ISO 13253:2017

(Main)Ducted air-conditioners and air-to-air heat pumps — Testing and rating for performance

Ducted air-conditioners and air-to-air heat pumps — Testing and rating for performance

ISO 13253:2017 specifies performance testing, the standard conditions and the test methods for determining the capacity and efficiency ratings of air-cooled, air-conditioners and air-to-air heat pumps. ISO 13253:2017 is applicable to the following equipment: - ducted air-cooled air conditioners and ducted air to air heat pumps. ISO 13253:2017 is limited to - residential, commercial and industrial single-package, and split-system air conditioners and heat pumps, - factory-made, electrically driven and use mechanical compression, - utilizing single, multiple and variable capacity components, and - multiple split-system utilizing one or more refrigeration systems, one outdoor unit and one or more indoor units, controlled by a single thermostat/controller. The requirements of testing and rating contained in this document are based on the use of matched assemblies. ISO 13253:2017 is not applicable to the rating and testing of the following: a) water-source heat pumps or water-cooled air-conditioners; b) multi-split-system air-conditioners and air-to-air heat pumps (see ISO 15042 for testing of such equipment); c) mobile (windowless) units having a condenser exhaust duct; d) individual assemblies not constituting a complete refrigeration system; e) equipment using the absorption refrigeration cycle; f) non-ducted equipment (see ISO 5151 for testing of such equipment); g) ducted air conditioners and/or ducted heat pumps, rated at less than 8 kW and intended to operate at external static pressures of less than 25 Pa, controlled by a single thermostat/controller (refer to ISO 5151). ISO 13253:2017 does not cover the determination of seasonal efficiencies, which can be required in some countries because they provide a better indication of efficiency under actual operating conditions. NOTE Throughout this document, the terms "equipment" and "systems" mean "air-conditioners" and/or "heat pumps".

Climatiseurs et pompes à chaleur air/air raccordés — Essais et détermination des caractéristiques de performance

General Information

- Status

- Published

- Publication Date

- 17-Jul-2017

- Technical Committee

- ISO/TC 86/SC 6 - Testing and rating of air-conditioners and heat pumps

- Drafting Committee

- ISO/TC 86/SC 6/WG 1 - Air-source air-conditioners and heat pumps

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 13-Dec-2022

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 09-May-2020

- Effective Date

- 19-Jan-2013

Overview

ISO 13253:2017 - "Ducted air-conditioners and air-to-air heat pumps - Testing and rating for performance" defines standardized performance testing and rating procedures for ducted, air-cooled air-conditioners and air-to-air heat pumps. The standard establishes test methods, standard conditions, and reporting required to determine capacity and efficiency ratings for residential, commercial and industrial single-package and split-system units that are electrically driven and mechanically compressed. Ratings are based on matched assemblies and the document explicitly excludes water-cooled systems, absorption-cycle equipment, non-ducted units (see ISO 5151), multi-split systems (see ISO 15042), and certain small low-pressure ducted units (< 8 kW or < 25 Pa).

Key topics and technical requirements

- Scope and applicability: Applies to ducted air-cooled units and ducted air-to-air heat pumps in single-package, split, and multiple/variable-capacity configurations.

- Airflow settings and external static pressure (ESP): Defines indoor/outdoor airflow requirements and ESP considerations for rating.

- Cooling tests: Procedures for cooling capacity tests, maximum and minimum cooling performance, condensate control and enclosure sweat tests.

- Heating tests: Heating capacity measurements, defrost operation and automatic defrost performance tests, and transient test considerations.

- Test methods: Calorimeter, indoor-air enthalpy, refrigerant enthalpy and outdoor-air enthalpy methods are provided (see normative and informative annexes).

- Uncertainty and tolerances: Guidance on measurement uncertainty, test tolerances and adjustments for steady-state and performance tests.

- Reporting and marking: Required test data, test reports, nameplate information and publication of standard and other ratings.

Practical applications and users

ISO 13253:2017 is used by:

- HVAC manufacturers to validate product capacity and efficiency for ducted air-conditioners and heat pumps.

- Independent test laboratories and certification bodies to carry out reproducible performance tests and produce regulatory or market ratings.

- Product certifiers and compliance authorities for conformity assessment and labeling.

- System designers, specifiers and procurement teams to compare ducted equipment performance and ensure correct sizing and ESP selection.

- R&D engineers assessing system-level behavior of matched assemblies and variable-capacity equipment.

