ISO/IEC TR 5469:2024

(Main)Artificial intelligence — Functional safety and AI systems

Artificial intelligence — Functional safety and AI systems

This document describes the properties, related risk factors, available methods and processes relating to: — use of AI inside a safety related function to realize the functionality; — use of non-AI safety related functions to ensure safety for an AI controlled equipment; — use of AI systems to design and develop safety related functions.

Intelligence artificielle — Sécurité fonctionnelle et systèmes d'intelligence artificielle

General Information

- Status

- Published

- Publication Date

- 07-Jan-2024

- Technical Committee

- ISO/IEC JTC 1/SC 42 - Artificial intelligence

- Drafting Committee

- ISO/IEC JTC 1/SC 42 - Artificial intelligence

- Current Stage

- 6060 - International Standard published

- Start Date

- 08-Jan-2024

- Due Date

- 09-Jun-2023

- Completion Date

- 08-Jan-2024

Overview

ISO/IEC TR 5469:2024 is a Technical Report that addresses functional safety and AI systems. It summarizes properties, risk factors, methods and processes for using AI in safety-critical contexts, including:

- AI embedded inside safety-related functions to realize required behavior;

- Non‑AI safety functions used to ensure safety for AI‑controlled equipment;

- AI systems used to design or develop safety‑related functions.

The report provides practical guidance for engineers, architects and safety managers on integrating AI into electrical/electronic/programmable electronic (E/E/PE) systems while addressing functional safety concerns.

Key topics and technical requirements

ISO/IEC TR 5469:2024 covers the full scope of AI‑related functional safety topics without prescribing a single recipe. Major technical areas include:

- Overview of functional safety and applicability to AI in E/E/PE systems.

- AI technology elements and the three‑stage realization principle (model creation, validation, execution) with guidance on deriving acceptance criteria.

- Properties and risk factors such as automation level, transparency/explainability, environment complexity, learning dynamics, adversarial vulnerabilities and hardware issues.

- Verification and validation (V&V) challenges and techniques: data preparation, model‑level validation, choice of AI metrics, system‑level testing, virtual and physical testing, test coverage limits and drift mitigation.

- Control and mitigation measures: AI subsystem architectures, detection and switching mechanisms, supervision with constraints, redundancy/ensembles and diversity, robustness techniques, optimization/compression, attention mechanisms and data/parameter protection.

- Processes and methodologies: relationship between AI life cycle and functional safety life cycle, documentation and artefacts, PFMEA for offline training, and fault models.

- Informative annexes include applicability to IEC 61508, worked examples, V&V process guidance, and mappings to related standards.

Practical applications and users

ISO/IEC TR 5469:2024 is intended for:

- Functional safety engineers and system integrators designing AI-enabled safety functions in automotive, industrial automation, robotics, medical devices and transportation systems.

- AI developers implementing models for safety‑relevant tasks and needing to align model lifecycle with safety lifecycle.

- Certification bodies, safety assessors and regulators seeking a reference for assessing AI-related safety risks and mitigation measures.

- R&D teams exploring robust, explainable and testable AI for high‑assurance applications.

Practical uses include defining acceptance criteria for AI models, designing supervisory safety architectures, planning V&V strategies (virtual + physical), and mapping AI elements to established safety frameworks.

Related standards

- IEC 61508 series (functional safety for E/E/PE systems) - applicability discussed in Annex A.

- ISO/IEC 5338 and other AI lifecycle standards - mappings included in Annex D.

Keywords: ISO/IEC TR 5469:2024, functional safety, AI systems, verification and validation, E/E/PE, three-stage realization, explainable AI, adversarial robustness, safety lifecycle.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

NYCE

Mexican standards and certification body.

Sponsored listings

Frequently Asked Questions

ISO/IEC TR 5469:2024 is a technical report published by the International Organization for Standardization (ISO). Its full title is "Artificial intelligence — Functional safety and AI systems". This standard covers: This document describes the properties, related risk factors, available methods and processes relating to: — use of AI inside a safety related function to realize the functionality; — use of non-AI safety related functions to ensure safety for an AI controlled equipment; — use of AI systems to design and develop safety related functions.

This document describes the properties, related risk factors, available methods and processes relating to: — use of AI inside a safety related function to realize the functionality; — use of non-AI safety related functions to ensure safety for an AI controlled equipment; — use of AI systems to design and develop safety related functions.

