ISO 15864:2021

(Main)Space systems — General test methods for spacecraft, subsystems and units

Space systems — General test methods for spacecraft, subsystems and units

This document provides the baseline standard on the subject of testing at the system, subsystem and unit levels for applicable unmanned spacecraft programmes. It also provides the requirements for documentation associated with testing activities. This document contains provisions for qualification and acceptance testing, or proto-flight testing (PFT). It assumes that hardware development is complete.

Systèmes spatiaux — Méthodes d'essai générales pour véhicules spatiaux, sous-systèmes et équipements

General Information

- Status

- Published

- Publication Date

- 30-Jun-2021

- Technical Committee

- ISO/TC 20/SC 14 - Space systems and operations

- Current Stage

- 6060 - International Standard published

- Start Date

- 01-Jul-2021

- Due Date

- 08-Jul-2021

- Completion Date

- 01-Jul-2021

Relations

- Effective Date

- 23-Apr-2020

Overview

ISO 15864:2021 - Space systems - General test methods for spacecraft, subsystems and units - is the baseline ISO standard for testing unmanned spacecraft at system, subsystem and unit levels. The standard defines qualification, acceptance and proto‑flight testing (PFT) practices and the required test documentation for missions that assume hardware development is complete. It guides test planning, execution and reporting for spacecraft programmes and supports consistent, auditable spacecraft testing across suppliers and integrators.

Key technical topics and requirements

ISO 15864:2021 covers a comprehensive set of test topics and program-level requirements, including:

- Testing philosophy and tailoring - how to tailor test requirements to programme needs.

- Test types - development tests, qualification tests, acceptance tests, proto‑flight tests, prelaunch validation and retest conditions.

- Test documentation - required test plans, specifications, procedures, test data, reports and test logs.

- Facilities and instrumentation - general facility requirements, condition tolerances and instrumentation needs.

- System-level and subsystem/unit-level testing - sequencing, test items, levels and durations.

- Specific test methods - functional tests, electromagnetic compatibility (EMC), magnetic testing, antenna pattern measurement, optical alignment, physical property measurement, dynamic balance and launcher/spacecraft interface tests.

- Monitoring and configuration control - guidance on test article configuration and monitoring during tests.

- Retest scenarios - rules for retest after design changes, non‑conformance, refurbishment or long‑term storage.

Practical applications and who uses this standard

ISO 15864:2021 is primarily used by:

- Spacecraft test engineers and test laboratories for creating and executing qualification, acceptance and proto‑flight test programs.

- Systems and integration engineers to plan end‑to‑end test sequences and interface tests with launchers.

- Manufacturers and subsystem suppliers for supplier verification and acceptance criteria.

- Mission assurance, quality and procurement teams to define contractual test deliverables and required documentation.

- Launch providers and mission integrators to ensure compatibility and compliance at the launcher/spacecraft interface.

Practical uses include developing test plans and procedures, defining pass/fail criteria, establishing test configuration and data-management practices, and harmonizing test approaches across multinational programmes.

Related standards

ISO 15864 complements other space and environmental testing standards and national/agency test guidelines. Organizations typically apply ISO 15864 alongside agency technical requirements (e.g., mission organization standards) and facility-specific environmental test standards to ensure comprehensive spacecraft verification.

For implementation, obtain the full ISO 15864:2021 document from the ISO website or your national standards body.

ISO 15864:2021 - Space systems -- General test methods for spacecraft, subsystems and units

ISO 15864:2021 - Space systems — General test methods for spacecraft, subsystems and units Released:7/1/2021

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

ISO 15864:2021 is a standard published by the International Organization for Standardization (ISO). Its full title is "Space systems — General test methods for spacecraft, subsystems and units". This standard covers: This document provides the baseline standard on the subject of testing at the system, subsystem and unit levels for applicable unmanned spacecraft programmes. It also provides the requirements for documentation associated with testing activities. This document contains provisions for qualification and acceptance testing, or proto-flight testing (PFT). It assumes that hardware development is complete.

This document provides the baseline standard on the subject of testing at the system, subsystem and unit levels for applicable unmanned spacecraft programmes. It also provides the requirements for documentation associated with testing activities. This document contains provisions for qualification and acceptance testing, or proto-flight testing (PFT). It assumes that hardware development is complete.

