SIST ISO 13876:2019

Soil quality - Determination of polychlorinated biphenyls (PCB) by gas chromatography with mass selective detection (GC-MS) and gas chromatography with electron-capture detection (GC-ECD)

Soil quality - Determination of polychlorinated biphenyls (PCB) by gas chromatography with mass selective detection (GC-MS) and gas chromatography with electron-capture detection (GC-ECD)

ISO 13876:2013 specifies a method for quantitative determination of seven selected polychlorinated biphenyls (PCB28, PCB52, PCB101, PCB118, PCB138, PCB153, and PCB180) in sludge, treated biowaste, and soil using GC-MS and GC-ECD.

Qualité du sol - Détermination des polychlorobiphényles (PCB) par chromatographie en phase gazeuse avec détection sélective de masse (GC-MS) et chromatographie en phase gazeuse avec détection par capture d'électrons (GC-ECD)

Kakovost tal - Določevanje polikloriranih bifenilov (PCB) s plinsko kromatografijo z masno selektivnim detektorjem (GC-MS) ali s plinsko kromatografijo z detektorjem z zajetjem elektronov (GC-ECD)

Ta mednarodni standard določa metodo za kvantitativno določevanje sedmih izbranih polikloriranih bifenilov (PCB28, PCB52, PCB101, PCB118, PCB138, PCB153 in PCB180) v blatu,

obdelanih bioloških odpadkih in tleh z uporabo metod GC-MS in GC-ECD (glej preglednico 2).

Meja zaznavanja je odvisna od determinant, uporabljene opreme, kakovosti kemikalij, uporabljenih

za ekstrakcijo vzorca, in očiščenja ekstrakta.

Pod pogoji, določenimi v tem mednarodnem standardu, je mogoče doseči mejo uporabe 1 μg/kg (izraženo

kot suho snov).

Blato in obdelani biološki odpadki se lahko razlikujejo glede lastnosti, predvidenih stopenj onesnaženja s polikloriranimi bifenili ter prisotnosti motečih snovi. Zaradi teh razlik ni možen opis enotnega splošnega postopka. Ta mednarodni standard vključuje tabele odločanja, ki temeljijo na lastnostih vzorca, ter postopek za ekstrakcijo in očiščenje, ki ga je treba uporabiti.

General Information

Standards Content (Sample)

SLOVENSKI STANDARD

01-oktober-2019

Kakovost tal - Določevanje polikloriranih bifenilov (PCB) s plinsko kromatografijo

z masno selektivnim detektorjem (GC-MS) ali s plinsko kromatografijo z

detektorjem z zajetjem elektronov (GC-ECD)

Soil quality - Determination of polychlorinated biphenyls (PCB) by gas chromatography

with mass selective detection (GC-MS) and gas chromatography with electron-capture

detection (GC-ECD)

Qualité du sol - Détermination des polychlorobiphényles (PCB) par chromatographie en

phase gazeuse avec détection sélective de masse (GC-MS) et chromatographie en

phase gazeuse avec détection par capture d'électrons (GC-ECD)

Ta slovenski standard je istoveten z: ISO 13876:2013

ICS:

13.080.10 Kemijske značilnosti tal Chemical characteristics of

soils

71.040.50 Fizikalnokemijske analitske Physicochemical methods of

metode analysis

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

INTERNATIONAL ISO

STANDARD 13876

First edition

2013-11-15

Soil quality — Determination of

polychlorinated biphenyls (PCB)

by gas chromatography with mass

selective detection (GC-MS) and

gas chromatography with electron-

capture detection (GC-ECD)

Qualité du sol — Détermination des polychlorobiphényles (PCB) par

chromatographie en phase gazeuse avec détection sélective de masse

(GC-MS) et chromatographie en phase gazeuse avec détection par

capture d’électrons (GC-ECD)

Reference number

©

ISO 2013

© ISO 2013

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2013 – All rights reserved

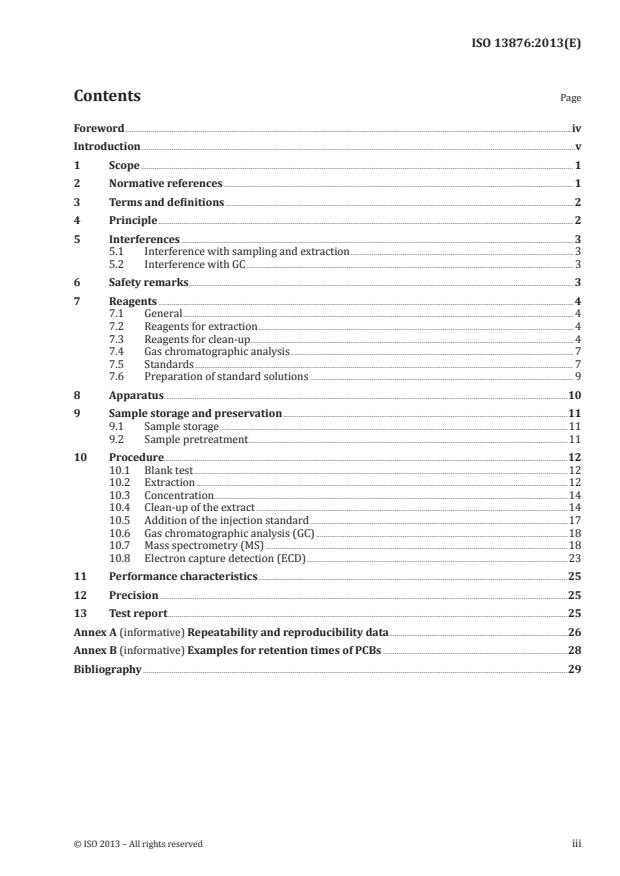

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Principle . 2

5 Interferences . 3

5.1 Interference with sampling and extraction . 3

5.2 Interference with GC . 3

6 Safety remarks . 3

7 Reagents . 4

7.1 General . 4

7.2 Reagents for extraction . 4

7.3 Reagents for clean-up . 4

7.4 Gas chromatographic analysis . 7

7.5 Standards . 7

7.6 Preparation of standard solutions . 9

8 Apparatus .10

9 Sample storage and preservation .11

9.1 Sample storage .11

9.2 Sample pretreatment .11

10 Procedure.12

10.1 Blank test .12

10.2 Extraction .12

10.3 Concentration.14

10.4 Clean-up of the extract .14

10.5 Addition of the injection standard .17

10.6 Gas chromatographic analysis (GC) .18

10.7 Mass spectrometry (MS) .18

10.8 Electron capture detection (ECD) .23

11 Performance characteristics .25

12 Precision .25

13 Test report .25

Annex A (informative) Repeatability and reproducibility data .26

Annex B (informative) Examples for retention times of PCBs .28

Bibliography .29

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 190, Soil quality, Subcommittee SC 3, Chemical

methods and soil characteristics.

iv © ISO 2013 – All rights reserved

Introduction

Polychlorinated biphenyls (PCB) have been widely used as additives in industrial applications where

chemical stability has been required. This stability, on the other hand, creates environmental problems

when PCBs are eventually released into the environment. Since some of these PCB compounds are highly

toxic, their presence in the environment (air, water, soil, sediment, and waste) is regularly monitored

and controlled. At present, determination of PCB is carried out in these matrices in most of the routine

laboratories following the preceding steps for sampling, pretreatment, extraction, and clean-up by

measurement of specific PCB by means of gas chromatography in combination with mass spectrometric

detection (GC-MS) or gas chromatography with electron capture detector (GC-ECD).

The European Standard EN 16167:2012 on which this International Standard is based, was developed

in the European project ‘HORIZONTAL’. It is the result of a desk study “3-12 PCB” and aims at evaluation

of the latest developments in assessing PCBs in sludge, soil, treated biowaste, and neighbouring fields.

Taken into account the different matrices and possible interfering compounds, this European Standard

does not contain one possible way of working. Several choices are possible, in particular, relating to

clean-up. Detection with both MS-detection and ECD-detection is possible. Two different extraction

procedures and 11 clean-up procedures are described. The use of internal and injection standards is

described in order to have an internal check on choice of the extraction and clean-up procedure. The

method is, as far as possible, in agreement with the method described for PAHs (see ISO 13859). It has

been tested for ruggedness.

This International Standard is applicable and validated for several types of matrices as indicated in

Table 1 (see also Annex A for the results of the validation).

Table 1 — Matrices for which this International Standard is applicable and validated

Matrix Materials used for validation

Sludge Municipal sewage sludge

Biowaste Compost

INTERNATIONAL STANDARD ISO 13876:2013(E)

Soil quality — Determination of polychlorinated biphenyls

(PCB) by gas chromatography with mass selective

detection (GC-MS) and gas chromatography with electron-

capture detection (GC-ECD)

WARNING — Persons using this International Standard should be familiar with usual laboratory

practice. This International Standard does not purport to address all of the safety problems, if

any, associated with its use. It is the responsibility of the user to establish appropriate safety and

health practices and to ensure compliance with any national regulatory conditions.

