SIST EN 459-1:2015

(Main)Building lime - Part 1: Definitions, specifications and conformity criteria

Building lime - Part 1: Definitions, specifications and conformity criteria

This European Standard applies to building lime used for:

- preparation of binder for mortar (for example for masonry, rendering and plastering);

- production of other construction products (for example calcium silicate bricks, autoclaved aerated concrete, concrete, etc.);

- civil engineering applications (for example soil treatment, asphalt mixtures, etc.).

It gives definitions for the different types of building lime and their classification. It also gives requirements for their chemical and physical properties which depend on the type of building lime and specifies the conformity criteria.

Terms of delivery or other contractual conditions, normally included in documents exchanged between the supplier and the purchaser of building lime, are outside the scope of this European Standard.

Baukalk - Teil 1: Begriffe, Anforderungen und Konformitätskriterien

Diese Europäische Norm gilt für Baukalk für:

- die Herstellung von Bindemittel für Mörtel (z. B. für Mauerwerk, Außenputz und Innenputz);

- die Herstellung anderer Bauprodukte (z. B. für Kalksandsteine, Porenbeton, Beton, usw.);

- Anwendungen im Ingenieurbau (z. B. Bodenverbesserung, Asphaltmischungen, usw.).

Sie enthält Definitionen der verschiedenen Baukalkarten und deren Klassifizierung. Sie enthält darüber hinaus die Anforderungen an die chemischen und physikalischen Eigenschaften, die von der jeweiligen Baukalkart abhängig sind, und legt die Konformitätskriterien für Baukalk fest.

Lieferbedingungen und andere Vertragsvereinbarungen, die üblicherweise in den zwischen dem Lieferanten und dem Abnehmer von Baukalk ausgetauschten Dokumenten enthalten sind, sind nicht Gegenstand dieser Europäischen Norm.

Chaux de construction - Partie 1 : Définitions, spécifications et critères de conformité

La présente Norme européenne s'applique à la chaux de construction utilisée pour :

- la préparation de liant pour mortier (par exemple, pour la maçonnerie, les enduits intérieurs et extérieurs) ;

- la fabrication d'autres produits de construction (par exemple, briques de silicates de calcium, béton cellulaire autoclavé, béton, etc.)

- des applications de génie civil (par exemple traitement des sols, mélange bitumineux à chaud, etc.).

Elle donne les définitions des différents types de chaux de construction et leur classification. Elle prescrit également des exigences concernant leurs propriétés chimiques et physiques, celles-ci étant fonction du type de chaux de construction, et spécifie les critères de conformité.

Les modalités de mise à disposition ou autres conditions contractuelles faisant normalement partie des documents échangés entre fournisseur et acheteur de la chaux de construction, n'entrent pas dans le domaine d'application de la présente Norme européenne

Gradbeno apno - 1. del: Definicije, zahteve in merila skladnosti

General Information

- Status

- Published

- Public Enquiry End Date

- 04-Dec-2014

- Publication Date

- 16-Jun-2015

- Technical Committee

- CAA - Mineral binders and masonry

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 15-May-2015

- Due Date

- 20-Jul-2015

- Completion Date

- 17-Jun-2015

Relations

- Replaces

SIST EN 459-1:2010 - Building lime - Part 1: Definitions, specifications and conformity criteria - Effective Date

- 01-Jul-2015

Overview

EN 459-1:2015 - Building lime, Part 1: Definitions, specifications and conformity criteria - is the CEN (European) standard that defines types of building lime, specifies their required chemical and physical properties, and sets out conformity criteria for use in construction and civil engineering. The standard covers lime used as a binder for mortars (masonry, rendering, plastering), for manufacture of other construction products (calcium silicate bricks, autoclaved aerated concrete, concrete) and for civil engineering applications (soil treatment, asphalt mixtures). Delivery terms and commercial contract conditions are outside its scope.

Key topics and technical requirements

- Classification: Distinguishes two main families - air lime and lime with hydraulic properties - with sub-families:

- Air lime: Calcium lime (CL) and Dolomitic lime (DL); forms include quicklime (Q), hydrated lime (S), lime putty (S PL) and milk/slurry (S ML).

- Lime with hydraulic properties: Natural hydraulic lime (NHL), formulated lime (FL) and hydraulic lime (HL).

- Chemical composition: Characteristic values (e.g., total CaO + MgO, MgO, CO2, SO3, available lime) are specified for product types (for example CL 90, CL 80, CL 70).