ISO 15864:2021 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 15864:2021 has the following relationships with other standards: It is inter standard links to ISO 15864:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 15864:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 15864

Second edition

2021-07

Space systems — General test methods

for spacecraft, subsystems and units

Systèmes spatiaux — Méthodes d'essai générales pour véhicules

spatiaux, sous-systèmes et équipements

Reference number

©

ISO 2021

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

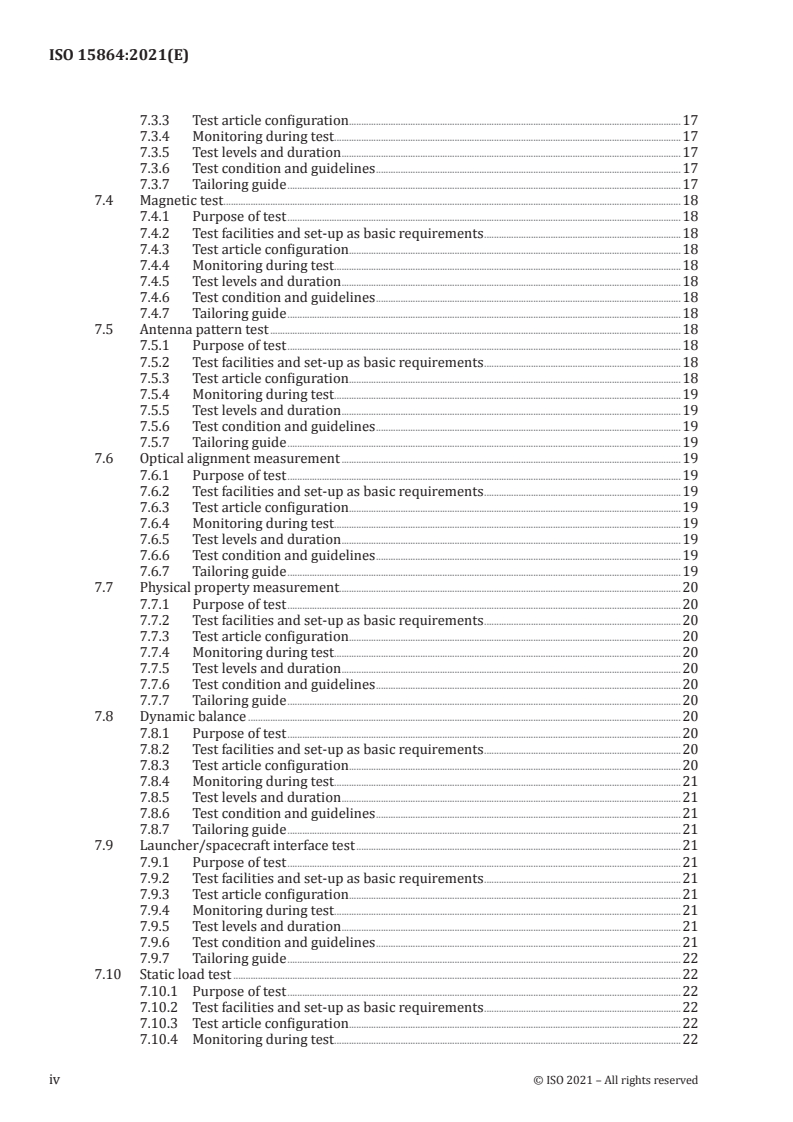

Contents Page

Foreword .vii

Introduction .viii

1 Scope . 1

2 Normative references . 1

3 Terms, definitions and abbreviated terms . 1

3.1 Terms and definitions . 1

3.2 Abbreviated terms . 3

4 General requirements . 3

4.1 Testing philosophy . 3

4.2 Tailoring of requirements . 3

4.3 Development tests . 4

4.4 Qualification tests . 4

4.5 Acceptance tests . 4

4.6 Proto-flight tests . 4

4.7 Prelaunch validation tests . 4

4.8 Retest . 5

4.8.1 General. 5

4.8.2 Retest due to design modification after completion of qualification. 5

4.8.3 Retest due to non-conformance . 5

4.8.4 Retest after refurbishment . 5

4.8.5 Retest during and after long-term storage . 5

4.9 Test documentation . 5

4.9.1 General. 5

4.9.2 Test plans . 5

4.9.3 Test specifications . . . 6

4.9.4 Test procedures. 6

4.9.5 Test data . 6

4.9.6 Test reports. 7

4.9.7 Test log . 7

4.10 Tests facilities and other requirements . 7

4.10.1 General. 7

4.10.2 Test condition tolerances . 7

4.10.3 Instrumentation . 7

5 Spacecraft system tests . 7

5.1 Test items and sequence . 7

5.2 Test levels and duration . 8

6 Subsystem/unit tests . 8

6.1 Test items and sequence . 8

6.2 Test levels and duration . 8

7 Test requirements .16

7.1 General .16

7.2 Functional test .16

7.2.1 Purpose of test .16

7.2.2 Test facilities and set-up as basic requirements .16

7.2.3 Test article configuration .16

7.2.4 Monitoring during test . .16

7.2.5 Test levels and duration .16

7.2.6 Test condition and guidelines .16

7.2.7 Tailoring guide .17

7.3 Electromagnetic compatibility (EMC) test .17

7.3.1 Purpose of test .17

7.3.2 Test facilities and set-up as basic requirements .17

7.3.3 Test article configuration .17

7.3.4 Monitoring during test . .17

7.3.5 Test levels and duration .17

7.3.6 Test condition and guidelines .17

7.3.7 Tailoring guide .17

7.4 Magnetic test .18

7.4.1 Purpose of test .18

7.4.2 Test facilities and set-up as basic requirements .18

7.4.3 Test article configuration .18

7.4.4 Monitoring during test . .18

7.4.5 Test levels and duration .18

7.4.6 Test condition and guidelines .18

7.4.7 Tailoring guide .18

7.5 Antenna pattern test .18

7.5.1 Purpose of test .18

7.5.2 Test facilities and set-up as basic requirements .18

7.5.3 Test article configuration .18

7.5.4 Monitoring during test . .19