Practical outputs include rated cooling/heating capacities, efficiency metrics under specified conditions, test reports, and nameplate data used for specification, compliance and procurement decisions.

Related standards

- ISO 5151 - Testing of non-ducted equipment

- ISO 15042 - Testing of multi-split air-conditioners and heat pumps

Keywords: ISO 13253:2017, ducted air-conditioners, air-to-air heat pumps, testing and rating, performance testing, cooling tests, heating tests, calorimeter test, airflow, efficiency ratings.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

ISO 13253:2017 is a standard published by the International Organization for Standardization (ISO). Its full title is "Ducted air-conditioners and air-to-air heat pumps — Testing and rating for performance". This standard covers: ISO 13253:2017 specifies performance testing, the standard conditions and the test methods for determining the capacity and efficiency ratings of air-cooled, air-conditioners and air-to-air heat pumps. ISO 13253:2017 is applicable to the following equipment: - ducted air-cooled air conditioners and ducted air to air heat pumps. ISO 13253:2017 is limited to - residential, commercial and industrial single-package, and split-system air conditioners and heat pumps, - factory-made, electrically driven and use mechanical compression, - utilizing single, multiple and variable capacity components, and - multiple split-system utilizing one or more refrigeration systems, one outdoor unit and one or more indoor units, controlled by a single thermostat/controller. The requirements of testing and rating contained in this document are based on the use of matched assemblies. ISO 13253:2017 is not applicable to the rating and testing of the following: a) water-source heat pumps or water-cooled air-conditioners; b) multi-split-system air-conditioners and air-to-air heat pumps (see ISO 15042 for testing of such equipment); c) mobile (windowless) units having a condenser exhaust duct; d) individual assemblies not constituting a complete refrigeration system; e) equipment using the absorption refrigeration cycle; f) non-ducted equipment (see ISO 5151 for testing of such equipment); g) ducted air conditioners and/or ducted heat pumps, rated at less than 8 kW and intended to operate at external static pressures of less than 25 Pa, controlled by a single thermostat/controller (refer to ISO 5151). ISO 13253:2017 does not cover the determination of seasonal efficiencies, which can be required in some countries because they provide a better indication of efficiency under actual operating conditions. NOTE Throughout this document, the terms "equipment" and "systems" mean "air-conditioners" and/or "heat pumps".

ISO 13253:2017 specifies performance testing, the standard conditions and the test methods for determining the capacity and efficiency ratings of air-cooled, air-conditioners and air-to-air heat pumps. ISO 13253:2017 is applicable to the following equipment: - ducted air-cooled air conditioners and ducted air to air heat pumps. ISO 13253:2017 is limited to - residential, commercial and industrial single-package, and split-system air conditioners and heat pumps, - factory-made, electrically driven and use mechanical compression, - utilizing single, multiple and variable capacity components, and - multiple split-system utilizing one or more refrigeration systems, one outdoor unit and one or more indoor units, controlled by a single thermostat/controller. The requirements of testing and rating contained in this document are based on the use of matched assemblies. ISO 13253:2017 is not applicable to the rating and testing of the following: a) water-source heat pumps or water-cooled air-conditioners; b) multi-split-system air-conditioners and air-to-air heat pumps (see ISO 15042 for testing of such equipment); c) mobile (windowless) units having a condenser exhaust duct; d) individual assemblies not constituting a complete refrigeration system; e) equipment using the absorption refrigeration cycle; f) non-ducted equipment (see ISO 5151 for testing of such equipment); g) ducted air conditioners and/or ducted heat pumps, rated at less than 8 kW and intended to operate at external static pressures of less than 25 Pa, controlled by a single thermostat/controller (refer to ISO 5151). ISO 13253:2017 does not cover the determination of seasonal efficiencies, which can be required in some countries because they provide a better indication of efficiency under actual operating conditions. NOTE Throughout this document, the terms "equipment" and "systems" mean "air-conditioners" and/or "heat pumps".