IMPORTANT — It is absolutely essential that tests conducted according to this International

Standard be carried out by suitably trained staff.

1 Scope

This International Standard specifies a method for quantitative determination of seven selected

polychlorinated biphenyls (PCB28, PCB52, PCB101, PCB118, PCB138, PCB153, and PCB180) in sludge,

treated biowaste, and soil using GC-MS and GC-ECD (see Table 2).

Table 2 — Target analytes of this International Standard

a

Target analyte CAS-RN

PCB28 2,4,4’-trichlorobiphenyl 7012-37-5

PCB52 2,2’,5,5’-tetrachlorobiphenyl 35693-99-3

PCB101 2,2’,4,5,5’-pentachlorobiphenyl 37680-37-2

PCB118 2,3’,4,4’,5-pentachlorobiphenyl 31508-00-6

PCB138 2,2’,3,4,4’,5’-hexachlorobiphenyl 35056-28-2

PCB153 2,2’,4,4’,5,5’-hexachlorobiphenyl 35065-27-1

PCB180 2,2’,3,4,4’,5,5’-heptachlorobiphenyl 35065-29-3

a

Chemical Abstracts Service Registry Number.

The limit of detection depends on the determinants, the equipment used, the quality of chemicals used

for the extraction of the sample, and the clean-up of the extract.

Under the conditions specified in this International Standard, a limit of application of 1 µg/kg (expressed

as dry matter) can be achieved.

Sludge and treated biowaste can differ in properties and also in the expected contamination levels

of PCBs and presence of interfering substances. These differences make it impossible to describe one

general procedure. This International Standard contains decision tables based on the properties of the

sample and the extraction and clean-up procedure to be used.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 5667-15, Water quality — Sampling — Part 15: Guidance on the preservation and handling of sludge

and sediment samples

ISO 8466-1, Water quality — Calibration and evaluation of analytical methods and estimation of performance

characteristics — Part 1: Statistical evaluation of the linear calibration function

ISO 11465, Soil quality — Determination of dry matter and water content on a mass basis — Gravimetric method

ISO 14507, Soil quality — Pretreatment of samples for determination of organic contaminants

ISO 16720, Soil quality — Pretreatment of samples by freeze-drying for subsequent analysis

ISO 18512, Soil quality — Guidance on long and short term storage of soil samples

ISO 22892, Soil quality — Guidelines for the identification of target compounds by gas chromatography and

mass spectrometry

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

polychlorinated biphenyl

PCB

biphenyl substituted by one to ten chlorine atoms

[SOURCE: EN 15308:2008, 3.1]

3.2

congener

member of the same kind, class, or group of chemicals, e.g. anyone of the 209 individual PCBs

[SOURCE: EN 15308:2008, 3.2]

Note 1 to entry: The IUPAC congener numbers are for easy identification; they do not represent the order of

chromatographic elution.

3.3

critical pair

pair of congeners that is separated to a predefined degree (e.g. R = 0,5) to ensure chromatographic

separation meets minimum quality criteria

[SOURCE: EN 15308:2008, 3.6]

4 Principle

Due to the horizontal character of this International Standard, different procedures for different steps

(modules) are allowed. Which modules should be used depends on the sample. A recommendation is

given in this International Standard. Performance criteria are described and it is the responsibility of

the laboratories applying this International Standard to show that these criteria are met. Use of spiking

standards (internal standards) allows an overall check on the efficiency of a specific combination of

modules for a specific sample. However, it does not necessarily give the information upon the extensive

extraction efficiency of the native PCB bonded to the matrix.

After pretreatment, according to the methods referred to in 9.2, the test sample is extracted with a

suitable solvent.

The extract is concentrated by evaporation. If necessary, interfering compounds are removed by a clean-

up method suitable for the specific matrix. The eluate is concentrated by evaporation.

The extract is analysed by gas chromatography. The various compounds are separated using a capillary

column with a stationary phase of low polarity. Detection occurs with mass spectrometry (MS) or an

electron capture detector (ECD) (8.2.1).

2 © ISO 2013 – All rights reserved

PCBs are identified and quantified by comparison of relative retention times and relative peak heights

(or peak areas) with respect to internal standards added. The efficiency of the procedure depends on

the composition of the matrix that is investigated.

5 Interferences

5.1 Interference with sampling and extraction

Use sampling containers of materials (preferably of steel, aluminium, or glass) that do not change the

sample during the contact time. Avoid plastics and other organic materials during sampling, sample

storage, or extraction. Keep the samples from direct sunlight and prolonged exposure to light.

During storage of the samples, losses of PCBs can occur due to adsorption on the walls of the containers.

The extent of the losses depends on the storage time.

5.2 Interference with GC

Substances that co-elute with the target PCB can interfere with the determination. These interferences

can lead to incompletely resolved signals and, depending on their magnitude, can affect accuracy

and precision of the analytical results. Peak overlap does not allow an interpretation of the result.

Asymmetric peaks and peaks being broader than the corresponding peaks of the reference substance

suggest interferences.

Chromatographic separation between the following pairs can be critical. The critical pair PCB28 and

PCB31 is used for selection of the capillary column (8.2.1). If molecular mass differences are present,

quantification can be made by mass selective detection. If not or using ECD, the specific PCB is reported

as the sum of all PCBs present in the peak. Typically, the concentrations of the co-eluting congeners

compared to those of the target congeners are low. When incomplete resolution is encountered, peak

integration shall be checked and, when necessary, corrected.

— PCB28 – PCB31

— PCB52 – PCB73

— PCB101 – PCB89/PCB90

— PCB118 – PCB106

— PCB138 – PCB164/PCB163

Presence of considerable amounts of mineral oil in the sample can interfere with the quantification of

PCB in GC-MS. In presence of mineral oil, GC-ECD can be preferred or mineral oil can be removed using

clean-up procedure G (see 10.4.8) using DMF/n-hexane.

Presence of tetrachlorobenzyltoluene (TCBT)-mixtures can disturb the determination of the PCB with

GC-ECD.

6 Safety remarks

PCBs are highly toxic and shall be handled with extreme care. Avoid contact with solid materials, solvent

extracts, and solutions of standard PCB. It is strongly advised that standard solutions are prepared centrally

in suitably equipped laboratories or are purchased from suppliers specialized in their preparation.

Solvent solutions containing PCB shall be disposed of in a manner approved for disposal of toxic wastes.

For the handling of hexane, precautions shall be taken because of its neurotoxic properties.

National regulations shall be followed with respect to all hazards associated with this method.

7 Reagents

7.1 General

All reagents shall be of recognized analytical grade. The purity of the reagents used shall be checked by

running a blank test as described in 10.1. The blank shall be less than 50 % of the lowest reporting limit.

7.2 Reagents for extraction

7.2.1 Acetone (2-propanone), (CH ) CO.

3 2

7.2.2 n-heptane, C H .

7 16

7.2.3 Petroleum ether, boiling range 40 °C to 60 °C.

Hexane-like solvents with a boiling range between 30 °C and 69 °C are allowed.

7.2.4 Anhydrous sodium sulfate, Na SO .

2 4

The anhydrous sodium sulfate shall be kept carefully sealed.

7.2.5 Distilled water, or water of equivalent quality, H O.

7.2.6 Sodium chloride, NaCl, anhydrous.

7.2.7 Keeper substance, high-boiling compound, i.e. octane, nonane.

7.3 Reagents for clean-up

7.3.1 Clean-up A using aluminium oxide

7.3.1.1 Aluminium oxide, Al O , basic or neutral, specific surface of 200 m /g, activity Super I

2 3

according to Brockmann.

7.3.1.2 Deactivated aluminium oxide.

Deactivated with approximately 10 % water.

Add approximately 10 g of water (7.2.5) to 90 g of aluminium oxide (7.3.1.1). Shake until all lumps have

disappeared. Allow the aluminium oxide to condition before use for some 16 h, sealed from the air; use

it for maximum two weeks.

NOTE The activity depends on the water content. It can be necessary to adjust the water content.

7.3.2 Clean-up B using silica gel 60 for column chromatography

7.3.2.1 Silica gel 60, particle size 63 µm to 200 µm.

7.3.2.2 Silica gel 60, water content: mass fraction w(H O) = 10 %.

Silica gel 60 (7.3.2.1) is heated for at least 3 h at 450 °C, cooled down in a desiccator and stored containing

magnesium perchlorate or a suitable drying agent. Before use, heat at for least 5 h at 130 °C in a drying

oven. Then, allow cooling in a desiccator and add 10 % water (mass fraction) in a flask. Shake for 5 min

intensively by hand until all lumps have disappeared and then for 2 h in a shaking device. Store the

deactivated silica gel in the absence of air; use it for maximum of two weeks.

