oSIST prEN 62146-1:2005

Grading capacitors for high-voltage alternating current circuit-breakers

Grading capacitors for high-voltage alternating current circuit-breakers

Project stopped because deleted at IEC level (lack of experts)

Zaščitni kondenzatorji za visokonapetostne izmenične odklopnike

General Information

- Status

- Not Published

- Current Stage

- 4020 - Public enquire (PE) (Adopted Project)

- Start Date

- 01-Jul-2005

- Due Date

- 01-Jul-2005

- Completion Date

- 01-Jul-2005

Overview

The oSIST prEN 62146-1:2005 is a European pre-standard project focused on grading capacitors specifically designed for high-voltage alternating current (AC) circuit-breakers. Although the project was stopped and deleted at the IEC level due to a lack of experts, it provides valuable insights into the technical framework for grading capacitors used in this critical electrical equipment.

Grading capacitors play a vital role in controlling and equalizing the voltage distribution across interrupting chambers in high-voltage circuit-breakers during switching operations such as opening and closing. The standard aimed to define uniform rules for performance, testing, rating, safety, and to give practical guidance on installation and operation of these capacitors.

Key Topics

Scope and Application

oSIST prEN 62146-1:2005 applies to grading capacitors mounted on:- Air-insulated circuit-breakers

- Immersed circuit-breakers (e.g., SF6 gas, oil)

- Replacement capacitors for both categories above

Performance and Ratings

The standard details specifications such as:- Rated frequency and voltages

- Standard insulation levels with different voltage categories

- Temperature ratings, mechanical stress resistance, and capacitance tolerances

- Capacitor loss requirements and mounting angle considerations

Service Conditions

It addresses normal and special operating conditions, including:- Overvoltage, altitude, temperature, humidity

- Mechanical stresses, vibrations, and environments for outdoor and indoor use

- Radio interference voltage (RIV) testing parameters

Testing Protocols

Comprehensive testing is a crucial aspect:- Type tests (dielectric, impulse voltage, partial discharge, mechanical bending)

- Routine tests (capacitance, loss angle, dielectric, tightness, visual inspection)

- Special tests (radio interference, overvoltage at various temperatures, vibration)

Installation and Maintenance Guidance The standard provides detailed recommendations for:

- Transport, storage, and unpacking procedures

- Assembly, mounting, and connection best practices

- Operation monitoring and maintenance routines

- Safety considerations including electrical, mechanical, and thermal aspects

Environmental and Safety Considerations It covers national regulations and environmental compliance to ensure safe and eco-friendly capacitor usage.

Applications

Grading capacitors as outlined in oSIST prEN 62146-1:2005 are essential components in:

High-voltage air-insulated circuit-breakers

Used to control voltage distribution and improve the reliability of switchgear.Gas or oil immersed circuit-breakers

Crucial in GIS (Gas-Insulated Switchgear) or oil-based circuit-breakers for stable operation under high stress.Circuit-breaker upgrades and replacements

Standards-compliant grading capacitors help enhance system performance and ensure compatibility.Electrical power systems and substations

The capacitors help maintain adequate voltage sharing and stability during transient switching conditions, contributing to overall grid safety and efficiency.

Related Standards

Understanding oSIST prEN 62146-1:2005 involves reference to related international standards, including:

- IEC 60060-1 – High-voltage test techniques

- IEC 60071-1 – Insulation coordination principles

- IEC 60270 – Partial discharge measurements

- IEC 60694 – Common specifications for high-voltage switchgear

- IEC 62271-100 – High-voltage AC circuit-breakers

- IEC 60376 – Sulfur hexafluoride specification for gas-insulated equipment

- IEC 60721 – Classification of environmental conditions

- IEC 61462 – Composite insulators testing and design

- IEC 62271-203 – Gas-insulated switchgear specifications

These complementary standards ensure integrated quality assurance, performance verification, and safety compliance for grading capacitors and their application environments.

By understanding oSIST prEN 62146-1:2005, electrical engineers and manufacturers can better align grading capacitor design, testing, and installation with industry best practices, thereby enhancing the performance and longevity of high-voltage AC circuit-breakers across a wide range of power systems.

Frequently Asked Questions

oSIST prEN 62146-1:2005 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Grading capacitors for high-voltage alternating current circuit-breakers". This standard covers: Project stopped because deleted at IEC level (lack of experts)

Project stopped because deleted at IEC level (lack of experts)

oSIST prEN 62146-1:2005 is classified under the following ICS (International Classification for Standards) categories: 31.060.70 - Power capacitors. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN 62146-1:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI oSIST prEN 62146-1:2005

PREDSTANDARD

julij 2005

Zaščitni kondenzatorji za visokonapetostne izmenične odklopnike

Grading capacitors for high-voltage alternating current circuit-breakers

ICS 31.060.70 Referenčna številka

© Standard je založil in izdal Slovenski inštitut za standardizacijo. Razmnoževanje ali kopiranje celote ali delov tega dokumenta ni dovoljeno

33/413/CDV

COMMITTEE DRAFT FOR VOTE (CDV)

PROJET DE COMITÉ POUR VOTE (CDV)