ISO 13253:2017 is classified under the following ICS (International Classification for Standards) categories: 23.120 - Ventilators. Fans. Air-conditioners; 27.080 - Heat pumps. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 13253:2017 has the following relationships with other standards: It is inter standard links to ISO 13253:2017/Amd 1:2020, ISO 13253:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 13253:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 13253

Third edition

2017-07

Ducted air-conditioners and air-to-air

heat pumps — Testing and rating for

performance

Climatiseurs et pompes à chaleur air/air raccordés — Essais et

détermination des caractéristiques de performance

Reference number

©

ISO 2017

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

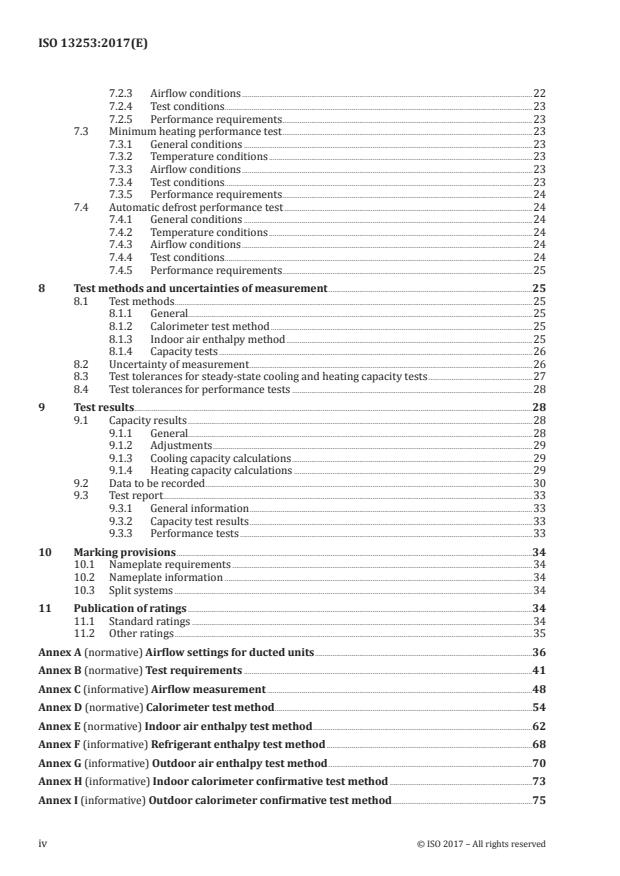

Contents Page

Foreword .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Symbols . 4

5 Airflow setting . 7

5.1 General . 7

5.2 Indoor airflow setting . 7

5.3 ESP for rating . 7

5.4 Outdoor airflow . 9

5.5 Unit supplied without indoor fan. 9

6 Cooling tests . 9

6.1 Cooling capacity tests . 9

6.1.1 General conditions . 9

6.1.2 Temperature conditions .10

6.1.3 Test conditions.11

6.2 Maximum cooling performance test.11

6.2.1 General conditions .11

6.2.2 Temperature conditions .11

6.2.3 Airflow conditions .12

6.2.4 Test conditions.12

6.2.5 Performance requirements .12

6.3 Minimum cooling performance test .13

6.3.1 General conditions .13

6.3.2 Temperature conditions .13

6.3.3 Airflow conditions .13

6.3.4 Test conditions.14

6.3.5 Performance requirements .14

6.4 Condensate control and enclosure sweat performance test .15

6.4.1 General conditions .15

6.4.2 Temperature conditions .15

6.4.3 Airflow conditions .15

6.4.4 Test conditions.15

6.4.5 Performance requirements .15

7 Heating tests.16

7.1 Heating capacity tests .16

7.1.1 General conditions .16

7.1.2 Temperature conditions .17

7.1.3 Airflow conditions .17

7.1.4 Defrost operation .18

7.1.5 Test procedure — General .18

7.1.6 Preconditioning period .19

7.1.7 Equilibrium period . . .19

7.1.8 Data collection period .19

7.1.9 Test procedure when a defrost cycle (whether automatically or manually

initiated) ends the preconditioning period .20

7.1.10 Test procedure when a defrost cycle does not end the preconditioning period .20

7.1.11 Test procedure for transient tests .20

7.1.12 Heating capacity test results . .22

7.2 Maximum heating performance test .22

7.2.1 General conditions .22

7.2.2 Temperature conditions .22

7.2.3 Airflow conditions .22

7.2.4 Test conditions.23

7.2.5 Performance requirements .23

7.3 Minimum heating performance test .23

7.3.1 General conditions .23

7.3.2 Temperature conditions .23

7.3.3 Airflow conditions .23

7.3.4 Test conditions.23

7.3.5 Performance requirements .24

7.4 Automatic defrost performance test .24

7.4.1 General conditions .24

7.4.2 Temperature conditions .24

7.4.3 Airflow conditions .24

7.4.4 Test conditions.24

7.4.5 Performance requirements .25

8 Test methods and uncertainties of measurement .25

8.1 Test methods .25

8.1.1 General.25

8.1.2 Calorimeter test method .25

8.1.3 Indoor air enthalpy method .25

8.1.4 Capacity tests .26

8.2 Uncertainty of measurement .26

8.3 Test tolerances for steady-state cooling and heating capacity tests .27

8.4 Test tolerances for performance tests .28

9 Test results .28

9.1 Capacity results .28

9.1.1 General.28

9.1.2 Adjustments .29

9.1.3 Cooling capacity calculations .29

9.1.4 Heating capacity calculations .29

9.2 Data to be recorded .30

9.3 Test report .33

9.3.1 General information .33

