SIST EN 14601:2025

(Main)Railway applications - Straight and angled end cocks for brake pipe and main reservoir pipe

Railway applications - Straight and angled end cocks for brake pipe and main reservoir pipe

This document is applicable to manually operated end cocks designed to cut-off the brake pipe and the main reservoir pipe of the air brake and compressed air system of rail vehicles; without taking the type of vehicles and track-gauge into consideration.

This document specifies requirements for the design, dimensions, testing and certification (qualification and/or type test), and marking.

Bahnanwendungen - Gerade und abgewinkelte Luftabsperrhähne für die Hauptluftleitung und Hauptbehälterleitung

Dieses Dokument ist anwendbar für manuell bediente Luftabsperrhähne an den Enden der Hauptluft- und der Hauptbehälterleitung im Druckluft(brems )system von Schienenfahrzeugen, ohne Berücksichtigung der Bauart der Fahrzeuge und der Spurweite.

Dieses Dokument legt Anforderungen hinsichtlich der Gestaltung, der Abmessungen, der Prüfung und der Zertifizierung (Qualifizierung und/oder Typprüfung) und der Kennzeichnung fest.

Applications ferroviaires - Robinets d'arrêt droit ou coudé pour conduite générale de frein et conduite principale

Le présent document est applicable aux robinets d’arrêt manœuvrables manuellement, conçus pour interrompre la conduite générale et la conduite principale des systèmes de freinage par air comprimé des véhicules ferroviaires, sans considération du type des véhicules et de gabarit de la voie.

Le présent document donne les exigences à respecter pour la conception, les dimensions, les essais, la certification (qualification et / ou essai de type), et le marquage.

Železniške naprave - Ravne in kotne zaporne pipe za zavorne in glavne zračne vode

Ta dokument se uporablja za ročno upravljane zaporne pipe, zasnovane za zapiranje zavornega in glavnega zračnega voda zračne zavore ter sistema stisnjenega zraka v železniških vozilih, brez upoštevanja vrste vozila in širine tira.

Ta dokument določa zahteve za načrtovanje, mere, preskušanje in certificiranje (preskus ustreznosti in/ali tipski preskus) ter označevanje.

General Information

- Status

- Published

- Public Enquiry End Date

- 30-Apr-2023

- Publication Date

- 25-Nov-2024

- Technical Committee

- IŽNP - Reilway applications

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 21-Nov-2024

- Due Date

- 26-Jan-2025

- Completion Date

- 26-Nov-2024

Relations

- Effective Date

- 01-Jan-2025

Overview

EN 14601:2024 - published by CEN - specifies requirements for manually operated end cocks used to cut off the brake pipe and the main reservoir pipe in the compressed‑air braking systems of rail vehicles. It applies to both straight and angled end cocks (angled outlet axis = 35 ± 2°) regardless of vehicle type or track gauge and covers design, dimensions, testing, certification (qualification and/or type test), marking and in‑service assessment.

Key topics and technical requirements

- Scope & applicability: Manually operated, two‑position, three‑way cocks with rotary spindle and handle; standard applies across rolling stock types.

- Design and types: Definitions for straight and angled end cocks, and orientation options (right‑hand / left‑hand handle positions).

- Functional characteristics: Requirements for open/closed states, venting port behaviour, lubrication, torque limits, spindle handle, fall time (pressure decay characteristic), leakage (internal/external), vacuum withstanding and resistance to pneumatic shock.

- Constructional characteristics: External appearance, connection types, space envelope, mechanical shock resistance, torque resistance and defined life expectancy.

- Testing and certification: Detailed type and qualification tests including:

- physical and geometrical checks,

- operating torque measurement and drift,

- pressure fall time measurement,

- hydraulic (water) proof test,

- pneumatic performance at specified pressures and temperatures,

- endurance under reduced air flow,

- vibration and shock tests,

- vacuum, corrosion (salt spray) and resistance to torque tests.

- Marking & designation: Requirements for product identification and conformity marking; dimensions provided in Annex A.

- Standards lifecycle: EN 14601:2024 supersedes EN 14601:2005+A2:2021 and was approved by CEN in August 2024.

Practical applications and users

Who uses EN 14601:2024:

- Rolling stock manufacturers (OEMs) specifying compliant end cocks for new vehicles.

- Component manufacturers designing and certifying end cocks to meet European requirements.

- Rail operators and maintenance organisations selecting replacement parts and verifying in‑service conformity.

