SIST EN 17140:2021

(Main)Thermal insulation products for buildings - Factory made Vacuum Insulation Panels (VIP) - Specification

Thermal insulation products for buildings - Factory made Vacuum Insulation Panels (VIP) - Specification

This document specifies characteristics of factory-made vacuum insulation panels (VIP) intended to be used for the thermal insulation of buildings.

This document is applicable for all types of factory-made vacuum insulation panels (VIP), independent of the core material (see 3.1.10) or type of envelope (see 3.1.11).

This document is applicable for factory-made vacuum insulation panels (VIP) with or without desiccants (see 3.1.12) and with and without evacuation valve (3.1.14).

The products covered by this document can be used in roofs, walls, ceilings and floors.

This document specifies procedures for assessment and verification of constancy of performance (AVCP) of characteristics of factory-made vacuum insulation panels (VIP).

This document does not cover products:

- intended to be used for the thermal insulation of building equipment and industrial installations;

- intended to be used for civil engineering works;

- intended to be used as perimeter or foundation;

- with a thermal resistance RD lower than 0,5 m2⋅K/W;

- that contain getters (3.1.13);

- that have protective layers (3.1.9).

Wärmedämmstoffe für Gebäude - Werksmäßig hergestellte Vakuumisolationspanele (VIP) - Spezifikation

Dieses Dokument legt die Merkmale für werksmäßig hergestellte Vakuumisolationspaneele (VIP) fest, die für die Wärmedämmung von Gebäuden verwendet werden.

Dieses Dokument gilt für alle Arten von werksmäßig hergestellten Vakuumisolationspaneelen (VIP), unabhängig vom Kernmaterial (siehe 3.1.10) oder der Art der Hülle (siehe 3.1.11).

Dieses Dokument gilt für werksmäßig hergestellte Vakuumisolationspaneele (VIP) mit oder ohne Trocknungsmittel (siehe 3.1.12) und mit oder ohne Evakuierungsventil (3.1.14).

Die von diesem Dokument abgedeckten Produkte können in Dächern, Wänden, Decken und Böden verwendet werden.

Dieses Dokument legt Verfahren zur Bewertung und Überprüfung der Leistungsbeständigkeit (AVCP) von Merkmalen von werksmäßig hergestellten Vakuumisolationspaneelen (VIP) fest.

Dieses Dokument gilt nicht für Produkte

- die für die Wärmedämmung von Haustechnik und Betriebsanlagen vorgesehen sind,

- die für die Verwendung in Hoch- und Tiefbauten vorgesehen sind,

- die als Einfassung oder Fundament verwendet werden sollen,

- die einen niedrigeren Wärmedurchlasswiderstand als 0,5 m2⋅K/W aufweisen,

- die Getter (3.1.13) enthalten, und

- die mit Schutzschichten (3.1.9) versehen sind.

Produits isolants thermiques pour le bâtiment - Panneaux Isolants sous Vide produits de façon industrielle (VIP) - Spécification

Le présent document définit les caractéristiques pour les panneaux isolants sous vide (VIP) produits de façon industrielle, qui sont utilisés pour l’isolation thermique des bâtiments.

Le présent document est applicable à tous les types de panneaux isolants sous vide (VIP) produits de façon industrielle, indépendamment du matériau du coeur (voir 3.1.10) ou du type d’enveloppe (voir 3.1.11).

Le présent document s'applique aux panneaux isolants sous vide (VIP) produits de façon industrielle, avec ou sans dessicant (voir 3.1.12) et avec ou sans soupape d’évacuation (3.1.14).

Les produits couverts par le présent document peuvent être utilisés dans le cadre de travaux sur des toitures, murs, plafonds et sols.

Le présent document définit le mode opératoire à suivre pour l’évaluation et la vérification de la constance des performances (EVCP) des caractéristiques des panneaux isolants sous vide (VIP) produits de façon industrielle.

Le présent document ne couvre pas les produits :

- conçus pour être utilisés pour l’isolation de l’équipement du bâtiment et des installations industrielles ;

- conçus pour être utilisés dans le cadre de travaux de génie civil ;

- conçus pour être utilisés en tant que périmètre ou fondation ;

- dont la résistance thermique RD est inférieure à 0,5 m2 K/W ;

- qui contiennent des sorbeurs (3.1.13) ;

- qui disposent de couches de protection (3.1.9).

Toplotnoizolacijski proizvodi za stavbe - Industrijsko izdelani vakuumski izolacijski paneli (VIP) - Specifikacija

General Information

- Status

- Published

- Public Enquiry End Date

- 19-Sep-2017

- Publication Date

- 06-Dec-2020

- Technical Committee

- TOP - Thermal insulation

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 17-Nov-2020

- Due Date

- 22-Jan-2021

- Completion Date

- 07-Dec-2020

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 26-May-2021

Overview

SIST EN 17140:2021 (EN 17140:2020) specifies the characteristics, testing and assessment procedures for factory-made Vacuum Insulation Panels (VIP) used for the thermal insulation of buildings. The standard applies to all types of factory-made VIPs regardless of core material or envelope type and covers panels with or without desiccants and with or without evacuation valves. VIPs covered by this standard are intended for use in roofs, walls, ceilings and floors. The standard also defines procedures for Assessment and Verification of Constancy of Performance (AVCP).

SIST EN 17140 excludes VIPs intended for building services or industrial installations, civil engineering works, perimeter/foundation use, products with thermal resistance R < 0.5 m2·K/W, products containing getters, and those with protective layers.

Key topics and technical requirements

- Scope and definitions - Clear definitions for VIP, core material, envelope, desiccant, inner pressure, edge effect and centre of panel (COP).