Project number IEC 62146-1 Ed. 1.0

Numéro de projet

IEC/TC or SC: Date of circulation Closing date for voting (Voting

TC 33

Date de diffusion mandatory for P-members)

CEI/CE ou SC:

Date de clôture du vote (Vote

2005-05-13

obligatoire pour les membres (P))

2005-10-14

Titre du CE/SC: TC/SC Title: Power capacitors

Secretary: Giancarlo Testi, Assistant Secretary TC 33

Secrétaire:

Also of interest to the following committees Supersedes document

Intéresse également les comités suivants : SC 17A Remplace le document : 33/412/NP

Functions concerned

Fonctions concernées

Safety EMC Environment Quality assurance

Sécurité

CEM Environnement Assurance qualité

CE DOCUMENT EST TOUJOURS À L'ÉTUDE ET SUSCEPTIBLE DE THIS DOCUMENT IS STILL UNDER STUDY AND SUBJECT TO CHANGE. IT

MODIFICATION. IL NE PEUT SERVIR DE RÉFÉRENCE. SHOULD NOT BE USED FOR REFERENCE PURPOSES.

LES RÉCIPIENDAIRES DU PRÉSENT DOCUMENT SONT INVITÉS À RECIPIENTS OF THIS DOCUMENT ARE INVITED TO SUBMIT, WITH THEIR

PRÉSENTER, AVEC LEURS OBSERVATIONS, LA NOTIFICATION DES COMMENTS, NOTIFICATION OF ANY RELEVANT PATENT RIGHTS OF

DROITS DE PROPRIÉTÉ DONT ILS AURAIENT ÉVENTUELLEMENT WHICH THEY ARE AWARE AND TO PROVIDE SUPPORTING

CONNAISSANCE ET À FOURNIR UNE DOCUMENTATION EXPLICATIVE. DOCUMENTATION.

Titre : Title : IEC 62146-1 Ed. 1.0: Grading capacitors

for high-voltage alternating current circuit-

breakers

Note d'introduction- Introductory note:

This project was studied by the JWG (TC 33/JWG TC

La version française sera diffuse ultérieurement

33-SC 17A) which prepared the first CD that was

discussed during the TC 33 meeting held in Florence

in October 2001. A second CD was discussed in

Montreal in October 2003. A third CD was prepared,

but having the relevant project more than five years,

the SMB (SMB/2946/INF, 2004-12-06) decided to put

the project to the preliminary stage.

The text of the attached NP/CDV document is

integrated taking into consideration the NC comments

on the last third CD 33/408/CD according to the

procedures. It is therefore decided to apply the

procedure given in AC/8/2003 for the simultaneous

submission of NPs and CDVs. If this NP is not

approved the RVN will immediately be issued and the

CDV ballot will be cancelled. When this NP is

accepted, the CDV ballot will continue and the project

will be considered as being at CDV stage.

- French version will be circulated later

ATTENTION ATTENTION

CDV soumis en parallèle au vote (CEI) Parallel IEC CDV/CENELEC Enquiry

et à l’enquête (CENELEC)

download this electronic file, to make a copy and to print out the content for the sole purpose of preparing

National Committee positions. You may not copy or "mirror" the file or printed version of the document, or

any part of it, for any other purpose without permission in writing from IEC.