9.3.2 Capacity test results .33

9.3.3 Performance tests .33

10 Marking provisions .34

10.1 Nameplate requirements .34

10.2 Nameplate information .34

10.3 Split systems .34

11 Publication of ratings .34

11.1 Standard ratings .34

11.2 Other ratings .35

Annex A (normative) Airflow settings for ducted units .36

Annex B (normative) Test requirements .41

Annex C (informative) Airflow measurement .48

Annex D (normative) Calorimeter test method .54

Annex E (normative) Indoor air enthalpy test method .62

Annex F (informative) Refrigerant enthalpy test method .68

Annex G (informative) Outdoor air enthalpy test method .70

Annex H (informative) Indoor calorimeter confirmative test method .73

Annex I (informative) Outdoor calorimeter confirmative test method.75

iv © ISO 2017 – All rights reserved

Annex J (informative) Balanced-type calorimeter confirmative test method .77

Annex K (informative) Cooling condensate measurements .78

Annex L (normative) Supplemental requirements when rating fan-less (coil-only) type units .79

Annex M (informative) Pictorial examples of the heating capacity test procedures given in 7.1 .82

Bibliography .89

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment,

as well as information about ISO’s adherence to the World Trade Organization (WTO) principles in the

Technical Barriers to Trade (TBT) see the following URL: www . i so .org/ iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 86, Refrigeration and air-conditioning,

Subcommittee SC 6, Testing and rating of air-conditioners and heat pumps.

This third edition cancels and replaces the second edition (ISO 13253:2011), which has been technically

revised.

vi © ISO 2017 – All rights reserved

INTERNATIONAL STANDARD ISO 13253:2017(E)

Ducted air-conditioners and air-to-air heat pumps —

Testing and rating for performance

1 Scope

This document specifies performance testing, the standard conditions and the test methods for

determining the capacity and efficiency ratings of air-cooled, air-conditioners and air-to-air heat pumps.

This document is applicable to the following equipment:

— ducted air-cooled air conditioners and ducted air to air heat pumps.

This document is limited to

— residential, commercial and industrial single-package, and split-system air conditioners and

heat pumps,

— factory-made, electrically driven and use mechanical compression,

— utilizing single, multiple and variable capacity components, and

— multiple split-system utilizing one or more refrigeration systems, one outdoor unit and one or more

indoor units, controlled by a single thermostat/controller.

The requirements of testing and rating contained in this document are based on the use of matched

assemblies.

This document is not applicable to the rating and testing of the following:

a) water-source heat pumps or water-cooled air-conditioners;

b) multi-split-system air-conditioners and air-to-air heat pumps (see ISO 15042 for testing of such

equipment);

c) mobile (windowless) units having a condenser exhaust duct;

d) individual assemblies not constituting a complete refrigeration system;

e) equipment using the absorption refrigeration cycle;

f) non-ducted equipment (see ISO 5151 for testing of such equipment);

g) ducted air conditioners and/or ducted heat pumps, rated at less than 8 kW and intended to operate

at external static pressures of less than 25 Pa, controlled by a single thermostat/controller (refer to

ISO 5151).

This document does not cover the determination of seasonal efficiencies, which can be required in some

countries because they provide a better indication of efficiency under actual operating conditions.

