SIST EN 12976-2:2019

(Main)Thermal solar systems and components - Factory made systems - Part 2: Test methods

Thermal solar systems and components - Factory made systems - Part 2: Test methods

This document specifies test methods for validating the requirements for Factory Made Thermal Solar Heating Systems as specified in EN 12976-1. The document also includes two test methods for thermal performance characterization by means of whole system testing.

Thermische Solaranlagen und ihre Bauteile - Vorgefertigte Anlagen - Teil 2: Prüfverfahren

Dieses Dokument legt Verfahren für die Prüfung der Erfüllung der Anforderungen für vorgefertigte thermische Solaranlagen fest, wie sie in EN 12976 1 angegeben sind. Dieses Dokument enthält auch zwei Prüfverfahren zur Charakterisierung der thermischen Leistungsfähigkeit durch Prüfung der Gesamtanlage.

Installations solaires thermiques et leurs composants - Installations préfabriquées en usine - Partie 2 : Méthodes d'essai

Le présent document spécifie des méthodes d’essai permettant de valider les exigences applicables aux installations de chauffage solaire thermique préfabriquées en usine, telles que spécifiées dans le EN 12976-1. Le document comprend également deux méthodes d’essai pour la caractérisation des performances thermiques de l’installation dans son ensemble.

Toplotni sončni sistemi in sestavni deli - Industrijsko izdelani sistemi - 2. del: Preskusne metode

Ta evropski standard določa preskusne metode za preverjanje zahtev za industrijsko izdelane sončne ogrevalne sisteme, kot je določeno v standardu EN 12976-1. Standard vključuje tudi dve preskusni metodi za opredelitev toplotne učinkovitosti s pomočjo preskušanja sistema.

General Information

- Status

- Published

- Publication Date

- 10-Jun-2019

- Technical Committee

- TOP - Thermal insulation

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 04-Jun-2019

- Due Date

- 09-Aug-2019

- Completion Date

- 11-Jun-2019

Relations

- Effective Date

- 01-Jul-2019

Overview

SIST EN 12976-2:2019 - "Thermal solar systems and components - Factory made systems - Part 2: Test methods" - defines the laboratory and whole‑system test methods used to validate the requirements set out in EN 12976-1 for factory‑made solar heating systems. Published by CEN and adopted by SIST, this part focuses on proving safety, durability and thermal performance of complete, ready‑to‑install solar thermal kits (factory made systems), and includes tests that support regulatory reporting and energy‑labelling (ErP) requirements.

Key topics and technical requirements

The standard sets out standardized test methods and reporting formats for a broad set of technical areas, including:

- Freeze resistance - procedures for systems using antifreeze, drain‑back and drain‑down principles, and combined freeze‑protection/control functions.

- Over‑temperature protection - test apparatus, procedures and reporting to verify safe operation under high‑temperature conditions.

- Pressure resistance - pressure test procedures, safety precautions and reporting requirements.

- Water contamination - assessment methods related to drinking water quality where applicable.

- Mechanical load testing - design of mechanical load tests, calculation procedures and reporting to verify structural resistance (wind, snow, etc.).

- Lightning protection and electrical safety - assessment and test guidance for protection against lightning and electrical hazards.

- Safety equipment - testing of safety valves, expansion and blow‑off lines.

- Labelling and documentation - required data presentation, including a normative thermal performance presentation sheet (Annex A) and harmonized reporting formats for EU Regulations (Annex G).

- Thermal performance characterization - whole‑system testing methods and procedures for predicting yearly performance indicators and system ability to meet domestic hot water (DHW) loads.

- Ability to cover load - methods (testing and simulation) to determine how well solar‑plus‑supplementary systems meet daily and maximum loads.

The standard also contains informative and normative annexes addressing reference conditions for performance prediction, ageing tests, lightning test protocols, and relationships to EU energy‑labelling and ecodesign regulations (Regulations (EU) No 811/2013, 812/2013 and 814/2013).

Applications and users

SIST EN 12976-2:2019 is used by:

- Manufacturers of factory‑made solar thermal systems for product development, type testing and demonstrating compliance.

- Accredited test laboratories executing the standardized methods for certification and performance claims.

- Certification and conformity assessment bodies assessing CE marking, ErP energy‑labelling and national approvals.

- Specifiers, consultants and installers who need validated performance data for system selection and design.

- Regulators and procurement teams referencing harmonized test results for public tenders or compliance checks.