FORM CDV (IEC) 2002-08-09

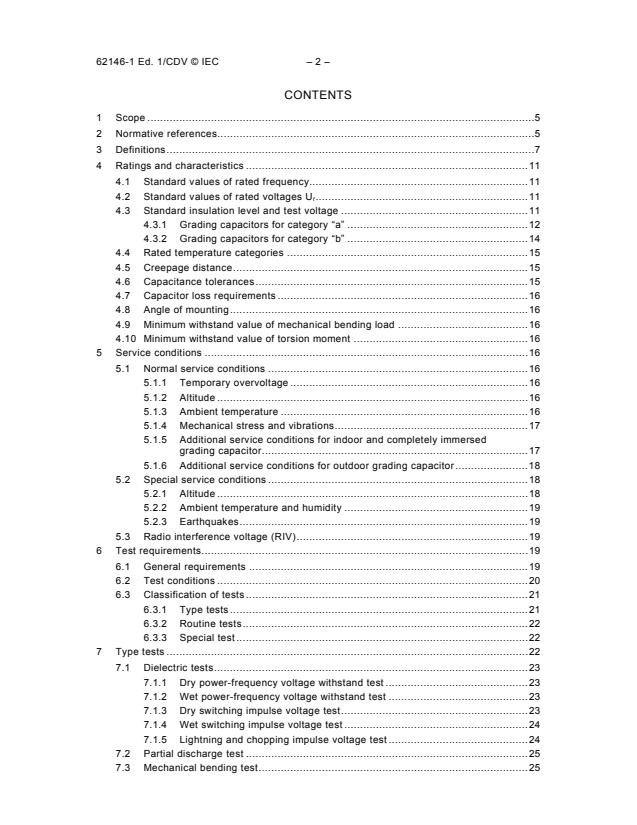

62146-1 Ed. 1/CDV © IEC – 2 –

CONTENTS

1 Scope .5

2 Normative references.5

3 Definitions.7

4 Ratings and characteristics .11

4.1 Standard values of rated frequency.11

4.2 Standard values of rated voltages U .11

r

4.3 Standard insulation level and test voltage .11

4.3.1 Grading capacitors for category “a” .12

4.3.2 Grading capacitors for category “b” .14

4.4 Rated temperature categories .15

4.5 Creepage distance.15

4.6 Capacitance tolerances.15

4.7 Capacitor loss requirements .16

4.8 Angle of mounting.16

4.9 Minimum withstand value of mechanical bending load .16

4.10 Minimum withstand value of torsion moment .16

5 Service conditions .16

5.1 Normal service conditions .16

5.1.1 Temporary overvoltage .16

5.1.2 Altitude .16

5.1.3 Ambient temperature .16

5.1.4 Mechanical stress and vibrations.17

5.1.5 Additional service conditions for indoor and completely immersed

grading capacitor.17

5.1.6 Additional service conditions for outdoor grading capacitor.18

5.2 Special service conditions .18

5.2.1 Altitude .18

5.2.2 Ambient temperature and humidity .19

5.2.3 Earthquakes.19

5.3 Radio interference voltage (RIV).19

6 Test requirements.19

6.1 General requirements .19

6.2 Test conditions .20

6.3 Classification of tests .21

6.3.1 Type tests .21

6.3.2 Routine tests.22

6.3.3 Special test .22

7 Type tests .22

7.1 Dielectric tests.23

7.1.1 Dry power-frequency voltage withstand test .23

7.1.2 Wet power-frequency voltage withstand test .23

7.1.3 Dry switching impulse voltage test.23

7.1.4 Wet switching impulse voltage test .24

7.1.5 Lightning and chopping impulse voltage test .24

7.2 Partial discharge test .25

7.3 Mechanical bending test.25

62146-1 Ed. 1/CDV © IEC – 3 –

8 Routine tests .26

8.1 Capacitance measurement at power frequency.26

8.2 Measurement of the tangent of the loss angle (tan δ).27

8.3 Dielectric tests.27

8.4 Partial discharge test .27

8.5 Tightness test.28

8.6 Tightness test to check gas ingress from pressurised environment .29

8.7 Visual inspection and dimensional check.29

9 Special tests .30

9.1 Radio interference voltage test .30

9.2 Overvoltage test at low and high temperature.31

9.3 Tightness test at different temperatures .31

9.4 Vibration test .32

9.5 Resonance frequency measurements.32

10 Recommendations for transport, storage, erection, operation and maintenance .32

10.1 Conditions during transport, storage and installation.33

10.2 Installation.33

10.3 Unpacking and lifting.33

10.4 Assembly .33

10.4.1 Mounting.33

10.4.2 Connections to metal parts .33

10.4.3 Final installation inspection .34

10.5 Operation .34

10.6 Maintenance .34

10.6.1 General.34

10.6.2 Recommendation for the manufacturer .34

10.5.1 Recommendations for the user.35

10.5.2 Failure report .35

11 Safety .37

11.1 Electrical aspects.37

11.2 Mechanical aspects .37

11.3 Thermal aspects .37

11.4 National regulations .37

12 Environmental aspects.37

13 Marking of the grading capacitor .37

13.1 Nameplate.37

Annex A (informative) .42

A.1 Alternative method for the switching impulse voltage type test .42

A.2 Alternative method for the lightning impulse voltage type test .42

Figure 1 – Grading capacitor diagram .38

Figure 2 – Altitude correction factor (see 5.2.1) .39

Figure 3 – RIV test circuit (see 9.1) .40

Figure 4 – Example of resonance frequency measurement recording (see 9.5) .41

62146-1 Ed. 1/CDV © IEC – 4 –

Table 1a – Standard insulation levels for 3,6 kV ≤ Um < 300 kV (range I, series I

according to IEC 60694) .12

Table 1b – Standard insulation levels for 4,76 kV ≤ Um < 362 kV (range I, series II,

used in North America, according to IEC 60694). .13

Table 2a – Standard insulation levels for Um ≥ 300 kV (range II according to

IEC 60694).13

Table 2b – Standard insulation levels for Um ≥ 362 kV (range II, used in North

America, according to IEC 60694). .14

Table 3 – Standard insulation levels for 72,5 kV ≤ Um < 300 kV (range I according to

IEC 62271).14

Table 4 – Standard insulation levels for Um ≥ 300 kV (range II according to

IEC 62271).14

Table 5 .17

Table 6 .21

Table 7 .28

62146-1 Ed. 1/CDV © IEC – 5 –

GRADING CAPACITORS FOR HIGH-VOLTAGE

ALTERNATING CURRENT CIRCUIT-BREAKERS

1 Scope

This standard is applicable to the grading capacitors used on circuit-breakers to control the

voltage distribution across the individual interrupting chambers.

The capacitors are also used to equalise the voltage distribution across the interrupting

chambers both during circuit-breaker opening and closing operations.

Grading capacitors can also be used in parallel on single break circuit-breakers to improve

the circuit-breaker capability.