- Performance characteristics - Requirements and assessment methods for:

- Thermal resistance and thermal conductivity, including expressed and aged values and edge-effect considerations.

- Mechanical properties such as compressive strength, tensile/flexural strength and deformation/creep.

- Durability aspects and factory production control (FPC).

- Reaction to fire and propensity to undergo continuous smouldering.

- Release of volatile organic compounds (VOCs) and emissions testing.

- Inner pressure measurement and envelope barrier performance.

- Test methods and annexes - Normative annexes provide detailed procedures for determining aged thermal values, measuring inner pressure, barrier performance, desiccant service life, and FPC requirements.

- Assessment & AVCP - Procedures for assessing product performance and verification of constancy of performance per regulatory frameworks.

Practical applications

- Use in high-performance thermal envelopes where space is limited (thin-profile insulation for retrofit or new-build).

- Ideal for renovation projects, façades, floors and roofs requiring very low thermal conductivity materials.

- Enables designers and builders to meet stringent energy performance and retrofit targets without large increases in wall or roof thickness.

Who should use this standard

- Manufacturers of factory-made VIPs (design, production control, product declaration).

- Test laboratories and certification bodies conducting AVCP and FPC.

- Architects, specifiers and façade engineers selecting high-performance insulation solutions.

- Regulators and product assessors verifying compliance with Construction Products Regulation (CPR) and national implementations.

Related standards (examples)

- EN 12667, EN 12664 (thermal testing)

- EN 13501‑1 (fire classification)

- EN 16516 (emissions / VOCs)

- EN ISO 10211 (thermal bridges)

Keywords: EN 17140, SIST EN 17140:2021, vacuum insulation panels, VIP, thermal insulation, factory-made VIP, AVCP, thermal resistance, inner pressure, desiccant.

Frequently Asked Questions

SIST EN 17140:2021 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Thermal insulation products for buildings - Factory made Vacuum Insulation Panels (VIP) - Specification". This standard covers: This document specifies characteristics of factory-made vacuum insulation panels (VIP) intended to be used for the thermal insulation of buildings. This document is applicable for all types of factory-made vacuum insulation panels (VIP), independent of the core material (see 3.1.10) or type of envelope (see 3.1.11). This document is applicable for factory-made vacuum insulation panels (VIP) with or without desiccants (see 3.1.12) and with and without evacuation valve (3.1.14). The products covered by this document can be used in roofs, walls, ceilings and floors. This document specifies procedures for assessment and verification of constancy of performance (AVCP) of characteristics of factory-made vacuum insulation panels (VIP). This document does not cover products: - intended to be used for the thermal insulation of building equipment and industrial installations; - intended to be used for civil engineering works; - intended to be used as perimeter or foundation; - with a thermal resistance RD lower than 0,5 m2⋅K/W; - that contain getters (3.1.13); - that have protective layers (3.1.9).

This document specifies characteristics of factory-made vacuum insulation panels (VIP) intended to be used for the thermal insulation of buildings. This document is applicable for all types of factory-made vacuum insulation panels (VIP), independent of the core material (see 3.1.10) or type of envelope (see 3.1.11). This document is applicable for factory-made vacuum insulation panels (VIP) with or without desiccants (see 3.1.12) and with and without evacuation valve (3.1.14). The products covered by this document can be used in roofs, walls, ceilings and floors. This document specifies procedures for assessment and verification of constancy of performance (AVCP) of characteristics of factory-made vacuum insulation panels (VIP). This document does not cover products: - intended to be used for the thermal insulation of building equipment and industrial installations; - intended to be used for civil engineering works; - intended to be used as perimeter or foundation; - with a thermal resistance RD lower than 0,5 m2⋅K/W; - that contain getters (3.1.13); - that have protective layers (3.1.9).

SIST EN 17140:2021 is classified under the following ICS (International Classification for Standards) categories: 91.100.60 - Thermal and sound insulating materials. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 17140:2021 has the following relationships with other standards: It is inter standard links to oSIST prEN 17140:2021, oSIST prEN 17140:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 17140:2021 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/103. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 17140:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2021

Toplotnoizolacijski proizvodi za stavbe - Industrijsko izdelani vakuumski

izolacijski paneli (VIP) - Specifikacija

Thermal insulation products for buildings - Factory made Vacuum Insulation Panels (VIP)

- Specification

Wärmedämmstoffe für Gebäude - Werksmäßig hergestellte Vakuumisolationspanele

(VIP) - Spezifikation

Produits isolants thermiques pour le bâtiment - Panneaux Isolants sous Vide produits de

façon industrielle (VIP) - Spécification

Ta slovenski standard je istoveten z: EN 17140:2020

ICS:

91.100.60 Materiali za toplotno in Thermal and sound insulating

zvočno izolacijo materials

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17140

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2020

EUROPÄISCHE NORM

ICS 91.100.60

English Version

Thermal insulation products for buildings - Factory-made

vacuum insulation panels (VIP) - Specification

Produits isolants thermiques pour le bâtiment - Wärmedämmstoffe für Gebäude - Werksmäßig

Panneaux Isolants sous Vide produits de façon hergestellte Vakuumisolationspaneele (VIP) -

industrielle (PIV) - Spécification Spezifikation

This European Standard was approved by CEN on 1 September 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17140:2020 E

worldwide for CEN national Members.