4 © ISO 2013 – All rights reserved

7.3.3 Clean-up C using gel permeation chromatography (GPC)

1) ®

7.3.3.1 Bio-Beads S-X3.

7.3.3.2 Ethyl acetate, C H O .

4 8 2

7.3.3.3 Cyclohexane, C H .

6 12 ®

Preparation of GPC, for example: Put 50 g Bio-Beads S-X3 (7.3.3.1) into a 500-ml Erlenmeyer flask and

add 300 ml of elution mixture made up of cyclohexane (7.3.3.3) and ethyl acetate (7.3.3.2) 1:1 (volume)

in order to allow the beads to swell; after swirling for a short time until no lumps are left, maintain

the flask closed for 24 h. Drain the slurry into the chromatography tube for GPC. After approximately

three days, push in the plungers of the column so that a filling level of approximately 35 cm is obtained.

To further compress the gel, pump approximately 2 l of elution mixture through the column at a flow

−1

rate of 5 ml · min and push in the plungers to obtain a filling level of approximately 33 cm.

2) ®

7.3.4 Clean-up D using Florisil ®

7.3.4.1 Florisil , baked for 2 h at 600 °C, particle size of 150 µm to 750 µm.

7.3.4.2 Iso-octane, C H .

8 18

7.3.4.3 Toluene, C H .

7 8

7.3.4.4 Iso-octane/Toluene 95/5.

7.3.5 Clean-up E using silica H SO /silica NaOH

2 4

7.3.5.1 Silica, SiO , particle size of 70 µm to 230 µm, baked at 180 °C for a minimum of 1 h, and stored

in a pre-cleaned glass bottle with screw cap that prevents moisture from entering.

7.3.5.2 Silica, treated with sulfuric acid.

Mix 56 g of silica (7.3.5.1) and 44 g of sulfuric acid (7.3.8.1).

7.3.5.3 Sodium hydroxide solution, c(NaOH) = 1 mol/l.

7.3.5.4 Silica, treated with sodium hydroxide.

Mix 33 g of silica (7.3.5.1) and 17 g of sodium hydroxide (7.3.5.3).

7.3.5.5 n-hexane, C H .

6 14

7.3.6 Clean-up F using benzenesulfonic acid/sulfuric acid

7.3.6.1 3-ml silica gel column, of adsorbent mass 500 mg, particle size of 40 µm. ®

1) Bio-Beads is an example of a suitable product available commercially. This information is given for the

convenience of users of this International Standard and does not constitute an endorsement by ISO of this product.

Equivalent products may be used if they can be shown to lead to the same result. ®

2) Florisil is a trade name for a prepared diatomaceous substance, mainly consisting of anhydrous magnesium

silicate. This information is given for the convenience of users of this International Standard and does not constitute

an endorsement by ISO of this product. Equivalent products may be used if they can be shown to lead to the same

results.

7.3.6.2 3-ml benzenesulfonic acid column, of adsorbent mass 500 mg, particle size of 40 µm.

7.3.7 Clean-up G using DMF/hexane partitioning

7.3.7.1 Dimethylformamide(DMF), C H NO.

3 7

7.3.8 Clean-up H using concentrated sulfuric acid

7.3.8.1 Sulfuric acid, H SO of purity 96 % to 98 % (mass fraction).

2 4

7.3.9 Clean-up I using TBA sulfite reagent

7.3.9.1 Tetrabutylammonium reagent (TBA sulfite reagent).

Saturate a solution of tetrabutylammonium hydrogen sulfate in a mixture of equal volume of water and

2-propanol, c[(C H ) NHSO ] = 0,1 mol/l, with sodium sulfite.

4 9 4 4

NOTE 25 g of sodium sulfite should be sufficient for 100 ml of solution.

7.3.9.2 2-Propanol, C H O.

3 8

7.3.9.3 Sodium sulfite, Na SO .

2 3

7.3.10 Clean-up J using pyrogenic copper

WARNING — Pyrogenic copper is spontaneously inflammable. Suitable precautions shall be taken.

7.3.10.1 Copper(II)-sulfate pentahydrate, CuSO · 5 H O.

4 2

7.3.10.2 Hydrochloric acid, c(HCl) = 2 mol/l.

7.3.10.3 Zinc granules, Zn, particle size of 0,3 mm to 1,4 mm.

7.3.10.4 Anionic detergent aqueous solution, {e.g. 35 g/100 ml, n-dodecane-1-sulfonic acid sodium

salt [CH (CH ) SO Na]}.

3 2 11 3

NOTE Other commercially available detergents can also be suitable.

7.3.10.5 Deoxygenated water.

7.3.10.6 Pyrogenic copper.

Dissolve 45 g of copper(II)-sulfate pentahydrate (7.3.10.1) in 480 ml of water containing 20 ml of

hydrochloric acid (7.3.10.2) in a 1 000-ml beaker.

Take 15 g of zinc granules size (7.3.10.3), add 25 ml of water and one drop of anionic detergent solution

(7.3.10.4) in another 1 000-ml beaker.

Stir with a magnetic stirrer at a high speed to form a slurry. Then while stirring at this high speed,

carefully add the copper(II)-sulfate solution drop by drop using a glass rod.

Hydrogen is liberated and elemental pyrogenic copper is precipitated (red precipitate).

Stirring is continued until the hydrogen generation almost ceases. Then, the precipitated copper is allowed

to settle. The supernatant water is carefully removed and the product washed with deoxygenated water

(7.3.10.5) three times to eliminate residual salts.

6 © ISO 2013 – All rights reserved

Then, the water is carefully replaced with 250 ml of acetone (7.2.1) (while continuously stirring the

mixture). This operation is repeated twice more to ensure elimination of water.

Then, the above procedure is repeated three times with 250 ml of hexane (7.3.5.5) to ensure elimination

of the acetone.

Carefully transfer the copper with hexane into an Erlenmeyer flask and store under hexane. The flask

shall be sealed to prevent ingress of air and stored in an explosion-proof refrigerator at 2 °C to 8 °C.

The shelf life of the pyrogenic copper is at least two months. The clean-up efficiency then declines. The

copper changes colour as the clean-up efficiency decreases.

7.3.11 Clean-up K using silica/silver nitrate

7.3.11.1 Silver nitrate, AgNO .

7.3.11.2 Silver nitrate/silica adsorbent.

Dissolve 10 g of AgNO (7.3.11.1) in 40 ml of water and add this mixture in portions to 90 g of silica

(7.3.5.1). Shake the mixture until it is homogenous and leave it for 30 min. Put the mixture into a drying

oven at (70 ± 5) °C. Within 5 h, regularly increase the temperature from 70 °C to 125 °C. Activate the

mixture for 15 h at 125 °C. Store the mixture in brown glass bottles.

7.4 Gas chromatographic analysis

Operating gases for gas chromatography/ECD or MS are of high purity and in accordance with the

manufacturer’s specifications.

7.5 Standards

7.5.1 General

Choose the internal standards substances whose physical and chemical properties (such as extraction

behaviour, retention time) are similar to those of the compounds to be analysed. C -PCBs should be

used as internal standards for the GC-MS method for evaluation of results. Verify the stability of the

internal standards regularly.

NOTE Certified solutions of PCB and single solid PCB substances with certified purity are available from

a limited number of suppliers e.g. Institute for Reference Materials and Measurements (IRMM) B-2440 Geel,

Belgium; National Institute of Science and Technology Office of Standard Ref. Data, Washington DC 20 234 U.S.A;

or from other commercial providers.

7.5.2 Calibration standards

The calibration standard should contain the following compounds:

PCB28 2,4,4’-trichlorobiphenyl (CAS-RN 7012-37-5)

PCB52 2,2’,5,5’-tetrachlorobiphenyl (CAS-RN 35693-99-3)

PCB101 2,2’,4,5,5’-pentachlorobiphenyl (CAS-RN 37680-37-2)

PCB118 2,3’,4,4’,5-pentachlorobiphenyl (CAS-RN 31508-00-6)

PCB138 2,2’,3,4,4’,5’-hexachlorobiphenyl (CAS-RN 35056-28-2)

PCB153 2,2’,4,4’,5,5’-hexachlorobiphenyl (CAS-RN 35065-27-1)

PCB180 2,2’,3,4,4’,5,5’-heptachlorobiphenyl (CAS-RN 35065-29-3)

NOTE The numbers 28, 52, etc. correspond to the sequential numbers of chlorobiphenyls according to the

IUPAC rules for the nomenclature of organic compounds.