Practical uses include type testing, durability verification, performance prediction for annual energy yield, documentation for energy labelling, and evidence for compliance with EU ecodesign and labelling rules.

Related standards

- EN 12976-1: General requirements for factory made solar heating systems

- EN 12977 series: Test methods and requirements for custom‑built solar systems (EN 12977-1 to -5)

Keywords: SIST EN 12976-2:2019, thermal solar systems, factory made systems, test methods, solar heating systems, thermal performance characterization, freeze resistance, mechanical load testing, ErP, energy labelling, EU regulations.

Frequently Asked Questions

SIST EN 12976-2:2019 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Thermal solar systems and components - Factory made systems - Part 2: Test methods". This standard covers: This document specifies test methods for validating the requirements for Factory Made Thermal Solar Heating Systems as specified in EN 12976-1. The document also includes two test methods for thermal performance characterization by means of whole system testing.

This document specifies test methods for validating the requirements for Factory Made Thermal Solar Heating Systems as specified in EN 12976-1. The document also includes two test methods for thermal performance characterization by means of whole system testing.

SIST EN 12976-2:2019 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 12976-2:2019 has the following relationships with other standards: It is inter standard links to SIST EN 12976-2:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 12976-2:2019 is associated with the following European legislation: EU Directives/Regulations: 811/2013, 812/2013, 814/2013, TRRTP126; Standardization Mandates: M/534, M/535. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 12976-2:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2019

Nadomešča:

SIST EN 12976-2:2017

Toplotni sončni sistemi in sestavni deli - Industrijsko izdelani sistemi - 2. del:

Preskusne metode

Thermal solar systems and components - Factory made systems - Part 2: Test methods

Thermische Solaranlagen und ihre Bauteile - Vorgefertigte Anlagen - Teil 2:

Prüfverfahren

Installations solaires thermiques et leurs composants - Installations préfabriquées en

usine - Partie 2 : Méthodes d'essai

Ta slovenski standard je istoveten z: EN 12976-2:2019

ICS:

27.160 Sončna energija Solar energy engineering

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12976-2

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2019

EUROPÄISCHE NORM

ICS 27.160 Supersedes EN 12976-2:2017

English Version

Thermal solar systems and components - Factory made

systems - Part 2: Test methods

Installations solaires thermiques et leurs composants - Thermische Solaranlagen und ihre Bauteile -

Installations préfabriquées en usine - Partie 2 : Vorgefertigte Anlagen - Teil 2: Prüfverfahren

Méthodes d'essai

This European Standard was approved by CEN on 30 December 2018.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12976-2:2019 E

worldwide for CEN national Members.

EN 12976-2 2019 (E)