This standard applies to grading capacitors falling into one or both of the following categories

for:

a) mounting on air-insulated circuit-breakers;

b) mounting on immersed (e.g. SF6 in GIS, oil, etc.) circuit-breakers.

This standard is applicable also to the grading capacitors used as replacement for both

categories a) and b).

The object of this standard is:

– to define uniform rules regarding performances, testing and rating;

– to define specific safety rules;

– to provide a guidance for installation and operation.

The testing necessary for each of the above applications is different

For new circuit-breaker applications, the environmental and mechanical testing should be

undertaken as part of the testing of the circuit-breaker as far as the requirements regarding

the grading capacitors are met. This ensures that the correct stresses, taking into account

mounting conditions, can be applied. Similarly grading capacitors should be fitted to the

circuit-breaker during electrical switching tests (e.g. short-circuit) to verify their ability to

withstand these conditions.

For replacement grading capacitors for circuit-breakers already in service, environmental and

mechanical tests are recommended. It should be recognised that these tests may be

inadequate to guarantee adequate performance in actual applications and prospective

purchasers must satisfy themselves of the validity or otherwise of these tests for specific

applications.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050(212):1990, International Electrotechnical Vocabulary (IEV) – Chapter 212:

Insulating solids, liquids and gases

62146-1 Ed. 1/CDV © IEC – 6 –

IEC 60050(436):1990, International Electrotechnical Vocabulary (IEV) – Chapter 436: Power

capacitors

IEC 60050(441):1984, International Electrotechnical Vocabulary (IEV) – Chapter 441:

Switchgear, controlgear and fuses

IEC 60050(471):1984, International Electrotechnical Vocabulary (IEV) – Chapter 471:

Insulators

IEC 60060-1:1989, High-voltage test techniques – Part 1: General definitions and test

Requirements

IEC 60068-2-17:1994, Basic environmental testing procedures – Part 2: Tests – Test Q:

Sealing

IEC 60071-1:1993, Insulation co-ordination – Part 1: Definitions, principles and rules

IEC 60270:2000, Partial discharge measurements

IEC 60376:1971, Specification and aceptance of new sulphur hexafluoride

IEC 60507:1991, Artificial pollution tests on high-voltage insulators to be used on a.c.

systems

IEC 60694:1996, Common specifications for high-voltage switchgear and controlgear

Standards

IEC 60721: Classification of environmental conditions

IEC 60815:1986, Guide for the selection of insulators in respect of polluted conditions

IEC 61166:1993, High-voltage alternating current circuit-breakers – Guide for seismic

qualification of high-voltage alternating current circuit-breakers

IEC 61462:1998, Composite insulators-Hollow insulators for use in outdoor and indoor

electrical equipment – definitions, test methods, acceptance criteria and design

recommendations

IEC 62155:2003, Hollow pressurized and unpressurizzed ceramic and glass insulators for use

in electrical equipment with rated voltages greater than 1000 V

IEC 62271-100:2003, High-voltage switchgear and controlgear – Part 100 High voltage

alternating-current circuit-breakers

IEC 62271-203:2003, High-voltage switchgear and controlgear – Part 203: Gas-insulated

metalenclosed switchgear for rated voltages above 52 kV

Project IEC 60815-3 TS Ed. 1.0: Selection and dimensioning of high-voltage insulators for

polluted conditions – Part 3: Composite insulators for a.c. systems

IEC Guide 109: Environmental aspects – Inclusion in electrotechnical product standards

CISPR 18-2:1986, Radio interference characteristics of overhead power lines and high-

voltage equipment – Part 2: Methods of measurement and procedure for determining limits

62146-1 Ed. 1/CDV © IEC – 7 –

3 Definitions

3.1

capacitor element (or element)

device consisting essentially of two electrodes separated by a dielectric (IEV 436-01-03).

3.2

capacitor unit (or unit)

assembly of one or more capacitor elements in the same container with terminals brought out

(IEV 436-01-04).

NOTE A common type of unit for grading capacitors has a cylindrical housing of insulating material and metal end

flanges which serve as terminals.

3.3

Capacitor stack (or stack)

assembly of capacitor units connected in series (IEV 436-01-05).

3.4

Capacitor

general term used when it is not necessary to state whether reference is made to a capacitor

unit or to a capacitor stack.

3.5

dielectric of a capacitor

insulating material between the electrodes.

NOTE The major insulation generally consists of paper, plastic film, or a mixed of paper and plastic film

subsequently treated and impregnated with oil or gas at atmospheric pressure or higher.

3.6

rated capacitance of a capacitor (C )

r

capacitance value for which the capacitor has been designed.

3.7

rated frequency of a capacitor (f )

r

frequency for which the capacitor has been designed (IEV 436-01-14).

3.8

rated voltage of a capacitor (U )

r

r.m.s. value of the alternating voltage assigned to the capacitor for identification and at which

the capacitor is designed to operate continuously.

3.9

rated temperature category of a capacitor

range of temperature of the ambient air or other medium in which the capacitor is immersed

during the service life and for which it has been designed.