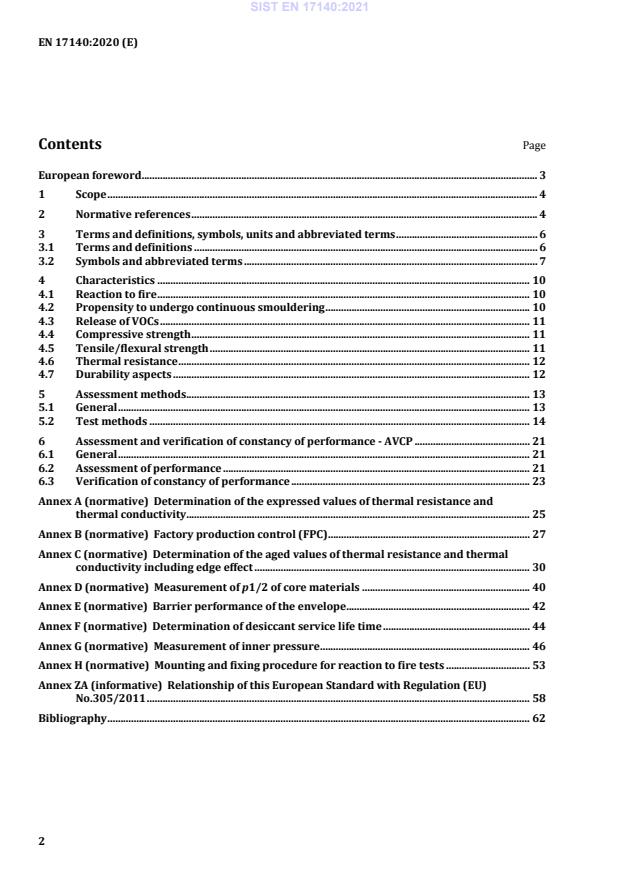

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms and definitions, symbols, units and abbreviated terms . 6

3.1 Terms and definitions . 6

3.2 Symbols and abbreviated terms . 7

4 Characteristics . 10

4.1 Reaction to fire . 10

4.2 Propensity to undergo continuous smouldering . 10

4.3 Release of VOCs . 11

4.4 Compressive strength . 11

4.5 Tensile/flexural strength . 11

4.6 Thermal resistance . 12

4.7 Durability aspects . 12

5 Assessment methods . 13

5.1 General . 13

5.2 Test methods . 14

6 Assessment and verification of constancy of performance - AVCP . 21

6.1 General . 21

6.2 Assessment of performance . 21

6.3 Verification of constancy of performance . 23

Annex A (normative) Determination of the expressed values of thermal resistance and

thermal conductivity . 25

Annex B (normative) Factory production control (FPC) . 27

Annex C (normative) Determination of the aged values of thermal resistance and thermal

conductivity including edge effect . 30

Annex D (normative) Measurement of p1/2 of core materials . 40

Annex E (normative) Barrier performance of the envelope . 42

Annex F (normative) Determination of desiccant service life time . 44

Annex G (normative) Measurement of inner pressure . 46

Annex H (normative) Mounting and fixing procedure for reaction to fire tests . 53

Annex ZA (informative) Relationship of this European Standard with Regulation (EU)

No.305/2011 . 58

Bibliography . 62

European foreword

This document (EN 17140:2020) has been prepared by Technical Committee CEN/TC 88 “Thermal

insulating materials and products”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2021, and conflicting national standards shall be

withdrawn at the latest by July 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a standardization request given to CEN by the European

Commission and the European Free Trade Association.

For relationship with (EU) Regulation 305/2011, see informative Annex ZA, which is an integral part of

this document.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

This document specifies characteristics of factory-made vacuum insulation panels (VIP) intended to be

used for the thermal insulation of buildings.

This document is applicable for all types of factory-made vacuum insulation panels (VIP), independent

of the core material (see 3.1.10) or type of envelope (see 3.1.11).

This document is applicable for factory-made vacuum insulation panels (VIP) with or without

desiccants (see 3.1.12) and with and without evacuation valve (3.1.14).

The products covered by this document can be used in roofs, walls, ceilings and floors.

This document specifies procedures for assessment and verification of constancy of performance

(AVCP) of characteristics of factory-made vacuum insulation panels (VIP).

This document does not cover products:

— intended to be used for the thermal insulation of building equipment and industrial installations;

— intended to be used for civil engineering works;

— intended to be used as perimeter or foundation;

— with a thermal resistance R lower than 0,5 m ⋅K/W;

D

— that contain getters (3.1.13);

— that have protective layers (3.1.9).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 822:2013, Thermal insulating products for building applications — Determination of length and width

EN 823:2013, Thermal insulating products for building applications — Determination of thickness

EN 824:2013, Thermal insulating products for building applications — Determination of squareness

EN 825:2013, Thermal insulating products for building applications — Determination of flatness

EN 826:2013, Thermal insulating products for building applications — Determination of compression

behaviour

EN 1604:2013, Thermal insulating products for building applications — Determination of dimensional

stability under specified temperature and humidity conditions

EN 1605:2013, Thermal insulating products for building applications — Determination of deformation

under specified compressive load and temperature conditions

EN 1606:2013, Thermal insulating products for building applications — Determination of compressive

creep

EN 1607:2013, Thermal insulating products for building applications — Determination of tensile strength

perpendicular to faces

EN 12090:2013, Thermal insulating products for building applications — Determination of shear

behaviour

EN 12664:2001, Thermal performance of building materials and products — Determination of thermal

resistance by means of guarded hot plate and heat flow meter methods — Dry and moist products of

medium and low thermal resistance

EN 12667:2001, Thermal performance of building materials and products — Determination of thermal

resistance by means of guarded hot plate and heat flow meter methods — Products of high and medium

thermal resistance

EN 13238:2010, Reaction to fire tests for building products — Conditioning procedures and general rules

for selection of substrates

EN 13501-1:2018, Fire classification of construction products and building elements — Part 1:

Classification using data from reaction to fire tests

EN 13820:2003, Thermal insulating materials for building applications — Determination of organic

content

EN 13823:2020, Reaction to fire tests for building products — Building products excluding floorings

exposed to the thermal attack by a single burning item

EN 16516:2017+A1:2020, Construction products: Assessment of release of dangerous substances —

Determination of emissions into indoor air

EN 16733:2016, Reaction to fire tests for building products — Determination of a building product's

propensity to undergo continuous smouldering

EN ISO 1182:2020, Reaction to fire tests for products — Non-combustibility test (ISO 1182:2020)

EN ISO 1716:2018, Reaction to fire tests for products — Determination of the gross heat of combustion

(calorific value) (ISO 1716:2018)

EN ISO 10211:2017, Thermal bridges in building construction — Heat flows and surface temperatures —

Detailed calculations (ISO 10211:2017)

EN ISO 10456:2007, Building materials and products — Hygrothermal properties — Tabulated design

values and procedures for determining declared and design thermal values (ISO 10456:2007)

EN ISO 11925-2:2020, Reaction to fire tests — Ignitability of products subjected to direct impingement of

flame - Part 2: Single-flame source test (ISO 11925-2:2020)

ISO 16269-6:2014, Statistical interpretation of data — Part 6: Determination of statistical tolerance

intervals

As impacted by corrigendum EN ISO 10456:2007/AC:2009.

3 Terms and definitions, symbols, units and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• ISO Online browsing platform: available at https://www.iso.org/obp

• IEC Electropedia: available at http://www.electropedia.org/

3.1.1

vacuum insulation panel

VIP

insulation product made of a sealed barrier envelope containing a core material with an open porosity

structure, where the gas pressure inside the sealed barrier envelope is lowered below atmospheric

pressure

3.1.2

centre of panel

COP

area of the VIP whose thermal performance is not affected by the edge effect

3.1.3

edge effect

form of thermal bridging along the edge due to the higher thermal conductivity of the outer envelope,

both through the material of the envelope itself and the sealed folded envelope, compared to the core

3.1.4

inner pressure

total gas pressure within the VIP, measured in mbar

3.1.5

pressure compensation method

method of testing inner pressure of a VIP using a laminate-lift-off technique with a vacuum chamber or

suction bell

Note 1 to entry: In some literature also called foil-lift-off technique.

3.1.6

vacuum chamber

device to remove air or other gases from a volume around a VIP to determine the inner pressure of a

VIP by the pressure compensation method

3.1.7

suction bell

device to remove air or other gases from a volume connected to a part of a VIP to determine the inner

pressure of a VIP by the pressure compensation method

3.1.8

pressure sensor

device to measure the inner pressure of a VIP

3.1.9

protective layer

functional surface material, e.g. paper, glass fibre textile or rubber, which is not considered as separate

thermal insulation layer to be added to the thermal resistance of the product, intended to improve the

handling of the product and protect it from damage

3.1.10

core material

insulation material with an open porosity structure constituting the main component inside the VIP

envelope

3.1.11

envelope

airtight and water-tight outer layer of the VIP securing the vacuum inside the VIP

3.1.12

desiccant

additive material different from the core material which intends to absorb or adsorb water vapour in

the sealed panel

3.1.13

getter

additive material different from the core material which intends to absorb or adsorb other gases than

water vapour in the sealed panel

3.1.14

evacuation valve

device to connect the VIP to a vacuum pump

3.2 Symbols and abbreviated terms

For the purposes of this document, the following symbols, units and abbreviated terms apply.

A surface area of the VIP m

A metering area of the GHP or HFM apparatus used for the m

m

measurement

b core width m

c

b working width m

w

CS(Y) compressive stress/strength(Y=yield) kPa

d thickness m

dambient thickness of the ventilated VIP m

d nominal thickness of the product m

N

f acceleration factor for dry air of the VIP envelope –

air

f acceleration factor for water vapour of the VIP envelope –

v

k factor related to the number of test results available –

l core length m

c

l working length m

w

l length of the joints within the metering area m

ψ

N number of test results –

3 2

P air permeability of the VIP envelope m Pa/ (m ⋅s)

air

P water intake rate of the VIP envelope kg/(m ⋅s)

v

p pressure inside the VIP Pa

air

p maximum value of the inner pressure measured at least Pa

lim

24 h after production

p water vapour pressure inside the VIP Pa

v

p initial value of the inner pressure Pa

p inner pressure of a VIP, where λ increases by 1/2 of the Pa

1/2

thermal conductivity of still air.

R R at centre of panel plus ageing m ⋅K/W

COP,90/90aged 90/90

R expressed thermal resistance including ageing, edge-effect m ⋅K/W

D

and rounding rules

R mean thermal resistance m ⋅K/W

mean

R one test result of thermal resistance m ⋅K/W

i

R 90 % fractile with a confidence level of 90 % for the m ⋅K/W

90/90

thermal resistance

S top surface area (length x width) of the VIP m

S deviation from squareness on width or length mm/m

b

S deviation from flatness mm

max

S nominal perimeter of the product m

N

s estimate of the standard deviation of the thermal m ⋅K/W

R

resistance

s estimate of the standard deviation of the thermal W/(m⋅K)

λ

conductivity

s estimate of the standard deviation of the initial thermal W/(m⋅K)

λi

conductivity within 90 days of production

T temperature K

t time s

t service life time of the desiccant a

Des

Χ water content inside the VIP mass-%

change of water content with time at 50°C 70 % RH mass-%/s

X´

t,50/70

X compressive creep mm

ct

X total thickness reduction mm

t

λ thermal conductivity W/(m⋅K)