7.5.5 Test levels and duration .19

7.5.6 Test condition and guidelines .19

7.5.7 Tailoring guide .19

7.6 Optical alignment measurement .19

7.6.1 Purpose of test .19

7.6.2 Test facilities and set-up as basic requirements .19

7.6.3 Test article configuration .19

7.6.4 Monitoring during test . .19

7.6.5 Test levels and duration .19

7.6.6 Test condition and guidelines .19

7.6.7 Tailoring guide .19

7.7 Physical property measurement.20

7.7.1 Purpose of test .20

7.7.2 Test facilities and set-up as basic requirements .20

7.7.3 Test article configuration .20

7.7.4 Monitoring during test . .20

7.7.5 Test levels and duration .20

7.7.6 Test condition and guidelines .20

7.7.7 Tailoring guide .20

7.8 Dynamic balance .20

7.8.1 Purpose of test .20

7.8.2 Test facilities and set-up as basic requirements .20

7.8.3 Test article configuration .20

7.8.4 Monitoring during test . .21

7.8.5 Test levels and duration .21

7.8.6 Test condition and guidelines .21

7.8.7 Tailoring guide .21

7.9 Launcher/spacecraft interface test .21

7.9.1 Purpose of test .21

7.9.2 Test facilities and set-up as basic requirements .21

7.9.3 Test article configuration .21

7.9.4 Monitoring during test . .21

7.9.5 Test levels and duration .21

7.9.6 Test condition and guidelines .21

7.9.7 Tailoring guide .22

7.10 Static load test .22

7.10.1 Purpose of test .22

7.10.2 Test facilities and set-up as basic requirements .22

7.10.3 Test article configuration .22

7.10.4 Monitoring during test . .22

iv © ISO 2021 – All rights reserved

7.10.5 Test levels and duration .22

7.10.6 Test condition and guidelines .22

7.10.7 Tailoring guide .22

7.11 Acceleration test .22

7.11.1 Purpose of test .22

7.11.2 Test facilities and set-up as basic requirements .23

7.11.3 Test article configuration .23

7.11.4 Monitoring during test . .23

7.11.5 Test levels and duration .23

7.11.6 Test condition and guidelines .23

7.11.7 Tailoring guide .23

7.12 Modal survey .23

7.12.1 Purpose of test .23

7.12.2 Test facilities and set-up as basic requirements .23

7.12.3 Test article configuration .23

7.12.4 Monitoring during test . .24

7.12.5 Test levels and duration .24

7.12.6 Test condition and guidelines .24

7.12.7 Tailoring guide .24

7.13 Sinusoidal vibration test .24

7.13.1 Purpose of test .24

7.13.2 Test facilities and set-up as basic requirements .24

7.13.3 Test article configuration .24

7.13.4 Monitoring during test . .24

7.13.5 Test levels and duration .25

7.13.6 Test condition and guidelines .25

7.13.7 Tailoring guide .25

7.14 Random vibration test .25

7.14.1 Purpose of test .25

7.14.2 Test facilities and set-up as basic requirements .25

7.14.3 Test article configuration .25

7.14.4 Monitoring during test . .25

7.14.5 Test levels and duration .26

7.14.6 Test condition and guidelines .26

7.14.7 Tailoring guide .26

7.15 Acoustic test .26

7.15.1 Purpose of test .26