3.10

grading capacitor

capacitor installed on high-voltage circuit-breakers to control the voltage distribution across

the individual interrupter unit or in parallel on single break circuit-breakers to improve the

breaker capability.

3.11

Indoor capacitor

capacitor, both ends of which are intended to be in ambient air at atmospheric pressure, but

not exposed to outdoor atmospheric conditions

(IEV 471-02-03).

62146-1 Ed. 1/CDV © IEC – 8 –

NOTE This definition include the completely immersed capacitor according to definition 3.13.

3.12

outdoor capacitor

capacitor, both ends of which are intended to be in ambient air at atmospheric pressure, and

exposed to outdoor atmospheric conditions.

(IEV 471-02-04).

3.13

completely immersed capacitor

capacitor both ends of which are intended to be immersed in an insulating medium other than

ambient air (e.g. oil or gas).

(IEV 471-02-08).

NOTE This definition includes capacitors operating in air or immersed in an insulating medium at temperatures

above ambient, such as occur with air-insulated or gas-insulated enclosure (e.g.: GIS).

3.14

capacitor terminals

terminals intended for electrical and mechanical connection to the terminals of the interrupter

units of circuit-breakers.

3.15

capacitance tolerance

permissible difference between the actual capacitance and the rated capacitance under

specified conditions

(IEV 436-04-01).

NOTE The actual capacitance should be measured at, or referred to, the temperature at which the rated

capacitance is defined.

3.16

resonance frequency

frequency for which the reactance of the intrinsic capacitance of the capacitor is equal to the

reactance of the self-inductance of the capacitor.

3.17

capacitor losses

active power dissipated in the capacitor

(IEV 436-04-10).

3.18

tangent of the loss angle (tan δ) of a capacitor

ratio between the equipment series resistance and the capacitive reactance of a capacitor at

specified sinusoidal alternating voltage and frequency

(IEV 436-04-11).

3.19

insulating envelope

Hollow insulator which is open from end to end, with or without sheds

(IEV 471-01-17).

NOTE 1 An insulating envelope may consists of one insulator unit or two or more permanently assembled

insulator units.

NOTE 2 The insulating envelope may be in ceramic, glass or analogous inorganic material, cast or moulded

resin, composite insulating material, in one piece or more pieces permanently assembled.

62146-1 Ed. 1/CDV © IEC – 9 –

3.20

creepage distance

shortest distance along the surface of an insulator between two conductive parts

(IEV 471- 01-08).

NOTE 1 The surface of cement or any other non-insulating jointing material is not considered as forming part of

the creepage distance.

NOTE 2 If high-resistance coating is applied to parts of the insulating part of an insulator, such parts are

considered to be effective insulating surface and the distance over them is included in the creepage distance.

3.21

flashover distance

Shortest distance in air external to the insulator between metallic parts which normally have

the operating voltage between them

(IEV 471-01-07).

3.22

voltage grading factor F of circuit-breaker

VG

The voltage grading factor F is the value that defines the standard values of rated voltages

VG

for the grading capacitor.

This factor is the ratio between the actual maximum power frequency voltage fraction across

one interrupting unit of a multi-break circuit-breaker and the calculated linear power frequency

voltage distribution per interrupting unit.

It is dependant on the circuit-breaker design, of the capacitance value of the grading

capacitor and its tolerance and of the safety margin.

The voltage grading factor shall be defined by the circuit-breaker manufacturer.

3.23

highest voltage for equipment (Um)

highest r.m.s. phase-to-phase voltage for which the equipment (e.g. circuit-breaker) is

designed, in respect of its insulation as well as other characteristics which relate to this

voltage in the relevant equipment standards.

The circuit-breaker with the grading capacitors installed is considered an equipment and Um

is the rated voltage of the circuit-breaker according to IEC 60694; the grading capacitors

alone are only accessories of the equipment.

3.24

external insulation

distance in air and the surfaces in contact with open air of insulation of the grading capacitor

which are subject to dielectric stresses and to the effects of the atmospheric and other

external conditions such as pollution, humidity, ice, vermin, etc.

3.25

internal insulation

internal solid, liquid or gaseous parts of the insulation of the grading capacitor which are

protected from the effects of atmospheric and other external conditions such as pollution,

humidity, ice, vermin, etc.

3.26

rated short duration power frequency withstand voltage

prescribed r.m.s. value of sinusoidal power frequency voltage that the equipment shall

withstand during tests made under specified conditions and for a duration of 1 min unless

otherwise specified.

62146-1 Ed. 1/CDV © IEC – 10 –

3.27

rated switching impulse withstand voltage

prescribed peak value of the switching impulse withstand voltage which characterises the

insulation of an equipment as regards the withstand tests.

NOTE The standard switching impulse has a time-to-crest of 250 µs and a time-to-half-value of 2500 µs as

specified in IEC 60060-1.

3.28

rated lightning impulse withstand voltage

prescribed peak value of the lightning impulse withstand voltage which characterises the

insulation of an equipment as regards the withstand tests.

NOTE The standard lightning impulse has a front time of 1.2 µs and a time-to-half-value of 50 µs as specified in

IEC 60060-1.