λ thermal conductivity of a ventilated VIP at centre of the W/(m⋅K)

ambient

panel

λ thermal conductivity for centre of panel W/(m·K)

COP

λ (25years) average value of thermal conductivity over the first 25 W/(m⋅K)

COP,mean

years in use at centre of panel

λ , λ at centre of panel plus ageing W/(m⋅K)

COP 90/90,aged 90/90

λ expressed thermal conductivity including ageing, edge- W/(m⋅K)

D

effect and rounding rules

λ equivalent thermal conductivity including edge effects for W/(m·K)

eq ja

the specific joint assembly

λ mean value of thermal conductivity W/(m⋅K)

mean

λ one test result of thermal conductivity W/(m⋅K)

i

λ’ change of thermal conductivity with pressure W/(m⋅K⋅Pa)

p

λ’ change of thermal conductivity with time W/(m⋅K⋅s)

t

λ’ change of thermal conductivity with humidity W/(m⋅K)/mass-%

Χ

λ 90 % fractile with a confidence level of 90 % for the W/(m⋅K)

90/90

thermal conductivity

λ’ change of thermal conductivity with time at 23°C 50 % RH W/(m⋅K⋅a)

t, 23, 50

’ change of thermal conductivity with time at 50°C 70 % RH W/(m⋅K⋅a)

λ

t, 50, 70

λ(t) time-dependent thermal conductivity value W/(m⋅K)

λ(t) time dependent value of thermal conductivity at 23°C W/(m⋅K)

, 23, 50

50 % RH

λ* (t = 0) interpolated initial value of thermal conductivity W/(m∙K)

σ compressive stress kPa

c

σ compressive strength kPa

m

σ tensile strength perpendicular to faces kPa

mt

σ compressive stress at 10 % deformation kPa

τ shear strength kPa

Φ relative humidity inside the VIP %

Φ’ change of relative humidity inside the VIP as function of (rel. humidity-

X

water content %)/(mass-%)

Ψ linear thermal transmittance W/(m∙K)

ψ linear thermal transmittance for the joints in the metering W/(m·K)

m

area

Abbreviated terms used in this document:

VIP vacuum insulation panel

COP centre of panel

AVCP assessment and verification of constancy of performance (previously named attestation of

conformity)

DoP declaration of performance

FPC factory production control

STP standard condition for temperature and pressure

RtF reaction to fire

ThIB thermal insulation for buildings

VOC volatile organic compounds

4 Characteristics

4.1 Reaction to fire

4.1.1 Determination

Reaction to fire classification shall be determined according to 5.2.1.

4.1.2 Expression

The reaction to fire shall be classified and expressed according to EN 13501-1:2018, Clause 11.

EXAMPLE Class E.

4.2 Propensity to undergo continuous smouldering

4.2.1 Determination

Propensity to undergo continuous smouldering of the core material shall be determined according to

5.2.2.

4.2.2 Evaluation and expression

Propensity to undergo continuous smouldering shall be expressed according to EN 16733:2016, Clause

11. If the test according to EN 16733:2016, Clause 11 has been passed, the result shall be expressed as

follows: “the product does not show propensity for continuous smouldering combustion”. If the test

according to EN 16733:2016, Clause 11 has been failed, the result shall be expressed as follows: “the

product shows propensity for continuous smouldering combustion”. If the assessment was not possible

according to EN 16733:2016, Clause 11, the result shall be expressed as follows: “assessment of the

propensity for continuous smouldering combustion is not possible”.

If a designation code is given, the following abbreviations shall be used:

— the product does not show propensity for continuous smouldering combustion: NoS

— the product shows propensity for continuous smouldering combustion: S

— the assessment of the propensity for continuous smouldering combustion is not possible: ANP.

EXAMPLE NoS.

4.3 Release of VOCs

4.3.1 Determination

The release of VOCs into indoor air shall be determined according to 5.2.3.

4.3.2 Expression

The release of VOCs into indoor air shall be expressed as values in accordance with

EN 16516:2017+A1:2020, 10.6.

4.4 Compressive strength

4.4.1 Determination

The compressive strength shall be determined according to 5.2.4.

4.4.2 Evaluation and expression

The compressive strength shall be expressed as a designation code CS(Y)i or CS(10)i, depending on the

result of the testing of 5.2.4. The test result i shall be rounded downwards in steps of 10 kPa.

EXAMPLE 1 CS(Y)120.

EXAMPLE 2 CS(10)120.

4.5 Tensile/flexural strength

4.5.1 Tensile strength perpendicular to faces

4.5.1.1 Determination

The tensile strength perpendicular to faces, σ , shall be determined according to 5.2.5.1.

mt

4.5.1.2 Expression

The tensile strength perpendicular to faces, σ , shall be expressed as a designation code TRi. The value i

mt

of the tensile strength shall be rounded downwards in steps of 10 kPa.

EXAMPLE TR80.

4.5.2 Shear strength

4.5.2.1 Determination

Shear strength, τ, shall be determined according to 5.2.5.2.

4.5.2.2 Expression

The shear strength shall be expressed as a designation code SSi. The value i of the shear strength shall

be rounded downwards in steps of 50 kPa.

EXAMPLE SS150.

4.6 Thermal resistance

4.6.1 Thermal resistance of the VIP

4.6.1.1 Determination

The thermal resistance shall be determined according to 5.2.6.1.