- Physical properties: Requirements include soundness after slaking, reactivity (R values) and particle size distribution for quicklime.

- Conformity and testing: Conformity is determined using the test methods of EN 459-2 and statistical evaluation procedures in Annex A (sampling plans, characteristic values, allowable probability of acceptance). Annex D covers declaration of composition for formulated lime; Annex B lists optional additional properties; Annex C provides a schematic diagram of types and applications.

- Regulatory linkage: Informative Annex ZA relates the standard to the EU Construction Products Regulation.

Applications and practical value

EN 459-1:2015 is directly applicable where consistent material performance and interoperability are required:

- Specifying binders for traditional and restoration mortars (masonry, rendering, plaster)

- Ensuring material properties for precast products and autoclaved aerated concrete

- Guiding lime selection in geotechnical and road construction (soil stabilization, asphalt modifiers)

- Supporting quality control and procurement criteria for manufacturers, suppliers and contractors

Who should use this standard

- Lime manufacturers - to classify products and declare conformity

- Mortar and masonry product producers - to select appropriate lime types (e.g., CL 90 vs CL 70)

- Civil engineers, architects and specifiers - to specify compliant lime for performance and durability

- Test laboratories and conformity assessors - to apply EN 459-2 test methods and EN 459-3 conformity evaluation

- Procurement and compliance teams - to verify declarations and statistical conformity criteria

Related standards

- EN 459-2: Test methods for building lime

- EN 459-3: Conformity evaluation for building lime

- EN 197-1: Cement composition and conformity (referenced)

Frequently Asked Questions

SIST EN 459-1:2015 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Building lime - Part 1: Definitions, specifications and conformity criteria". This standard covers: This European Standard applies to building lime used for: - preparation of binder for mortar (for example for masonry, rendering and plastering); - production of other construction products (for example calcium silicate bricks, autoclaved aerated concrete, concrete, etc.); - civil engineering applications (for example soil treatment, asphalt mixtures, etc.). It gives definitions for the different types of building lime and their classification. It also gives requirements for their chemical and physical properties which depend on the type of building lime and specifies the conformity criteria. Terms of delivery or other contractual conditions, normally included in documents exchanged between the supplier and the purchaser of building lime, are outside the scope of this European Standard.

This European Standard applies to building lime used for: - preparation of binder for mortar (for example for masonry, rendering and plastering); - production of other construction products (for example calcium silicate bricks, autoclaved aerated concrete, concrete, etc.); - civil engineering applications (for example soil treatment, asphalt mixtures, etc.). It gives definitions for the different types of building lime and their classification. It also gives requirements for their chemical and physical properties which depend on the type of building lime and specifies the conformity criteria. Terms of delivery or other contractual conditions, normally included in documents exchanged between the supplier and the purchaser of building lime, are outside the scope of this European Standard.

SIST EN 459-1:2015 is classified under the following ICS (International Classification for Standards) categories: 91.100.10 - Cement. Gypsum. Lime. Mortar. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 459-1:2015 has the following relationships with other standards: It is inter standard links to SIST EN 459-1:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 459-1:2015 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/114. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase SIST EN 459-1:2015 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Gradbeno apno - 1. del: Definicije, zahteve in merila skladnostiBaukalk - Teil 1: Begriffe, Anforderungen und KonformitätskriterienChaux de construction - Partie 1 : Définitions, spécifications et critères de conformitéBuilding lime - Part 1: Definitions, specifications and conformity criteria91.100.10Cement. Mavec. Apno. MaltaCement. Gypsum. Lime. MortarICS:Ta slovenski standard je istoveten z:EN 459-1:2015SIST EN 459-1:2015en,fr,de01-julij-2015SIST EN 459-1:2015SLOVENSKI

STANDARDSIST EN 459-1:20101DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 459-1

April 2015 ICS 91.100.10 Supersedes EN 459-1:2010English Version

Building lime - Part 1: Definitions, specifications and conformity criteria

Chaux de construction - Partie 1 : Définitions, spécifications et critères de conformité

Baukalk - Teil 1: Begriffe, Anforderungen und Konformitätskriterien This European Standard was approved by CEN on 16 February 2015.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2015 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 459-1:2015 ESIST EN 459-1:2015