7.15.2 Test facilities and set-up as basic requirements .26

7.15.3 Test article configuration .26

7.15.4 Monitoring during test . .26

7.15.5 Test levels and duration .26

7.15.6 Test condition and guidelines .27

7.15.7 Tailoring guide .27

7.16 Shock test .27

7.16.1 Purpose of test .27

7.16.2 Test facilities and set-up as basic requirements .27

7.16.3 Test article configuration .27

7.16.4 Monitoring during test . .27

7.16.5 Test levels and duration .27

7.16.6 Test condition and guidelines .27

7.16.7 Tailoring guide .27

7.17 Thermal balance test .28

7.17.1 Purpose of test .28

7.17.2 Test facilities and set-up as basic requirements .28

7.17.3 Test article configuration .28

7.17.4 Monitoring during test . .28

7.17.5 Test levels and duration .28

7.17.6 Test condition and guidelines .28

7.17.7 Tailoring guide .28

7.18 Thermal vacuum test .29

7.18.1 Purpose of test .29

7.18.2 Test facilities and set-up as basic requirements .29

7.18.3 Test article configuration .29

7.18.4 Monitoring during test . .29

7.18.5 Test levels and duration .29

7.18.6 Test condition and guidelines .30

7.18.7 Tailoring guide .30

7.19 Thermal cycle test .30

7.19.1 Purpose of test .30

7.19.2 Test facilities and set-up as basic requirements .30

7.19.3 Test article configuration .30

7.19.4 Monitoring during test . .30

7.19.5 Test levels and duration .30

7.19.6 Test condition and guidelines .30

7.19.7 Tailoring guide .31

7.20 Pressure test .31

7.20.1 Purpose of test .31

7.20.2 Test facilities and set-up as basic requirements .31

7.20.3 Test article configuration .31

7.20.4 Monitoring during test . .31

7.20.5 Test levels and duration .31

7.20.6 Test condition and guidelines .32

7.20.7 Tailoring guide .32

7.21 Leakage test .32

7.21.1 Purpose of test .32

7.21.2 Test facilities and set-up as basic requirements .32

7.21.3 Test article configuration .32

7.21.4 Monitoring during test . .32

7.21.5 Test levels and duration .32

7.21.6 Test condition and guidelines .32

7.21.7 Tailoring guide .32

7.22 Burn-in and wear-in test .33

7.22.1 Purpose of test .33

7.22.2 Test facilities and set-up as basic requirements .33

7.22.3 Test article configuration .33

7.22.4 Monitoring during test . .33

7.22.5 Test levels and duration .33

7.22.6 Test condition and guidelines .33

7.22.7 Tailoring guide .33

7.23 Tracking and control system/spacecraft compatibility test .33

7.23.1 Purpose of test .33

7.23.2 Test facilities and set-up as basic requirements .34

7.23.3 Test article configuration .34

7.23.4 Monitoring during test . .34

7.23.5 Test levels and duration .34

7.23.6 Test condition and guidelines .34

7.23.7 Tailoring guide .34

vi © ISO 2021 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 20, Aircraft and space vehicles,

Subcommittee SC 14, Space systems and operations.

This second edition cancels and replaces the first edition (ISO 15864:2004), which has been technically

revised.

