ISO 16422:2014

(Main)Pipes and joints made of oriented unplasticized poly(vinyl chloride) (PVC-O) for the conveyance of water under pressure - Specifications

Pipes and joints made of oriented unplasticized poly(vinyl chloride) (PVC-O) for the conveyance of water under pressure - Specifications

ISO 16422:2014 specifies the requirements of pipes and joints made of oriented unplasticized poly(vinyl chloride) (PVC-O), for piping systems intended to be used underground or above-ground where not exposed to direct sunlight, for water mains and services, pressurized sewer systems and irrigation systems. The piping system according to ISO 16422:2014 is intended for the conveyance of cold water under pressure, for drinking water and for general purposes up to and including 45 °C, and especially in those applications where special performance requirements are needed, such as impact loads and pressure fluctuations, up to pressure of 25 bars[1]. Joints constructed of other materials should meet their own relevant standards in addition to the fitness-for-purpose requirements of ISO 16422:2014. [1] 1 bar = 0,1 MPa = 105 Pa; 1 MPa = 1 N/mm2

Tubes et assemblages en poly(chlorure de vinyle) non plastifié orienté (PVC-O) pour le transport de l'eau sous pression — Spécifications

General Information

Relations

Frequently Asked Questions

ISO 16422:2014 is a standard published by the International Organization for Standardization (ISO). Its full title is "Pipes and joints made of oriented unplasticized poly(vinyl chloride) (PVC-O) for the conveyance of water under pressure - Specifications". This standard covers: ISO 16422:2014 specifies the requirements of pipes and joints made of oriented unplasticized poly(vinyl chloride) (PVC-O), for piping systems intended to be used underground or above-ground where not exposed to direct sunlight, for water mains and services, pressurized sewer systems and irrigation systems. The piping system according to ISO 16422:2014 is intended for the conveyance of cold water under pressure, for drinking water and for general purposes up to and including 45 °C, and especially in those applications where special performance requirements are needed, such as impact loads and pressure fluctuations, up to pressure of 25 bars[1]. Joints constructed of other materials should meet their own relevant standards in addition to the fitness-for-purpose requirements of ISO 16422:2014. [1] 1 bar = 0,1 MPa = 105 Pa; 1 MPa = 1 N/mm2

ISO 16422:2014 specifies the requirements of pipes and joints made of oriented unplasticized poly(vinyl chloride) (PVC-O), for piping systems intended to be used underground or above-ground where not exposed to direct sunlight, for water mains and services, pressurized sewer systems and irrigation systems. The piping system according to ISO 16422:2014 is intended for the conveyance of cold water under pressure, for drinking water and for general purposes up to and including 45 °C, and especially in those applications where special performance requirements are needed, such as impact loads and pressure fluctuations, up to pressure of 25 bars[1]. Joints constructed of other materials should meet their own relevant standards in addition to the fitness-for-purpose requirements of ISO 16422:2014. [1] 1 bar = 0,1 MPa = 105 Pa; 1 MPa = 1 N/mm2

ISO 16422:2014 is classified under the following ICS (International Classification for Standards) categories: 23.040.20 - Plastics pipes; 23.040.45 - Plastics fittings; 91.140.60 - Water supply systems. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 16422:2014 has the following relationships with other standards: It is inter standard links to ISO 16422-2:2024, ISO 16422-5:2024, ISO 16422-1:2024, ISO 16422:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 16422:2014 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 16422

Second edition

2014-02-15

Pipes and joints made of oriented

unplasticized poly(vinyl chloride)