NOTE Throughout this document, the terms “equipment” and “systems” mean “air-conditioners” and/or

“heat pumps”.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO/IEC Guide 98-3, Uncertainty of measurement — Part 3: Guide to the expression of uncertainty in

me a s ur ement (GUM: 1995)

ISO 817, Refrigerants — Designation and safety classification

ISO 5151, Non-ducted air conditioners and heat pumps — Testing and rating for performance

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http:// www .electropedia .org/

— ISO Online browsing platform: available at http:// www .iso .org/ obp

3.1

ducted air-conditioner

encased assembly or assemblies designed primarily to provide ducted delivery of conditioned air to an

enclosed space, room or zone (conditioned space)

Note 1 to entry: It can be either single-package or split-system and comprises a primary source of refrigeration

for cooling and dehumidification. It can also include means for heating other than a heat pump, as well as means

for circulating, cleaning, humidifying, ventilating or exhausting air. Such equipment can be provided in more

than one assembly; the separated assemblies (split-systems) of which are intended to be used together.

3.2

ducted heat pump

encased assembly or assemblies designed primarily to provide ducted delivery of conditioned air to an

enclosed space, room or zone (conditioned space), including a prime source of refrigeration for heating

Note 1 to entry: It can be constructed to remove heat from the conditioned space and discharge it to a heat sink

if cooling and dehumidification are desired from the same equipment. It can also include means for circulating,

cleaning, humidifying, ventilating or exhausting air. Such equipment can be provided in more than one assembly;

the separated assemblies (split-systems) of which are intended to be used together.

3.3

standard air

dry air at 20,0 °C and at a standard barometric pressure of 101,325 kPa, having a mass density of

1 204 kg/m

3.4

total cooling capacity

amount of sensible and latent heat that the equipment can remove from the conditioned space in a

defined interval of time

Note 1 to entry: Total cooling capacity is expressed in units of watts.

3.5

heating capacity

amount of heat that the equipment can add to the conditioned space (but not including supplementary

heat) in a defined interval of time

Note 1 to entry: Heating capacity is expressed in units of watts.

2 © ISO 2017 – All rights reserved

3.6

latent cooling capacity

room dehumidifying capacity

amount of latent heat that the equipment can remove from the conditioned space in a defined

interval of time

Note 1 to entry: Latent cooling capacity and room dehumidifying capacity are expressed in units of watts.

3.7

sensible cooling capacity

amount of sensible heat that the equipment can remove from the conditioned space in a defined

interval of time

Note 1 to entry: Sensible cooling capacity is expressed in units of watts.

3.8

sensible heat ratio

SHR

ratio of the sensible cooling capacity (3.7) to the total cooling capacity (3.4)

3.9

rated voltage

voltage shown on the nameplate of the equipment

3.10

rated frequency

frequency shown on the nameplate of the equipment

3.11

energy efficiency ratio

EER

ratio of the total cooling capacity (3.4) to the effective power input (3.14) to the device at any given set of

rating conditions

Note 1 to entry: Where the EER is stated without an indication of units, it is understood that it is derived from

watts/watts.

3.12

coefficient of performance

COP

ratio of the heating capacity (3.5) to the effective power input (3.14) to the device at any given set of

rating conditions

Note 1 to entry: Where the COP is stated without an indication of units, it is understood that it is derived from

watts/watts.

3.13

total power input

P

t

average electrical power input to the equipment as measured during the test

Note 1 to entry: Total power input is expressed in units of watts.

3.14

effective power input

P

E

average electrical power input to the equipment, obtained from the following:

— the power input for operation of the compressor(s);

— the power input to electric heating devices used only for defrosting;

— the power input to all control and safety devices of the equipment;

— the power input for operation of all fans, whether provided with the equipment or not

Note 1 to entry: Effective power input is expressed in units of watts.

3.15

full-load operation

operation with the equipment and controls configured for the maximum continuous duty refrigeration

capacity specified by the manufacturer and allowed by the unit controls

Note 1 to entry: Unless otherwise regulated by the automatic controls of the equipment, all indoor units and

compressors are functioning during full-load operations.

4 Symbols

Symbol Description Unit

A coefficient, heat leakage J/(s·K)

l

A nozzle area m

n

b b

c specific heat of moist air entering indoor-side J/(kg ⋅K)

pa1

b b

c specific heat of moist air leaving indoor-side J/(kg ⋅K)

pa2

b b

c specific heat of moist air entering outdoor-side J/(kg ⋅K)

pa3

b b

c specific heat of moist air leaving outdoor-side J/(kg ⋅K)

pa4

b

c specific heat of water J/(kg ⋅K)

pw

3 2

C airflow coefficient Pa/(m /s)