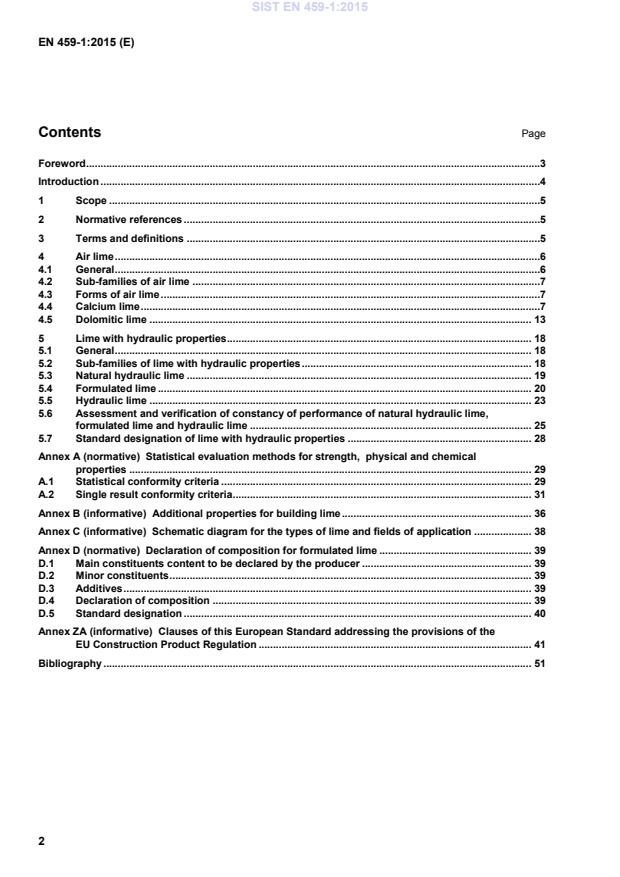

Statistical evaluation methods for strength,

physical and chemical properties . 29 A.1 Statistical conformity criteria . 29 A.2 Single result conformity criteria . 31 Annex B (informative)

Additional properties for building lime . 36 Annex C (informative)

Schematic diagram for the types of lime and fields of application . 38 Annex D (normative)

Declaration of composition for formulated lime . 39 D.1 Main constituents content to be declared by the producer . 39 D.2 Minor constituents . 39 D.3 Additives . 39 D.4 Declaration of composition . 39 D.5 Standard designation . 40 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Product Regulation . 41 Bibliography . 51

Annexes A and D are normative, Annexes B, C and ZA are informative. According to the CEN-CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 459-1:2015

1) Translation of a term used in most European countries. SIST EN 459-1:2015

Conformity with this classification is assessed by means of statistical quality control as described in Annex A of this European Standard. 4.4.2 Chemical requirements for calcium lime The properties of the type of calcium lime shown in Table 2 determined in accordance with EN 459-2 shall conform to the requirements in that table. All types of calcium lime listed in Table 2 may contain additives in small quantities to improve the manufacture or properties of calcium lime. When the total content exceeds 0,1 %, the actual types and amounts shall be declared. Table 2 — Chemical requirements of calcium lime given as characteristic values Type of calcium lime Values given as mass fraction in percent CaO + MgO MgOa CO2b SO3 Available limec CL 90 ≥ 90 ≤ 5 ≤ 4 ≤ 2 ≥ 80 CL 80 ≥ 80 ≤ 5 ≤ 7 ≤ 2 ≥ 65 CL 70 ≥ 70 ≤ 5 ≤ 12 ≤ 2 ≥ 55 The values for CaO + MgO, MgO, CO2 and SO3 are applicable to all forms of calcium lime. For quicklime these values correspond to the finished product; for all other forms of lime (hydrated lime, lime putty and milk of lime) the values are based on the product after subtraction of its free water and bound water content. The values for available lime (calcium oxide for quicklime, calcium hydroxide for hydrated lime) refer to the product when tested in accordance with EN 459–2. a MgO content up to 7 % is permitted if the soundness test in accordance with EN 459–2 is passed. b A higher content of CO2 is permitted, if all other chemical requirements in Table 2 are satisfied and the test frequency satisfies the requirements in Table 7. c Higher values of available lime may be requested.