ISO/IEC TR 5469:2024 is classified under the following ICS (International Classification for Standards) categories: 35.020 - Information technology (IT) in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/IEC TR 5469:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

Technical

Report

ISO/IEC TR 5469

First edition

Artificial intelligence — Functional

2024-01

safety and AI systems

Intelligence artificielle — Sécurité fonctionnelle et systèmes

d'intelligence artificielle

Reference number

© ISO/IEC 2024

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

© ISO/IEC 2024 – All rights reserved

ii

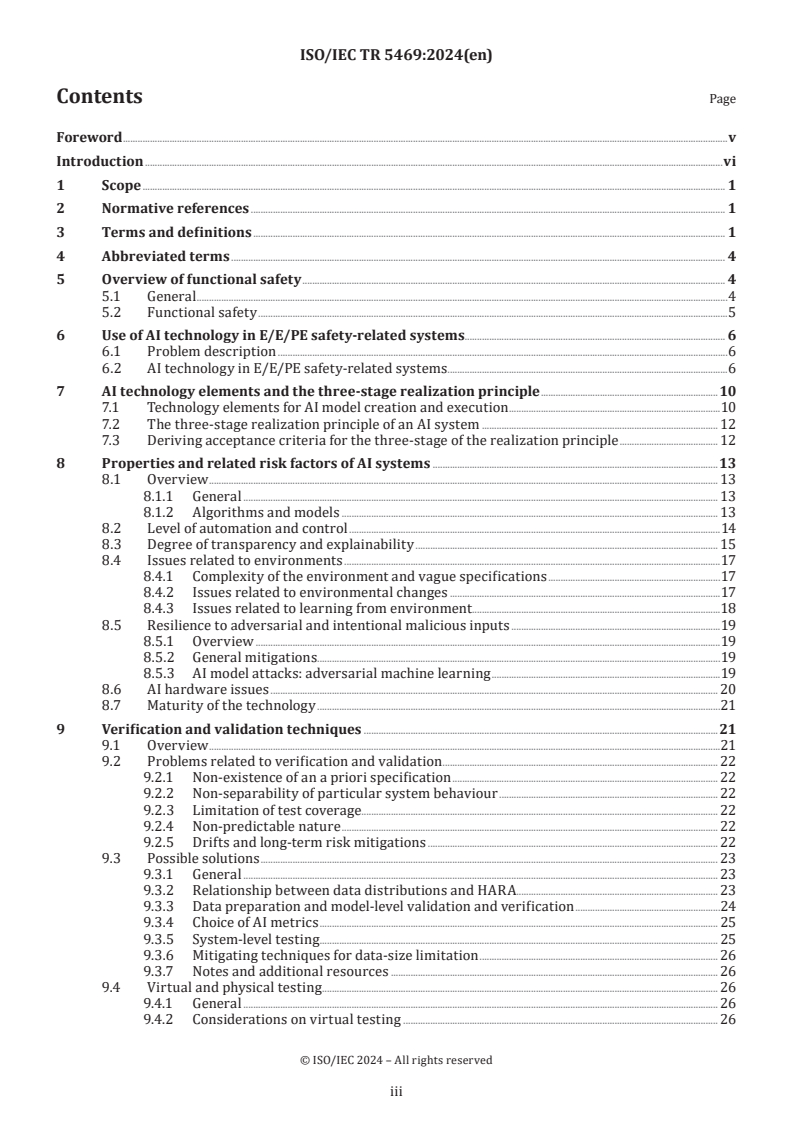

Contents Page

Foreword .v

Introduction .vi

1 Scope .1

2 Normative references .1

3 Terms and definitions .1

4 Abbreviated terms . 4

5 Overview of functional safety . 4

5.1 General .4

5.2 Functional safety .5

6 Use of AI technology in E/E/PE safety-related systems. 6

6.1 Problem description .6

6.2 AI technology in E/E/PE safety-related systems .6

7 AI technology elements and the three-stage realization principle .10

7.1 Technology elements for AI model creation and execution .10

7.2 The three-stage realization principle of an AI system . 12

7.3 Deriving acceptance criteria for the three-stage of the realization principle . 12

8 Properties and related risk factors of AI systems .13

8.1 Overview . 13

8.1.1 General . 13

8.1.2 Algorithms and models . 13

8.2 Level of automation and control .14

8.3 Degree of transparency and explainability . 15

8.4 Issues related to environments .17

8.4.1 Complexity of the environment and vague specifications .17

8.4.2 Issues related to environmental changes .17

8.4.3 Issues related to learning from environment .18

8.5 Resilience to adversarial and intentional malicious inputs .19

8.5.1 Overview .19

8.5.2 General mitigations.19

8.5.3 AI model attacks: adversarial machine learning .19

8.6 AI hardware issues . 20

8.7 Maturity of the technology .21

9 V erification and validation techniques .21

9.1 Overview .21

9.2 Problems related to verification and validation . 22

9.2.1 Non-existence of an a priori specification . 22

9.2.2 Non-separability of particular system behaviour . 22

9.2.3 Limitation of test coverage . . 22

9.2.4 Non-predictable nature . 22

9.2.5 Drifts and long-term risk mitigations . 22

9.3 Possible solutions . 23

9.3.1 General . 23

9.3.2 Relationship between data distributions and HARA. 23

9.3.3 Data preparation and model-level validation and verification .24

9.3.4 Choice of AI metrics . 25

9.3.5 System-level testing . . 25

9.3.6 Mitigating techniques for data-size limitation . 26

9.3.7 Notes and additional resources . 26

9.4 Virtual and physical testing . . 26

9.4.1 General . 26

9.4.2 Considerations on virtual testing . 26

© ISO/IEC 2024 – All rights reserved

iii

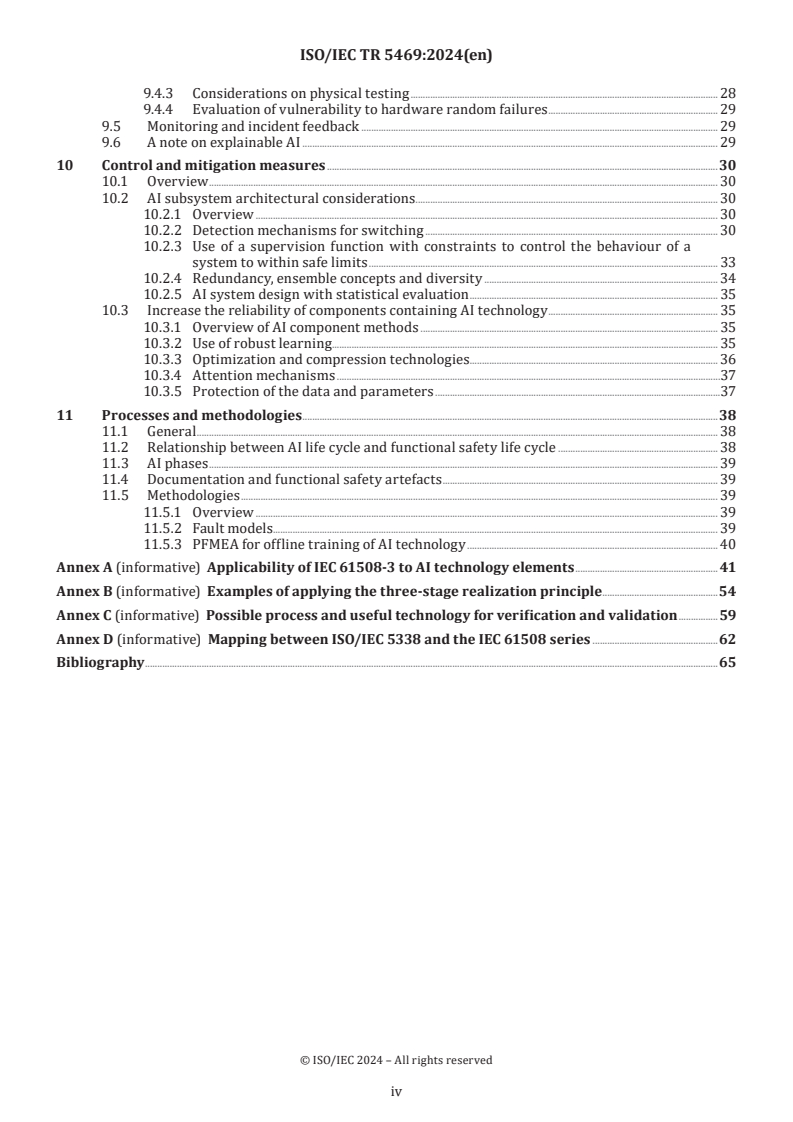

9.4.3 Considerations on physical testing . 28