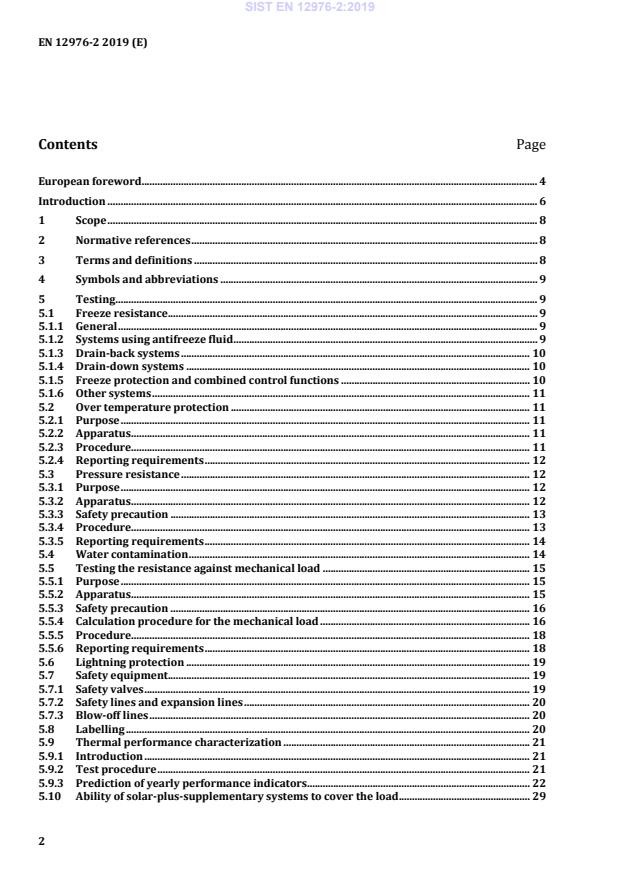

Contents Page

European foreword . 4

Introduction . 6

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 8

4 Symbols and abbreviations . 9

5 Testing . 9

5.1 Freeze resistance . 9

5.1.1 General . 9

5.1.2 Systems using antifreeze fluid . 9

5.1.3 Drain-back systems . 10

5.1.4 Drain-down systems . 10

5.1.5 Freeze protection and combined control functions . 10

5.1.6 Other systems . 11

5.2 Over temperature protection . 11

5.2.1 Purpose . 11

5.2.2 Apparatus . 11

5.2.3 Procedure. 11

5.2.4 Reporting requirements . 12

5.3 Pressure resistance . 12

5.3.1 Purpose . 12

5.3.2 Apparatus . 12

5.3.3 Safety precaution . 13

5.3.4 Procedure. 13

5.3.5 Reporting requirements . 14

5.4 Water contamination . 14

5.5 Testing the resistance against mechanical load . 15

5.5.1 Purpose . 15

5.5.2 Apparatus . 15

5.5.3 Safety precaution . 16

5.5.4 Calculation procedure for the mechanical load . 16

5.5.5 Procedure. 18

5.5.6 Reporting requirements . 18

5.6 Lightning protection . 19

5.7 Safety equipment. 19

5.7.1 Safety valves . 19

5.7.2 Safety lines and expansion lines . 20

5.7.3 Blow-off lines . 20

5.8 Labelling . 20

5.9 Thermal performance characterization . 21

5.9.1 Introduction . 21

5.9.2 Test procedure . 21

5.9.3 Prediction of yearly performance indicators . 22

5.10 Ability of solar-plus-supplementary systems to cover the load . 29

5.10.1 General . 29

5.10.2 Boundary conditions for auxiliary heating . 30

5.10.3 Boundary conditions for daily load . 30

5.10.4 Determination of the ability to cover the maximum daily load by means of testing

the system. 31

5.10.5 Determination of the ability to cover the maximum daily load by means of numerical

simulations. 31

5.10.6 Determination of the ability to cover the daily load defined by the European load

profiles by means of numerical simulations . 31

5.10.7 Requirements for mixed water at 40 °C . 32

5.11 Reverse flow protection . 33

5.12 Electrical safety . 33

Annex A (normative) Thermal performance presentation sheet. 34

Annex B (normative) Reference conditions for performance prediction . 36

Annex C (informative) Assessment of the ability of solar DHW systems to resist the extreme

climatic conditions . 45

Annex D (informative) Ageing test for thermostatic valves . 54

Annex E (informative) Lightning protection test for solar heating systems . 57

Annex F (informative) Lightning Protection testing sheet . 60

Annex G (normative) Reporting format in the framework of the EU Regulations CDR 811,

812 and 814 dated 2013 . 64

Annex ZA (informative) Relationship between this European Standard and the energy

labelling requirements of Commission Delegated Regulation (EU) No 811/2013

aimed to be covered . 65

Annex ZB (informative) Relationship between this European Standard and the energy

labelling requirements of Commission Delegated Regulation (EU) No 812/2013

aimed to be covered . 67

Annex ZC (informative) Relationship between this European Standard and the ecodesign

requirements of Commission Regulation (EU) No 814/2013 aimed to be covered . 70

Bibliography . 72

EN 12976-2 2019 (E)

European foreword

This document (EN 12976-2:2019) has been prepared by Technical Committee CEN/TC 312 “Thermal

solar systems and components”, the secretariat of which is held by ELOT.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by September 2019, and conflicting national standards

shall be withdrawn at the latest by September 2019.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12976-2:2017.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annexes ZA, ZB or ZC, which are an integral part

of this document.

Most significant changes in EN 12976-1:2019 and EN 12976-2:2019 since the 2017 editions of both

parts:

The first edition of the EN 12976 series was published in 2000. The standard series provided an

important basis for the assessment of the performance as well as the reliability and durability of

Factory made solar thermal systems. In the past 15 years or so, several important technological

developments and changes of the framework conditions, such as e.g. the aspect of requiring “Energy

Labelling”, the EN 12976 series underwent several important changes.

The following modifications are the most important ones that have been implemented in this new

edition of EN 12976-2:

— beside few editorial changes, more clarification with respect to testing requirements of reverse

flow protection (Clause 5.11) and mechanical load testing (Clause 5.5).