7.5.3 Internal and injection standards

7.5.3.1 General

The PCB congeners to be considered as internal and injection standards are listed below. The internal

standard shall be added to the sample. For MS-detection, labelled PCB congeners are advised.

When highly contaminated samples are analysed, an aliquot of the extract is often used for further clean-

up. This makes the costs of analyses caused by the use of labelled standard very high. In these cases, it

is allowed to add the internal standard in two steps. Step 1, addition of unlabelled internal standards to

the sample. Step 2, addition of labelled congeners to the aliquot of the extract used for clean-up.

At least three congeners, covering the chromatogram, shall be used as internal standard.

Other PCB not present in the sample, or C -labelled PCBs not used as internal standard, can be used

as injection standard.

NOTE 1 Some PCB mixtures contain up to 2,5 % of PCB155.

NOTE 2 PCB30, PCB143, and PCB207 are recommended as internal standards.

NOTE 3 PCB198 or PCB209 are recommended as injection standards for ECD-detection because of lesser

interferences.

7.5.3.2 Labelled PCB congeners

PCB28 C -2,4,4’-trichlorobiphenyl

PCB52 C -2,2’,5,5’-tetrachlorobiphenyl

PCB101 C -2,2’,4,5,5’-pentachlorobiphenyl (CAS-RN 37680-73-2)

PCB118 C -2,3’,4,4’,5-pentachlorobiphenyl

PCB138 C -2,2’,3,4,4’,5’-hexachlorobiphenyl (CAS-RN 35065-28-2)

PCB153 C -2,2’,4,4’,5,5’-hexachlorobiphenyl

PCB180 C -2,2’,3,4,4’,5,5’-heptachlorobiphenyl

8 © ISO 2013 – All rights reserved

7.5.3.3 Non-labelled PCB congeners

PCB29 2,4,5-trichlorobiphenyl (CAS-RN 15862-07-4)

PCB30 2,4,6-trichlorobiphenyl (CAS-RN 35693-92-6)

PCB143 2,2’,3,4,5,6’-hexachlorobiphenyl (CAS-RN 68194-15-0)

PCB155 2,2’,4,4’,6,6’-hexachlorobiphenyl (CAS-RN 33979-03-2)

PCB198 2,2’,3,3’,4,5,5’,6,-octachlorobiphenyl (CAS-RN 68194-17-2)

PCB207 2,2’,3,3’,4,4’,5,6,6’-nonachlorobiphenyl (CAS-RN 52663-79-3)

PCB209 2,2’,3,3’,4,4’,5,5’,6,6’-decachlorobiphenyl (CAS-RN 2051-24-3)

7.5.3.4 PCB congeners for resolution check

PCB28 2,4,4’-trichlorobiphenyl (CAS-RN 7012-37-5)

PCB31 2,4’,5-trichlorobiphenyl (CAS-RN 16606-02-3)

7.6 Preparation of standard solutions

7.6.1 Preparation of calibration standard solutions of PCBs

Prepare individual concentrated primary standard solutions of about 0,4 mg/ml in n-heptane (7.2.2)

by weighing approximately 10 mg of each of the calibration standards (7.5.2) to the nearest 0,1 mg and

dissolving them in 25 ml of n-heptane.

Combine small quantities (2 ml to 10 ml) of these individual primary standard solutions into a mixed

standard solution of PCB.

NOTE Because of the dangerous nature of the substances to be used, commercially available, preferably

certified, standard solutions or mixed standard solutions are preferred. Avoid skin contact.

The working standard solutions shall be in the same solvent like the extract.

Store the primary and diluted standard solutions in a dark place at a temperature of (5 ± 3) °C. The

solutions are stable for at least one year, provided that evaporation of solvent is negligible.

Components present in mixed standard solutions should be completely separated by the gas

chromatographic columns used.

7.6.2 Preparation of internal standard solution

Prepare a concentrated primary internal standard solution, containing at least three different

components (7.5.3), of about 0,4 mg/ml in n-heptane (7.2.2) by weighing approximately 10 mg of each of

the chosen internal standards to the nearest 0,1 mg and dissolving them in 25 ml of n-heptane. Prepare

from this a secondary internal solution with such a concentration that the added amount gives a peak

with measurable peak area or peak height in the chromatogram (at least 10 times the detection limit).

If the two step procedure for GC-MS is used, make two different internal standard solutions, one

containing the non-labelled compounds. At least two unlabelled congeners shall be used in the first

internal standard solution and at least three labelled congeners in the second solution.

7.6.3 Preparation of injection standard solution

Prepare a concentrated primary injection standard solution, containing at least two different

components (7.5.3), of about 0,4 mg/ml in n-heptane (7.2.2) by weighing approximately 10 mg of each of

the chosen injection standards to the nearest 0,1 mg and dissolving them in 25 ml of n-heptane. Prepare

from this a secondary internal solution which such a concentration that the added amount gives a peak

with measurable peak area or peak surface in the chromatogram (at least 10 times the detection limit).

8 Apparatus

8.1 Extraction and clean-up procedures, usual laboratory glassware.

All glassware and material that comes into contact with the sample or extract shall be thoroughly cleaned.

8.1.1 Sample bottles, made of glass, stainless steel, or aluminium, with glass stopper or screw top and

polytetrafluoroethylene (PTFE) seal of appropriate volume.

Glass is not appropriate for sludge samples.

WARNING — For safety reasons, biologically active sludge samples shall not be stored in a

sealed container.

8.1.2 Shaking device, with horizontal movement (200 strokes to 300 strokes per min).

8.1.3 Water bath, adjustable up to 100 °C.

8.1.4 Separating funnels, of appropriate volume.

8.1.5 Conical flasks, of appropriate volume.

8.1.6 Soxhlet extraction apparatus, consisting of round bottom flask, e.g. 100 ml, Soxhlet extractors

and Soxhlet thimbles, e.g. 27 mm × 100 mm, vertical condensers, e.g. 300 mm, heating device.

8.1.7 Concentrator, Kuderna Danish type.

Other evaporators, e.g. a rotary evaporator, can be used if found to be equally suitable.

8.1.8 Boiling chips, glass or porcelain beads.

8.1.9 Quartz wool, or silanized glass wool.

WARNING — Working with quartz wool imposes a risk to health through the release of fine quartz

particles. Inhalation of these should be prevented by using a fume cupboard and wearing a dust mask.

8.1.10 Calibrated test tubes, with a nominal capacity of 10 ml to 15 ml and ground glass stopper.

8.1.11 Chromatography tubes, chromatography column of glass, 5 mm to 10 mm inside diameter,

length e.g. 600 mm.

10 © ISO 2013 – All rights reserved

8.2 Gas chromatograph

8.2.1 General

Equipped with a capillary column, mass spectrometric detection (MS), or electron capture detector

(ECD) based on Ni.

NOTE Working with an encapsulated radioactive source as present in an ECD requires a licence according to

the appropriate national regulations.

Using ECD, gas chromatographs equipped with two detectors and with facilities for connecting two

capillary columns to the same injection system are very well suited for this analysis; with such apparatus,

the confirmatory analysis can be performed simultaneously.

8.2.2 Capillary columns, each comprising a 5 % phenyl-methyl silicone stationary phase coated onto

fused silica capillary column or an equivalent chemically bonded phase column.

The chromatographic peaks of PCB28 and PCB31 shall be resolved sufficiently (resolution at least 0,5)

for integrating the PCB28 peak. In general, column length should be 25 m to 60 m, internal diameter be

0,18 mm to 0,32 mm, and film thickness be 0,1 μm to 0,5 μm.

3)

Using ECD-detection, a second column, coated with a moderate polar phase (e.g. CP-Sil 19, OV 1701 ,

etc.) shall be used to confirm the result obtained.

NOTE The retention times for the PCB on different capillary columns are given in Annex B.

9 Sample storage and preservation

9.1 Sample storage

The samples shall be analysed as soon as possible after sampling. This applies in particular to the

examination of microbiologically active solids.

If necessary, sludge samples shall be stored according to ISO 5667-15.

Dried samples can be stored at room temperature in a dark place up to one month. Soil samples shall be

stored according to ISO 18512.

9.2 Sample pretreatment

Pretreat samples according to ISO 14507, if not otherwise specified, and considering the specific drying

procedures as specified in Table 3 to obtain a test sample.

Pretreatment is necessary to reduce the moisture content to enable extraction of the PCBs and to

increase the homogeneity.

Complete drying of the sample is essential if Soxhlet is used for extraction or to increase the homogeneity.

Complete drying is also recommended if the sample shall be stored for a long period.