9.4.4 E valuation of vulnerability to hardware random failures . 29

9.5 M onitoring and incident feedback . 29

9.6 A note on explainable AI . 29

10 Control and mitigation measures .30

10.1 Overview . 30

10.2 AI subsystem architectural considerations . . 30

10.2.1 Overview . 30

10.2.2 Detection mechanisms for switching . 30

10.2.3 Use of a supervision function with constraints to control the behaviour of a

system to within safe limits . 33

10.2.4 Redundancy, ensemble concepts and diversity . 34

10.2.5 AI system design with statistical evaluation . 35

10.3 Increase the reliability of components containing AI technology . 35

10.3.1 Overview of AI component methods . 35

10.3.2 Use of robust learning . . . 35

10.3.3 Optimization and compression technologies. 36

10.3.4 Attention mechanisms .37

10.3.5 Protection of the data and parameters .37

11 Processes and methodologies .38

11.1 General . 38

11.2 Relationship between AI life cycle and functional safety life cycle . 38

11.3 AI phases . 39

11.4 Documentation and functional safety artefacts . 39

11.5 Methodologies . 39

11.5.1 Overview . 39

11.5.2 Fault models. 39

11.5.3 PFMEA for offline training of AI technology . 40

Annex A (informative) Applicability of IEC 61508-3 to AI technology elements . 41

Annex B (informative) Examples of applying the three-stage realization principle .54

Annex C (informative) Possible process and useful technology for verification and validation .59

Annex D (informative) Mapping between ISO/IEC 5338 and the IEC 61508 series .62

Bibliography .65

© ISO/IEC 2024 – All rights reserved

iv

Foreword

ISO (the International Organization for Standardization) and IEC (the International Electrotechnical

Commission) form the specialized system for worldwide standardization. National bodies that are

members of ISO or IEC participate in the development of International Standards through technical

committees established by the respective organization to deal with particular fields of technical activity.

ISO and IEC technical committees collaborate in fields of mutual interest. Other international organizations,

governmental and non-governmental, in liaison with ISO and IEC, also take part in the work.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types

of document should be noted. This document was drafted in accordance with the editorial rules of the ISO/

IEC Directives, Part 2 (see www.iso.org/directives or www.iec.ch/members_experts/refdocs).

ISO and IEC draw attention to the possibility that the implementation of this document may involve the

use of (a) patent(s). ISO and IEC take no position concerning the evidence, validity or applicability of any

claimed patent rights in respect thereof. As of the date of publication of this document, ISO and IEC had not

received notice of (a) patent(s) which may be required to implement this document. However, implementers

