ISO 11221:2011

(Main)Space systems — Space solar panels — Spacecraft charging induced electrostatic discharge test methods

Space systems — Space solar panels — Spacecraft charging induced electrostatic discharge test methods

ISO 11221:2011 specfies qualification and characterization test methods to simulate plasma interactions and electrostatic discharges on solar array panels in space. ISO 11221:2011 is applicable to solar array panels made of crystalline silicon, gallium arsenide (GaAs) or multi-junction solar cells. ISO 11221:2011 addresses only surface discharges on solar panels.

Systèmes spatiaux — Panneaux solaires spatiaux — Matériaux d'essai de décharge électrostatique induite par la charge du vaisseau spatial

General Information

- Status

- Published

- Publication Date

- 20-Jul-2011

- Technical Committee

- ISO/TC 20/SC 14 - Space systems and operations

- Drafting Committee

- ISO/TC 20/SC 14/WG 4 - Space environment (natural and artificial)

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 20-Mar-2022

- Completion Date

- 14-Feb-2026

Overview

ISO 11221:2011 - Space systems: Space solar panels - Spacecraft charging induced electrostatic discharge test methods specifies qualification and characterization test methods that simulate plasma interactions and electrostatic discharges (ESD) on space solar array panels. The standard applies to panels using crystalline silicon, gallium arsenide (GaAs) or multi‑junction solar cells and focuses on surface discharges (surface flashover and related phenomena) rather than internal or bulk breakdown.

Key topics and technical requirements

- Scope and applicability: Test methods tailored for space solar panels subject to spacecraft charging and plasma environments; tailoring allowed by agreement between supplier and customer.

- ESD statistics: Preliminary tests to determine ESD inception statistics and estimate the expected number of ESD events in orbit.

- Secondary-arc qualification: Procedures for triggering and characterizing secondary arcs, including required test facilities, external circuit configurations, CIC (coverglass interconnect cell) gap tests, panel-level tests and defined success criteria.

- Characterization tests: Methods to assess robustness to ESD and plasma interaction, covering:

- Power degradation and I–V changes after ESD events

- Secondary arc behavior (temporary vs. permanent sustained arcs)

- Power leakage to plasma and leakage current measurements

- Solar array back-surface testing

- Definitions and symbols: Comprehensive terms (e.g., primary/secondary arc, surface flashover, inverted/normal potential gradient) and electrical symbols used in test circuits.

- Test reporting and annexes: Required test report contents plus informative and normative annexes on plasma interaction background, chamber sizing for LEO‑like plasma, external circuit designs, statistical analyses and measurement procedures.

Practical applications and users

ISO 11221 is intended for:

- Satellite designers and system engineers validating solar array architecture against spacecraft charging risks.

- Solar array manufacturers qualifying panels (Si, GaAs, multi‑junction) for flight.

- Environmental test laboratories that simulate LEO/GEO plasma and ESD conditions.

- Mission assurance, reliability and safety teams performing risk assessments, failure analysis and acceptance testing.

Use cases include qualification testing prior to flight, comparative evaluation of coverglass/interconnect designs, supplier verification, and root‑cause analysis after anomalous in‑orbit behavior.

Related standards

ISO 11221 was prepared by ISO/TC 20 (Space systems and operations) and aligns with broader electrotechnical and space‑system test practice. Organizations typically consider ISO 11221 alongside other space charging and environmental standards (national, industry or agency standards) and tailor requirements by agreement between customer and supplier.

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

ISO 11221:2011 is a standard published by the International Organization for Standardization (ISO). Its full title is "Space systems — Space solar panels — Spacecraft charging induced electrostatic discharge test methods". This standard covers: ISO 11221:2011 specfies qualification and characterization test methods to simulate plasma interactions and electrostatic discharges on solar array panels in space. ISO 11221:2011 is applicable to solar array panels made of crystalline silicon, gallium arsenide (GaAs) or multi-junction solar cells. ISO 11221:2011 addresses only surface discharges on solar panels.

ISO 11221:2011 specfies qualification and characterization test methods to simulate plasma interactions and electrostatic discharges on solar array panels in space. ISO 11221:2011 is applicable to solar array panels made of crystalline silicon, gallium arsenide (GaAs) or multi-junction solar cells. ISO 11221:2011 addresses only surface discharges on solar panels.

