIST EN 13979-1:2004/kprA2:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13979-1:2004+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2001/16/EC, 2008/57/EC; Standardization Mandates: M/334. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13979-1:2004+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Bahnanwendungen - Radsätze und Drehgestelle - Vollräder - Technische Zulassungsverfahren - Teil 1: Geschmiedete und gewalzte RäderApplications ferroviaires - Essieux montés et bogies - Roues monobloc - Procédure d'homologation technique - Partie 1: Roues forgées et laminéesRailway applications - Wheelsets and bogies - Monobloc wheels - Technical approval procedure - Part 1: Forged and rolled wheels45.040Materiali in deli za železniško tehnikoMaterials and components for railway engineeringICS:Ta slovenski standard je istoveten z:EN 13979-1:2003+A1:2009SIST EN 13979-1:2004+A1:2009en,fr01-maj-2009SIST EN 13979-1:2004+A1:2009SLOVENSKI

STANDARDSIST EN 13979-1:2004/kprA1:2009SIST EN 13979-1:20041DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13979-1:2003+A1

April 2009 ICS 45.040; 45.060.01 Supersedes EN 13979-1:2003English Version

Railway applications - Wheelsets and bogies - Monobloc wheels - Technical approval procedure - Part 1: Forged and rolled wheels

Applications ferroviaires - Essieux montés et bogies - Roues monobloc - Procédure d'homologation technique - Partie 1: Roues forgées et laminées

Bahnanwendungen - Radsätze und Drehgestelle - Vollräder - Technische Zulassungsverfahren - Teil 1: Geschmiedete und gewalzte Räder This European Standard was approved by CEN on 3 November 2003 and includes Amendment 1 approved by CEN on 24 February 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13979-1:2003+A1:2009: ESIST EN 13979-1:2004+A1:2009

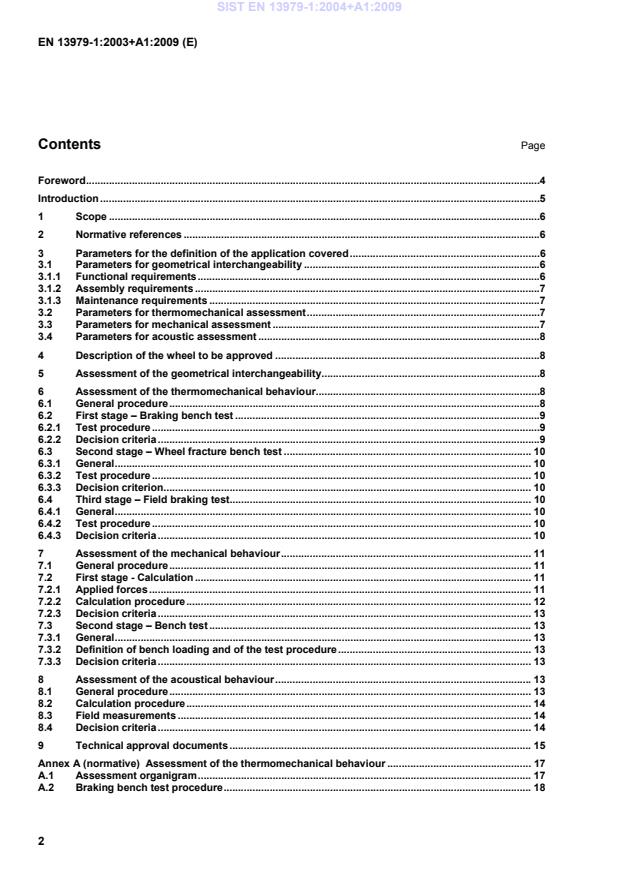

Assessment of the thermomechanical behaviour . 17A.1Assessment organigram . 17A.2Braking bench test procedure . 18SIST EN 13979-1:2004+A1:2009

Organigram of the mechanical behaviour assessment . 27Annex C (informative)

Mechanical behaviour – Finite element code assessment . 28Annex D (informative)

Mechanical behaviour – Bench loading and test procedure . 29D.1Principle of bench loading and test procedure . 29D.2Definition of loading . 29D.2.1General . 29D.2.2Measurement of the stresses during field tests . 30D.3Fatigue bench test . 30D.3.1Method 1 – Random fatigue test . 30D.3.2Method 2 – Single-stage fatigue test . 31Annex E (informative)