3) CP-Sil 19, OV 1701 are examples of suitable products available commercially. This information is given for

the convenience of users of this International Standard and does not constitute an endorsement by ISO of these

products. Equivalent product may be used if they can be shown to lead to the same results.

Table 3 — Drying techniques for samples of different matrices for subsequent analyses of PCB

Matrix Drying technique

Air drying Freeze drying Na SO No drying

2 4

(ISO 16720)

a

Sludge x x x

Biowaste

x x x

(compost, mixed waste)

Soil

x x x x

(e.g. sand, clay)

a

Na SO can be used for the preservation of hygroscopic dried sludge.

2 4

10 Procedure

10.1 Blank test

Perform a blank test following the applied procedure (selected extraction and clean-up procedure)

using the same amount of reagents that are used for the pretreatment, extraction, clean-up, and analysis

of a sample. Analyse the blank immediately prior to analysis of the samples to demonstrate sufficient

freedom from contamination. The blank shall be less than 50 % of the lowest reporting limit.

10.2 Extraction

10.2.1 General

Depending on the test sample (matrix and moisture content), choose a suitable extraction method (see

Table 4). Extraction method 1 (see 10.2.2) or 3 (see 10.2.4) are recommended if it is important to break up

aggregates in the sample to access the PCBs. With wet samples, these methods shall be applied in order to

eliminate the presence of water. If dissolving of the PCBs is the most important step (waste and organic

rich materials) and the sample is dry, extraction method 2 (see 10.2.3) using Soxhlet is recommended.

For sludge, it has been shown that Soxhlet is applicable. In presence of plastics, use of acetone shall be

avoided because the use of acetone leads to a high amount of co-extractives. However, a general rule

cannot be given, because samples can contain all aggregates, organic matter, and (plastic) waste.

Other extraction procedures, e.g. ultrasonic extraction, microwave, or high-pressure liquid extraction

can be used provided

— the laboratory can show that the extraction efficiency is equivalent to one of the extraction

procedures 1, 2, or 3 as described in this International Standard, or

— the sample requires another approach as shown by the laboratory and the results of the procedures

are in agreement with the performance criteria as described in 10.7.4 and 10.8.6.

NOTE For application of this International Standard for some types of waste, the addition of acetone with

Soxhlet extraction has been shown to be effective.

Extraction procedures described in this International standard are suitable to extract up to 20 g of dry

sample. If the test sample has a low density (i.e. some wastes) or the sample is homogeneous, depending

on the expected PCB content and on the homogeneity of the sample, less sample can be used. In general,

the following amounts of dry sample can be used: 2 g to 10 g of sewage sludge, 5 g to 20 g of compost, or

2 g to 20 g of biowaste. The amount of sample shall be weighed with an accuracy of at least 1 %.

12 © ISO 2013 – All rights reserved

Table 4 — Extraction procedures to

...

INTERNATIONAL ISO

STANDARD 13876

First edition

2013-11-15

Soil quality — Determination of

polychlorinated biphenyls (PCB)

by gas chromatography with mass

selective detection (GC-MS) and

gas chromatography with electron-

capture detection (GC-ECD)

Qualité du sol — Détermination des polychlorobiphényles (PCB) par

chromatographie en phase gazeuse avec détection sélective de masse

(GC-MS) et chromatographie en phase gazeuse avec détection par

capture d’électrons (GC-ECD)

Reference number

©

ISO 2013

© ISO 2013

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2013 – All rights reserved

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Principle . 2

5 Interferences . 3

5.1 Interference with sampling and extraction . 3

5.2 Interference with GC . 3

6 Safety remarks . 3

7 Reagents . 4

7.1 General . 4

7.2 Reagents for extraction . 4

7.3 Reagents for clean-up . 4

7.4 Gas chromatographic analysis . 7

7.5 Standards . 7

7.6 Preparation of standard solutions . 9

8 Apparatus .10

9 Sample storage and preservation .11

9.1 Sample storage .11

9.2 Sample pretreatment .11

10 Procedure.12

10.1 Blank test .12

10.2 Extraction .12

10.3 Concentration.14

10.4 Clean-up of the extract .14

10.5 Addition of the injection standard .17

10.6 Gas chromatographic analysis (GC) .18

10.7 Mass spectrometry (MS) .18

10.8 Electron capture detection (ECD) .23

11 Performance characteristics .25

12 Precision .25

13 Test report .25

Annex A (informative) Repeatability and reproducibility data .26

Annex B (informative) Examples for retention times of PCBs .28

Bibliography .29

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 190, Soil quality, Subcommittee SC 3, Chemical

methods and soil characteristics.

iv © ISO 2013 – All rights reserved

Introduction

Polychlorinated biphenyls (PCB) have been widely used as additives in industrial applications where

chemical stability has been required. This stability, on the other hand, creates environmental problems

when PCBs are eventually released into the environment. Since some of these PCB compounds are highly

toxic, their presence in the environment (air, water, soil, sediment, and waste) is regularly monitored

and controlled. At present, determination of PCB is carried out in these matrices in most of the routine

laboratories following the preceding steps for sampling, pretreatment, extraction, and clean-up by

measurement of specific PCB by means of gas chromatography in combination with mass spectrometric

detection (GC-MS) or gas chromatography with electron capture detector (GC-ECD).

The European Standard EN 16167:2012 on which this International Standard is based, was developed

in the European project ‘HORIZONTAL’. It is the result of a desk study “3-12 PCB” and aims at evaluation

of the latest developments in assessing PCBs in sludge, soil, treated biowaste, and neighbouring fields.

Taken into account the different matrices and possible interfering compounds, this European Standard

does not contain one possible way of working. Several choices are possible, in particular, relating to

clean-up. Detection with both MS-detection and ECD-detection is possible. Two different extraction

procedures and 11 clean-up procedures are described. The use of internal and injection standards is

described in order to have an internal check on choice of the extraction and clean-up procedure. The

method is, as far as possible, in agreement with the method described for PAHs (see ISO 13859). It has

been tested for ruggedness.

This International Standard is applicable and validated for several types of matrices as indicated in

Table 1 (see also Annex A for the results of the validation).

Table 1 — Matrices for which this International Standard is applicable and validated

Matrix Materials used for validation

Sludge Municipal sewage sludge

Biowaste Compost

INTERNATIONAL STANDARD ISO 13876:2013(E)

Soil quality — Determination of polychlorinated biphenyls

(PCB) by gas chromatography with mass selective

detection (GC-MS) and gas chromatography with electron-

capture detection (GC-ECD)

WARNING — Persons using this International Standard should be familiar with usual laboratory

practice. This International Standard does not purport to address all of the safety problems, if

any, associated with its use. It is the responsibility of the user to establish appropriate safety and

health practices and to ensure compliance with any national regulatory conditions.

IMPORTANT — It is absolutely essential that tests conducted according to this International

Standard be carried out by suitably trained staff.

1 Scope

This International Standard specifies a method for quantitative determination of seven selected

polychlorinated biphenyls (PCB28, PCB52, PCB101, PCB118, PCB138, PCB153, and PCB180) in sludge,

treated biowaste, and soil using GC-MS and GC-ECD (see Table 2).

Table 2 — Target analytes of this International Standard

a

Target analyte CAS-RN

PCB28 2,4,4’-trichlorobiphenyl 7012-37-5

PCB52 2,2’,5,5’-tetrachlorobiphenyl 35693-99-3

PCB101 2,2’,4,5,5’-pentachlorobiphenyl 37680-37-2

PCB118 2,3’,4,4’,5-pentachlorobiphenyl 31508-00-6

PCB138 2,2’,3,4,4’,5’-hexachlorobiphenyl 35056-28-2

PCB153 2,2’,4,4’,5,5’-hexachlorobiphenyl 35065-27-1

PCB180 2,2’,3,4,4’,5,5’-heptachlorobiphenyl 35065-29-3

a

Chemical Abstracts Service Registry Number.

The limit of detection depends on the determinants, the equipment used, the quality of chemicals used

for the extraction of the sample, and the clean-up of the extract.

Under the conditions specified in this International Standard, a limit of application of 1 µg/kg (expressed

as dry matter) can be achieved.