3.29

rated chopped lightning impulse withstand voltage

prescribed peak value of the chopped lightning impulse withstand voltage which

characterises the insulation of a grading capacitor as regards the withstand tests.

NOTE The definitions and the standard parameters applicable to chopped impulses are specified in IEC 60060-1.

3.30

rated insulation level

a) The rated chopped and lightning impulse and short duration power frequency withstand

voltages for capacitors installed on circuit-breaker with rated voltage lower than 300 kV.

b) The rated switching, lightning, chopped impulse and short duration power frequency

withstand voltages for capacitors installed on circuit-breaker with rated voltage equal to

or greater than 300 kV.

The rated insulation levels of the grading capacitor should be equal to or higher than the

relevant requirements for the circuit-breaker interrupting unit.

3.31

overvoltage (in a system)

Any voltage between one phase and earth or between phases having a peak value or values

exceeding the corresponding peak of the highest voltage for equipment.

(IEV 604- 03-09).

NOTE Overvoltages are always transient phenomena. A broad distinction may be made between highly damped

overvoltages of relatively short duration (e.g. 3.27 and 3.28) and undamped or only weakly damped overvoltages

of relatively long duration (see 3.33). The border-line between these two groups cannot be clearly fixed.

3.32

temporary overvoltage

An oscillatory overvoltage at a given location of relatively long duration and which is

undamped or only weakly damped.

Temporary overvoltages usually originate from switching operations or faults (e.g. load

rejection, single phase faults) and/or from non-linearities (ferro-resonance effects,

harmonics). They may be characterised by their amplitude, their oscillation frequencies, and

by their total duration or their decrement.

3.33

out-of-phase conditions

condition characterised by the loss of synchronism of two parts of a network resulting in

exceptionally high voltage across the open circuit-breaker. In the worst case the phase angle

of the voltage across the circuit-breaker can reach a value of 180° (phase opposition).

62146-1 Ed. 1/CDV © IEC – 11 –

3.34

mechanical stress

Any mechanical stress applied to the insulating envelope and to the terminals of the grading

capacitor.

It is a function of the following main forces:

– forces on the terminals due to the circuit-breaker connection;

– forces due to the wind and ice;

– seismic forces;

– forces due to the operating conditions, opening and closing, of the circuit- breaker;

– thermal forces due to the ambient medium conditions;

– forces due to the transportation of the circuit-breaker or grading capacitors.

3.35

flashover

breakdown between electrodes in a gas or in a liquid, at least partly along the surface of solid

insulation

IEV 60050(212), 212-01-37.

3.36

puncture

path produced through a solid by a breakdown producing permanent damage. The term is

also used as a synonym for electrical breakdown in solid

IEV 60050(212), 212-01-38.

4 Ratings and characteristics

4.1 Standard values of rated frequency

Standard values are 50 and 60 Hz.

4.2 Standard values of rated voltages U

r

The standard value of rated voltages U for grading capacitor is the highest voltage of the

r

circuit-breaker, on which the grading capacitor shall be installed, given in Column 1 of Tables

1, 2, 3, and 4, divided by √3, divided by the number n of breaks in series and multiplied by the

voltage grading factor of the circuit-breaker .

U x F

m VG

U = –-----------------

r

√3 x n

4.3 Standard insulation level and test voltage

Tables 1, 2, 3, and 4 specify the standard insulation levels with the corresponding highest

voltage for equipment, on which the grading capacitor is installed, U (r.m.s.).

m

The insulation level is defined by the r.m.s. value of the rated short duration power frequency

withstand voltage and the peak value of the rated lightning impulse withstand voltage for U <

m

300 kV and by the peak values of the rated switching and lightning impulse withstand voltages

for U ≥ 300 kV.

m

The value listed in the bellow tables, by the criteria defined in the type and routine test

clauses are the base to calculate the standard insulation level of the grading capacitor.

62146-1 Ed. 1/CDV © IEC – 12 –

NOTE Guidance for the choice of the insulation level is given in IEC Publication 60071-1 Clause 26, in

IEC 60694, in IEC 62271-100 and in IEC 60271-203.

4.3.1 Grading capacitors for category “a”

Table 1a – Standard insulation levels for 3,6 kV ≤ Um < 300 kV

(range I, series I according to IEC 60694)

The values in column 2 and 3 are taken from common value of IEC 60694.

1 2 3

Highest voltage for equipment U Rated lightning impulse withstand Rated short-duration power-

m

voltage frequency withstand voltage

KV r.m.s. kV peak kV r.m.s.

3,6 20 10

7,2 40 20

12 60 28

17,5 75 38

24 95 50

36 145 70

52 250 95

72,5 325 140

100 380 150

450 185

123 450 185

550 230

145 550 230

650 275

170 650 275

750 325

245 850 360

950 395

1050 460

62146-1 Ed. 1/CDV © IEC – 13 –

Table 1b – Standard insulation levels for 4,76 kV ≤ Um < 362 kV (range I, series II, used

in North America, according to IEC 60694).

The values in column 2 and 3 are taken from common value of IEC 60694.