(PVC-O) for the conveyance of water

under pressure — Specifications

Tubes et assemblages en poly(chlorure de vinyle) non plastifié orienté

(PVC-O) pour le transport de l’eau sous pression — Spécifications

Reference number

©

ISO 2014

© ISO 2014

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2014 – All rights reserved

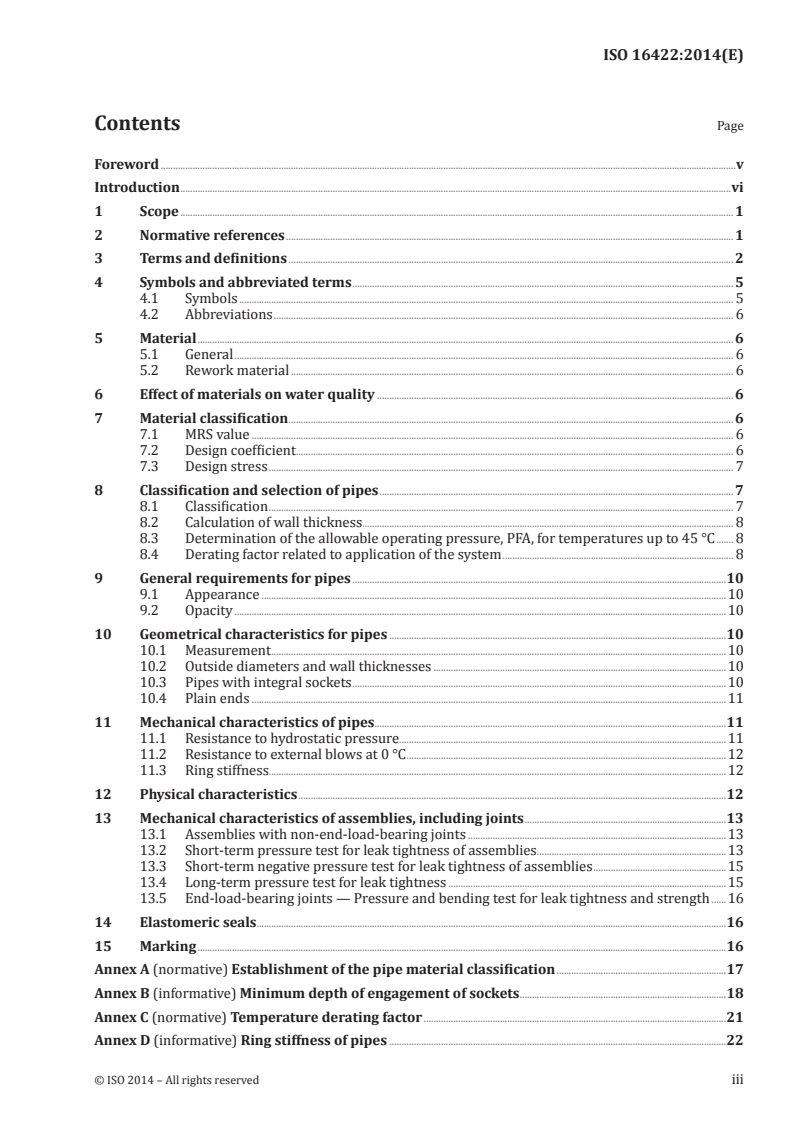

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Symbols and abbreviated terms . 5

4.1 Symbols . 5

4.2 Abbreviations . 6

5 Material . 6

5.1 General . 6

5.2 Rework material . 6

6 Effect of materials on water quality . 6

7 Material classification . 6

7.1 MRS value . 6

7.2 Design coefficient. 6

7.3 Design stress . 7

8 Classification and selection of pipes . 7

8.1 Classification . 7

8.2 Calculation of wall thickness . 8

8.3 Determination of the allowable operating pressure, PFA, for temperatures up to 45 °C . 8

8.4 Derating factor related to application of the system . 8

9 General requirements for pipes .10

9.1 Appearance .10

9.2 Opacity .10

10 Geometrical characteristics for pipes .10

10.1 Measurement .10

10.2 Outside diameters and wall thicknesses .10

10.3 Pipes with integral sockets .10

10.4 Plain ends .11

11 Mechanical characteristics of pipes .11

11.1 Resistance to hydrostatic pressure .11

11.2 Resistance to external blows at 0 °C .12

11.3 Ring stiffness . .12

12 Physical characteristics .12

13 Mechanical characteristics of assemblies, including joints .13

13.1 Assemblies with non-end-load-bearing joints .13

13.2 Short-term pressure test for leak tightness of assemblies .13

13.3 Short-term negative pressure test for leak tightness of assemblies .15

13.4 Long-term pressure test for leak tightness .15

13.5 End-load-bearing joints — Pressure and bending test for leak tightness and strength .16

14 Elastomeric seals .16

15 Marking .16

Annex A (normative) Establishment of the pipe material classification .17

Annex B (informative) Minimum depth of engagement of sockets .18

Annex C (normative) Temperature derating factor .21

Annex D (informative) Ring stiffness of pipes .22

Annex E (informative) Determination of the long-term test pressure by creep consideration .24

Annex F (informative) Determination of axial and tangential orientation factor .25

iv © ISO 2014 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 138, Plastics pipes, fittings and valves for the

transport of fluids, Subcommittee SC 2, Plastics pipes and fittings for water supplies.