- Test laboratories and notified bodies conducting type and qualification tests and issuing certificates.

- Procurement and safety engineers ensuring interoperability and safety of compressed‑air brake systems.

Benefits:

- Ensures interchangeability, safety and predictable performance of end cocks across fleets.

- Provides clear test regimes and acceptance criteria for compliance and procurement.

Related standards

Normative references used in EN 14601:2024 include:

- EN 50125‑1 (environmental conditions for rolling stock),

- EN 61373 (shock & vibration),

- EN ISO 228‑1 (pipe threads),

- EN ISO 9227 (salt spray corrosion tests),

- ISO 4975 (compressed air quality),

- ISO 5208 (pressure testing of metallic valves).

Keywords: EN 14601:2024, end cocks, brake pipe, main reservoir pipe, railway applications, straight end cock, angled end cock, type test, CEN.

Frequently Asked Questions

SIST EN 14601:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Railway applications - Straight and angled end cocks for brake pipe and main reservoir pipe". This standard covers: This document is applicable to manually operated end cocks designed to cut-off the brake pipe and the main reservoir pipe of the air brake and compressed air system of rail vehicles; without taking the type of vehicles and track-gauge into consideration. This document specifies requirements for the design, dimensions, testing and certification (qualification and/or type test), and marking.

This document is applicable to manually operated end cocks designed to cut-off the brake pipe and the main reservoir pipe of the air brake and compressed air system of rail vehicles; without taking the type of vehicles and track-gauge into consideration. This document specifies requirements for the design, dimensions, testing and certification (qualification and/or type test), and marking.

SIST EN 14601:2025 is classified under the following ICS (International Classification for Standards) categories: 45.040 - Materials and components for railway engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14601:2025 has the following relationships with other standards: It is inter standard links to SIST EN 14601:2005+A2:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14601:2025 is associated with the following European legislation: EU Directives/Regulations: 2016/797/EU; Standardization Mandates: M/483, M/591. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 14601:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2025

Železniške naprave - Ravne in kotne zaporne pipe za zavorne in glavne zračne

vode

Railway applications - Straight and angled end cocks for brake pipe and main reservoir

pipe

Bahnanwendungen - Gerade und abgewinkelte Luftabsperrhähne für die Hauptluftleitung

und Hauptbehälterleitung

Applications ferroviaires - Robinets d'arrêt droit ou coudé pour conduite générale de frein

et conduite principale

Ta slovenski standard je istoveten z: EN 14601:2024

ICS:

45.040 Materiali in deli za železniško Materials and components

tehniko for railway engineering

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14601

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2024

EUROPÄISCHE NORM

ICS 45.060.01 Supersedes EN 14601:2005+A2:2021

English Version

Railway applications - Straight and angled end cocks for

brake pipe and main reservoir pipe

Applications ferroviaires - Robinets d'arrêt droit ou Bahnanwendungen - Gerade und abgewinkelte

coudé pour conduite générale de frein et conduite Luftabsperrhähne für die Hauptluftleitung und

principale Hauptbehälterleitung

This European Standard was approved by CEN on 5 August 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14601:2024 E

worldwide for CEN national Members.