Sludge and treated biowaste can differ in properties and also in the expected contamination levels

of PCBs and presence of interfering substances. These differences make it impossible to describe one

general procedure. This International Standard contains decision tables based on the properties of the

sample and the extraction and clean-up procedure to be used.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 5667-15, Water quality — Sampling — Part 15: Guidance on the preservation and handling of sludge

and sediment samples

ISO 8466-1, Water quality — Calibration and evaluation of analytical methods and estimation of performance

characteristics — Part 1: Statistical evaluation of the linear calibration function

ISO 11465, Soil quality — Determination of dry matter and water content on a mass basis — Gravimetric method

ISO 14507, Soil quality — Pretreatment of samples for determination of organic contaminants

ISO 16720, Soil quality — Pretreatment of samples by freeze-drying for subsequent analysis

ISO 18512, Soil quality — Guidance on long and short term storage of soil samples

ISO 22892, Soil quality — Guidelines for the identification of target compounds by gas chromatography and

mass spectrometry

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

polychlorinated biphenyl

PCB

biphenyl substituted by one to ten chlorine atoms

[SOURCE: EN 15308:2008, 3.1]

3.2

congener

member of the same kind, class, or group of chemicals, e.g. anyone of the 209 individual PCBs

[SOURCE: EN 15308:2008, 3.2]

Note 1 to entry: The IUPAC congener numbers are for easy identification; they do not represent the order of

chromatographic elution.

3.3

critical pair

pair of congeners that is separated to a predefined degree (e.g. R = 0,5) to ensure chromatographic

separation meets minimum quality criteria

[SOURCE: EN 15308:2008, 3.6]

4 Principle

Due to the horizontal character of this International Standard, different procedures for different steps

(modules) are allowed. Which modules should be used depends on the sample. A recommendation is

given in this International Standard. Performance criteria are described and it is the responsibility of

the laboratories applying this International Standard to show that these criteria are met. Use of spiking

standards (internal standards) allows an overall check on the efficiency of a specific combination of

modules for a specific sample. However, it does not necessarily give the information upon the extensive

extraction efficiency of the native PCB bonded to the matrix.

After pretreatment, according to the methods referred to in 9.2, the test sample is extracted with a

suitable solvent.

The extract is concentrated by evaporation. If necessary, interfering compounds are removed by a clean-

up method suitable for the specific matrix. The eluate is concentrated by evaporation.

The extract is analysed by gas chromatography. The various compounds are separated using a capillary

column with a stationary phase of low polarity. Detection occurs with mass spectrometry (MS) or an

electron capture detector (ECD) (8.2.1).

2 © ISO 2013 – All rights reserved

PCBs are identified and quantified by comparison of relative retention times and relative peak heights

(or peak areas) with respect to internal standards added. The efficiency of the procedure depends on

the composition of the matrix that is investigated.

5 Interferences

5.1 Interference with sampling and extraction

Use sampling containers of materials (preferably of steel, aluminium, or glass) that do not change the

sample during the contact time. Avoid plastics and other organic materials during sampling, sample

storage, or extraction. Keep the samples from direct sunlight and prolonged exposure to light.

During storage of the samples, losses of PCBs can occur due to adsorption on the walls of the containers.

The extent of the losses depends on the storage time.

5.2 Interference with GC

Substances that co-elute with the target PCB can interfere with the determination. These interferences

can lead to incompletely resolved signals and, depending on their magnitude, can affect accuracy

and precision of the analytical results. Peak overlap does not allow an interpretation of the result.

Asymmetric peaks and peaks being broader than the corresponding peaks of the reference substance

suggest interferences.

Chromatographic separation between the following pairs can be critical. The critical pair PCB28 and

PCB31 is used for selection of the capillary column (8.2.1). If molecular mass differences are present,

quantification can be made by mass selective detection. If not or using ECD, the specific PCB is reported

as the sum of all PCBs present in the peak. Typically, the concentrations of the co-eluting congeners

compared to those of the target congeners are low. When incomplete resolution is encountered, peak

integration shall be checked and, when necessary, corrected.

— PCB28 – PCB31

— PCB52 – PCB73

— PCB101 – PCB89/PCB90

— PCB118 – PCB106

— PCB138 – PCB164/PCB163

Presence of considerable amounts of mineral oil in the sample can interfere with the quantification of

PCB in GC-MS. In presence of mineral oil, GC-ECD can be preferred or mineral oil can be removed using

clean-up procedure G (see 10.4.8) using DMF/n-hexane.

Presence of tetrachlorobenzyltoluene (TCBT)-mixtures can disturb the determination of the PCB with

GC-ECD.

6 Safety remarks

PCBs are highly toxic and shall be handled with extreme care. Avoid contact with solid materials, solvent

extracts, and solutions of standard PCB. It is strongly advised that standard solutions are prepared centrally

in suitably equipped laboratories or are purchased from suppliers specialized in their preparation.

Solvent solutions containing PCB shall be disposed of in a manner approved for disposal of toxic wastes.

For the handling of hexane, precautions shall be taken because of its neurotoxic properties.

National regulations shall be followed with respect to all hazards associated with this method.

7 Reagents

7.1 General

All reagents shall be of recognized analytical grade. The purity of the reagents used shall be checked by

running a blank test as described in 10.1. The blank shall be less than 50 % of the lowest reporting limit.

7.2 Reagents for extraction

7.2.1 Acetone (2-propanone), (CH ) CO.

3 2

7.2.2 n-heptane, C H .

7 16

7.2.3 Petroleum ether, boiling range 40 °C to 60 °C.

Hexane-like solvents with a boiling range between 30 °C and 69 °C are allowed.

7.2.4 Anhydrous sodium sulfate, Na SO .

2 4

The anhydrous sodium sulfate shall be kept carefully sealed.

7.2.5 Distilled water, or water of equivalent quality, H O.

7.2.6 Sodium chloride, NaCl, anhydrous.

7.2.7 Keeper substance, high-boiling compound, i.e. octane, nonane.

7.3 Reagents for clean-up

7.3.1 Clean-up A using aluminium oxide

7.3.1.1 Aluminium oxide, Al O , basic or neutral, specific surface of 200 m /g, activity Super I

2 3

according to Brockmann.

7.3.1.2 Deactivated aluminium oxide.

Deactivated with approximately 10 % water.

Add approximately 10 g of water (7.2.5) to 90 g of aluminium oxide (7.3.1.1). Shake until all lumps have

disappeared. Allow the aluminium oxide to condition before use for some 16 h, sealed from the air; use

it for maximum two weeks.

NOTE The activity depends on the water content. It can be necessary to adjust the water content.

7.3.2 Clean-up B using silica gel 60 for column chromatography

7.3.2.1 Silica gel 60, particle size 63 µm to 200 µm.

7.3.2.2 Silica gel 60, water content: mass fraction w(H O) = 10 %.

Silica gel 60 (7.3.2.1) is heated for at least 3 h at 450 °C, cooled down in a desiccator and stored containing

magnesium perchlorate or a suitable drying agent. Before use, heat at for least 5 h at 130 °C in a drying

oven. Then, allow cooling in a desiccator and add 10 % water (mass fraction) in a flask. Shake for 5 min

intensively by hand until all lumps have disappeared and then for 2 h in a shaking device. Store the

deactivated silica gel in the absence of air; use it for maximum of two weeks.

4 © ISO 2013 – All rights reserved

7.3.3 Clean-up C using gel permeation chromatography (GPC)

1) ®

7.3.3.1 Bio-Beads S-X3.

7.3.3.2 Ethyl acetate, C H O .

4 8 2

7.3.3.3 Cyclohexane, C H .

6 12 ®

Preparation of GPC, for example: Put 50 g Bio-Beads S-X3 (7.3.3.1) into a 500-ml Erlenmeyer flask and

add 300 ml of elution mixture made up of cyclohexane (7.3.3.3) and ethyl acetate (7.3.3.2) 1:1 (volume)

in order to allow the beads to swell; after swirling for a short time until no lumps are left, maintain

the flask closed for 24 h. Drain the slurry into the chromatography tube for GPC. After approximately

three days, push in the plungers of the column so that a filling level of approximately 35 cm is obtained.

To further compress the gel, pump approximately 2 l of elution mixture through the column at a flow

−1

rate of 5 ml · min and push in the plungers to obtain a filling level of approximately 33 cm.

2) ®

7.3.4 Clean-up D using Florisil ®

7.3.4.1 Florisil , baked for 2 h at 600 °C, particle size of 150 µm to 750 µm.

7.3.4.2 Iso-octane, C H .

8 18

7.3.4.3 Toluene, C H .

7 8

7.3.4.4 Iso-octane/Toluene 95/5.

7.3.5 Clean-up E using silica H SO /silica NaOH

2 4

7.3.5.1 Silica, SiO , particle size of 70 µm to 230 µm, baked at 180 °C for a minimum of 1 h, and stored

in a pre-cleaned glass bottle with screw cap that prevents moisture from entering.

7.3.5.2 Silica, treated with sulfuric acid.

Mix 56 g of silica (7.3.5.1) and 44 g of sulfuric acid (7.3.8.1).

7.3.5.3 Sodium hydroxide solution, c(NaOH) = 1 mol/l.

7.3.5.4 Silica, treated with sodium hydroxide.

Mix 33 g of silica (7.3.5.1) and 17 g of sodium hydroxide (7.3.5.3).

7.3.5.5 n-hexane, C H .