a

C nozzle discharge coefficient —

d

D equivalent diameter M

e

D diameter of circular ducts, inlet m

i

D nozzle throat diameter m

n

D diameter of circular ducts, outlet m

o

D outside diameter of refrigerant tube m

t

b

h specific enthalpy of air entering the indoor-side J/kg

a1

b

h specific enthalpy of air leaving the indoor-side J/kg

a2

b

h specific enthalpy of air entering the outdoor-side J/kg

a3

b

h specific enthalpy of air leaving the outdoor-side J/kg

a4

h specific enthalpy of refrigerant liquid entering expansion device J/kg

f1

h specific enthalpy of refrigerant liquid leaving condenser J/kg

f2

h specific enthalpy of refrigerant vapour entering compressor J/kg

g1

h specific enthalpy of refrigerant vapour leaving compressor J/kg

g2

h specific enthalpy of refrigerant entering the indoor-side J/kg

r1

h specific enthalpy of refrigerant leaving the indoor-side J/kg

r2

h specific enthalpy of water or steam supplied to the indoor side test chamber J/kg

w1

h specific enthalpy of condensed moisture leaving the indoor side test chamber J/kg

w2

h specific enthalpy of condensed moisture leaving outdoor-side test chamber J/kg

w3

h specific enthalpy of the water supplied to the outdoor side test chamber J/kg

w4

a

Dimensionless value.

b

It means the mass of dry air; the mass, kg of denominator in this unit is based on dry air (or DA). For units practically

used in the air conditioning field, “kg (DA)” is very often used for denominator.

Example: J/kg(DA), m /kg(DA), kg/kg(DA).

NOTE All parameters are in relation to the unit being tested unless specified otherwise.

4 © ISO 2017 – All rights reserved

Symbol Description Unit

h specific enthalpy of the condensed water (in the case of H1 test condition) and the J/kg

w5

frost, respectively (in the case of H2 or H3 test conditions) in the test unit

K latent heat of vaporization of water (2 460 × 10 J/kg at 15 °C) J/kg

L length of refrigerant line m

L length of duct m

d

L length to external static pressure measuring point m

m

p barometric pressure kPa

a

p test chamber equalization pressure Pa

c

p external static pressure (ESP) Pa

e

p internal static pressure drop of the indoor coil cabinet assembly measured from the Pa

isc

cooling capacity test

p external static pressure (p during the blowing test) Pa

m e

p absolute pressure at nozzle throat Pa

n

p velocity pressure at nozzle throat or static pressure difference across the nozzle Pa

v

P estimated fan power to circulate indoor air W

fan

P power input, indoor-side data W

i

P power input to the compressor W

K

P total power input to the equipment W

t

q air mass flow rate kg/s

m

q refrigerant flow rate kg/s

r

q refrigerant and oil mixture flow rate kg/s

ro

q air volume flow rate m /s

v

q air volume flow rate, outdoor-side m /s

vi

q air volume flow rate, outdoor-side m /s

vo

q condenser water flow rate kg/s

w

q rate at which water vapour is condensed by the equipment kg/s

wc

q water mass flow supplied to the outside test chamber for maintaining the test kg/s

wo

conditions

a

R Reynolds number —

e

a

SHR Sensible heat ratio —

T thickness of tubing insulation m

t temperature, ambient of compressor calorimeter °C

a

t temperature of air entering the indoor-side, dry bulb °C

a1

t temperature of air leaving the indoor-side, dry bulb °C

a2

t temperature of air entering the outdoor-side, dry bulb °C

a3

t temperature of air leaving the outdoor-side, dry bulb °C

a4

t temperature of surface of condenser of the compressor calorimeter °C

c

t temperature of surface of evaporator of the compressor calorimeter °C

e

t temperature of water entering condenser of the compressor calorimeter °C

w1

t temperature of water leaving condenser of the compressor calorimeter °C

w2

v velocity of air, at nozzle m/s

a

a

Dimensionless value.

b

It means the mass of dry air; the mass, kg of denominator in this unit is based on dry air (or DA). For units practically

used in the air conditioning field, “kg (DA)” is very often used for denominator.

Example: J/kg(DA), m /kg(DA), kg/kg(DA).

NOTE All parameters are in relation to the unit being tested unless specified otherwise.