4.6.1.2 Expression

The thermal resistance shall be rounded downwards to the nearest 0,05 m ⋅K/W and be expressed as a

value in m ⋅K/W. It shall be expressed together with thermal conductivity rounded upwards in steps of

0,000 5 W/(m⋅K) and expressed as a value in W/(m⋅K). It shall be expressed together with the thickness

given as a value in mm.

EXAMPLE RD= 4,60 m ⋅K/W (λD= 0,0065 W/(m⋅K), d= 30 mm).

4.6.2 Thermal resistance of the ventilated VIP under ambient pressure due to damage

4.6.2.1 Determination

The thermal resistance of the ventilated VIP under ambient pressure due to damage shall be

determined according to 5.2.6.2.

4.6.2.2 Expression

The thermal resistance of the ventilated VIP under ambient pressure due to damage shall be rounded

2 2

downwards to the nearest 0,05 m ⋅K/W and be expressed as a value in m ⋅K/W. It shall be expressed

together with the thickness given as a value in mm.

EXAMPLE R = 1,00 m ⋅K/W (d = 20 mm).

ambient, eff ambient

4.7 Durability aspects

4.7.1 Dimensional stability under specified temperature and humidity conditions

4.7.1.1 Determination

Dimensional stability under specified temperature or under specified temperature and humidity

conditions shall be determined according to 5.2.7.1.

4.7.1.2 Expression

Dimensional stability under specified temperature or under specified temperature and humidity

conditions shall be expressed as a code in the following way: If the relative changes in core length and

core width do not exceed 1 % and the relative reduction in thickness does not exceed 3 %, the code

shall be DS. Otherwise, the code shall be NoDS .

EXAMPLE DS.

4.7.2 Dimensional stability under specified compressive load and temperature conditions

4.7.2.1 Determination

Dimensional stability under specified compressive load and temperature conditions shall be

determined according to 5.2.7.2.

4.7.2.2 Expression

Dimensional stability under specified compressive load and temperature conditions shall be expressed

as a code in the following way: If the relative changes in thickness do not exceed 3 %, the code shall be

DSC. Otherwise, the code shall be NoDSC.

EXAMPLE DSC.

4.7.3 Compressive creep

4.7.3.1 Determination

The compressive creep shall be determined according to 5.2.7.3.

4.7.3.2 Expression

Compressive creep, X , shall be expressed as a designation code CC(i /i /y)σ together with the total

ct 1 2 c

thickness reduction, X . The value of the total thickness reduction i and the value of compressive creep

t 1

i after y years shall be given in steps of 0,1 mm and at the expressed stress σ .

2 c

EXAMPLE CC(2,5/2/10)50.

5 Assessment methods

5.1 General

5.1.1 Sampling

Unlike other insulating materials, VIP cannot be cut to the sizes required by the test standards. They

shall be produced in the sizes stated in Table 1.

5.1.2 Conditioning

Conditioning of the test specimens shall be at least 24 h at (23 ± 5) °C unless otherwise specified in the

test standard. In case of dispute, the test specimens shall be stored at (23 ± 2) °C and (50 ± 5) % relative

humidity for at least 24 h prior to testing.

Table 1 — Characteristics and test specimens

Clause Test specimen

length and width

No Title

5.2.1 Reaction to fire See Annex H

Propensity to undergo 800 x 300

5.2.2

continuous smouldering

5.2.3 Release of VOCs Full-size

Compressive stress or ≥ 200

5.2.4

compressive strength

Tensile strength ≥ 200

5.2.5

perpendicular to faces

5.2.5 Shear strength 200 x 100

Thermal resistance and ≥ 300

5.2.6

thermal conductivity

Inner pressure at least ≥ 300

5.2.6

24 h after production

5.2.6 Length and width Full-size

Squareness on length Full-size

5.2.6

and width

5.2.6 Flatness Full-size

5.2.6 Thickness Full-size

Dimensional stability ≥ 200

5.2.7 according to specified

temperature conditions

Deformation under ≥ 200

specified compressive

5.2.7

load and temperature

conditions

5.2.7 Compressive creep ≥ 200

5.2 Test methods

5.2.1 Reaction to fire

Reaction to fire classification shall be determined using the test standards referred to within

EN 13501-1:2018, Clause 8 for the claimed class. For specific tests, the mounting and fixing procedure

shall be as given in Annex H.

5.2.2 Propensity to undergo continuous smouldering

The propensity to undergo continuous smouldering of the VIP shall be tested on the core material. The

material shall be tested according to EN 16733:2016. The following conditions and parameters shall be

considered within the tests:

— organic content (in percentage per mass), to be determined by tests according to EN 13820:2003;

— absolute organic content expressed in [kg/m ];

— density according to EN 1602;

— thickness to be determined by test according to EN 823:2013;

The tests shall be done without consideration of the intended end-use conditions. If the paragraph 6.2.5

of EN 16733:2016 applies, a permanent contact between the pieces shall be assured.

The results of tests considering the aforementioned parameters in full are also valid for products

— having tested absolute organic content in [kg/m ] identical or lower, when the organic content in

[%] is the same or lower as tested;

— with equal or lower density;

— with lower thickness and also with higher thickness when 100 mm thick specimens were tested;

— with any envelopes;

— for any end-use conditions.

5.2.3 Release of VOCs

The release of VOCs into indoor air shall be tested according to EN 16516:2017+A1:2020, 8.2.

NOTE An informative database covering European and national provisions on dangerous substances is

available at the Construction web site on EUROPA accessed through: https://ec.europa.eu/growth/tools-

databases/cp-ds.

5.2.4 Compressive strength

In accordance with EN 826:2013 either the compressive stress at 10 % or the compressive strength

shall be determined.