are cautioned that this may not represent the latest information, which may be obtained from the patent

database available at www.iso.org/patents and https://patents.iec.ch. ISO and IEC shall not be held

responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www.iso.org/iso/foreword.html.

In the IEC, see www.iec.ch/understanding-standards.

This document was prepared by Joint Technical Committee ISO/IEC JTC 1, Information technology,

Subcommittee SC 42, Artificial intelligence.

Any feedback or questions on this document should be directed to the user’s national standards

body. A complete listing of these bodies can be found at www.iso.org/members.html and

www.iec.ch/national-committees.

© ISO/IEC 2024 – All rights reserved

v

Introduction

The use of artificial intelligence (AI) technology in industry has increased significantly in recent years and

AI has been demonstrated to deliver benefits in certain applications. However, there is limited information

on specification, design, and verification of functionally safe AI systems or on how to apply AI technology

for functions that have safety-related effects. For functions realized with AI technology, such as machine

learning (ML), it is difficult to explain why they behave in a particular manner and to guarantee their

performance. Therefore, whenever AI technology is used in general and especially when it is used to realize

safety-related systems, special considerations are likely to arise.

The availability of powerful computational and data storage technologies makes the prospect of large-

scale deployment of ML possible. For more and more applications, adopting machine learning (as an AI

technology) is enabling the rapid and successful development of functions that detect trends and patterns

in data. This makes it possible to induce a function’s behaviour from observation and to quickly extract the

key parameters that determine its behaviour. Machine learning is also used to identify anomalous behaviour

or to converge on an optimal solution within a specific environment. Successful ML applications are found

in analysis of, for example, financial data, social networking applications and language recognition, image

recognition (particularly face recognition), healthcare management and prognostics, digital assistants,

manufacturing robotics, machine health monitoring and automated vehicles.

In addition to ML, other AI technologies are also gaining importance in engineering applications. Applied

statistics, probability theory and estimation theory have, for example, enabled significant progress in the

field of robotics and perception. As a result, AI technology and AI systems are starting to realize applications

that affect safety.

Models play a central role in the implementation of AI technology. The properties of these models are used

to demonstrate the compatibility of AI technology and AI systems with functional safety requirements.