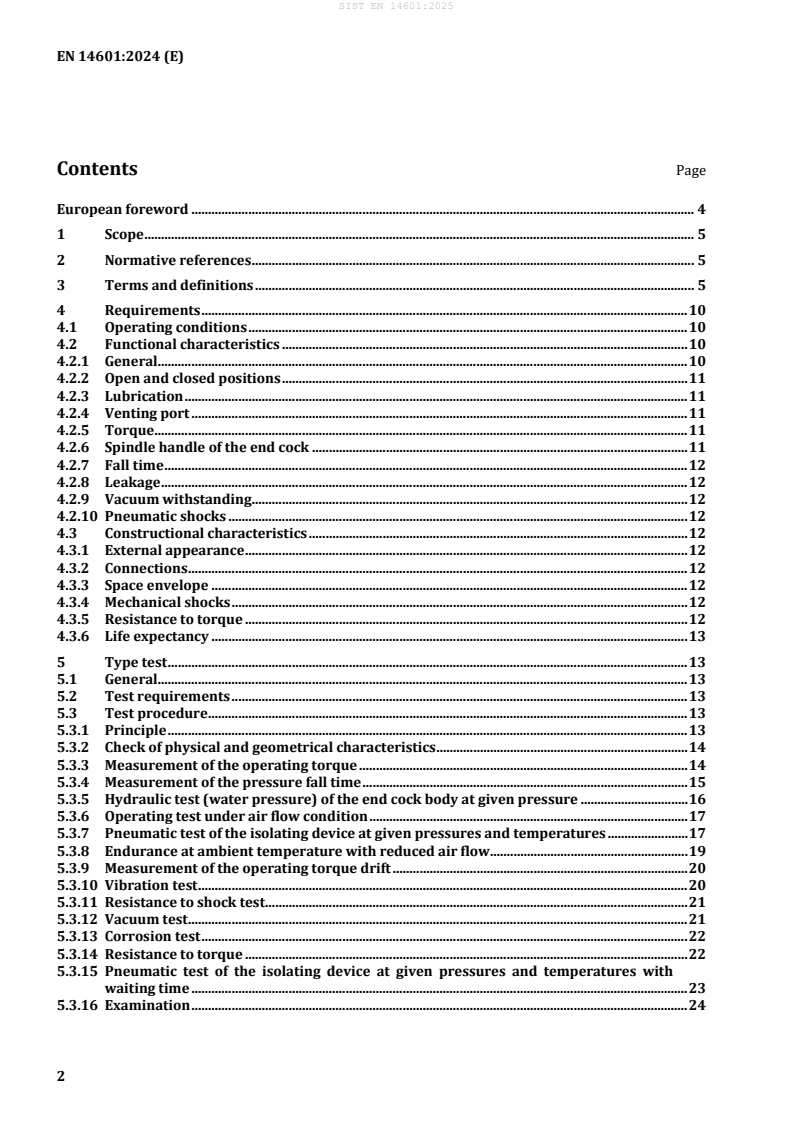

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Requirements . 10

4.1 Operating conditions . 10

4.2 Functional characteristics . 10

4.2.1 General. 10

4.2.2 Open and closed positions . 11

4.2.3 Lubrication . 11

4.2.4 Venting port . 11

4.2.5 Torque. 11

4.2.6 Spindle handle of the end cock . 11

4.2.7 Fall time . 12

4.2.8 Leakage . 12

4.2.9 Vacuum withstanding . 12

4.2.10 Pneumatic shocks . 12

4.3 Constructional characteristics . 12

4.3.1 External appearance . 12

4.3.2 Connections . 12

4.3.3 Space envelope . 12

4.3.4 Mechanical shocks . 12

4.3.5 Resistance to torque . 12

4.3.6 Life expectancy . 13

5 Type test . 13

5.1 General. 13

5.2 Test requirements . 13

5.3 Test procedure . 13

5.3.1 Principle . 13

5.3.2 Check of physical and geometrical characteristics . 14

5.3.3 Measurement of the operating torque . 14

5.3.4 Measurement of the pressure fall time . 15

5.3.5 Hydraulic test (water pressure) of the end cock body at given pressure . 16

5.3.6 Operating test under air flow condition . 17

5.3.7 Pneumatic test of the isolating device at given pressures and temperatures . 17

5.3.8 Endurance at ambient temperature with reduced air flow . 19

5.3.9 Measurement of the operating torque drift . 20

5.3.10 Vibration test . 20

5.3.11 Resistance to shock test . 21

5.3.12 Vacuum test . 21

5.3.13 Corrosion test . 22

5.3.14 Resistance to torque . 22

5.3.15 Pneumatic test of the isolating device at given pressures and temperatures with

waiting time . 23

5.3.16 Examination . 24

5.4 Approval validity . 24

6 In-service assessment . 24

7 Designation . 25

8 Marking . 25

Annex A (normative) Dimensions of end cocks . 26

Bibliography . 30

European foreword

This document (EN 14601:2024) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2025, and conflicting national standards shall be

withdrawn at the latest by May 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 14601:2005+A2:2021.

EN 14601:2005+A2:2021:

— normative references have been updated;

— tested end cock numbers in Table 1 “Operations to carry out for qualification” have been

supplemented for 5.3.7;

— in 5.3.7 “Pneumatic test of the isolating device at given pressures and temperatures” a new time

requirement for performance of the test has been added.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the

United Kingdom.

1 Scope

This document is applicable to manually operated end cocks designed to cut-off the brake pipe and the

main reservoir pipe of the air brake and compressed air system of rail vehicles; without taking the type

of vehicles and track-gauge into consideration.