ISO 11221:2011 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 11221:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 11221

First edition

2011-08-01

Space systems — Space solar panels —

Spacecraft charging induced electrostatic

discharge test methods

Systèmes spatiaux — Panneaux solaires spatiaux — Matériaux d'essai

de décharge électrostatique induite par la charge du vaisseau spatial

Reference number

©

ISO 2011

© ISO 2011

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2011 – All rights reserved

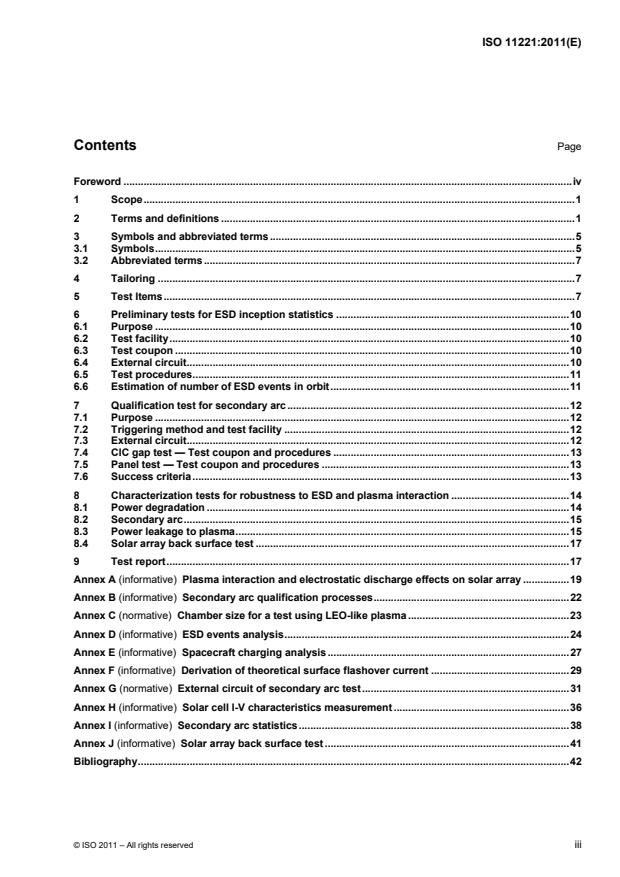

Contents Page

Foreword . iv

1 Scope . 1

2 Terms and definitions . 1

3 Symbols and abbreviated terms . 5

3.1 Symbols . 5

3.2 Abbreviated terms . 7

4 Tailoring . 7

5 Test Items . 7

6 Preliminary tests for ESD inception statistics . 10

6.1 Purpose . 10

6.2 Test facility . 10

6.3 Test coupon . 10

6.4 External circuit . 10

6.5 Test procedures . 11

6.6 Estimation of number of ESD events in orbit . 11

7 Qualification test for secondary arc . 12

7.1 Purpose . 12

7.2 Triggering method and test facility . 12

7.3 External circuit . 12

7.4 CIC gap test — Test coupon and procedures . 13

7.5 Panel test — Test coupon and procedures . 13

7.6 Success criteria . 13

8 Characterization tests for robustness to ESD and plasma interaction . 14

8.1 Power degradation . 14

8.2 Secondary arc . 15

8.3 Power leakage to plasma . 15

8.4 Solar array back surface test . 17

9 Test report . 17

Annex A (informative) Plasma interaction and electrostatic discharge effects on solar array . 19

Annex B (informative) Secondary arc qualification processes . 22

Annex C (normative) Chamber size for a test using LEO-like plasma . 23

Annex D (informative) ESD events analysis . 24

Annex E (informative) Spacecraft charging analysis . 27

Annex F (informative) Derivation of theoretical surface flashover current . 29

Annex G (normative) External circuit of secondary arc test . 31

Annex H (informative) Solar cell I-V characteristics measurement . 36

Annex I (informative) Secondary arc statistics . 38

Annex J (informative) Solar array back surface test . 41

Bibliography . 42

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 11221 was prepared by Technical Committee ISO/TC 20, Aircraft and space vehicles, Subcommittee

SC 14, Space systems and operations.

iv © ISO 2011 – All rights reserved

INTERNATIONAL STANDARD ISO 11221:2011(E)

Space systems — Space solar panels — Spacecraft charging

induced electrostatic discharge test methods

1 Scope

This International Standard specifies qualification and characterization test methods to simulate plasma

interactions and electrostatic discharges on solar array panels in space. This International Standard is

applicable to solar array panels made of crystalline silicon, gallium arsenide (GaAs) or multi-junction solar

cells. This International Standard addresses only surface discharges on solar panels.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

active gap

gap between solar cells across which a potential difference is present when the solar array power is available

2.2

blow-off

emission of negative charges into space due to an electrostatic discharge

2.3

collisionless plasma

plasma in which the mean free paths of electron-neutral, ion-neutral and coulomb collisions are longer than

the scale length of interest

NOTE Chamber length is an example of a scale length of interest.