The main changes compared to the previous edition are as follows:

— harmonized expressions throughout this document, including terminologies;

— added necessary but minimum modifications to requirements such as traceability in 4.9.6 and

magnetic test in 7.4;

— added the most current published documents as normative references: ISO 19924 and ISO 21494.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

Introduction

Throughout this document, the minimum essential criteria are identified by the use of the keyword

“shall”. Recommended criteria are identified by the use of the keyword “should” and, while not

mandatory, are considered to be of primary importance in providing serviceable, economical

and practical designs. Deviations from the recommended criteria should occur only after careful

consideration, extensive testing and thorough service evaluation have shown alternative methods to be

satisfactory. The acceptance criteria, specifications or procedures, and other detail test requirements

applicable to a particular programme are defined in the applicable technical specifications and

statement of work. When requirements have to be verified by measuring product performance and

function under various simulated environments, the method is referred to as “Test”. The requirements

of this document may be tailored for each specific space programme application.

viii © ISO 2021 – All rights reserved

INTERNATIONAL STANDARD ISO 15864:2021(E)

Space systems — General test methods for spacecraft,

subsystems and units

1 Scope

This document provides the baseline standard on the subject of testing at the system, subsystem and

unit levels for applicable unmanned spacecraft programmes. It also provides the requirements for

documentation associated with testing activities.

This document contains provisions for qualification and acceptance testing, or proto-flight testing

(PFT). It assumes that hardware development is complete.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 14302, Space systems — Electromagnetic compatibility requirements

ISO 14303, Space systems — Launch-vehicle-to-spacecraft interfaces

ISO 14623, Space systems - Pressure vessels and pres

...