— confusion about different Qref values in Table B.5 has been solved by using the complete equation

for the annual loads. Finally, there should only be one Qref value.

— main changes related to ErP and the new mechanical load test;

— Annex ZA (new): harmonisation with Regulation (EC) No 811/2013;

— Annex ZB (new): harmonisation with Regulation (EC) No 812/2013:

— Annex ZC (new): harmonisation with Regulation (EC) No 814/2013.

It is worth to notice that, based on these changes and developments, the need for the elaboration of a

future strategy of the structure of the EN 12976 series is foreseen.

EN 12976, Thermal solar systems and components — Factory made systems, is currently composed with

the following parts:

— Part 1: General requirements;

— Part 2: Test methods.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

EN 12976-2 2019 (E)

Introduction

Drinking water quality:

In respect of potential adverse effects on the quality of water intended for human consumption, caused

by the product covered by this document:

a) this standard provides no information as to whether the product may be used without restriction in

any of the Member States of the EU or EFTA;

b) it should be noted that, while awaiting the adoption of verifiable European criteria, existing

national regulations concerning the use and/or the characteristics of this product remain in force.

Factory Made and Custom Built solar heating systems:

The standards EN 12976-1, EN 12976-2, EN 12977-1, EN 12977-2, EN 12977-3, EN 12977-4 and

EN 12977-5 distinguish two categories of solar heating systems: Factory Made solar heating systems

and Custom Built solar heating systems. The classification of a system as Factory Made or Custom Built

is a choice of the final supplier, in accordance with the following definitions:

Factory Made solar heating systems are batch products with one trade name, sold as complete and

ready to install kits, with fixed configurations. Systems of this category are considered as a single

product and assessed as a whole.

If a Factory Made Solar Heating System is modified by changing its configuration or by changing one or

more of its components, the modified system is considered as a new system for which a new test report

is necessary. Requirements and test methods for Factory Made solar heating systems are given in

EN 12976-1 and EN 12976-2.

Custom Built solar heating systems are either uniquely built, or assembled by choosing from an

assortment of components. Systems of this category are regarded as a set of components. The

components are separately tested and test results are integrated to an assessment of the whole system.

Requirements for Custom Built solar heating systems are given in EN 12977-1; test methods are

specified in EN 12977-2, EN 12977-3, EN 12977-4 and EN 12977-5. Custom Built solar heating systems

are subdivided into two categories:

— Large Custom Built systems are uniquely designed for a specific situation. In general HVAC

engineers, manufacturers or other experts design them.

— Small Custom Built systems offered by a company are described in a so-called assortment file, in

which all components and possible system configurations, marketed by the company, are specified.

Each possible combination of a system configuration with components from the assortment is

considered as one Custom Built system.

Table 1 shows the division for different system types:

Table 1 — Division for factory made and custom built solar heating systems

Factory Made Solar Heating Systems Custom Built Solar Heating Systems

(EN 12976–1 and EN 12976–2) (EN 12977–1, EN 12977–2 and EN 12977–3)

Integrated collector storage systems for domestic Forced-circulation systems for hot water

hot water preparation preparation and/or space heating, assembled

using components and configurations described in

Thermosiphon systems for domestic hot water

an assortment file (mostly small systems)

preparation

Forced-circulation systems as batch product with Uniquely designed and assembled systems for hot

fixed configuration for domestic hot water water preparation and/or space heating (mostly

preparation large systems)

NOTE Forced circulation systems can be classified either as Factory Made or as Custom Built, depending on

the market approach chosen by the final supplier.

Both Factory Made and Custom Built systems are performance tested under the same set of reference

conditions as specified in Annex B of the present standard and EN 12977–2:2018, Annex A. In practice,

the installation conditions may differ from these reference conditions.

A Factory Made System for domestic hot water preparation may have an option for space heating,

however this option should not be used or considered during testing as a Factory Made system.