1 2 3

Highest voltage for equipment U Rated lightning impulse withstand Rated short-duration power-

m

voltage frequency withstand voltage

Dry Wet

KV r.m.s. kV peak kV r.m.s. KV r.m.s.

4,76 60 19 -

8,25 75 26 24

95 35 30

15 95 35 30

110 50 45

25,8 125 50 45

150 70 60

38 150 70 60

200 95 80

48,3 250 120 100

72,5 350 160 140

NOTE 1 For highest voltage for equipment higher than 72,5 kV up to and including 245 kV, the values of tab. 1a

are applicable.

NOTE 2 Wet values are a 10s withstand for equipment used outdoors. See 9.2 of IEC 60060-1.

Table 2a – Standard insulation levels for Um ≥ 300 kV

(range II according to IEC 60694).

The values in column 2, 3 and 4 are taken from the “across open switching device and/or

isolating distance value” of IEC 60694.

1 2 3 4

Highest voltage for Rated switching impulse Rated lightning impulse Rated short-duration

equipment U withstand voltage withstand voltage power-frequency

m

withstand voltage

KV r.m.s. KV peak kV peak KV r.m.s.

300 945 1120 435

362 1095 1255 520

420 1245 1540 610

550 1350 1740 800

800 1750 2255 1150

62146-1 Ed. 1/CDV © IEC – 14 –

Table 2b – Standard insulation levels for Um ≥ 362 kV

(range II, used in North America, according to IEC 60694).

The values in column 2, 3 and 4 are taken from the “across open switching device and/or

isolating distance value” of IEC 60694.

1 2 3 4

Highest voltage for Rated switching impulse Rated lightning impulse Rated short-duration

equipment U withstand voltage withstand voltage power-frequency

m

withstand voltage

KV r.m.s. KV peak kV peak KV r.m.s.

362 1095 1505 610

550 1350 2115 890

4.3.2 Grading capacitors for category “b”

Table 3 – Standard insulation levels for 72,5 kV ≤ Um < 300 kV

(range I according to IEC 62271).

The values in column 2 and 3 are taken from “phase-to-earth across open switching device

and between phases” value of IEC 62271-203.

1 2 3

Highest voltage for equipment U Rated lightning impulse withstand Rated short-duration power-

m

voltage frequency withstand voltage

KV r.m.s. kV peak kV r.m.s.

72,5 325 140

100 450 185

123 550 230

145 650 275

170 750 325

245 950 395

1050 460

Table 4 – Standard insulation levels for Um ≥ 300 kV

(range II according to IEC 62271)

The values in column 2, 3 and 4 are taken from the “across open switching device and/or

isolating distance” value of IEC 62271-203.

1 2 3 4

Highest voltage for Rated switching impulse Rated lightning impulse Rated short-duration

equipment U withstand voltage withstand voltage power-frequency

m

withstand voltage

KV r.m.s. KV peak kV peak KV r.m.s.

300 945 1220 595

362 1095 1380 675

420 1245 1665 815

550 1350 1865 925

800 1750 2555 1270

62146-1 Ed. 1/CDV © IEC – 15 –

4.4 Rated temperature categories

Capacitors are classified in temperature categories, each category being specified by two

numbers. The first number represents the lowest limits of the ambient air temperature and the

second number represents the upper limits of the ambient air temperature at which the

capacitor may operate continuously with the rated voltage applied.

For the completely immersed grading capacitor the temperature limits refers to the medium

around the capacitor

The temperature categories cover the temperature range –40°C to +60°C

The lowest ambient air temperature should be chosen from the four preferred values:

+5°C, –5 °C, –25 °C, –40 °C.

The highest ambient air temperature should be chosen from the three preferred values:

+40°C, +50 °C, +60.

4.5 Creepage distance

For outdoor insulation susceptible to contamination, the required minimum nominal creepage

distance, measured on the insulation surface of the insulator envelope, porcelain and

composite type, shall comply with the following values of the minimum nominal specific

creepage distance (in mm per kV of the rated voltage U of the grading capacitor multiplied by

r

√3):

- for light pollution level 16 mm/kV

- for medium pollution level 20 mm/kV

- for heavy pollution level 25 mm/kV

- for very heavy pollution level 31 mm/kV

In addition, the ratio of the minimum nominal creepage distance to the arcing distance should

generally not exceed 4/1.

The profile shed of the porcelain insulator envelope have to satisfy the characterising

parameters in accordance to IEC 60815 Appendix D.

The selection and dimensioning of composite insulator envelope have to be in accordance to

Project IEC 60815-3 TS Ed. 1.0 .

If artificial pollution tests are required they shall be performed in accordance with IEC 60507.

NOTE The actual value of the creepage distance can differ from the rated value by the manufacturing tolerances

stated in 7.1 of IEC 62155.

– The definition for the various pollution classes is based on the IEC 60815.

– It is recognised that the performance of the surface insulation is greatly affected by the insulator shape. Also

other measures, such as periodical cleaning of the insulator surface with water or greasing the surface, can

improve the performance of the insulating enclosure under pollution.