INTERNATIONAL ISO

STANDARD 15864

Second edition

2021-07

Space systems — General test methods

for spacecraft, subsystems and units

Systèmes spatiaux — Méthodes d'essai générales pour véhicules

spatiaux, sous-systèmes et équipements

Reference number

©

ISO 2021

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

Contents Page

Foreword .vii

Introduction .viii

1 Scope . 1

2 Normative references . 1

3 Terms, definitions and abbreviated terms . 1

3.1 Terms and definitions . 1

3.2 Abbreviated terms . 3

4 General requirements . 3

4.1 Testing philosophy . 3

4.2 Tailoring of requirements . 3

4.3 Development tests . 4

4.4 Qualification tests . 4

4.5 Acceptance tests . 4

4.6 Proto-flight tests . 4

4.7 Prelaunch validation tests . 4

4.8 Retest . 5

4.8.1 General. 5

4.8.2 Retest due to design modification after completion of qualification. 5

4.8.3 Retest due to non-conformance . 5

4.8.4 Retest after refurbishment . 5

4.8.5 Retest during and after long-term storage . 5

4.9 Test documentation . 5

4.9.1 General. 5

4.9.2 Test plans . 5

4.9.3 Test specifications . . . 6

4.9.4 Test procedures. 6

4.9.5 Test data . 6

4.9.6 Test reports. 7

4.9.7 Test log . 7

4.10 Tests facilities and other requirements . 7

4.10.1 General. 7

4.10.2 Test condition tolerances . 7

4.10.3 Instrumentation . 7

5 Spacecraft system tests . 7

5.1 Test items and sequence . 7

5.2 Test levels and duration . 8

6 Subsystem/unit tests . 8

6.1 Test items and sequence . 8

6.2 Test levels and duration . 8

7 Test requirements .16

7.1 General .16

7.2 Functional test .16

7.2.1 Purpose of test .16

7.2.2 Test facilities and set-up as basic requirements .16

7.2.3 Test article configuration .16

7.2.4 Monitoring during test . .16

7.2.5 Test levels and duration .16

7.2.6 Test condition and guidelines .16

7.2.7 Tailoring guide .17

7.3 Electromagnetic compatibility (EMC) test .17

7.3.1 Purpose of test .17

7.3.2 Test facilities and set-up as basic requirements .17

7.3.3 Test article configuration .17

7.3.4 Monitoring during test . .17

7.3.5 Test levels and duration .17

7.3.6 Test condition and guidelines .17

7.3.7 Tailoring guide .17

7.4 Magnetic test .18

7.4.1 Purpose of test .18

7.4.2 Test facilities and set-up as basic requirements .18

7.4.3 Test article configuration .18

7.4.4 Monitoring during test . .18

7.4.5 Test levels and duration .18

7.4.6 Test condition and guidelines .18

7.4.7 Tailoring guide .18

7.5 Antenna pattern test .18

7.5.1 Purpose of test .18

7.5.2 Test facilities and set-up as basic requirements .18

7.5.3 Test article configuration .18

7.5.4 Monitoring during test . .19

7.5.5 Test levels and duration .19

7.5.6 Test condition and guidelines .19

7.5.7 Tailoring guide .19

7.6 Optical alignment measurement .19

7.6.1 Purpose of test .19

7.6.2 Test facilities and set-up as basic requirements .19

7.6.3 Test article configuration .19

7.6.4 Monitoring during test . .19

7.6.5 Test levels and duration .19

7.6.6 Test condition and guidelines .19

7.6.7 Tailoring guide .19

7.7 Physical property measurement.20

7.7.1 Purpose of test .20

7.7.2 Test facilities and set-up as basic requirements .20

7.7.3 Test article configuration .20

7.7.4 Monitoring during test . .20

7.7.5 Test levels and duration .20

7.7.6 Test condition and guidelines .20

7.7.7 Tailoring guide .20

7.8 Dynamic balance .20

7.8.1 Purpose of test .20

7.8.2 Test facilities and set-up as basic requirements .20

7.8.3 Test article configuration .20

7.8.4 Monitoring during test . .21

7.8.5 Test levels and duration .21

7.8.6 Test condition and guidelines .21

7.8.7 Tailoring guide .21

7.9 Launcher/spacecraft interface test .21

7.9.1 Purpose of test .21

7.9.2 Test facilities and set-up as basic requirements .21

7.9.3 Test article configuration .21

7.9.4 Monitoring during test . .21

7.9.5 Test levels and duration .21

7.9.6 Test condition and guidelines .21

7.9.7 Tailoring guide .22

7.10 Static load test .22

7.10.1 Purpose of test .22

7.10.2 Test facilities and set-up as basic requirements .22

7.10.3 Test article configuration .22

7.10.4 Monitoring during test . .22

iv © ISO 2021 – All rights reserved

7.10.5 Test levels and duration .22

7.10.6 Test condition and guidelines .22

7.10.7 Tailoring guide .22

7.11 Acceleration test .22

7.11.1 Purpose of test .22

7.11.2 Test facilities and set-up as basic requirements .23

7.11.3 Test article configuration .23

7.11.4 Monitoring during test . .23

7.11.5 Test levels and duration .23

7.11.6 Test condition and guidelines .23

7.11.7 Tailoring guide .23

7.12 Modal survey .23

7.12.1 Purpose of test .23

7.12.2 Test facilities and set-up as basic requirements .23

7.12.3 Test article configuration .23

7.12.4 Monitoring during test . .24

7.12.5 Test levels and duration .24

7.12.6 Test condition and guidelines .24

7.12.7 Tailoring guide .24

7.13 Sinusoidal vibration test .24

7.13.1 Purpose of test .24

7.13.2 Test facilities and set-up as basic requirements .24

7.13.3 Test article configuration .24

7.13.4 Monitoring during test . .24

7.13.5 Test levels and duration .25

7.13.6 Test condition and guidelines .25

7.13.7 Tailoring guide .25

7.14 Random vibration test .25

7.14.1 Purpose of test .25

7.14.2 Test facilities and set-up as basic requirements .25

7.14.3 Test article configuration .25

7.14.4 Monitoring during test . .25