EN 12976-2 2019 (E)

1 Scope

This document specifies test methods for validating the requirements for Factory Made Thermal Solar

Heating Systems as specified in EN 12976-1. The document also includes two test methods for thermal

performance characterization by means of whole system testing.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1489:2000, Building valves - Pressure safety valves — Tests and requirements

EN 1717:2000, Protection against pollution of potable water in water installations and general

requirements of devices to prevent pollution by backflow

EN ISO 4126-1, Safety devices for protection against excessive pressure — Part 1: Safety valves

(ISO 4126-1)

EN 12976-1:2017, Thermal solar systems and components — Factory made systems — Part 1: General

requirements

EN 12977-2:2018, Thermal solar systems and components — Custom built systems — Part 2: Test

methods for solar water heaters and combisystems

EN 15502-1, Gas-fired heating boilers — Part 1: General requirements and tests

EN ISO 9488:1999, Solar energy — Vocabulary (ISO 9488:1999)

EN ISO 9806:2017, Solar energy — Solar thermal collectors — Test methods (ISO 9806:2017)

ISO 9459-1:1993, Solar heating — Domestic water heating systems — Part 1: Performance rating

procedure using indoor test methods

ISO 9459-2:1995, Solar heating — Domestic water heating systems — Part 2: Outdoor test methods for

system performance characterization and yearly performance prediction of solar-only systems

ISO 9459-5:2007, Solar heating — Domestic water heating systems — Part 5: System performance

characterization by means of whole-system tests and computer simulation

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 9488:1999 and

EN 12976-1:2017 apply.

4 Symbols and abbreviations

Q net auxiliary energy demand of a solar heating system delivered by the auxiliary heater

aux, net

to the store or directly to the distribution system (see 5.9.3.2)

Q heat demand

d

Q energy delivered at the outlet of the solar heating system

L

Q parasitic energy (electricity) for the collector loop pump(s) and control unit

par

H hemispherical solar irradiation in the collector plane

c

Q store heat loss

l

Q heat diverted from the store as active overheating protection, if any

ohp

Q heat delivered by the collector loop to the store

sol

5 Testing

5.1 Freeze resistance

5.1.1 General

The following checks are given to ensure that the protective anti-freezing provisions are operating

properly. There are many possible forms of protective provisions, and the testing authority shall first

identify which method has been employed.

The provision shall then be checked in accordance with the appropriate section of the following list

(see 5.1.2 to 5.1.6) in accordance with the manufacturer’s recommendations.

5.1.2 Systems using antifreeze fluid

The system components which are exposed to low ambient temperature are filled with an antifreeze

fluid usually a glycol/water mixture, having a low enough freezing point. For thermosiphon systems

declared as freeze resistant down to a specific temperature, one possible test procedure described in

AS/NZS 2712 is recommended. This procedure could also be adapted to other systems containing pure

water. So far, electrical heater for freeze protection will not be tested for suitability.

For these systems, no freezing test is performed. However, if no sufficient data are available on the

freezing point of the antifreeze fluid, the freezing point shall be measured and checked against the

minimum system temperature as given by the manufacturer.

NOTE In general, the minimum allowed temperature of the system is equal to the freezing point of the

antifreeze fluid. If the concentration of some antifreeze fluids like glycols - exceeds a certain limit, they can freeze

without damaging the system. In this case the minimum allowed temperature can be lower than the freezing point

of the antifreeze fluid.

Check the freezing point by measuring the glycol concentration (e.g. using a portable refractometer)

before and after the over temperature protection test (5.2). The freezing point shall not differ more

than 2 K from the value recommended by the manufacturer in agreement with the local climate

(minimum expected air temperature, radiative cooling of the collectors).

The composition of the fluid shall be checked to see whether it is in accordance with the manufacturer’s

specifications.

EN 12976-2 2019 (E)

5.1.3 Drain-back systems

When freezing danger occurs, the fluid in the system components that is exposed to low ambient

temperature, is drained into a storage vessel for subsequent reuse.

The collector loop piping should be in accordance with the manufacturer’s recommendations in the

installer manual and if there is no instruction, according to reference conditions given in Annex B.

Filling may be observed from the pressure gauge or from water level indicator. Switch the pump on, and

observe the pressure gauge or water level indicator. If the system does not include a pressure gauge or

level indicator, other means for checking filling provided by the manufacturer shall be used in

accordance with the instruction manual.

Drain-back may be observed from the decreasing reading of the pressure gauge or water level indicator.

Switch the pump OFF, and observe the pressure gauge or water level indicator. If the system does not

include a pressure gauge or level indicator, other means for checking drain-back provided by the

manufacturer shall be used in accordance with the instruction manual.

A system in which components and/or piping are subject to damage by freezing shall have the proper

fittings, pipe slope and collector design to allow for manual gravity draining and air filling of the

affected components and piping. Pipe slope for gravity draining shall be as the manufacturer

recommendation or shall have a minimum 2 cm vertical drop for each meter of horizontal length. This

also applies to any header pipes or absorber plate riser tubes internal to the collector.