6 14

7.3.6 Clean-up F using benzenesulfonic acid/sulfuric acid

7.3.6.1 3-ml silica gel column, of adsorbent mass 500 mg, particle size of 40 µm. ®

1) Bio-Beads is an example of a suitable product available commercially. This information is given for the

convenience of users of this International Standard and does not constitute an endorsement by ISO of this product.

Equivalent products may be used if they can be shown to lead to the same result. ®

2) Florisil is a trade name for a prepared diatomaceous substance, mainly consisting of anhydrous magnesium

silicate. This information is given for the convenience of users of this International Standard and does not constitute

an endorsement by ISO of this product. Equivalent products may be used if they can be shown to lead to the same

results.

7.3.6.2 3-ml benzenesulfonic acid column, of adsorbent mass 500 mg, particle size of 40 µm.

7.3.7 Clean-up G using DMF/hexane partitioning

7.3.7.1 Dimethylformamide(DMF), C H NO.

3 7

7.3.8 Clean-up H using concentrated sulfuric acid

7.3.8.1 Sulfuric acid, H SO of purity 96 % to 98 % (mass fraction).

2 4

7.3.9 Clean-up I using TBA sulfite reagent

7.3.9.1 Tetrabutylammonium reagent (TBA sulfite reagent).

Saturate a solution of tetrabutylammonium hydrogen sulfate in a mixture of equal volume of water and

2-propanol, c[(C H ) NHSO ] = 0,1 mol/l, with sodium sulfite.

4 9 4 4

NOTE 25 g of sodium sulfite should be sufficient for 100 ml of solution.

7.3.9.2 2-Propanol, C H O.

3 8

7.3.9.3 Sodium sulfite, Na SO .

2 3

7.3.10 Clean-up J using pyrogenic copper

WARNING — Pyrogenic copper is spontaneously inflammable. Suitable precautions shall be taken.

7.3.10.1 Copper(II)-sulfate pentahydrate, CuSO · 5 H O.

4 2

7.3.10.2 Hydrochloric acid, c(HCl) = 2 mol/l.

7.3.10.3 Zinc granules, Zn, particle size of 0,3 mm to 1,4 mm.

7.3.10.4 Anionic detergent aqueous solution, {e.g. 35 g/100 ml, n-dodecane-1-sulfonic acid sodium

salt [CH (CH ) SO Na]}.

3 2 11 3

NOTE Other commercially available detergents can also be suitable.

7.3.10.5 Deoxygenated water.

7.3.10.6 Pyrogenic copper.

Dissolve 45 g of copper(II)-sulfate pentahydrate (7.3.10.1) in 480 ml of water containing 20 ml of

hydrochloric acid (7.3.10.2) in a 1 000-ml beaker.

Take 15 g of zinc granules size (7.3.10.3), add 25 ml of water and one drop of anionic detergent solution

(7.3.10.4) in another 1 000-ml beaker.

Stir with a magnetic stirrer at a high speed to form a slurry. Then while stirring at this high speed,

carefully add the copper(II)-sulfate solution drop by drop using a glass rod.

Hydrogen is liberated and elemental pyrogenic copper is precipitated (red precipitate).

Stirring is continued until the hydrogen generation almost ceases. Then, the precipitated copper is allowed

to settle. The supernatant water is carefully removed and the product washed with deoxygenated water

(7.3.10.5) three times to eliminate residual salts.

6 © ISO 2013 – All rights reserved

Then, the water is carefully replaced with 250 ml of acetone (7.2.1) (while continuously stirring the

mixture). This operation is repeated twice more to ensure elimination of water.

Then, the above procedure is repeated three times with 250 ml of hexane (7.3.5.5) to ensure elimination

of the acetone.

Carefully transfer the copper with hexane into an Erlenmeyer flask and store under hexane. The flask

shall be sealed to prevent ingress of air and stored in an explosion-proof refrigerator at 2 °C to 8 °C.

The shelf life of the pyrogenic copper is at least two months. The clean-up efficiency then declines. The

copper changes colour as the clean-up efficiency decreases.

7.3.11 Clean-up K using silica/silver nitrate

7.3.11.1 Silver nitrate, AgNO .

7.3.11.2 Silver nitrate/silica adsorbent.

Dissolve 10 g of AgNO (7.3.11.1) in 40 ml of water and add this mixture in portions to 90 g of silica

(7.3.5.1). Shake the mixture until it is homogenous and leave it for 30 min. Put the mixture into a drying

oven at (70 ± 5) °C. Within 5 h, regularly increase the temperature from 70 °C to 125 °C. Activate the

mixture for 15 h at 125 °C. Store the mixture in brown glass bottles.

7.4 Gas chromatographic analysis

Operating gases for gas chromatography/ECD or MS are of high purity and in accordance with the

manufacturer’s specifications.

7.5 Standards

7.5.1 General

Choose the internal standards substances whose physical and chemical properties (such as extraction

behaviour, retention time) are similar to those of the compounds to be analysed. C -PCBs should be

used as internal standards for the GC-MS method for evaluation of results. Verify the stability of the

internal standards regularly.

NOTE Certified solutions of PCB and single solid PCB substances with certified purity are available from

a limited number of suppliers e.g. Institute for Reference Materials and Measurements (IRMM) B-2440 Geel,

Belgium; National Institute of Science and Technology Office of Standard Ref. Data, Washington DC 20 234 U.S.A;

or from other commercial providers.

7.5.2 Calibration standards

The calibration standard should contain the following compounds:

PCB28 2,4,4’-trichlorobiphenyl (CAS-RN 7012-37-5)

PCB52 2,2’,5,5’-tetrachlorobiphenyl (CAS-RN 35693-99-3)

PCB101 2,2’,4,5,5’-pentachlorobiphenyl (CAS-RN 37680-37-2)

PCB118 2,3’,4,4’,5-pentachlorobiphenyl (CAS-RN 31508-00-6)

PCB138 2,2’,3,4,4’,5’-hexachlorobiphenyl (CAS-RN 35056-28-2)

PCB153 2,2’,4,4’,5,5’-hexachlorobiphenyl (CAS-RN 35065-27-1)

PCB180 2,2’,3,4,4’,5,5’-heptachlorobiphenyl (CAS-RN 35065-29-3)

NOTE The numbers 28, 52, etc. correspond to the sequential numbers of chlorobiphenyls according to the

IUPAC rules for the nomenclature of organic compounds.

7.5.3 Internal and injection standards

7.5.3.1 General

The PCB congeners to be considered as internal and injection standards are listed below. The internal

standard shall be added to the sample. For MS-detection, labelled PCB congeners are advised.

When highly contaminated samples are analysed, an aliquot of the extract is often used for further clean-

up. This makes the costs of analyses caused by the use of labelled standard very high. In these cases, it

is allowed to add the internal standard in two steps. Step 1, addition of unlabelled internal standards to

the sample. Step 2, addition of labelled congeners to the aliquot of the extract used for clean-up.

At least three congeners, covering the chromatogram, shall be used as internal standard.

Other PCB not present in the sample, or C -labelled PCBs not used as internal standard, can be used

as injection standard.

NOTE 1 Some PCB mixtures contain up to 2,5 % of PCB155.

NOTE 2 PCB30, PCB143, and PCB207 are recommended as internal standards.

NOTE 3 PCB198 or PCB209 are recommended as injection standards for ECD-detection because of lesser

interferences.

7.5.3.2 Labelled PCB congeners

PCB28 C -2,4,4’-trichlorobiphenyl

PCB52 C -2,2’,5,5’-tetrachlorobiphenyl

PCB101 C -2,2’,4,5,5’-pentachlorobiphenyl (CAS-RN 37680-73-2)

PCB118 C -2,3’,4,4’,5-pentachlorobiphenyl

PCB138 C -2,2’,3,4,4’,5’-hexachlorobiphenyl (CAS-RN 35065-28-2)

PCB153 C -2,2’,4,4’,5,5’-hexachlorobiphenyl

PCB180 C -2,2’,3,4,4’,5,5’-heptachlorobiphenyl

8 © ISO 2013 – All rights reserved

7.5.3.3 Non-labelled PCB congeners

PCB29 2,4,5-trichlorobiphenyl (CAS-RN 15862-07-4)

PCB30 2,4,6-trichlorobiphenyl (CAS-RN 35693-92-6)

PCB143 2,2’,3,4,5,6’-hexachlorobiphenyl (CAS-RN 68194-15-0)

PCB155 2,2’,4,4’,6,6’-hexachlorobiphenyl (CAS-RN 33979-03-2)

PCB198 2,2’,3,3’,4,5,5’,6,-octachlorobiphenyl (CAS-RN 68194-17-2)

PCB207 2,2’,3,3’,4,4’,5,6,6’-nonachlorobiphenyl (CAS-RN 52663-79-3)

PCB209 2,2’,3,3’,4,4’,5,5’,6,6’-decachlorobiphenyl (CAS-RN 2051-24-3)

7.5.3.4 PCB congeners for resolution check

PCB28 2,4,4’-trichlorobiphenyl (CAS-RN 7012-37-5)

PCB31 2,4’,5-trichlorobiphenyl (CAS-RN 16606-02-3)

7.6 Preparation of standard solutions

7.6.1 Preparation of calibration standard solutions of PCBs

Prepare individual concentrated primary standard solutions of about 0,4 mg/ml in n-heptane (7.2.2)

by weighing approximately 10 mg of each of the calibration standards (7.5.2) to the nearest 0,1 mg and

dissolving them in 25 ml of n-heptane.