4.4.3 Physical requirements and other physical properties for quicklime The physical properties of the type of quicklime shown in Table 3 and Table 4 determined in accordance with EN 459-2 shall conform to the requirements in those tables. SIST EN 459-1:2015

Table 4 — Reactivity (R) of quicklime given as characteristic values Type of quicklime Reactivity (time in min), in accordance with EN 459–2:2010, 6.6 R5 R 4 R3 R2 Rsv CL 90 t60 < 10 t60 < 25 — — other specified value or no requirement CL 80 t60 < 10 t60 < 25 t50 < 25 — CL 70 — — — t40 < 25

The particle size distribution of all types of quicklime shown in Table 1 shall conform to the requirements in Table 5 and shall be determined in accordance with EN 459-2. Table 5 — Particle size distribution (P) of quicklime given as characteristic values Sieve size Particle size distributiona (mass fraction passing the sieve in percent),

in accordance with EN 459–2:2010, Clause 6 P4 P3 P2 P1 Psv 10 mm 100 — — — other specified value or no requirement 5 mm ≥ 95 100 100 — 2 mm — ≥ 95 ≥ 95 100 0,2 mm — — ≥ 70 ≥ 95 0,09 mm — ≥ 30 ≥ 50 ≥ 85 a Particle size ≥ 2 mm shall be determined by dry sieving in accordance with EN 459–2:2010, 6.1 and particle size < 2 mm by air-jet sieving in accordance with EN 459–2:2010, 6.2.

4.4.4 Physical requirements and other physical properties for hydrated lime and lime putty The physical properties of hydrated lime and lime putty of the type shown in Table 6 determined in accordance with EN 459-2 shall conform to the requirements in that table. SIST EN 459-1:2015

4.4.5 Additional properties Other properties may be subject either to requirements in application standards dealing with the use of calcium lime or to requests from the user. These properties are given in informative Annex B. 4.4.6 Durability requirements The choice of calcium lime, particularly as regards types for different applications and exposure conditions shall follow the appropriate European or national application standards and/or regulations valid in the place of use. 4.4.7 Dangerous substances National regulations on dangerous substances may require verification and declaration on release, and sometimes content, when construction products covered by this standard are placed on those markets. In the absence of European harmonized test methods, verification and declaration on release/content should be done taking into account national provisions in the place of use. NOTE An informative database covering European and national provisions on dangerous substances is available at the Construction website on EUROPA accessed through: http://ec.europa.eu/enterprise/construction/cpd-ds/. SIST EN 459-1:2015

Hydrated limem 1/day 2/day X

Soundness Quicklimee Hydrated lime 1/dayg 2/day

X Lime putty 1/week 2/week

X Penetration/ Water demand Hydrated lime 2/year 1/month

X Air content Hydrated limek 2/year 1/month

X CaO + MgO, MgOf Quicklime Hydrated lime Lime putty

1/week 2/week

X SIST EN 459-1:2015

1/week 2/week

X SO3 Quicklime Hydrated lime Lime putty

1/month 2/month

X Available limef, o Quicklime Hydrated lime Lime putty

1/week 2/week

X Free water Hydrated lime Lime putty

1/month 2/month

X Reactivity Quicklime

1/week 2/week

X a The methods used to take and prepare samples shall be in accordance with EN 459–2. Tests may be carried out at any time between production and dispatch. The producer shall ensure that the requirements are met at the time of dispatch. b See 4.3 and Table 1. c Any other methods may be used provided they are calibrated, either against the reference methods or against internationally accepted reference materials, in order to demonstrate their equivalence. d The control period for conformity evaluation is 12 months. e After slaking (see Table 3, Footnote a). f If the test frequency of CaO + MgO and CO2 is higher than the required frequency (e.g. CaO + MgO > 1/week and CO2 > 1/week) then the test frequency of available lime may be reduced to twice per year. If the test frequency of available lime and CO2 is higher than the required frequency (e.g. available lime > 1/week and CO2 > 1/week) then the test frequency of CaO + MgO may be reduced to twice per year. g For hydrated lime: If 30 consecutive test results are less than 10 % of the required value then the test frequency may be reduced to once per month. If any single result is higher than 10 % of the required value then return to daily testing. For quicklime: If 30 consecutive test results meet the requirement, then the test frequency may be reduced to once per month. If any single result fails the requirement, then return to daily testing. h If the data are not normally distributed the evaluation shall be made by attributes. j If the number of samples taken during the control period is at least one per week the evaluation may be made by variables. k For lime without additives this test is required only for product type determination. l See EN 459–3:2015, 4.4. m See Table 6, Footnote g. n See Table 2, Footnote b. o See Table 2, Footnote c.