2.4

differential charging

spacecraft charging where any two points are charged to different potentials

2.5

differential capacitance

capacitance between any two points in a spacecraft, especially between the insulator surface and the

spacecraft body

2.6

differential voltage

potential difference between any two points in a spacecraft during spacecraft charging, especially between the

insulator exterior surface potential and the spacecraft chassis potential

2.7

discharge inception voltage

lowest voltage at which discharges of specified magnitude will recur when a DC voltage is applied between

any two points in a spacecraft, especially between the insulator surface and the spacecraft body

2.8

electrical breakdown

failure of the insulation properties of a dielectric, resulting in a sudden release of charge with possible damage

to the dielectric concerned

2.9

electric propulsion

spacecraft propulsion system in which the thrust is generated by accelerating charged particles that are

neutralized before they are ejected in order to produce a jet

2.10

electrostatic discharge

electrical breakdown of dielectric or gas or vacuum gaps, and also of surface interface of dissimilar materials,

caused by differential charging of parts of dielectric materials and their interfaces

2.11

gap distance

distance between biased cells or conductors

2.12

glow discharge

gaseous discharge with a surface glow near the cathode surface

NOTE The origin of the ionized gas is mostly ambient neutral gas molecules rather than metal vapour from the

cathode surface.

2.13

inverted potential gradient

inverted voltage gradient

result of differential charging where the insulating surface or dielectric reaches a positive potential with respect

to the neighbouring conducting surface or metal

NOTE This phenomenon is also known as PDNM (positive dielectric negative metal).

2.14

non-sustained arc

passage of current from an external source through a conductive path that lasts only while the primary

discharge current flows

See Figure 1.

2.15

normal potential gradient

normal voltage gradient

result of differential charging where the insulating surface or dielectric reaches a negative potential with

respect to the neighbouring conducting surface or metal

NOTE This phenomenon is also known as NDPM (negative dielectric positive metal).

2.16

permanent sustained arc

passage of current from an external source through a conductive path that keeps flowing until the external

source is intentionally shut down

See Figure 1.

NOTE Some permanent sustained arcs may leave a permanent conductive path even after the shut-down.

2.17

Poisson process

stochastic process in which events occur independently of one another

2 © ISO 2011 – All rights reserved

2.18

power generation voltage

potential difference between the positive and negative terminals of a solar array string

2.19

primary arc

trigger arc

developed phase of a primary discharge, under an inverted potential gradient, which is associated with

cathodic spot formation at a metallic or semiconductor surface

2.20

primary discharge

initial electrostatic discharge which, by creating a conductive path, can trigger a secondary arc

See Figure 1.

NOTE The current can include blow-off current and surface flashover current.

2.21

punch-through

dielectric breakdown between two sides of an insulator material

2.22

ram

space in front of and adjacent to a spacecraft in which the plasma density can be enhanced by the motion of

the spacecraft

2.23

satellite capacitance

absolute capacitance

capacitance between a satellite body and the ambient plasma

2.24

secondary arc

passage of current from an external source, such as a solar array, through a conductive path initially

generated by a primary discharge

NOTE Figure 1 shows the various stages of a secondary arc.

2.25

snapover

phenomenon caused by secondary electron emission that can lead to electron collection on insulating

surfaces in an electric field

2.26

solar array front surface

solar array surface where solar cells are laid down

NOTE Solar cells are laid down on the side of a solar panel that normally faces the sun.

2.27

solar array back surface

solar array surface where solar cells are not laid down

NOTE Solar cells are not laid down on the side of a solar panel that normally faces away from the sun.

2.28

surface charging

deposition of electrical charges onto, or their removal from, external surfaces

2.29

surface flashover

surface discharge propagating laterally over a dielectric material

NOTE Surface flashover is sometimes called a “brushfire discharge”.

2.30

temporary sustained arc

passage of current from an external source through a conductive path that lasts longer than a primary

discharge current pulse but terminates without leaving a permanent conductive path

See Figure 1.

2.31

wake

trail of rarefied plasma left behind by a moving spacecraft

Key

1 primary discharge (blow-off + flashover)

2 non-sustained arc (NSA)

3 temporary sustained arc (TSA)

4 permanent sustained arc (PSA)

5 secondary arc

i current

I short-circuit current of one or more solar array circuits

sc

t time

The primary discharge is fed by absolute and differential capacitances. The secondary arc is fed by the solar

array power.