Assessment of the acoustical behaviour . 34E.1Assessment organigram. 34E.2Calculation procedure . 35E.2.1Preliminary comment . 35E.2.2Calculation of the wheel modal basis . 35E.2.3Selection of the reference track model . 35E.2.4Definition of the calculation parameters . 35E.2.5Power calculation . 35E.2.6Insertion. 36E.2.7Calculations of the decision criteria for acoustical technical approval of the wheel . 37E.2.8Optional calculations . 37E.3Field measurement procedure . 37E.3.1Objective and preliminary remark . 37E.3.2Recommendations for the operating conditions . 38E.3.3Measurement procedure . 41E.3.4Analysis of results . 43Annex F (informative)

!!!!Drag braking values for interoperability"""" . 46Annex ZA (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2008/57/EC of the European Parliament and of the Council of 17 June 2008 on the interoperability of the rail system within the Community"""" . 47Bibliography . 49 SIST EN 13979-1:2004+A1:2009

!Part 2: Cast wheels." !For relationship with EU Directives, see informative Annex ZA, which is an integral part of this document." According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom. SIST EN 13979-1:2004+A1:2009

1 Scope The aim of this European Standard is to define the requirements that a monobloc wheel of a freight of passenger railway vehicle non-powered axle shall meet in order to be able to be used on a European network. For wheels of powered axles or wheels with noise dampers, the requirements may be amended or supplemented. For light vehicles and tramways, other standards or documents accepted by the customer and supplier may be used. This European Standard only applies to wheels of new design. These requirements are intended to assess the validity of the design choice for the proposed use. The assessment of these requirements is the technical approval procedure. This European Standard is applicable to forged and rolled wheels for which the quality requirements are defined in !EN 13262". 2 Normative references !The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies." EN 12668-3, Non-destructive testing – Characterization and verification of ultrasonic examination equipment – Part 3: Combined equipment EN 13103, Railway applications – Wheelsets and bogies – Non-powered axles – Design !guide" !EN 13262", Railway applications – Wheelsets and bogies – Wheels –

Product requirements 3 Parameters for the definition of the application covered The application for which the wheel is to be approved shall be defined by the following parameters. If the application parameters are changed for an approved wheel, the customer and supplier shall review the assessments. 3.1 Parameters for geometrical interchangeability The application shall be defined by geometrical interchangeabliity parameters divided into three categories according to whether they are linked to functional, assembly or maintenance requirements. 3.1.1 Functional requirements the nominal tread diameter that influences the buffer height and the loading gauge; the maximum rim width

linked to the points and crossing and the track brakes; the tread profile outside the conical part of the tread; SIST EN 13979-1:2004+A1:2009

the conicity of the hub bore; the space required for disc brakes mounted on the wheel; the space needed on the bogie frame, braking equipment and suspension equipment. 3.1.2 Assembly requirements the bore diameter; the hub length to ensure overhanging of the hub on the wheelseat. 3.1.3 Maintenance requirements the wear limit diameter or the last reprofiling diameter; the wear groove shape; the geometry of the area for wheel clamping on reprofiling machines; the position and shape of the hole and groove for displacement under oil pressure; the general rim shape to allow ultrasonic measurement of residual stresses in wheels braked by shoes. 3.2 Parameters for thermomechanical assessment The application shall be defined by: the maximum braking energy created by the friction of the brake shoes on the rail surface. This energy may be defined by a power Pa, a time ta and a train speed Va during drag braking. If it is defined by other parameters (for braking to a stop, for example), these parameters are defined by agreement between the customer and the supplier; the type of brake shoes applied to the wheel (nature, dimensions and number). !NOTE For interoperable freight rolling stock, the thermomechanical behavior does not need to be verified when braking to a stop, but only drag braking, because of the lower energy in stop braking." 3.3 Parameters for mechanical assessment The application shall be defined by: the maximum vertical static force

per wheelset; the type of service to be provided by the vehicles that will be fitted with the wheels to be approved: description of the lines: geometric quality of the tracks, curve parameters, maximum speeds . ; running times on these lines; the calculated service life of the wheel, in kilometres. SIST EN 13979-1:2004+A1:2009