For instance, where there is an underlying known and understood scientific relationship between the key

parameters that determine a function’s behaviour, there is likely to be a strong correlation between the

observed input data and the output data. This leads to a transparent and sufficiently complete model as

the basis for AI technology. In this case, compatibility of the model with functional safety requirements is

demonstrated. However, AI technology is often used in cases where physical phenomena are so complex or

at such a small scale, or unobservable without influencing the experimental data, that consequently there

is no scientific model of the underlying behaviour. In this case, the model of the AI technology is possibly

neither transparent nor complete and the compatibility of the model with functional safety requirements is

hard to demonstrate.

Machine learning is used to create models and thus to extend the understanding of the world. However,

machine-learnt models are only as good as the information used to derive the model. If the training data

does not cover important cases, then the derived models are incorrect. As more known instances are

observed they are used to reinforce a model, but this biases the relative importance of observations, steering

the function away from less frequent, but still real, behaviours. Continuous observation and reinforcement

moves the model towards an optimum or it overemphasizes common data and overlook extreme, but critical,

conditions.

In the case of continuous improvement of the model through the use of AI technology, the verification and

validation activities in order to demonstrate its safety integrity are undermined as the function behaviour

progressively moves away from the rigorously tested, ideally deterministic and repeatable behaviour.

The purpose of this document is to enable the developer of safety-related systems to appropriately apply

AI technologies as part of safety functions by fostering awareness of the properties, functional safety risk

factors, available functional safety methods and potential constraints of AI technologies. This document also

provides information on the challenges and solution concepts related to the functional safety of AI systems.

Clause 5 provides an overview of functional safety and its relationship with AI technology and AI systems.

Clause 6 describes different classes of AI technology to show potential compliance with existing functional

safety International Standards when AI technology forms part of a safety function. Clause 6 further

introduces different usage levels of AI technology depending on their final impact on the system. Finally,

© ISO/IEC 2024 – All rights reserved

vi

Clause 6 also provides a qualitative overview of the relative levels of functional safety risk associated with

different combinations of AI technology class and usage level.

Clause 7 describes, based on ISO/IEC 22989, a three-stage realization principle for usage of AI technology in

safety-related systems, where compliance with existing functional safety International Standards cannot be

shown directly.

Clause 8 discusses properties and related functional safety risk factors of AI systems and presents challenges

that such use raises, as well as properties that are considered when attempting to treat or mitigate them.

Clauses 9, 10 and 11 show possible solutions to these challenges from the field of verification and validation,

control and mitigation measures, processes, and methodologies.

The annexes provide examples of application of this document and additional details. Annex A addresses

how IEC 61508-3 is applied to AI technology elements, and Annex B provides examples to how to apply

three-stage realization principles and define various properties. Annex C describes more detailed processes

related to 9.3. Annex D shows the mapping between safety life cycle in IEC 61508-3 and AI system life cycle

in ISO/IEC 5338.

© ISO/IEC 2024 – All rights reserved

vii

Technical Report ISO/IEC TR 5469:2024(en)

Artificial intelligence — Functional safety and AI systems

1 Scope

This document describes the properties, related risk factors, available methods and processes relating to:

— use of AI inside a safety related function to realize the functionality;

— use of non-AI safety related functions to ensure safety for an AI controlled equipment;

— use of AI systems to design and develop safety related functions.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

ISO/IEC 22989:2022, Information technology — Artificial intelligence — Artificial intelligence concepts and

terminology

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO/IEC 22989:2022 and the following

apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

safety

freedom from risk (3.3) which is not tolerable

[SOURCE: IEC 61508-4:2010, 3.1.11]

3.2

functional safety

part of the overall safety (3.1) relating to the EUC (Equipment Under Control) and the EUC control system

that depends on the correct functioning of the E/E/PE (Electrical/Electronic/Programmable Electronic)

safety-related systems and other risk reduction measures

[SOURCE: IEC 61508-4:2010, 3.1.12]

3.3

risk

functional safety risk

combination of the probability of occurrence of harm (3.5) and the severity of that harm

(3.5)

Note 1 to entry: For more discussion on this concept, see Annex A of IEC 61508-5.

[SOURCE: IEC 61508-4:2010, 3.1.6, modified — Added < functional safety > domain]

© ISO/IEC 2024 – All rights reserved

3.4

risk

organizational risk

effect of uncertainty on objectives

Note 1 to entry: An effect is a deviation from the expected. It can be positive, negative or both and can address, create

or result in opportunities and threats.