Figure 1 — Stages of secondary arc

4 © ISO 2011 – All rights reserved

3 Symbols and abbreviated terms

3.1 Symbols

A area of surface of plasma

s

C bypass capacitance

BC

C differential capacitance

CG

C capacitor representing capacitance between solar panel structure and ambient plasma

GS

C capacitor representing capacitance underneath the cells through the Kapton layer

kapton

C satellite capacitance

sat

C capacitor representing capacitance of solar array string

string

C capacitance per unit area of coverglass

v

C capacitor representing capacitance of solar array string and capacitance underneath the cells through

the Kapton layer

C capacitor representing capacitance of solar array string and capacitance underneath the cells through

the Kapton layer

C capacitor representing capacitance of solar array string and capacitance underneath the cells through

the Kapton layer

D fast switching diode

D fast switching diode

D fast switching diode

d sheath thickness

sh

I reverse saturation-current density, in amperes per square metre (A/m )

I power supply representing power generated by the solar array

I short-circuit current of one or more solar array circuits

sc

I current of a solar array section

section

I current of a solar array string

string

i current

j number of bins

k Boltzmann constant

L inductance to form the pulse current shape

ext

n diode constant

P probability that an event occurs in the i-th bin

i

Q charge

q elementary charge

R resistance

R resistance to form the pulse current shape

ext

R resistance to adjust the voltage between two strings under test

L

R U /I resistance needed to get the right voltage and current in the loop simulating the solar

section section section

panels section

R U /I resistance needed to get the right voltage and current across the solar cells simulating

string string string

the solar array string under arcing test

r radius of plasma

T temperature, in kelvins (K)

T

e electron temperature

T ion temperature

i

t time

t time to threshold differential voltage

ESD

U constant current source

U constant voltage source

U voltage of a solar array section

section

U voltage of a solar array string

string

V power supply representing charging potential of spacecraft body

b

v velocity of plasma wavefront

p

V potential difference

angle

Debye length

D

ρ electron density

e

ρ ion density

i

coverglass potential

CG

satellite body potential

sat

6 © ISO 2011 – All rights reserved

3.2 Abbreviated terms

19

eV electron volt (1 eV = 1,602 10 J)

CIC coverglass interconnect cell

ESD electrostatic discharge

GEO geosynchronous orbit

IPG inverted potential gradient

LEO low Earth orbit

NPG normal potential gradient

NSA non-sustained arc

PA primary arc

PEO polar Earth orbit

PI plasma interaction

PSA permanent sustained arc

TSA temporary sustained arc

4 Tailoring

Specifications described in this International Standard are tailorable upon agreement between the customer

and the supplier.

5 Test items

NOTE Annex A provides an overview of the subject of spacecraft charging and electrostatic discharge (ESD)

phenomena for readers who are not familiar with the subject.

The aims of the plasma interaction (PI) and ESD tests are to simulate the detrimental phenomena anticipated

in space for a given solar array design, to evaluate a design’s resistance to the phenomena and to provide

data necessary for the judgment of qualification and characterization.

Figures 2 and 3 present the test items specified in this International Standard, with flow charts to summarize

the logic flow of each test. The purpose of a preliminary test for ESD statistics is to define the statistics helpful

for selecting the test parameters (such as the number of primary discharges inflicted upon a test coupon),

defining the margins of the test parameters and defining the confidence level of the test results. If proper

statistics for these numbers and probabilities are already available, the preliminary test is not required for the

qualification of secondary arcs. Annex B provides a brief rationale of the structure of the flow chart in Figure 2.

Figure 2 — Logic flow of ESD tests

8 © ISO 2011 – All rights reserved

Figure 3 — Logic flow for determining the necessity of a power leakage characterization test

6 Preliminary tests for ESD inception statistics

6.1 Purpose

The purpose of this test is to characterize the ESD (primary discharge) inception threshold in terms of

differential voltage between the coverglasses and the solar array circuit. This differential voltage can be used

as a tool to estimate the number of ESD events during the mission lifetime in orbit.

6.2 Test facility

The test facility shall be able to simulate the charging processes of a solar array insulator in orbit. If the solar

array is for a GEO satellite, the solar array insulator shall be charged using either an energetic electron beam

3

or UV irradiation, or a combination of both, in a vacuum chamber with a pressure lower than 1 10 Pa

6

(7,5 10 Torr). The electron energy shall be less than 30 keV so that the charging takes place mostly over

the insulator surface, and not below it. The vacuum chamber for a geosynchronous orbit (GEO) solar array

test shall be equipped with an adequate device to determine the insulator charging potential, such as a

non-contacting surface potential probe, preferably mounted on an (x)-(y) scanning device.