4.4.9 Standard designation of calcium lime Calcium lime shall be identified by its notation specified in Table 1, by the form of the product given in 4.3 and for quicklime by the physical requirements given in 4.4.3 (see examples below). SIST EN 459-1:2015

Conformity with this classification is assessed by means of statistical quality control as described in Annex A of this European Standard. 4.5.2 Chemical requirements for dolomitic lime The properties of the type of dolomitic lime shown in Table 9 determined in accordance with EN 459-2 shall conform to the requirements in that table. All types of dolomitic lime listed in Table 9 may contain additives in small quantities to improve the manufacture or properties of dolomitic lime. When the total content exceeds 0,1 %, the actual types and amounts shall be declared. SIST EN 459-1:2015

4.5.3 Physical requirements and other physical properties for dolomitic quicklime The physical properties of dolomitic quicklime of the type shown in Tables 10 and 11 determined in accordance with EN 459-2 shall conform to the requirements in those Tables. Table 10 — Physical requirements of dolomitic quicklime Type of dolomitic quicklime Soundness after slaking in accordance with EN 459–2:2010, 6.4.4a DL 90–30 Pass DL 90–5 DL 85–30 DL 80–5 a Slaking according to the instructions of the lime producer.

Table 11 — Reactivity of dolomitic quicklime given as characteristic values Type of dolomitic quicklime Reactivity (time in minutes), in accordance with EN 459–2:2010, 6.6 R5 R2 R1 Rsv DL 90–30 — t40 < 25 — other specified value or no requirement DL 90–5 t60 < 10 t40 < 25 — DL 85–30 — t40 < 25 — DL 80–5 — — t35 < 25

The particle size distribution of all types of dolomitic quicklime shown in Table 8 shall conform to the requirements in Table 12 and shall be determined in accordance with EN 459-2. SIST EN 459-1:2015

in accordance with EN 459–2:2010, Clause 6 P4 P3 P2 P1 Psv 10 mm 100 — — — other specified value or no requirement 5 mm ≥ 95 100 100 — 2 mm — ≥ 95 ≥ 95 100 0,2 mm — — ≥ 70 ≥ 95 0,09 mm — ≥ 30 ≥ 50 ≥ 85 a Particle size ≥ 2 mm shall be determined by dry sieving in accordance with EN 459–2:2010, 6.1 and particle size < 2 mm by air-jet sieving in accordance with EN 459–2:2010, 6.2.

4.5.4 Physical requirements and other physical properties for dolomitic hydrated lime The physical properties of dolomitic hydrated lime of the type shown in Table 13 determined in accordance with EN 459-2 shall conform to the requirements in that table. Table 13 — Physical requirements of dolomitic hydrated lime a given as characteristic values Type of dolomitic hydrated lime Particle size Free water content Soundnessb, c Mortar testsd % residue by mass Penetration Air content 0,09 mm 0,2 mm % mm % DL 90–30 ≤ 7 ≤ 2 ≤ 2 Pass > 10 and < 50 ≤ 12 DL 90–5 DL 85–30 DL 80–5 a Particle size and free water content apply to dolomitic hydrated lime for all applications. Soundness, penetration and air content apply only to dolomitic hydrated lime for masonry mortar, plastering and rendering. b See EN 459–2:2010, 6.4.4. c Dolomitic hydrated lime which includes particles larger than 0,2 mm shall satisfy the requirements of the soundness test for dolomitic hydrated limes with grains larger than 0,2 mm in EN 459–2. d Tested in accordance with the test on standard mortar in EN 459–2.

4.5.5 Additional properties Other properties may be subject either to requirements in application standards dealing with the use of dolomitic lime or to requests from the users. These properties are given in informative Annex B. 4.5.6 Durability requirements The choice of dolomitic lime particularly as regards type for different applications and exposure conditions shall follow the appropriate European or national application standards and/or regulations valid in the place of use. SIST EN 459-1:2015