In order to even out seams, flaps and uneven surfaces of the VIPs and to enhance comparability of

different products on the market, gypsum coating shall be used to enhance the coupling of the

specimens to the testing machine – e.g. in a similar way as the procedure given for cellular glass in

EN 826:2013, subclause A.3.2.6 but using gypsum instead of bitumen.

5.2.5 Tensile/flexural strength

5.2.5.1 Tensile strength perpendicular to faces

, shall be determined in accordance with EN 1607:2013.

Tensile strength perpendicular to faces, σmt

5.2.5.2 Shear strength

Shear strength, τ, shall be determined according to EN 12090:2013.

5.2.6 Thermal resistance

5.2.6.1 Thermal resistance of the VIP

5.2.6.1.1 General

For the determination of the thermal resistance the following characteristics are needed:

— Thermal conductivity (5.2.6.1.2)

— Thickness (5.2.6.1.3)

— Length, width, squareness, flatness (5.2.6.1.4)

5.2.6.1.2 Thermal conductivity

Thermal conductivity shall be based upon measurements carried out at centre of panel in accordance

with EN 12667:2001.

The measurement shall be carried out directly on the VIP, or, for uneven surfaces, to avoid air gaps, the

measurement shall be carried out with the VIP positioned between two flexible contact sheets

according to EN 12664:2001, 6.3.2.2.

For VIP products the thermal conductivity including ageing shall be determined in accordance with

Annex A including ageing and thermal bridge effect according to Annex C and shall be determined

according to the following:

— The reference mean temperature for thermal conductivity shall be 10 °C.

— The measured values shall be expressed with two significant figures.

— λ is obtained from testing thermal conductivity in the centre of panels shortly after production.

90/90

It shall be representing at least 90 % of the production, determined with a confidence level of 90 %

in accordance with EN ISO 10456:2007 .

— The statistical value of thermal conductivity, λ , shall be rounded upwards to the nearest

90/90

0,0001 W/(m⋅K).

— The thermal conductivity, λ , shall be derived from λ by adding ageing and edge effect

D 90/90

according to Annex C.

— The thermal conductivity λ is achieved including ageing and edge effect according to Annex C and

D

shall be rounded upwards in steps of 0,000 5 W/(m⋅K).

— Different methods to include the aging apply for VIP with or without desiccants. Both methods are

described in Annex C.

5.2.6.1.3 Thickness

Thickness of the VIP, d, shall be determined in accordance with EN 823:2013. The seams and folded

edges or ends shall not be included in the measurement (see Figure 1).

The VIP should be placed even on the measuring table before measurements are taken.

No test result shall deviate from the nominal thickness, d , by more than the tolerances given in Table 2.

N

Table 2 — Tolerances for thickness

Thickness Tolerance

mm mm

< 15 +2/-0

15 ≤ d < 40 +2/-1

40 ≤ d < 50 ±2

≥ 50 +3/-2

Key

1 folded edges on the short side lw working length

2 folded edges on the long side b core width

c

d thickness bw working width

lc core length

Figure 1 — Dimensions of a Vacuum Insulation Panel

5.2.6.1.4 Length, width, squareness, flatness

The working length, l , and the working width, b , (see Figure 1) shall be determined in a similar way as

w w

the procedure given in EN 822:2013, but taking the measurement at the highest point of the folded

edge.

The core length, l , and the core width, b , (see Figure 1) shall be determined in accordance with

c c

EN 822:2013.

The deviation from squareness of the length and width, S , shall be determined in a similar way as the

b

procedure given in EN 824:2013, but both sides of the panel shall be measured and the higher value

shall be expressed.

The deviation from flatness, S , shall be measured in a similar way as the procedure given in

max

EN 825:2013, with the measuring points, when possible, excluding the welding or folding areas of the

envelopes of the products.

No test result shall deviate from the nominal values by exceeding the tolerances given in Table 3.

Table 3 — Tolerances of length, width, squareness and flatness

Tolerances

Length or width Squareness on length Flatness

and width

< 500 mm 500 ≤ (l, b) ≤ 1 000 > 1 000

S S

b max

mm mm/m mm

5 6

8 10 12

(e.g. +2 / −6) (e.g. ± 5) (e.g. +4 / −8)

or or or

(e.g. +0 / −8) (e.g. +4 / −6) (e.g. +10 / −2)

5.2.6.1.5 Inner pressure

The inner pressure of the panel shall be measured minimum 24 h after production according to Annex G

and shall be lower than the limit value plim. Different methods apply for VIP with or without evacuation

valve. Both methods are described in Annex G.

5.2.6.1.6 Report of thermal resistance

The thermal resistance, R , is derived by the thermal conductivity, λ , and the nominal thickness, d , via

D D N

the equation: R = d / λ . In addition to the thermal resistance the test report shall contain the thermal

D N D

conductivity, nominal thickness, length, width, squareness, flatness and inner pressure.

5.2.6.2 Thermal resistance of the ventilated VIP under ambient pressure due to damage

The thermal resistance of a ventilated VIP shall be recorded upon measurements in accordance with

EN 12667:2001. The value of ambient pressure should be recorded during the measurement. To this

extent the envelope of the VIP shall be opened at the edge. The length or diameter of the opening shall

be between 10 mm and 20 mm. For VIP with evacuation valves the valve can be opened until ambient

pressure is reached.

The thickness of the ventilated VIP might differ from the thickness of the evacuated VIP. Therefore, the

thickness of the ventilated VIP d should be measured according to EN 823:2013.

ambient

The edge effect measured or modelled with non-ventilated VIP according to C.5 should be used to

calculate the thermal conductivity and thermal resistance of the ventilated VIP according to

Formulae (1) and (2).