If the solar array is for a low Earth orbit (LEO) spacecraft, the solar array insulator shall be charged by a low-

energy plasma with a temperature below 10 eV in a vacuum chamber with a pressure that guarantees a

collisionless plasma. If the solar array is for a polar Earth orbit (PEO) spacecraft and auroral electrons are

responsible for differential charging, the solar array insulator should be charged using an energetic electron

beam. If the solar array is for a PEO spacecraft and low-energy ionospheric ions are responsible for

differential charging, the solar array insulator should be charged using a low-energy plasma. See Annex C for

the minimum chamber size for a low-energy plasma test.

The test facility shall be equipped with a device to record an adequate image of the test coupon during the test

so that ESD locations can be identified either during or after the test.

6.3 Test coupon

The test coupon(s) shall consist of at least three strings of three cells to represent a cell surrounded by other

cells. The test coupon(s) should

a) reflect the production variation with respect to parameters that can affect the ESD inception threshold,

such as degree of grouting, coverglass overhang, cell spacing, etc. on the total number of cells on the

test coupon(s),

b) include all the features of a flight panel, such as bus bars, through-holes, terminal strips, wire harness,

hold-down, etc.,

c) include the mitigation techniques that represent the flight model as closely as possible, if the solar panel

design involves ESD mitigation techniques such as a dissipative coating, and

d) consider the worst condition during the life of the spacecraft, such as after thermal cycling, repaired cells,

and other conditions that can lead to a greater risk of ESD and secondary arcs.

6.4 External circuit

In the test, the vacuum chamber serves as the circuit ground. If the charging situation in space is the inverted

potential gradient, bias the test coupon to a negative potential with a DC power supply. If the charging

situation is the normal potential gradient, ground the test coupon. (See Figure 4 for a circuit diagram.) A small

amount of capacitance may be connected to the DC power supply if a brighter flash of ESD light is needed to

identify its location. Limit the capacitance so that the electrostatic energy dissipated does not cause

degradation of the solar cells on the test coupon(s). An energy of less than 5 mJ is recommended. As the

capacitance of a coupon alone sometimes exceeds the limit, external capacitance should not be used for a

large coupon of more than about 20 cells. To record the ESD in this event, use a sensitive camera.

10 © ISO 2011 – All rights reserved

a) Inverted potential gradient b) Normal potential gradient

Key

1 coupon

2 vacuum chamber

Figure 4 — Test set-up for the ESD inception test

6.5 Test procedures

If an electron beam gun or a UV source is used for charging the test coupon, the test shall be carried out until

a statistically significant number of ESD events, no less than 10, occur on the test coupon. The test coupon

surface potential shall be measured repeatedly during the test by a non-contacting surface potential probe.

The coupon surface potential closest to each ESD location shall be identified and recorded. The minimum

differential voltage is the minimum value among all the ESD events recorded. Be aware of the uncertainties

associated with the spatial resolution of the probe and the temporal variation of the potential depending on the

time of measurement from the ESD inception.

If a low-energy plasma source is used, the differential charging voltage can be approximated by the chamber

plasma potential, which is usually positive by several times the electron temperature, minus the negative

coupon potential. The uncertainty is in the order of the electron temperature. The coupon bias voltage shall be

varied to cover all the possible charging potentials in orbit. In the case of PEO spacecraft, the waiting time at

each bias voltage should be no less than 20 min. In the case of LEO spacecraft, the waiting time at each bias

voltage should be no less than 90 min. At low bias voltages where the probability of ESD is very low, a longer

waiting time is recommended to improve the statistics. See Reference [1] for an example of characterizing the

arc rate per unit time under a low-energy plasma environment. If the threshold is unknown, plot the arc rates

at different bias voltages on a logarithmic scale and find the voltage where the probability of an arc over a

given time becomes negligible, assuming that ESD inception is modelled as a Poisson process (see

Reference [2] for an example).

6.6 Estimation of number of ESD events in orbit

It can be useful to analyse the number of ESD events expected in orbit as a basis for discussion to determine

the number of primary discharges in the subsequent tests. See Annex D for details. Other methods of analysis

may also be used to compute the number of ESD events.

7 Qualification test for secondary arc

7.1 Purpose

The purpose of this test is to qualify a given design of solar panel for flight. The purpose of the coverglass

interconnect cell (CIC) gap test (7.4) is to demonstrate that no damaging secondary arc occurs even when

primary discharges are forced to occur directly on the active CIC gap, which is a possible worst case scenario.

The purpose of the panel test (7.5) is to show that no damaging secondary arc occurs, even after a significant

number of primary discharges occur all over the flight-representative test coupon. See Annex B for a more

detailed rationale of both tests.