X Hydrated lime 1/day 2/day

X Soundness Quicklimee Hydrated lime 1/dayg 2/day

X Penetration/ Water demand Hydrated lime 2/year 1/month

X Air content Hydrated limek 2/year 1/month

X CaO + MgO, MgO Quicklime Hydrated lime 1/week 2/week

X CO2 Quicklime Hydrated lime 1/week 2/week

X SO3 Quicklime Hydrated lime 1/month 2/month

X Free water Hydrated lime 1/month 2/month

X Reactivity Quicklime 1/week 2/week

X a The methods used to take and prepare samples shall be in accordance with EN 459–2. Tests may be carried out at any time between production and dispatch. The producer shall ensure that the requirements are met at the time of dispatch. b See 4.3 and Table 8. c Any other methods may be used provided they are calibrated, either against the reference methods or against internationally accepted reference materials, in order to demonstrate their equivalence. d The control period for conformity evaluation is 12 months. e After slaking (see Table 10, Footnote a). g For hydrated lime: If 30 consecutive test results are less than 10 % of the required value then the test frequency may be reduced to once per month. If any single result is higher than 10 % of the required value, then return to daily testing. For quicklime: If 30 consecutive test results meet the requirement, then the test frequency may be reduced to once per month. If any single result fails the requirement, then return to daily testing. h If the data are not normally distributed the evaluation shall be made by attributes. j If the number of samples taken during the control period is at least one per week the evaluation may be made by variables. k For lime without additives this test is required only for product type determination. l See EN 459–3:2015, 4.4.

Conformity with this classification is assessed by means of statistical quality control as described in Annex A of this European Standard. 5.3.2 Chemical requirements for natural hydraulic lime The chemical properties of natural hydraulic lime of the type shown in Table 16 determined in accordance with EN 459-2 shall conform to the requirements in that table. Table 16 — Chemical requirements of natural hydraulic lime given as characteristic values Type of natural hydraulic lime SO3 Available lime as Ca(OH)2

in accordance with EN 459–2:2010, 5.8 Values in mass fraction in percent NHL 2 ≤ 2 ≥ 35 NHL 3,5 ≤ 2 ≥ 25 NHL 5 ≤ 2 ≥ 15 NOTE The values for SO3 are based on the product after subtraction of its free water and bound water content.

5.3.3 Physical requirements and other physical properties for natural hydraulic lime 5.3.3.1 Standard strength requirements for natural hydraulic lime The standard strengths of the types of natural hydraulic lime are the compressive strengths determined in accordance with EN 459-2 and shall conform to the requirements in Table 17. SIST EN 459-1:2015

5.3.3.2 Other physical properties of natural hydraulic lime The physical properties of natural hydraulic lime of the type shown in Table 18 determined in accordance with EN 459-2 shall conform to the requirements in that table. Table 18 — Physical requirements of natural hydraulic lime a given as characteristic values Type of natural hydraulic lime Particle size Free water content Soundnessb Mortar testsc Setting times % residue by mass Reference method Alternative method Penetration Air content initial final 0,09 mm 0,2 mm % mm mm mm % h NHL 2 ≤ 15 ≤ 2 ≤ 2 ≤ 2 ≤ 20 > 10 and < 50 ≤ 5 > 1 ≤ 40 NHL 3,5 ≤ 30 NHL 5 ≤ 15 a Particle size and free water content apply to natural hydraulic lime for all applications. Soundness, penetration, air content and setting time apply only to natural hydraulic lime for masonry mortar, plastering and rendering. b Tested in accordance with EN 459–2:2010, 6.4. c Tested in accordance with the test on standard mortar in EN 459–2.

5.3.4 Additional properties Other properties may be subject either to requirements in application standards dealing with the use of natural hydraulic lime or to requests from the user. These properties are given in informative Annex B. 5.3.5 Durability requirements The choice of natural hydraulic lime, particularly as regards types for different applications and exposure conditions shall follow the appropriate European or national application standards and/or regulations valid in the place of use. 5.4 Formulated lime 5.4.1 Classification of formulated lime Formulated lime shall be classified according to the notation given in Table 19, its available lime content in accordance with Table 20, and its compressive strength in accordance with Table 21. SIST EN 459-1:2015

Conformity with this classification is assessed by means of statistical quality control as described in Annex A of this European Standard. 5.4.2 Composition of formulated lime 5.4.2.1 General The composition of the formulated lime shall be declared by the producer in accordance with Annex D. 5.4.2.2 Constituents for formulated lime 5.4.2.2.1 General The presence of clinker and/or cement in formulated lime shall be declared by the producer (see examples in Annex D). 5.4.2.2.2 Main constituents of formulated lime The main constituents to be used in formulated lime shall be those identi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...