Symbol Description Unit

b 3 b

v specific volume of dry air portion of mixture at nozzle m /kg

n

v′ specific volume of dry air portion of mixture at nozzle m /kg

n

W mass of cylinder and bleeder assembly, empty g

W mass of cylinder and bleeder assembly, with sample g

W mass of cylinder and bleeder assembly, with oil from sample g

b b

W specific humidity of air entering the indoor-side kg/kg

i1

b b

W specific humidity of air leaving the indoor-side kg/kg

i2

b b

W specific humidity at nozzle inlet kg/kg

n

W water vapour (rate) condensed kg/s

r

a

X concentration of oil to refrigerant-oil mixture —

o

a

X mass ratio, refrigerant to refrigerant-oil mixture —

r

a

Y expansion factor —

a

α pressure ratio —

α Interconnecting tubing heat transfer coefficient W/(m ·K)

a

λ thermal conductivity W/(m·K)

ν kinematic viscosity of air m /s

a

η estimated indoor fan static efficiency —

fan,i

a

η estimated indoor motor efficiency —

mot,i

∑ P other power input to the indoor side test chamber (e.g. illumination, electrical and ther- W

ic

mal power input to the compensating device, heat balance of the humidification device)

∑ P sum of all total power input to the outdoor side test chamber, not including power to W

oc

the equipment under test

ϕ heat removed by the cooling coil in the outdoor-side test chamber W

c

ϕ heat removed by cooling coil in the indoor-side test chamber W

ci

ϕ latent cooling capacity (dehumidifying) W

d

ϕ heat input to evaporator of compressor calorimeter W

e

ϕ heating capacity, indoor-side test chamber W

hi

ϕ heating capacity, outdoor-side test chamber W

ho

ϕ heat leakage into the indoor side test chamber through walls, floor and ceiling W

li

ϕ heat leakage out of the outdoor side test chamber through walls, floor and ceiling W

lo

ϕ heat leakage into the indoor-side test chamber through the partition separating the W

lp

indoor-side from the outdoor-side

ϕ line heat loss in interconnecting tubing W

L

ϕ sensible cooling capacity, indoor-side W

sci

ϕ refrigerating capacity of a refrigerant compressor W

tc

ϕ total cooling capacity, indoor-side W

tci

ϕ total cooling capacity, outdoor-side W

tco

ϕ total heating capacity, indoor-side W

thi

ϕ total heating capacity, outdoor-side W

tho

a

Dimensionless value.

b

It means the mass of dry air; the mass, kg of denominator in this unit is based on dry air (or DA). For units practically

used in the air conditioning field, “kg (DA)” is very often used for denominator.

Example: J/kg(DA), m /kg(DA), kg/kg(DA).

NOTE All parameters are in relation to the unit being tested unless specified otherwise.

6 © ISO 2017 – All rights reserved

5 Airflow setting

5.1 General

The airflow rate shall be specified by the manufacturer. This flow rate shall be for full-load cooling

and be expressed in cubic metres per second (m /s) of standard air conditions, as defined in 3.3, and

correspond with the compressor or compressors not operating.

P is the estimated fan power required to circulate indoor air, in watts.

fan

5.2 Indoor airflow setting

The airflow rate setting shall be made when only the fan is operating, at an ambient temperature

between 20 °C to 30 °C and relative humidity between 30 % and 70 %. The airflow settings of the units

shall be in accordance with Annex A for units supplied with a fan, and in accordance with Annex L for

units supplied without a fan.

The rated airflow rate given by the manufacturer shall be set and the resulting external static pressure

(ESP), p , measured. The measured ESP shall be not less than the ESP for rating, defined in Table 1. If

e

the unit has an adjustable speed, it shall be adjusted to the lowest speed that provides the ESP for rating

or greater.

5.3 ESP for rating

5.3.1 If the rated ESP specified by the manufacturer is greater than or equal to the minimum value

given in Table 1, the specified rated ESP is used as the ESP for rating.

5.3.2 If the rated ESP specified by the manufacturer is less than the minimum value given in Table 1,

and greater than or equal to 80 % of the maximum ESP, the specified rated ESP is used as the ESP for

rating. The maximum ESP may either be specified by the manufacturer or be identified from fan curves

provided by the manufacturer.

5.3.3 If the rated ESP specified by the manufacturer is less than the minimum value given in Table 1,

and less than 80 % of the maximum ESP, the value of Table 1 or 80 % of the maximum ESP, whichever is

less, is used as the ESP for rating.

5.3.4 If the rated ESP is not specified by the manufacturer, the value of Table 1 or 80 % of the maximum

ESP, whichever is less, is used as the ESP for rating.