7.14.5 Test levels and duration .26

7.14.6 Test condition and guidelines .26

7.14.7 Tailoring guide .26

7.15 Acoustic test .26

7.15.1 Purpose of test .26

7.15.2 Test facilities and set-up as basic requirements .26

7.15.3 Test article configuration .26

7.15.4 Monitoring during test . .26

7.15.5 Test levels and duration .26

7.15.6 Test condition and guidelines .27

7.15.7 Tailoring guide .27

7.16 Shock test .27

7.16.1 Purpose of test .27

7.16.2 Test facilities and set-up as basic requirements .27

7.16.3 Test article configuration .27

7.16.4 Monitoring during test . .27

7.16.5 Test levels and duration .27

7.16.6 Test condition and guidelines .27

7.16.7 Tailoring guide .27

7.17 Thermal balance test .28

7.17.1 Purpose of test .28

7.17.2 Test facilities and set-up as basic requirements .28

7.17.3 Test article configuration .28

7.17.4 Monitoring during test . .28

7.17.5 Test levels and duration .28

7.17.6 Test condition and guidelines .28

7.17.7 Tailoring guide .28

7.18 Thermal vacuum test .29

7.18.1 Purpose of test .29

7.18.2 Test facilities and set-up as basic requirements .29

7.18.3 Test article configuration .29

7.18.4 Monitoring during test . .29

7.18.5 Test levels and duration .29

7.18.6 Test condition and guidelines .30

7.18.7 Tailoring guide .30

7.19 Thermal cycle test .30

7.19.1 Purpose of test .30

7.19.2 Test facilities and set-up as basic requirements .30

7.19.3 Test article configuration .30

7.19.4 Monitoring during test . .30

7.19.5 Test levels and duration .30

7.19.6 Test condition and guidelines .30

7.19.7 Tailoring guide .31

7.20 Pressure test .31

7.20.1 Purpose of test .31

7.20.2 Test facilities and set-up as basic requirements .31

7.20.3 Test article configuration .31

7.20.4 Monitoring during test . .31

7.20.5 Test levels and duration .31

7.20.6 Test condition and guidelines .32

7.20.7 Tailoring guide .32

7.21 Leakage test .32

7.21.1 Purpose of test .32

7.21.2 Test facilities and set-up as basic requirements .32

7.21.3 Test article configuration .32

7.21.4 Monitoring during test . .32

7.21.5 Test levels and duration .32

7.21.6 Test condition and guidelines .32

7.21.7 Tailoring guide .32

7.22 Burn-in and wear-in test .33

7.22.1 Purpose of test .33

7.22.2 Test facilities and set-up as basic requirements .33

7.22.3 Test article configuration .33

7.22.4 Monitoring during test . .33

7.22.5 Test levels and duration .33

7.22.6 Test condition and guidelines .33

7.22.7 Tailoring guide .33

7.23 Tracking and control system/spacecraft compatibility test .33

7.23.1 Purpose of test .33

7.23.2 Test facilities and set-up as basic requirements .34

7.23.3 Test article configuration .34

7.23.4 Monitoring during test . .34

7.23.5 Test levels and duration .34

7.23.6 Test condition and guidelines .34

7.23.7 Tailoring guide .34

vi © ISO 2021 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 20, Aircraft and space vehicles,

Subcommittee SC 14, Space systems and operations.

This second edition cancels and replaces the first edition (ISO 15864:2004), which has been technically

revised.

The main changes compared to the previous edition are as follows:

— harmonized expressions throughout this document, including terminologies;

— added necessary but minimum modifications to requirements such as traceability in 4.9.6 and

magnetic test in 7.4;

— added the most current published documents as normative references: ISO 19924 and ISO 21494.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

Introduction

Throughout this document, the minimum essential criteria are identified by the use of the keyword

“shall”. Recommended criteria are identified by the use of the keyword “should” and, while not

mandatory, are considered to be of primary importance in providing serviceable, economical

and practical designs. Deviations from the recommended criteria should occur only after careful

consideration, extensive testing and thorough service evaluation have shown alternative methods to be

satisfactory. The acceptance criteria, specifications or procedures, and other detail test requirements

applicable to a particular programme are defined in the applicable technical specifications and

statement of work. When requirements have to be verified by measuring product performance and

function under various simulated environments, the method is referred to as “Test”. The requirements

of this document may be tailored for each specific space programme application.

viii © ISO 2021 – All rights reserved

INTERNATIONAL STANDARD ISO 15864:2021(E)

Space systems — General test methods for spacecraft,

subsystems and units

1 Scope

This document provides the baseline standard on the subject of testing at the system, subsystem and

unit levels for applicable unmanned spacecraft programmes. It also provides the requirements for

documentation associated with testing activities.

This document contains provisions for qualification and acceptance testing, or proto-flight testing

(PFT). It assumes that hardware development is complete.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 14302, Space systems — Electromagnetic compatibility requirements

ISO 14303, Space systems — Launch-vehicle-to-spacecraft interfaces

ISO 14623, Space systems - Pressure vessels and pres

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...