It may not always be possible to replicate the orbital worst case scenario in the laboratory experiment (e.g. low

temperature at the end of eclipse, the effects of thermal cycling on gap distance, failure or aging of grouting,

and the outgassing time period in orbit). However, every effort shall be made to simulate the worst case

scenario or to extrapolate the test results to represent the worst case scenario parametrization.

7.2 Triggering method and test facility

If it can be confirmed that the probability of a transition from a primary discharge to a secondary arc does not

depend upon the method of primary discharge inception, any method may be used to cause primary

discharges, irrespective of the anticipated charging situation in orbit. If the transition probability depends upon

the testing plasma environment, the same test facility as used for the primary discharge inception threshold

test shall be used. In either case, the shape and amplitude of the primary discharge current in the test shall be

plausibly representative of the current expected in orbit.

There is a risk of primary discharge and subsequent secondary arcs in LEO even for a GEO spacecraft as it

passes through LEO during the orbit transfer. Also, if a plasma emission device is used, such as a plasma

contactor, LEO-type arcing may occur when the device is first turned on or off. Therefore, for a GEO

spacecraft, the test should be performed under the conditions in a LEO-type plasma in addition to the GEO-

type test. See Annex C for the minimum chamber size for a low-energy plasma test.

The test shall take place under vacuum in a test chamber with a pressure that guarantees the physical state of

3

a collisionless plasma if a low-energy plasma is used, or lower than 3 10 Pa if other triggering methods,

such as an energetic electron beam, UV ray, laser pulse, etc., are used. Care should be taken to choose a

power supply capable of reproducing the dynamic response of the array to transient short circuits (such as

limited overshoot current and fast recovery to the steady state). Simultaneous ESD current transient

monitoring and recording devices and a video imaging device are also required for the test.

7.3 External circuit

The cells need not be illuminated, but the available current and capacitance shall be simulated by power

sources and external capacitors, C and C , representing the satellite capacitance and solar array

sat CG

coverglass capacitance respectively. The capacitance of the missing coverglasses shall also be factored into

the test. The current waveform supplied by the external circuit shall be representative of the surface flashover

current in orbit. Under the present state of knowledge, the propagation distance is taken to be 2 m, confirmed

by a laboratory test using a 4 m 1 m coupon panel (see Reference [3]). The present best estimate of the

propagation speed of surface flashover is 10 km/s for a GEO solar array under inverted potential gradient.

See Annex F for an example of the current waveform derivation. The electric architecture of a solar paddle

shall be taken into account to determine the waveform. If a mitigation method for flashover current is included

in the design, the effect shall be taken into account in sizing energy in the capacitance C .

CG

The inductance of the wire harness should be representative of a flight solar panel. Excessive inductance

shall be avoided as it affects the transient current waveform. Short cable lengths or coaxial cables reduce the

unwanted inductance. Annex G specifies the external circuit for use in the case of inverted potential gradient.

If testing under normal potential gradient is imperative, a representative flashover current to the primary

discharge shall be provided.

12 © ISO 2011 – All rights reserved

7.4 CIC gap test — Test coupon and procedures

The test coupon(s) shall consist of at least two strings of two cells to represent a point surrounded by solar cell

corner edges. The total number of test coupon(s) shall reflect the production variation, including reworked

cells. The solar cells shall be laid down on the substrate in the same manner as for the flight model. The

substrate shall also be made of the same material as the flight model. If the solar panel design includes ESD

inception mitigation, whether the mitigation design is included in the test coupon or not depends on definition

of the worst case scenario in orbit. If failure of the mitigation method is regarded as the worst case scenario,

the mitigation method may be removed from the coupon. Before and after the test, the tasks specified in

Table 1 shall be carried out.

The primary discharges may be concentrated on the cell gap. The test shall ascertain that a significant

number of primary discharges (at least three, or more than three if agreed with the customer on the basis of

statistical discussion; see Reference [4] for an example) per given test condition occur in the active gap or in

the vicinity of the active gap if a grouted gap is tested.

Table 1 — Required tasks before and after the ESD test

Item Before test After test Comment

Visual inspection of the coupon x x With optical microscope

Output power measurement x x Same light source

Insulation check across the cell gap x x By measurement

Insulation check between the cells and

x x

the substrate

7.5 Panel test — Test coupon and procedures

The test coupon shall consist of at least three strings of three cells to represent means of cell surrounded by

other cells. The coupon shall be a flight-representative qualification coupon covering the production variation

of the string gap distance and CIC cell configuration (coverglass overhang, adhesive thickness, etc.), including

reworked cells. The solar cells shall be laid down on the substrate in the same manner as for the flight model.