4.6 Capacitance tolerances

The measured capacitance shall not differ from the rated capacitance by more than –5 % to

+5 %.

NOTE The purchaser has to specify any different tolerance value in the technical specification requirements (e.g.

for GIS grading capacitor application the tolerance of ± 3 % could be preferred).

62146-1 Ed. 1/CDV © IEC – 16 –

4.7 Capacitor loss requirements

The requirements relating to capacitor losses at rated frequency may be agreed upon

between manufacturer and purchaser.

NOTE 1 The purpose of the measurement of the losses is to check the uniformity of the production.

NOTE 2 The tan δ value is dependent on the insulation design and the voltage, the temperature and the

measuring frequency.

4.8 Angle of mounting

The capacitors shall be designed to be installed in any position: vertical, horizontal or oblique.

NOTE Due to shed profile a mounting in any position could be possible only taking in account of their orientation.

4.9 Minimum withstand value of mechanical bending load

The test force F depends on the capacitor dimensions, length l and largest shed diameter d

C

of the insulating envelope and shall be calculated as follow:

F = [l x d + 1] x 1000

C

where F is in Newtons and l and d are in metres.

C

In any case F shall be a minimum value which gives a bending moment of 2000 Nm.

C

NOTE The coefficients of the above equation for the test force F are based on a maximum wind velocity of 41,7

C

m/s, giving an equivalent wind pressure of 1000 N/m , for a maximum lateral line force at the top of the capacitor

of 500 N and for a safety factor of 2.

4.10 Minimum withstand value of torsion moment

The terminals of the grading capacitors shall be able to withstand a torsion moment M of at

T

least 3000 Nm.

5 Service conditions

Detailed information concerning classification of environmental conditions is given in

IEC 60721.

5.1 Normal service conditions

This standard gives requirements for capacitors intended for use in the conditions above

listed

They can be installed in the circuit-breaker used in accordance with the normal service

condition of IEC 60694.

5.1.1 Temporary overvoltage

The capacitors shall be able to withstand the voltage in out-of-phase conditions equivalent to

2,0 U r.m.s. for a period of 2 h without damage or any loss of life.

r

5.1.2 Altitude

The altitude does not exceed 1000 m.

5.1.3 Ambient temperature

Any combination of minimum and maximum values of rated ambient temperature can be

chosen to define the rated temperature category of a capacitor, e.g. –25 /40 or –5/50.

62146-1 Ed. 1/CDV © IEC – 17 –

The preferred rated temperature categories are: –40/40, –25/40, –5/40.

Table 5 specifies the relationship between the second number and the upper limits of the

ambient air temperature variation ranges

Table 5

Ambient air temperature (°C)

Highest mean over any period of

Max 24 h 1 year

40 30 20

50 40 30

60 50 40

NOTE 1 The temperature values according to Table 5 can be found in the meteorological temperature tables

relating to the installation site.

NOTE 2 It is understood that the capacitors are able to withstand frequent switching at temperatures within the

range of the rated temperature category.

5.1.4 Mechanical stress and vibrations

Mechanical stress and vibrations due to:

– forces on the terminals due to the circuit-breaker connection which value shall be defined

by agreement between purchaser and manufacturer;

– forces due to the wind and ice;

– forces due to the vibration consequent operations, opening and closing, of the circuit-

breaker.

Vibrations due to earthquakes are not considered for normal service conditions.

5.1.5 Additional service conditions for indoor and completely immersed grading

capacitor

Other considered service conditions are the following:

a) the influence of solar radiation may be neglected;

b) the ambient air is not significantly polluted by dust, smoke, corrosive gases, vapours or

salt;

c) the conditions of humidity are the follows:

1) the average value of the relative humidity, measured during a period of 24 h, does not

exceed 95 %;

2) the average value of the water vapour pressure for a period of 24 h, does not exceed

2.2 kPa;

3) the average value of relative humidity, for a period of one month, does not exceed

90 %;

4) the average value of the water vapour pressure, for a period of one month, does not

exceed 1.8 kPa.

For these conditions, condensation may occasionally occur.

NOTE 1 Condensation be expected where sudden temperature changes occur in periods of high humidity.

NOTE 2 To withstand the effects of high humidity and condensation, such as breakdown of insulation or corrosion

of metallic parts, grading capacitor designed for such conditions should be used.

NOTE 3 Condensation may be prevented by special design of the housing, by suitable ventilation and heating or

by the use of dehumidifying equipment.

62146-1 Ed. 1/CDV © IEC – 18 –

The completely immersed grading capacitors are subjected to the conditions a and b and to

the following other conditions:

– the influence of SF6 pressure;

– the resistance of the capacitor materials against the decomposition products of SF6

5.1.6 Additional service conditions for outdoor grading capacitor

Other considered service conditions are the following:

a) solar radiation up to a level of 1000 W/m (on a clear day at noon) should be considered;

b) the ambient air may be polluted by dust, smoke, corrosive gases, vapours or salt. The

pollution does not exceed the pollution levels given in 4.4;

c) the wind pressure does not exceed 700 Pa on cylindrical surface (corresponding to 34

m/s wind speed);

d) account should be taken of the presence of c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...