Combine small quantities (2 ml to 10 ml) of these individual primary standard solutions into a mixed

standard solution of PCB.

NOTE Because of the dangerous nature of the substances to be used, commercially available, preferably

certified, standard solutions or mixed standard solutions are preferred. Avoid skin contact.

The working standard solutions shall be in the same solvent like the extract.

Store the primary and diluted standard solutions in a dark place at a temperature of (5 ± 3) °C. The

solutions are stable for at least one year, provided that evaporation of solvent is negligible.

Components present in mixed standard solutions should be completely separated by the gas

chromatographic columns used.

7.6.2 Preparation of internal standard solution

Prepare a concentrated primary internal standard solution, containing at least three different

components (7.5.3), of about 0,4 mg/ml in n-heptane (7.2.2) by weighing approximately 10 mg of each of

the chosen internal standards to the nearest 0,1 mg and dissolving them in 25 ml of n-heptane. Prepare

from this a secondary internal solution with such a concentration that the added amount gives a peak

with measurable peak area or peak height in the chromatogram (at least 10 times the detection limit).

If the two step procedure for GC-MS is used, make two different internal standard solutions, one

containing the non-labelled compounds. At least two unlabelled congeners shall be used in the first

internal standard solution and at least three labelled congeners in the second solution.

7.6.3 Preparation of injection standard solution

Prepare a concentrated primary injection standard solution, containing at least two different

components (7.5.3), of about 0,4 mg/ml in n-heptane (7.2.2) by weighing approximately 10 mg of each of

the chosen injection standards to the nearest 0,1 mg and dissolving them in 25 ml of n-heptane. Prepare

from this a secondary internal solution which such a concentration that the added amount gives a peak

with measurable peak area or peak surface in the chromatogram (at least 10 times the detection limit).

8 Apparatus

8.1 Extraction and clean-up procedures, usual laboratory glassware.

All glassware and material that comes into contact with the sample or extract shall be thoroughly cleaned.

8.1.1 Sample bottles, made of glass, stainless steel, or aluminium, with glass stopper or screw top and

polytetrafluoroethylene (PTFE) seal of appropriate volume.

Glass is not appropriate for sludge samples.

WARNING — For safety reasons, biologically active sludge samples shall not be stored in a

sealed container.

8.1.2 Shaking device, with horizontal movement (200 strokes to 300 strokes per min).

8.1.3 Water bath, adjustable up to 100 °C.

8.1.4 Separating funnels, of appropriate volume.

8.1.5 Conical flasks, of appropriate volume.

8.1.6 Soxhlet extraction apparatus, consisting of round bottom flask, e.g. 100 ml, Soxhlet extractors

and Soxhlet thimbles, e.g. 27 mm × 100 mm, vertical condensers, e.g. 300 mm, heating device.

8.1.7 Concentrator, Kuderna Danish type.

Other evaporators, e.g. a rotary evaporator, can be used if found to be equally suitable.

8.1.8 Boiling chips, glass or porcelain beads.

8.1.9 Quartz wool, or silanized glass wool.

WARNING — Working with quartz wool imposes a risk to health through the release of fine quartz

particles. Inhalation of these should be prevented by using a fume cupboard and wearing a dust mask.

8.1.10 Calibrated test tubes, with a nominal capacity of 10 ml to 15 ml and ground glass stopper.

8.1.11 Chromatography tubes, chromatography column of glass, 5 mm to 10 mm inside diameter,

length e.g. 600 mm.

10 © ISO 2013 – All rights reserved

8.2 Gas chromatograph

8.2.1 General

Equipped with a capillary column, mass spectrometric detection (MS), or electron capture detector

(ECD) based on Ni.

NOTE Working with an encapsulated radioactive source as present in an ECD requires a licence according to

the appropriate national regulations.

Using ECD, gas chromatographs equipped with two detectors and with facilities for connecting two

capillary columns to the same injection system are very well suited for this analysis; with such apparatus,

the confirmatory analysis can be performed simultaneously.

8.2.2 Capillary columns, each comprising a 5 % phenyl-methyl silicone stationary phase coated onto

fused silica capillary column or an equivalent chemically bonded phase column.

The chromatographic peaks of PCB28 and PCB31 shall be resolved sufficiently (resolution at least 0,5)

for integrating the PCB28 peak. In general, column length should be 25 m to 60 m, internal diameter be

0,18 mm to 0,32 mm, and film thickness be 0,1 μm to 0,5 μm.

3)

Using ECD-detection, a second column, coated with a moderate polar phase (e.g. CP-Sil 19, OV 1701 ,

etc.) shall be used to confirm the result obtained.

NOTE The retention times for the PCB on different capillary columns are given in Annex B.

9 Sample storage and preservation

9.1 Sample storage

The samples shall be analysed as soon as possible after sampling. This applies in particular to the

examination of microbiologically active solids.

If necessary, sludge samples shall be stored according to ISO 5667-15.

Dried samples can be stored at room temperature in a dark place up to one month. Soil samples shall be

stored according to ISO 18512.

9.2 Sample pretreatment

Pretreat samples according to ISO 14507, if not otherwise specified, and considering the specific drying

procedures as specified in Table 3 to obtain a test sample.

Pretreatment is necessary to reduce the moisture content to enable extraction of the PCBs and to

increase the homogeneity.

Complete drying of the sample is essential if Soxhlet is used for extraction or to increase the homogeneity.

Complete drying is also recommended if the sample shall be stored for a long period.

3) CP-Sil 19, OV 1701 are examples of suitable products available commercially. This information is given for

the convenience of users of this International Standard and does not constitute an endorsement by ISO of these

products. Equivalent product may be used if they can be shown to lead to the same results.

Table 3 — Drying techniques for samples of different matrices for subsequent analyses of PCB

Matrix Drying technique

Air drying Freeze drying Na SO No drying

2 4

(ISO 16720)

a

Sludge x x x

Biowaste

x x x

(compost, mixed waste)

Soil

x x x x

(e.g. sand, clay)

a

Na SO can be used for the preservation of hygroscopic dried sludge.

2 4

10 Procedure

10.1 Blank test

Perform a blank test following the applied procedure (selected extraction and clean-up procedure)

using the same amount of reagents that are used for the pretreatment, extraction, clean-up, and analysis

of a sample. Analyse the blank immediately prior to analysis of the samples to demonstrate sufficient

freedom from contamination. The blank shall be less than 50 % of the lowest reporting limit.

10.2 Extraction

10.2.1 General

Depending on the test sample (matrix and moisture content), choose a suitable extraction method (see

Table 4). Extraction method 1 (see 10.2.2) or 3 (see 10.2.4) are recommended if it is important to break up

aggregates in the sample to access the PCBs. With wet samples, these methods shall be applied in order to

eliminate the presence of water. If dissolving of the PCBs is the most important step (waste and organic

rich materials) and the sample is dry, extraction method 2 (see 10.2.3) using Soxhlet is recommended.

For sludge, it has been shown that Soxhlet is applicable. In presence of plastics, use of acetone shall be

avoided because the use of acetone leads to a high amount of co-extractives. However, a general rule

cannot be given, because samples can contain all aggregates, organic matter, and (plastic) waste.

Other extraction procedures, e.g. ultrasonic extraction, microwave, or high-pressure liquid extraction

can be used provided

— the laboratory can show that the extraction efficiency is equivalent to one of the extraction

procedures 1, 2, or 3 as described in this International Standard, or

— the sample requires another approach as shown by the laboratory and the results of the procedures

are in agreement with the performance criteria as described in 10.7.4 and 10.8.6.

NOTE For application of this International Standard for some types of waste, the addition of acetone with

Soxhlet extraction has been shown to be effective.

Extraction procedures described in this International standard are suitable to extract up to 20 g of dry

sample. If the test sample has a low density (i.e. some wastes) or the sample is homogeneous, depending

on the expected PCB content and on the homogeneity of the sample, less sample can be used. In general,