Note 2 to entry: Objectives can have different aspects and categories and can be applied at different levels.

Note 3 to entry: Risk is usually expressed in terms of risk sources, potential events, their consequences and their

likelihood.

Note 4 to entry: This is the core definition of risk. As risks are specifically focused on harm (3.5) a discipline specific

definition of risk (3.3) is used in this document in addition to the core risk definition.

[SOURCE: ISO 31000:2018, 3.1, modified — Added domain and Note 4 to entry]

3.5

harm

physical injury or damage to the health of people, or damage to property or the environment

[SOURCE: IEC 61508-4:2010, 3.1.1]

3.6

hazard

potential source of harm (3.5)

[SOURCE: IEC 61508-4:2010, 3.1.2]

3.7

hazardous event

event that may result in harm (3.5)

[SOURCE: IEC 61508-4:2010, 3.1.4]

3.8

system

arrangement of parts or elements that together exhibit a stated behaviour or meaning that the individual

constituents do not

[SOURCE: ISO/IEC/IEEE 15288:2023, 3.46, modified — Removed the three Notes to entry]

3.9

systematic failure

failure, related in a deterministic way to a certain cause, which can only be eliminated by a modification of

the design or of the manufacturing process, operational procedures, documentation or other relevant factors

[SOURCE: IEC 61508-4:2010, 3.6.6]

3.10

safety-related system

designated system that both

— implements the required safety functions necessary to achieve or maintain a safe state for the EUC; and

— is intended to achieve, on its own or with other E/E/PE safety-related systems and other risk reduction

measures, the necessary safety integrity for the required safety functions

[SOURCE: IEC 61508-4:2010, 3.4.1]

© ISO/IEC 2024 – All rights reserved

3.11

safety function

function to be implemented by an E/E/PE safety-related system or other risk reduction measures, that is

intended to achieve or maintain a safe state for the EUC, in respect of a specific hazardous event (3.7)

[SOURCE: IEC 61508-4:2010, 3.5.1]

3.12

equipment under control

EUC

equipment, machinery, apparatus or plant used for manufacturing, process, transportation, medical or other

activities

Note 1 to entry: The EUC control system is separate and distinct from the EUC.

[SOURCE: IEC 61508-4:2010, 3.2.1]

3.13

programmable electronic

PE

based on computer technology which can be comprised of hardware, software and of input and/or output

units

Note 1 to entry: This term covers microelectronic devices based on one or more central processing units (CPUs)

together with associated memories, etc.

EXAMPLE The following are all programmable electronic devices:

— microprocessors;

— micro-controllers;

— programmable controllers;

— application specific integrated circuits (ASICs);

— programmable logic controllers (PLCs);

— other computer-based devices (e.g. smart sensors, transmitters, actuators).

[SOURCE: IEC 61508-4:2010, 3.2.12]

3.14

electrical/electronic/programmable electronic

E/E/PE

based on electrical (E) and/or electronic (E) and/or programmable electronic (PE) technology

Note 1 to entry: The term is intended to cover any and all devices or systems operating on electrical principles.

EXAMPLE Electrical/electronic/programmable electronic devices include:

— electro-mechanical devices (electrical);

— solid-state non-programmable electronic devices (electronic);

— electronic devices based on computer technology (programmable electronic).

[SOURCE: IEC 61508-4:2010, 3.2.13]

3.15

AI technology

technology used to implement an AI model (3.16)

© ISO/IEC 2024 – All rights reserved

3.16

AI model

physical, mathematical or otherwise logical representation of a system, entity, phenomenon, process or data

[SOURCE: ISO/IEC 22989:2022, 3.1.23, with the addition of AI]

3.17

test oracle

source of information for determining whether a test has passed or failed

[SOURCE: ISO/IEC/IEEE 29119-1:2022, 3.115]

4 Abbreviated terms

ALARP as low as reasonably practicable

ANN artificial neural network

CNN convolutional neural network

CPU central processing unit

CUDA compute unified device architecture

DL deep learning

DNN deep neural network

GPU graphics processing unit

EDDM early drift detection method

E/E electrical and/or electronic

E/E/PE electrical/electronic/programmable electronic

EUC equipment under control

FMEA failure modes and effects analysis

GAMAB globalement au moins aussi bon

HARA hazard analysis and risk assessment

HAZOP hazard and operability analysis

JPEG joint photographic experts group

KPI key performance indicator

MEM minimum endogenous mortality

SVM support vector machines

5 Overview of functional safety

5.1 General

The discipline of functional safety is focused on risks related to injury and damage to the health of people,

or damage to the environment and, in some cases, mitigation against damage to product or equipment. The

© ISO/IEC 2024 – All rights reserved

definition of risk differs based on the domain tags as shown in Clause 3. Both definitions are valid concepts

for the use of AI. All references to risk in this document from this point on are related to the definition from

the functional safety domain.