This document specifies requirements for the design, dimensions, testing and certification (qualification

and/or type test), and marking.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 50125-1:2014, Railway applications — Environmental conditions for equipment — Part 1: Rolling

stock and on-board equipment

EN 61373:2010, Railway applications — Rolling stock equipment — Shock and vibration tests

(IEC 61373:1999)

EN ISO 228-1:2003, Pipe threads where pressure-tight joints are not made on the threads — Part 1:

Dimensions, tolerances and designation (ISO 228-1:2000)

EN ISO 9227:2022, Corrosion tests in artificial atmospheres — Salt spray tests (ISO 9227:2022)

ISO 4975:2022, Railway applications — Braking system — Quality of compressed air for pneumatic

apparatus and systems

ISO 5208:2015, Industrial valves — Pressure testing of metallic valves

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

end cock

two position, three way cock, with no piped vent and, with a rotary spindle moved by the operating

handle

3.2

components

3.2.1

port

terminus of a fluid passage in a component (to which pipelines can be connected) for the transmission

of fluid to, or from the component

As impacted by EN 61373:2010/AC:2017-09.

3.2.1.1

venting port

port which provides passage to atmosphere

3.2.1.2

outlet port

port which is vented to atmosphere when the cock is closed

3.2.1.3

inlet port

port which is not vented when the cock is closed

3.2.1.4

threaded port

port arranged to accept screw threaded connection

3.2.2

direction of rotation

direction of rotation quoted as viewed looking at the handle side

3.2.3

mechanical detent

spring arrangement to retain moving parts in open or closed position and only able to be moved to

another position with the specified force

3.2.4

latch

mechanical device to retain moving parts in open or closed position which can only be moved when the

latch is released

3.3

types of end cocks

3.3.1

design

3.3.1.1

straight end cock

cock with axis of inlet and outlet ports in line

Note 1 to entry: See Figure 1.

Figure 1 — Straight end cock

3.3.1.2

angled end cock

cock with axis of outlet port at an angle of (35 ± 2)° with axis of inlet port

Note 1 to entry: See Figure 2.

Figure 2 — Angled end cock

3.3.2

location of the handle

3.3.2.1

right hand end cock

end cock with handle located at the right hand side of the end cock with the handle closed in a vertically

upwards position

Note 1 to entry: The end cock is opened by rotating the handle in an anticlockwise direction (see Figure 3).

Note 2 to entry: Standard mounting position. Other positions of handle are defined by drawing (see Figure 3).

Key

1 closed position

2 open position

3 outlet port

4 inlet port

Figure 3 — Right hand end cock

3.3.2.2

left hand end cock

end cock with handle located at the left hand side of the cock with the handle closed is in a vertically

upwards position

Note 1 to entry: The cock is opened by rotating the handle in a clockwise direction (see Figure 4).

Note 2 to entry: Standard mounting position. Other positions of handle are defined by drawing (see Figure 4).

Key

1 closed position

2 open position

3 outlet port

4 inlet port

Figure 4 — Left hand end cock

3.4

states

3.4.1

closed position

position of the valve component part in which the flow path between inlet and outlet ports is closed and

the venting passage is open and connected to the hose and coupling side of the cock

Note 1 to entry: The cock handle is closed in the vertically upwards position on the vehicle.

Note 2 to entry: The purchaser will define the angle between the cock inlet port axis and the vertically upwards

handle position for cocks not mounted horizontally.

3.4.2

open position

position of the valve member in which the flow path between inlet and outlet ports is fully open, and the

venting passage is closed

3.4.3

fall time

time taken in a device for a quantity of air to fall from a specified high pressure level down to a specified

lower pressure level

Note 1 to entry: Parameter used to define the fluid characteristic of the cock.

3.4.4

proof pressure

test pressure, in excess of a maximum rated pressure, which causes no malfunction or permanent

deformation damage

3.5

temperature range

range of the temperature within which the apparatus can operate satisfactorily

3.6

leakage

3.6.1

external leakage

leakage of the fluid contained in the end cock to atmosphere

3.6.2

internal leakage

leakage of the fluid contained in the end cock from one side to the other side with the valve component

part in the closed position

3.7

drift

change or variation of a condition with time under steady state operating conditions

3.8

life expectancy

predicted working period during which a component or system will maintain a specified level of

performance under specified conditions

Note 1 to entry: Sometimes expressed in statistical term as a probability.