The substrate shall also be made of the same material as the flight model. If the solar panel design includes

ESD inception mitigation, the mitigation design should be included in the test coupon so as to be as flight-

representative as possible. Before and after the test, the tasks specified in Table 1 shall be carried out.

The total number of primary discharges on the coupon shall be determined by means of statistical analysis.

The total number of ESD events, as derived in accordance with Annex D, is useful in determining the number

of primary discharges. No control shall be carried out at the primary discharge locations.

7.6 Success criteria

The test shall demonstrate that no damaging secondary arc occurs due to ESD.

8 Characterization tests for robustness to ESD and plasma interaction

8.1 Power degradation

8.1.1 Purpose

The purpose of this test is to characterize power degradation due to repeated ESD events after the desired

orbital lifetime. As the present knowledge about the power degradation is not mature enough to list power

degradation as a qualification item, the power degradation is measured for characterization purposes only.

This test may be performed simultaneously with the coupon panel test (7.5) provided the test requirements

listed in 7.2, 7.3 and 8.1 are satisfied.

8.1.2 Test facility

The test facility shall be the same as the one used for the ESD inception threshold test (6.2).

8.1.3 Test coupon

The CIC solar cells on the test coupon(s) shall be of flight quality. The definition of flight quality shall be

agreed upon with the customer prior to the test. The solar cell, coverglass, adhesive (both for coverglass and

substrate) and interconnector shall be of the same type and material as for the flight models. The illuminated

current-voltage (I-V) characteristics before the test shall be in accordance with the customer's specification of

flight quality. The substrate need not be of the same material as the flight model. The total number of test

coupon(s) shall reflect the production variation, including reworked cells.

8.1.4 External circuit

An external circuit shall provide additional electrostatic energy that would have been provided by the insulator

capacitance not accommodated inside the vacuum chamber. The current waveform supplied by the external

circuit shall be representative of the surface flashover current in orbit. Under the present state of knowledge,

the propagation distance is taken to be 2 m, confirmed by a laboratory test using a 4 m 1 m coupon panel

(see Reference [3]). The present best estimate of the propagation speed of surface flashover is 10 km/s for a

GEO solar array under inverted potential gradient. See Annex F for an example of the current waveform

derivation. The electric architecture of a solar paddle shall be taken into account in determining the waveform.

8.1.5 Test procedures

Illuminated current-voltage (I-V) characteristics shall be measured pre- and post-test with an appropriate light

source. The intensity of the light source shall be calibrated using a reference cell so that the relative change of

the power output can be measured precisely. The exact conditions of the illuminated I-V measurement shall

be based on an appropriate solar cell calibration standard, selected in agreement with the customer prior to

testing. A visual inspection shall be performed pre- and post-test using an optical microscope. The test can be

terminated once it satisfies one of the following:

a) the estimated number of ESD events during the mission in orbit (see 6.6) occurs;

b) ten discharges for any one cell do not create cell degradation;

c) a predetermined number of ESD events, as agreed with the programme customer, occurs.

It is advisable to measure dark current with a DC power supply in order to perform in situ monitoring of the

progress of degradation during the test by comparing the dark current with the pre-test value. See Annex H for

more information on the measurement of the dark current. The total drop of spacecraft power at the end of its

mission lifetime shall be derived and recorded.

14 © ISO 2011 – All rights reserved

8.2 Secondary arc

8.2.1 Purpose

The purpose of this test is to characterize the secondary arc for a given design of solar panel. The

characteristics include the probability of transition from a primary discharge to a secondary arc and the

duration of the secondary arcs if the transition probability is not zero. If the characteristics are already known

from past experience, this test is not necessary to qualify the solar panel for secondary arcs.

8.2.2 Triggering method and test facility

The triggering method and test facility shall be as specified in 7.2.

8.2.3 Test coupon

The test coupon(s) shall consist of at least two strings of two cells to represent a point surrounded by solar cell

corner edges. The total number of test coupon(s) shall reflect the production variation, including reworked

cells. The cell gap spacing should be kept within an allowable design tolerance from the specification. The

solar cells shall be laid down on the substrate in the same manner as for the flight model. The substrate shall

also be made of the same material as in the flight model.

If the solar panel design includes ESD inception mitigation, whether the mitigation design is included in the

test coupon or not depends on the definition of the worst case scenario in orbit. If failure of the mitigation

method is regarded as the worst case scenario, the mitigation method may be removed from the coupon.