5 Assessment of the geometrical interchangeability The wheel design shall conform to the requirements of 3.1. 6 Assessment of the thermomechanical behaviour 6.1 General procedure This assessment may comprise three stages. The transition from one stage to the next depends on the results obtained. The flowchart for this assessment is shown in normative annexe A. For each of the three stages, the test shall be carried out on a new rim (nominal tread diameter) and a worn rim (wear limit tread diameter). SIST EN 13979-1:2004+A1:2009

N/mm2 as the average of the three measurements; σiw ≤ + (Σr + 50) N/mm2 for each of the measurements; maximum lateral displacement of the rim after cooling: + 1,5 /- 0,5 mm The value of Σr shall be defined according to the criteria of the wheel rim steel grade. For grades ER6 and ER7 of !EN 13262", Σr = 200 N/mm2. The lateral displacement is positive if the distance between the two inner faces of the wheel of the wheelset increases. For domestic traffic, if the track tolerances differ from the general tolerances used in Europe, other values of lateral displacement may be agreed between the parties concerned 7 Assessment of the mechanical behaviour 7.1 General procedure This assessment may comprise two stages. The second stage is carried out depending on the results of the first stage. The purpose of this assessment is to ensure that there will be no risk of fatigue cracking either in the wheel web or in its connections with the hub or the rim during the service life of the wheel. Both for the calculation and the test, the wheel geometry shall the least favourable with regard to the mechanical behaviour. If that is not the case for the test, the test parameters shall be corrected by the calculation. The flowchart for this assessment is shown in normative annex B. 7.2 First stage - Calculation 7.2.1 Applied forces Conventional forces shall be used. They are calculated on the basis of the value of load P. Load P is defined in EN 13103. It is half the vertical force per wheelset on the rail. On the basis of the parameters necessary for the mechanical assessment defined in 3.3, additional forces shall be used if these parameters generate greater forces (for example,. tilting trains, curve parameters, frozen track, etc…). Three load cases shall be considered (see Figure 1): Case 1:

straight track (centred wheelset)

Fz = 1,25 P

Fy1 = 0 Case 2: curve (flange pressed against the rail)

Fz = 1,25 P SIST EN 13979-1:2004+A1:2009

Fy2 = 0,6 P for non-guiding wheelsets

Fy2 = 0,7 P for guiding wheelsets Case 3:

negotiation of points and crossings (inside surface of flange applied to the rail)

Fz = 1,25 P

Fy3 = 0,6 Fy2 = 0,36 P for non-guiding wheelsets

Fy3 = 0,6 Fy2 = 0,42 P for guiding wheelsets Figure 1 shows, for the general case, the application points of the different forces. Dimensions in millimetres

Key 1 Straight track 2 Curve 3 Negotiation of points and crossings Figure 1 — Application points of the different forces 7.2.2 Calculation procedure A finite element calculation code shall be used to determine the stresses. The validity of the code shall be proven and the choice of parameters having a critical influence on the results shall be justified.

Informative annexe C gives one method of demonstrating this. The stresses shall be analysed as follows: determination of the principal stresses at all points in the mesh (nodes) for each of the three load cases; assessment, for each node, of the maximum principal stress for the three load cases (σmax) and of the direction of this principal stress; SIST EN 13979-1:2004+A1:2009

1) Numerical calculations using the TWINS model developed at ERRI have been validated. 2) This procedure has been validated by ERRI [2], [3] and the model has been simplified for the specific requirements of the test for the technical approval. SIST EN 13979-1:2004+A1:2009

Assessment of the thermomechanical behaviour A.1 Assessment organigram

Braking bench test

Lateral displacement

conforms to 6.2.2 ? Residual stresses conform to 6.2.2 ?

Residual stresses conform to 6.2.2 ?

Wheel fracture bench testWheel rejectedFracture?Field braking test

Lateral displacement conforms to 6.4.3 ? Residual stresses conform to 6.4.3 ?

Wheel accepted YES NO YES NO YES YES NO NO

10 mm between the extern

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...