5.3.5 The process of selecting the ESP for rating is shown in Figure 1.

5.3.6 In the case that the determined ESP for rating is less than 25 Pa, the unit can be considered as a

non-ducted unit and be tested in accordance with ISO 5151.

Figure 1 — Flowchart of selecting the ESP for rating

Table 1 — Pressure requirement for comfort air-conditioners

Standard capacity Minimum external static

a

ratings pressure

kW Pa

0 < Q < 8 25

8 ≤ Q < 12 37

12 ≤ Q < 20 50

a

For equipment tested without an air filter installed, the minimum ESP,

p , shall be increased by 10 Pa.

e

8 © ISO 2017 – All rights reserved

Table 1 (continued)

Standard capacity Minimum external static

a

ratings pressure

kW Pa

20 ≤ Q < 30 62

30 ≤ Q < 45 75

45 ≤ Q < 82 100

82 ≤ Q < 117 125

117 ≤ Q < 147 150

Q > 147 175

a

For equipment tested without an air filter installed, the minimum ESP,

p , shall be increased by 10 Pa.

e

5.4 Outdoor airflow

If the outdoor airflow is adjustable, all tests shall be conducted at the outdoor-side air quantity or fan

control setting that is specified by the manufacturer. Where the fan is non-adjustable, all tests shall

be conducted at the outdoor-side air volume flow rate inherent in the equipment when operated with

the following in place: all of the resistance elements associated with inlets, louvers, and any ductwork

and attachments considered by the manufacturer as normal installation practice. Once established, the

outdoor-side air circuit of the equipment shall remain unchanged throughout all tests prescribed in

document, except to adjust for any change caused by the attachment of the airflow measuring device

when using the outdoor air enthalpy test method (see G.2.1).

5.5 Unit supplied without indoor fan

If no fan is supplied with the unit (i.e. coil only units), supplemental requirements given in Annex L

also apply.

6 Cooling tests

6.1 Cooling capacity tests

6.1.1 General conditions

6.1.1.1 All equipment within the scope of this document shall have the cooling capacities and energy

efficiency ratios (EERs) determined in accordance with the provisions of this document and rated

at the cooling test conditions specified in Table 2. All tests shall be carried out in accordance with the

requirements of Annex B and the test methods specified in Clause 8. All tests shall be conducted with

the equipment functioning at full-load operation, as defined in 3.15. The electrical input values used for

rating purposes shall be measured during the cooling capacity test.

6.1.1.2 If the manufacturer of equipment having a variable-speed compressor does not provide

information on the full-load frequency and how to achieve it during a cooling capacity test, the equipment

shall be operated with its thermostat or controller set to its minimum allowable temperature setting.

6.1.2 Temperature conditions

6.1.2.1 The temperature conditions specified in Table 2 (columns T1, T2 and T3) shall be considered

standard rating conditions for the determination of cooling capacity. For equipment intended for space

cooling, testing shall be conducted at one or more of the standard rating conditions specified in Table 2.

Table 2 — Cooling capacity rating conditions

Standard rating conditions

Parameter

T1 T2 T3

Temperature of air entering the indoor-side:

27 °C 21 °C 29 °C

— dry-bulb

19 °C 15 °C 19 °C

— wet-bulb

Temperature of air entering the outdoor-side:

35 °C 27 °C 46 °C

— dry-bulb

24 °C 19 °C 24 °C

a

— wet-bulb

b

Test frequency Rated frequency

Test voltage See Table 3

NOTE

T1 = Standard cooling capacity rating conditions for moderate climates.

T2 = Standard cooling capacity rating conditions for cool climates.

T3 = Standard cooling capacity rating conditions for hot climates.

a

The wet-bulb temperature condition shall be required only when testing air-cooled condensers that evaporate the

condensate.

b

Equipment with dual-rated frequencies shall be tested at each frequency.

6.1.2.2 Equipment manufactured for use only in a moderate climate similar to that specified in Table 2,

Column T1, shall have ratings determined by tests conducted at T1 conditions and shall be designated

type T1 equipment.

6.1.2.3 Equipment manufactured for use only in a cool climate similar to that specified in Table 2,

Column T2, shall have ratings determined by tests conducted at T2 conditions and shall be designated

type T2 equipment.

6.1.2.4 Equipment manufactured for use only in a hot climate similar to that specified in Table 2,

Column T3, shall have ratings determined by tests conducted at T3 conditions and shall be designated

type T3 equipment.

10 © ISO 2017 – All rights reserved

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...