According to IEC 61508-1, control of risk is an iterative process of risk assessment and risk reduction.

Risk assessment identifies sources of harm and evaluates the related risks for the intended use and the

reasonably foreseeable misuse of the product or system. Risk reduction reduces risks until they become

tolerable. Tolerable risk is a level of risk that is accepted in a given context based on the current state of the

art.

The IEC 61508 series recognizes the following three-step (prioritised) approach as being good practice for

risk reduction:

— Step 1: inherently functionally safe design;

— Step 2: guards and protective devices;

— Step 3: information for end users.

Risk reduction via the provision of functional safety is associated with Step 2.

This document focuses on the aspects of safety functions performed by a safety related system by making

use of AI technology, either within the safety related system or during design and development of the safety

related system (Step 2).

This document makes no provision of methodology for AI technology used for Steps 1 and 3.

5.2 Functional safety

[19]

IEC 61508-4 defines functional safety as that “part of the overall safety relating to the EUC (Equipment

Under Control) and the EUC control system that depends on the correct functioning of the E/E/PE (Electrical/

Electronic/Programmable Electronic) safety-related systems and other risk reduction measures.” The E/E/

PE safety-related system is delivering a “safety function”, which is defined in IEC 61508-4 as a “function to

be implemented by an E/E/PE safety-related system or other risk reduction measures, that is intended to

achieve or maintain a safe state for the EUC, in respect of a specific hazardous event.” In other words, the

safety functions control the risk associated with a hazard that leads to harm to people or the environment.

The safety functions also reduce the risk of having serious economic implications.

As the term implies, functional safety - as defined in IEC 61508-4 - aims to achieve and maintain functionally

safe system states of an EUC through the provision of safety functions. Based on the inclusion of “other risk

reduction measures” in the definition of functional safety and safety functions, non-technical functions are

explicitly included. The EUC is not limited to individual devices but it includes also systems.

Following these definitions, functional safety as a discipline is thus concerned with the proper engineering

of these technical and non-technical safety functions for risk reduction or risk level containment of a

particular equipment under control, from the component level up to the system level, including considering

human factors, and under operational or environmental stress.

Functional safety focuses on safety functions for risk reduction and the properties of these functions

required for risk reduction. While the functionality of a safety function is strongly use-case dependent,

the properties required for risk reduction and the related measures are the main focus of functional safety

standardization.

Prior to the advent of programmable systems, when safety functions were limited to implementation

in hardware, the focus of functional safety was to reduce the consequences and the likelihood of random

hardware failures. With software being increasingly used to implement safety functions, the focus shifted

towards systematic failures introduced during design and development.

[7]

NOTE ISO 21448:2022 includes requirements on safety of the intended functionality including aspects such as

performance limitation. Annex D describes implications for machine learning.

© ISO/IEC 2024 – All rights reserved

There is a robust body of knowledge on how to avoid systematic failures in non-AI systems and in software

[138]

development. This document considers the use of AI technology in the context of safety functions.

Functions containing AI technology, especially machine learning, typically follow a different development

paradigm to that of non-AI systems. They are less specification-driven and more driven by observation of

the data defining the system behaviour. For this reason, the catalogue of available measures for dealing

with systematic failures is extended with respect to the specificities of AI technologies: Annex A provides

an example of that extension. AI-specific risk reduction measures also differ from non-AI systems from a

functional perspective. Functional safety puts a focus on systematic capabilities (IEC 61508-4:2010, 3.5.9) in

addition to random hardware and systematic failures throughout the life cycle.

The relevance of AI technologies when used to realize a safety function is their potential to address new

methods for risk reduction. This document examines the use of such technologies for this purpose, while

maintaining existing risk reduction concepts, by introducing risk and classification considerations.

In general, achieving an acceptable risk level for increasingly complex and automated systems is likely to

depend on advanced safety concepts. This includes the adequate implementation of both technical and non-

technical risk reduction measures to achieve and maintain safe system states. Assuring the validity of such

advanced safety concepts is a great challenge in functional safety. It also leads to an increase in the number

of functional safety requirements. For all technical risk reduction measures, the distinction is made that

hardware random faults and systematic faults are considered, which is done in basic International Standards

like the IEC 61508 series or derived International Standards. However, for safety functions including AI

technology, it is inevitable that there is additional focus on the assurance that systematic capabilities of

systems that implement these functions are sufficient for the intended use environment.