4 Requirements

4.1 Operating conditions

The end cock shall be able to function under the following conditions:

a) with at least “compressed air purity (ISO 4975) 4 – 4 – X [-40 °C; +35 °C]” in accordance with

ISO 4975:2022 (or other specified maximum temperature than +35 °C). This requirement is

verified when tests are carried out in accordance with 5.2;

b) in the temperature range for the environmental conditions to which the rail vehicle is submitted

during its operation and at least for a temperature range defined by the class T2 of EN 50125-

1:2014. The purchaser can specify a higher temperature value if operational constraints demand it.

This requirement is tested in accordance with 5.3.3, 5.3.7 and 5.3.12;

c) the end cock shall withstand the external corrosion due to normal atmospheric pollutants as

specified in EN 50125-1:2014. The end cock is tested in accordance with the test shown in 5.3.13;

d) in the vibrational environment of the rail vehicle on which it is mounted and it shall remain in

either the open or closed position. The cock shall be tested in accordance with 5.3.10.

4.2 Functional characteristics

4.2.1 General

The operating handle of the end cock shall be equipped with a detent or latch system.

The requirements given in 4.2.2 to 4.2.10 are defined to ensure the air flow through the brake pipe and

main reservoir pipe and ensure no malfunction of the cock after the brake pipe test (as part of the

routine brake test before the trains start).

4.2.2 Open and closed positions

The opening and closing of the cock shall be achieved by turning its spindle through a minimum of 90°

and not more than 100°. Stops shall be provided at the extremes of rotation, so that the open and closed

positions are achieved positively. The open and closed positions are defined in 3.4.1 and 3.4.2.

4.2.3 Lubrication

It shall be possible to operate the end cock at all pressures without additional lubrication.

4.2.4 Venting port

The end cock shall incorporate a venting port with a minimum area of 80 mm , arranged so that when

the cock is closed the compressed air from the coupling hose end of the cock (outlet port connected to

the next vehicle) can be exhausted to atmosphere. Venting shall have commenced when the operation

of the end cock has reduced the cross-sectional area of the bore of the end cock by one third. The

venting port should not be able to be obstructed when the cock is mounted on the rail vehicle.

The venting port should be designed and arranged such that the under usual operation, the operating

personnel are not endangered by the exhaust-flow, or objects carried by it, nor by excessive noise level.

4.2.5 Torque

All end cocks with mechanical detent, or with latch engaged shall not be operated by vibration or

shocks. The end cock shall be capable of manual operation therefore the operating torque of the handle

shall be in the range of 9 Nm to 20 Nm for end cocks with detent and a maximum of 6 Nm for cocks with

latch. The torque is tested in accordance with 5.3.3. Torque drifts shall not be allowed. This requirement

is tested in accordance with 5.3.9.

4.2.6 Spindle handle of the end cock

Where the handle is detachable and the unique angular relationship between it and the spindle is not

constructionally ensured, permanent markings on the handle and the spindle (see for an example

Figure 5) shall allow to identify the correct assembly. The relative position of the handle and spindle,

when assembled, shall be maintained under all operating and environmental conditions.

Detachable handles and the spindle should be designed in such a way that an unambiguous angular

relationship between handle and spindle will remain.

Figure 5 — Marking example on the handle and on the end of the spindle

4.2.7 Fall time

The air passages shall be designed to minimize the air flow losses within the cock and the cross-

sectional area shall not be smaller than the cross-sectional area of a plain pipe of 25 mm internal

diameter. The pressure fall time should not be longer than that for an equivalent pipe of the same

nominal diameter, as tested in 5.3.4.

4.2.8 Leakage

The sealing arrangement within the end cock shall prevent any unacceptable loss of air. The allowable

loss of air shall be less than the leakage values when tested in accordance with 5.3.7.

4.2.9 Vacuum withstanding

If a vacuum withstand is required, the end cock shall be able to function with a pressure of 0,75 bar

below atmospheric pressure. The leakage is tested in accordance with 5.3.12.

4.2.10 Pneumatic shocks

The components shall be able to resist the pneumatic shocks to which the cock is subject when opening

quickly. This requirement is tested in accordance with 5.3.6.

4.3 Constructional characteristics

4.3.1 External appearance

The external surfaces of the end cock shall be free of sharp edges which could be a danger to those

persons handling the cock or to other equipment in the proximity of the end cock. This requirement

shall be checked while testing the other constructional features in accordance with 5.3.2.

At least the handles of the end cocks of the brake pipe should be in a red colour (e.g. RAL 2002,

RAL 3020) and of the end cocks of the main reservoir pipe should be in a light colour, e.g. yellow (e.g.

RAL 1003, RAL 1023) or white (e.g. RAL 9002, RAL 9003, RAL

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...