(1)

λ λψ+⋅ d ⋅ p / S

( )

ambient, eff ambient ambient

Rd= /λ (2)

ambient,, eff ambient ambient eff

5.2.7 Durability aspects

5.2.7.1 Dimensional stability under specified temperature and humidity conditions

Dimensional stability under specified temperature or under specified temperature and humidity

conditions shall be determined in accordance with EN 1604:2013. The test shall be carried out at 70 °C

and 90 % relative humidity.

The measuring points as stated in EN 1604:2013 shall exclude the welding or folding areas of the

envelopes of the products.

The test specimens shall be square section prisms with a side length of (200, 250 or 300 ± 1) mm

depending on the feasible productions.

5.2.7.2 Dimensional stability under specified compressive load and temperature conditions

Dimensional stability under specified compressive load and temperature conditions shall be

determined in accordance with EN 1605:2013. The conditioning shall be carried out at 40 kPa and

70 °C.

5.2.7.3 Compressive creep

Compressive creep, X , shall be determined in accordance with EN 1606:2013 after at least one

ct

hundred and twenty two days of testing (see Table 4) at a compressive stress, σ , given in steps of at

c

least 1 kPa. The results shall be extrapolated thirty times, corresponding to ten years.

NOTE Testing times: According to EN 1606:2013 the procedure at 10, 25 and 50 years respectively requires

the following testing times:

Table 4 — Extrapolation and minimum testing time

Extrapolation time Minimum testing time

years days

10 122

25 304

50 608

=

6 Assessment and verification of constancy of performance - AVCP

6.1 General

The technical details necessary for the implementation of the system of assessment and verification of

constancy of performance comprise provisions with regards to:

— the assessment of the performance of the construction product, which may be carried out on the

basis of testing (including sampling) and calculation; and

— the applicable factory production control.

6.2 Assessment of performance

6.2.1 General

When the intention is to declare any performance related to characteristics included in Annex ZA of this

document this shall be carried out on the basis of testing (including sampling) and calculation in

accordance with Clause 'Characteristics'.

Assessment previously performed in accordance with the provisions of this document, may be

considered, provided that this assessment was performed to the same or a more rigorous assessment

method, under the same AVCP system on the same product or products of similar design, construction

and functionality, such that the results are applicable to the product in question.

For the purposes of assessment, the products may be grouped into families, where it is considered that

the results for one or more characteristics from any one product within the family are representative

for that same characteristic for all products within that same family.

NOTE 1 Products may be grouped into different families for different characteristics.

In addition, the determination of the product performance shall be

— carried out for all characteristics included in the standard for which it is intended to declare the

performance:

— on first application of this document, or

— at the beginning of the production of a new or modified factory-made vacuum insulation panels

(VIP), unless a member of the same product family; or

— at the beginning of a new or modified method of production ,where the modification may affect

the stated properties;

— repeated for the characteristic(s) in question, whenever a change occurs in the factory-made

vacuum insulation panels (VIP) design, in the raw material(s) or in the supplier of the components,

and/or in the method of production (subject to the definition of a family), which may affect

significantly the performance in relation to one or more of the characteristics;

Where kit components are used whose performance in relation to their characteristics has already been

determined on the basis of assessment methods of other harmonized technical specifications and those

components bear CE marking in accordance with those harmonized technical specifications, these

performances do not need to be re-assessed, if the intended use and the assessment methods of this

document correspond to previously used. The specifications of these components shall be documented.

6.2.2 Test samples, testing and assessment criteria

The samples factory-made vacuum insulation panels (VIP) to be tested/assessed shall be in accordance

with Table 5.

Table 5 — Number of samples to be tested and assessment criteria

Characteristic Clause Assessment No. of Assessment criteria

method samples

Reaction to fire 4.1 5.2.1 1 4.1

Propensity to undergo

continuous 4.2 5.2.2 1 4.2

smouldering

Release of VOCs 4.3 5.2.3 1 4.3

Compressive strength 4.4 5.2.4 4 4.4

Tensile strength

4.5.1 5.2.5.1 4 4.5.1

perpendicular to faces

Shear strength 4.5.2 5.2.5.2 4 4.5.2

Thermal resistance of 5.2.6.1

4.6.1 4 4.6.1

the VIP

Thermal resistance of

the ventilated VIP

under ambient 4.6.2 5.2.6.2 4 4.6.2

pressure due to

damage

Dimensional stability

under specified

4.7.1 5.2.7.1 4 4.7.1

temperature and

humidity conditions

Dimensional stability

under specified

compressive load and 4.7.2 5.2.7.2 4 4.7.2

temperature

conditions

Compressive creep 4.7.3 5.2.7.3 4 4.7.3

6.3 Verification of constancy of performance

6.3.1 Factory production control (FPC)

6.3.1.1 General

An FPC system shall be established, documented, operated and maintained to ensure that the products

placed on the market comply with the declared performance in relation to the essential characteristics.

The FPC system shall consist of procedures, regular inspections and tests and/or assessments and the

use of the results to control raw and other incoming materials or components, equipment, the

production process and the product.

All the elements and provisions shall be documented in a systematic manner in the form of written

policies and procedures.

The responsibility, authority and the relationship between personnel that manages, performs or verifies

work affecting constancy of the performance of the product, shall be defined.

The qualification and competence (e.g. on the basis of education, training, skills, or experience) of

personnel performing tasks affecting the assessment and verification of constancy of performance of

the product shall be recorded.

Documents defining the factory production control system shall be drawn up and kept up-to-date.

Documentation and procedures should be appropriate to the product and production process. The FPC

system should achieve an appropriate l

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...