5.1.4 Drain-down systems

The fluid in the system components, which are exposed to low ambient temperature, is drained and run

to waste when freezing danger occurs.

To perform checks of the drain-down function the collector loop piping should be in accordance with

the manufacturer’s recommendations in the installer manual and if there is no instruction, according to

reference conditions given in Annex B.

In most cases the systems are equipped with a drain-down valve at the bottom and a vacuum relief

valve at the top of the fluid circuit.

The proper opening and closing of the vacuum relief valve shall be checked during drain-down

operation and after refilling the system.

If there is a solenoid drain valve independent of the control unit, simulate the opening temperature.

If there is a non-electrically operated freeze protection valve, a check can be made using a freezing

spray. The temperature-sensing element shall be sprayed. The measured temperature of the valve

opening shall be compared with the nominal value given by the manufacturer. It is important that the

sensing part of the freeze protection valve be properly placed.

If the system uses an electrically operated freeze-protection valve, drain down shall be checked while

interrupting the power.

The drain-down rate shall be measured (e.g. by using a vessel and a stop-watch) and documented

during drain-down operation.

5.1.5 Freeze protection and combined control functions

For systems where the freeze protection and control functions are combined, the control unit shall be

checked as follows:

Set the simulated temperature of the freeze-protection sensor to a value deactivating the freeze

protection. Decrease the simulated temperature slowly. Measure the temperature T (freeze

FP

protection) of the related actuator. Compare it with the nominal value given by the manufacturer.

5.1.6 Other systems

For all other systems, the pump control system, drain-down valve or any other freeze protection device

or system shall be checked to the manufacturer's specification and the minimum allowed temperature

specified by the manufacturer.

For Integrated Collector-Storage Systems (ICS), or other Solar Domestic Hot Water (SDHW) systems

with the tank placed outside, special frost resistance tests should be carried out, as described in C.1.

5.2 Over temperature protection

5.2.1 Purpose

The purpose of this test is to determine whether the solar water heating system is protected against

damage and the user is protected from scalding hot water delivery after a period of no hot water draw

and failure of electrical power.

5.2.2 Apparatus

The following apparatus is required:

a) a pyranometer having the minimum characteristics specified in EN ISO 9806:2017, 22.1.1.1, to

measure the total short wave radiation from both the sun and the sky or the short wave radiation

from a solar simulator lamp if the test is to be conducted inside a solar simulation chamber;

b) equipment to measure the temperature, flow rate and volume of hot water drawn from the system;

c) an outdoor or an indoor test stand for installing the solar hot water system with the collector array

at the manufacturer's specified tilt angle;

d) a temperature and pressure controlled water supply within the range of 5°C to 25 °C and 200 kPa

to 600 kPa or the manufacturer's maximum working pressure whichever is less.

This test may be conducted using a solar simulator or outdoors.

5.2.3 Procedure

The system, both as described in the installation manual and as installed on the test facility, shall be first

checked on overheating safety, e.g. if safety valves and other overheating protection devices are present

and installed at the right place, if there are no valves between components and relief valves, etc. For

systems containing antifreeze fluids, it shall be checked whether sufficient precautions have been taken

to prevent the antifreeze fluid from deterioration as a result of high temperature conditions

(see also 5.7).

Furthermore, if non-metallic materials are used in any circuit, the highest temperature in the circuit

during the over temperature protection test shall be measured at the main water inlet, for use in the

pressure resistance test.

The procedure of testing shall be as follows:

a) assemble the solar water heating system according to the installation instructions with the

collector array oriented towards solar noon for the outdoor test, or the simulator lamp may be

adjusted to normal incidence for the indoor test;

b) charge the system from the water supply and, for pressurized storage tanks, maintain the water

supply pressure;

c) energize the system as per installation instructions;

EN 12976-2 2019 (E)

d)

1) for the outdoor test, operate the system for three consecutive days without any hot water

withdrawal with a minimal solar irradiation of 20 MJ/m per day and with ambient

temperature higher than 20 °C during solar noon;

i) electric power (if any) in the installation shall be disconnected on the third day;

2) for the indoor test:

i) operate the system without any hot water withdrawal at an ambient temperature of

(25 ± 2) °C and a minimum solar lamp irradiance of 1 000 W/m2 at the plane of the

collector array, measured and with a uniformity as specified in ISO 9459-1:1993, 6.3.1.2

for a 5 h period or until the collector array drains;

ii) disconnect all electrical power to the system and subject the system to a solar lamp

irradiance of 1 000 W/m at the plane of the collector array for an additional 4 h or until

the collector array drains;

e) at the end of sequence d) or immediately after the collector drains, withdraw a volume of water

-4 -5 3

greater than the total volume of water in the system at a rate of (1,66 × 10 ± 1,66 × 10 ) m /s

(10 ± 1) l/min.