8.2.4 External circuit

The external circuit shall be as specified in 7.3.

8.2.5 Test procedures

Before and after the test, the tasks specified in Table 1 shall be carried out. Primary discharges may be

concentrated on the cell gap. For each pair of gap voltage and string current agreed upon with the customer,

the probability of transition from primary discharge to secondary arc shall be derived. The test shall ascertain

that at least ten primary discharges per given test condition occur in the active gap (or in the vicinity of the

active gap in the case of a grouted gap). If it is necessary to identify the confidence level of the transition

probability, a significant number of primary discharges (as agreed with the customer on the basis of statistical

discussion) per the given test condition shall occur in the active gap. If the transition probability is not zero,

statistics of secondary arc duration, such as the mean and the standard deviation, are useful to extrapolate

the probability of a damaging secondary arc with a very long duration. If any statistical distribution function is

proposed to describe the secondary arc duration, its goodness-of-fit shall be determined by an appropriate

method, such as the statistic. See Annex I for an example of deriving the statistics.

8.3 Power leakage to plasma

8.3.1 Purpose

The purpose of this test is to characterize the power leakage from a solar array to the surrounding plasma.

The plasma density and neutral gas density near the spacecraft shall be analysed first. Charging analysis

tools employing a particle simulation method (see Annex E) can estimate the amount of current for a given

plasma density. A rough estimate of the critical neutral gas density for transition of snapover to neutral gas

ionization can be obtained using formulas in References [5] and [6]. If the power leakage due to snapover is

low and neutral densities are too low for snapover to lead to neutral gas ionization, this test is not necessary.

8.3.2 Test facility

The test shall take place under vacuum in a test chamber equipped with a low-energy plasma source capable

of generating the plasma density expected around the solar array in orbit. The plasma species do not have to

be the same as those in orbit (see Reference [2]) A best effort shall be made to realize a plasma temperature

similar to the value in orbit. If the plasma temperature is higher than that in orbit, the test result on the

collected current shall be corrected based on either computer simulation or theory. The neutral background

pressure shall be kept below 0,01 Pa so that unrealistic electron-neutral collisions do not affect the test results.

The test facility shall be equipped with a DC power supply capable of supplying several amperes of current at

several hundred volts, a recording device to monitor the collection current and the coupon potential

simultaneously, a video imaging device and a plasma diagnostic device to determine the chamber plasma

properties including the plasma potential with respect to the chamber wall. See Annex C for the minimum

chamber size for a low-energy plasma test.

8.3.3 Test coupon

The number of CIC solar cells per coupon shall be as many as is practical. The minimum number shall be at

least three strings of three cells. The use of mechanical CIC cells (not electrically flight-like) is acceptable as

long as all the conductive parts, including the cell edge and interconnector, are exposed in the same manner

as the flight model. The substrate material shall be flight-representative. The total number of test coupon(s)

shall reflect the production variation including reworked cells.

8.3.4 External circuit

Both ends of the positive and negative electrodes of an array may be combined and connected to a DC power

supply as illustrated in Figure 5. The cells need not be illuminated during the test.

Key

1 coupon

2 plasma chamber

Figure 5 — Schematic of circuit diagram for the characterization test of plasma power leakage

16 © ISO 2011 – All rights reserved

8.3.5 Test procedures

Before the test, the solar array coupon shall be visually inspected with an optical microscope. The test coupon

bias voltage shall be changed step-wise while monitoring the potential of the coupon with respect to the

plasma potential until the potential reaches the maximum solar array output voltage in orbit. The current

collected at each potential shall be recorded after the current has become steady. After the test, the visual

inspection shall be repeated. The overall power leakage from the spacecraft to the plasma shall be derived

and reported.

8.4 Solar array back surface test

Although the scope of this International Standard is surface discharge and plasma interaction on the solar

array front surface, the possibility of ESD and plasma interaction on the solar array back surface cannot be

excluded (see Annex J).

9 Test report

The ESD test report shall include the following elements:

a) a title;

b) a description of the test facility (i.e. chamber size, chamber pressure, power supply, recording device,

etc.) with photographs of the test set-up; verify that all necessary facility criteria are met;

c) a description of the test coupon (i.e. solar cell type, solar cell output power, number of coupons tested,

etc.);

d) a description of the test conditions as follows:

1) when a low-temperature plasma is used, the plasma conditions, such as plasma density,

temperature and potential, shall be listed;

2) when an electron beam is used, the beam energy and current density shall be listed;

3) if the coupon is placed in a vacuum chamber for outgassing purposes prior to the test, the duration,

pressure and temperature shall be liste

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...