6 Use of AI technology in E/E/PE safety-related systems

6.1 Problem description

The use of AI technology and AI systems is currently not treated in mature functional safety International

Standards (indeed, in some International Standards their use is explicitly forbidden). International Standards

[7]

that include AI-related contents include ISO 21448 .

6.2 AI technology in E/E/PE safety-related systems

E/E/PE safety-related systems have a set of properties to ensure that they provide the intended safety

mitigation measures in a dependable way. These properties are ideally generic and application independent.

However, the data and the specifications vary based on application and technology domain. The process in

which properties are selected is described in Figure 3 for each of the three stages of the three-stage realization

principle. The properties are selected on a case-by-case basis, as relevant to a particular application or

technology domain, their data and specifications. Properties are based on existing International Standards,

[16]-[19] [12]-[15] [21]

including the IEC 61508 series , the ISO 26262 series , IEC 62061 and the ISO 13849 series.

[5],[8]

Clause 8 provides a list of typical properties.

Satisfying the selected properties is likely to place particular functional safety requirements on the

[18]

realization, installation, validation, operation and maintenance of such systems. For example, IEC 61508-3

defines such requirements for the software part of E/E/PE systems. However, several AI technologies use

different development approaches (e.g. learning-based) compared to the non-AI software engineering life

cycles targeted by IEC 61508-3.

To address the difference between traditional development processes and the approach typical of AI

technologies, this clause provides a general classification scheme for the applicability of AI technology in

E/E/PE safety-related systems, based on various contexts of the application of AI technology.

An example of a classification scheme is, summarized in Table 1 and the related flowchart represented in

Figure 1. The scheme is intended to provide insight on how an AI technology is addressed in the context of

functional safety for a specific application.

© ISO/IEC 2024 – All rights reserved

The classification scheme (see Table 1) is organized along two axes:

— AI Application and Usage Level. This axis considers the application of the AI technology and includes,

among other things, the way in which it is used. It is classified from A to D, with two intermediate levels

for A and B.

NOTE 1 The factors identified in Clause 8 are of high relevance in the context of the classification. These factors

are described further in Clause 8 and include the level of automation and control (see 8.2), the degree of decision

transparency and explainability (see 8.3), the complexity of the environment and vague specifications (see 8.4),

security (see 8.5), system hardware issues see (8.6) and the maturity of the technology (see 8.7).

An example of a classification of Usage Level is as follows:

— Usage Level A1 is assigned when the AI technology is used in a safety-relevant E/E/PE system and where

automated decision-making of the system function using AI technology is possible;

— Usage Level A2 is assigned when the AI technology is used in a safety-relevant E/E/PE system and where

no automated decision-making of the system function using AI technology is possible (e.g. AI technology

is used for diagnostic functionality within the E/E/PE system);

NOTE 2 The evaluation can change depending on the role of the diagnostic function, such as whether the

diagnostic is critical to maintaining the functional safety of the system or is merely a minor contributor to

functional safety amongst many others.

— Usage Level B1 is assigned when the AI technology is used only during the development of the safety-

relevant E/E/PE system (e.g. an offline support tool) and where automated decision-making of the

function developed using AI technology is possible;

— Usage Level B2 is assigned when the AI technology is used only during the development of the safety-

relevant E/E/PE system (e.g. an offline support tool) and where no automated decision-making of the

function is possible:

— Usage Level C is assigned when the AI technology is not part of a functional safety function in the E/E/

PE system, but can have an indirect impact on the function:

NOTE 3 The Usage Level C includes AI techniques clearly providing additional risk reduction and whose failure

is not critical to the level of acceptable risk.

EXAMPLE An AI technique that increases or decreases the demand rate placed on a safety system.

— Usage Level D is assigned if the AI technology is not part of a safety function in the E/E/PE system and

has no impact on the safety function due to sufficient segregation and behaviour control.

NOTE 4 An example is separation through a “sandbox” or ”hypervisor” in such a way that it does not affect the

safety functionality.

— AI Technology Class. This axis considers the level of fulfilment of AI technology in satisfying the identified

set of properties, in which:

— Class I is assigned if AI technology is developed and reviewed using existing functional safety

International Standards, for example, if the properties and the set of methods and techni

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...