5.2.4 Reporting requirements

The following results shall be reported:

a) the make and model identification of the system including ancillary scald and over temperature

protection devices fitted as well as a physical description of how over temperature protection

should work according to the manufacture’s documentation;

b) the inclination of the collector array;

c) a record of temperature of the hot water withdrawn from the system versus time and the total

volume of water withdrawn: note the presence of steam if observed;

d) details of the condition of the system and individual components following the test or any failure

modes during the test with particular regard to any defects which may affect the serviceability of

the system such as the swelling of pipes and components or fluid leakages.

5.3 Pressure resistance

5.3.1 Purpose

The purpose of this test is to evaluate hydraulic pressure rating of all components and interconnections

of a solar water heating system when installed according to the manufacturer's instructions.

5.3.2 Apparatus

The apparatus shall consist of the following:

a) suitable platform and support structure for installation of the system;

b) pressure regulated hydraulic pressure source;

c) pressure gauge suitable to determine the test pressure to within 5 %;

d) bleed valve;

e) isolation valve.

5.3.3 Safety precaution

An explosion safe enclosure is recommended when testing systems that have an integrated expansion

space or tank that contains entrapped air.

5.3.4 Procedure

The system, both as described in the installation manual and as installed on the test facility, shall be first

checked on pressure safety, e.g. if safety valves and other overheating protection devices are present

and installed at the right place, if there are no valves between components and relief valves, etc.

The vessels and tanks already subjected to pressure tests (at least the pressure level required in 5.3.4)

may be disconnected from the system (only the vessel may be disconnected, the connecting piping shall

not be removed).

The duration of the test is 15 min. If a non-metallic material is used in any circuit, this procedure shall

be applied after performing the “Over temperature protection” test (see 5.2).

a) Install the solar water heating system on the test platform in accordance with the manufacturer's

instructions.

b) Disable the pressure relief valves, if applicable, to prevent their opening during testing.

c) Connect the isolation valves to the (lower) fill ports of each circuit of the system.

d) Fill all circuits in the order described in the manufacturer’s installer manual using the required

fluid for each circuit. If no information about the fill procedure is provided in the manual, the inner

circuits should be filled first. After filling the upper port of each circuit should remain open to

provide pressure balance with the ambient pressure.

e) Perform the pressure tests of the circuits of the system in the same order as they shall be

pressurized (or installed) according to the manufacturer’s installer manual. If no installation order

is given by the manufacturer, perform the pressure tests of the internal heat transfer loops (and

other internal vessels) first.

f) For testing of each independent loop follow the steps listed below:

1) connect the bleed valve and pressure gauge to the (upper) drain port of the heat transfer loop;

2) connect the hydraulic pressure source to the fill port of the tested heat transfer circuit;

3) bleed all air, as far as possible, out of the loop through the bleed valve at the drain port;

4) apply a hydraulic pressure equal to 1,5 times the manufacturer's stated maximum individual

working pressures;

5) isolate the pressure source by closing the isolation valve and record the readings of the

pressure gauge at the beginning and end of the next 15 min interval;

EN 12976-2 2019 (E)

6) release the pressure through the bleed valve and record any visible permanent deformation

and heat transfer fluid leakage from system components and interconnections;

7) disconnect the hydraulic pressure source from the fill port, the bleed valve and pressure gauge

from the drain port and leave the circuit filled and opened at the ambient pressure;

8) repeat the steps 1) - 7) until all circuits have been tested.

g) Empty all circuits in the reversed fill order or according to emptying instructions contained in the

manufacturer’s installer manual, if present.

h) Disconnect all isolation valves from the system.

5.3.5 Reporting requirements

Report the maximum test pressures applied, the pressure readings at the beginning and end of the

15 min test intervals and any visible permanent deformation or leakage from system components and

interconnections. If the applied test pressures are lower than 1,5 times, note the manufacturer's stated

maximum working pressure.

The test may be considered as passed if the pressure drop during the test period does not exceed more

than 5 % of the test pressure.

5.4 Water contamination

Check if the documentation for the installer includes instructions for the installation of the adequate

means for preventing backflow from all circuits to drinking main supplies.

A method for analysing the risks in the use point and election of the suitable protection is described in

EN 1717.

According to EN 1717:2000, Table B.1, antifreeze protection is fluid category 3.

Secondary circuit or consumer loop: The working domestic hot water (DHW).

According to EN 1717:2000, Table B.1, DHW is fluid category 2.

Category 1 Water to be used for human consumption coming directly from a potable water

distribution system.

Category 2 Fluid presenting no human health hazard. Fluid recognized as being fit for human

consumption including water taken from a potable water distribution system, which can

have undergone a change in taste, odour, colour or a temperature change (heating or

cooling).

Category 3 Fluid representing some human health hazard due to the presence of one or more

harmful substances.

Category 4 Fluid representing a human health hazard due to the presence of one or more toxic or

very toxic substances or one or more radioactive, mutagenic or carcinogenic substances.

Category 5 Fluid presenting a human health hazard due to the presence of microbiological or viral

elements. The final outcome is the list containing the fluid category of each loop.

Step1 Determination of the fluid categories that could be in contact with potable water. First of

all determine the number of hydraulic circuits to protect in the factory made system.

Primary circuit or collector loop: The working fluid can be water with antifreeze

protection.

Step 2 Check the separation between collector loop and consumer loop. Check that the

separation between collector and consumer loop of the solar thermal system according to

the fluid category is at least a wall. Category 2 and 3 fluids may be separated from potable

water by a single wall, while a single wall is not sufficient for category 4 and 5 fluids. A

double wall with a safety medium in between (liquid or gas) and an acoustical or visual

alarm system is required when the fluid from which the potable water shall be protected

against is of category 4 or 5.

Step 3 Air opening for drain. Check that the factory made system have open air outlets before

draining to the building drain system. Outcome: TRUE/FALSE.

Step 4 Installation features. Check the pressure on the connection point between the system and

the mains water network.

P = 1 013,25 hPa

P > 1 013,25 hPa

Step 5 Determination of the protection units for the mains water network connection point

suitable for the fluid category.

Conclusion

According to EN 1717:2000, Table 2, usually for factory made systems with DHW in the consumer loop

it is enough to check that there is at least a reverse flow protection valve.

Outcome: reverse flow protection valve present? TRUE/FALSE

5.5 Testing the resistance against mechanical load

5.5.1 Purpose

This test is used to evaluate the carrying capacity of a (thermosiphon) system due to snow and wind

loads. The following procedure is for systems comprising a rack with a tilt angle where either the

collector is separable or not separable from the tank. In both cases, the whole system shall undergo a

mechanical load test, not only for systems with not separable collectors as described in

EN 12976-1:2017, 4.3.1. The mechanical load test with positive pressure (intended to assess the extent

to which the transparent cover of the collector, the collector box and the fixings are able to resist the

positive pressure load due to the effect of wind and snow) and with negative pressure (intended to

assess the deformation and the extent to which the collector box and the fixings between the collector

cover, collector box and collector mounting are able to resist uplift forces caused by the wind) needs to

be performed adopting the procedure according to EN ISO 9806:2017, Clause 16. Please note that only

the positive pressure test is performed as described in the remainder clause. The negative pressure (lift

of) test is already performed on the collector according to EN ISO 9806.

5.5.2 Apparatus

5.5.2.1 Plane surface to put the system on.

5.5.2.2 Load units (Sand sacks, stone plates…).

5.5.2.3 Measuring tape.

5.5.2.4 Stop watch.

5.5.2.5 Camera.

5.5.2.6 Straps for keeping single weights in position.

EN 12976-2 2019 (E)

5.5.3 Safety precaution

— Safety glasses;

— safety shoes;

— gloves;

— long sleeved clothing and cap.

5.5.4 Calculation procedure for the mechanical load

The requested pressure on the system is charged with load units (sand sacks, stone plates…) and should

be raised in 250 Pa steps until 1 000 Pa. To determine these four weights classes, to charge the system

with, first of all the system area Asys needs to be calculated.

a) Side view b) Front view

Figure 1 — Dimensions of the system to be measured

A = AT + A – A

sys brutt x

where

A = bt *d

T

where

A = area tank

T

bt = width tank

d = diameter

A = l*b

brutt

where

A = gross collector area

brutt

l = length of collector/ length mounting device

b = width collector/ width mounting device

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...