This second edition cancels and replaces the first edition (ISO 16422:2006), of which it constitutes a

minor revision with the following changes:

— Table 4: Physical characteristics: Resistance to dichloromethane and alternative tests.

— Annex A: Determination of pipe material classification: Procedures for classified and non-classified

feedstock material.

— Annex F: Determination of axial and tangential orientation factor.

Introduction

Molecular orientation of thermoplastics results in improvement of physical and mechanical properties.

Orientation is carried out at temperatures well above the glass transition temperature.

Orientation of PVC-U pipe-material can be induced by different processes.

In general the following production process is common. A thick-wall tube is extruded (feedstock) and

conditioned at the desired temperature. The orientation process is activated in circumferential and

axial directions under controlled conditions.

After the orientation process, the pipe is cooled down quickly to ambient temperature.

The orientation of the molecules creates a laminar structure in the material of the pipe wall. This

structure gives the ability to withstand brittle failure emanating from minor flaws in the material matrix

or from scratches at the surface of the pipe wall. PVC-O can therefore be considered as highly resistant

to notches and no testing is needed. Because of the morphology of oriented PVC-U pipe-material, there

is no risk of long-line rapid crack propagation.

Improved hoop strength, allows reduced wall thickness with material and energy savings. Improved

resistance to impact and fatigue also result.

The classification depends on material compound/formulation and stretch ratios used. Therefore, with

the classification, these characteristics may be specified or determined.

Variations in stretch ratios should be within 10 % of the value determined on the pipes used for

classification. The determination of the stretch ratios may be carried out as shown in Annex F.

vi © ISO 2014 – All rights reserved

INTERNATIONAL STANDARD ISO 16422:2014(E)

Pipes and joints made of oriented unplasticized poly(vinyl

chloride) (PVC-O) for the conveyance of water under

pressure — Specifications

1 Scope

This International Standard specifies the requirements of pipes and joints made of oriented unplasticized

poly(vinyl chloride) (PVC-O), for piping systems intended to be used underground or above-ground

where not exposed to direct sunlight, for water mains and services, pressurized sewer systems and

irrigation systems.

The piping system according to this International Standard is intended for the conveyance of cold water

under pressure, for drinking water and for general purposes up to and including 45 °C, and especially

in those applications where special performance requirements are needed, such as impact loads and

1)

pressure fluctuations, up to pressure of 25 bars .

Joints constructed of other materials should meet their own relevant standards in addition to the fitness-

for-purpose requirements of this International Standard.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 3:1973, Preferred numbers — Series of preferred numbers

ISO 161-1, Thermoplastics pipes for the conveyance of fluids — Nominal outside diameters and nominal

pressures — Part 1: Metric series

ISO 1167-1, Thermoplastics pipes, fittings and assemblies for the conveyance of fluids — Determination of

the resistance to internal pressure — Part 1: General method

ISO 1167-2, Thermoplastics pipes, fittings and assemblies for the conveyance of fluids — Determination of

the resistance to internal pressure — Part 2: Preparation of pipe test pieces

ISO 1167-4, Thermoplastics pipes, fittings and assemblies for the conveyance of fluids — Determination of

the resistance to internal pressure — Part 4: Preparation of assemblies

ISO 1452-2:2009, Plastics piping systems for water supply and for buried and above-ground drainage and

sewerage under pressure — Unplasticized poly(vinyl chloride) (PVC-U) — Part 2: Pipes

ISO 1452-5:2009, Plastics piping systems for water supply and for buried and above-ground drainage and

sewerage under pressure — Unplasticized poly(vinyl chloride) (PVC-U) — Part 5: Fitness for purpose of the

system

ISO 1628-2, Plastics — Determination of the viscosity of polymers in dilute solution using capillary

viscometers — Part 2: Poly(vinyl chloride) resins

ISO 2505, Thermoplastics pipes — Longitudinal reversion — Test method and parameters

ISO 2507-1, Thermoplastics pipes and fittings — Vicat softening temperature — Part 1: General test method

5 2

1) 1 bar = 0,1 MPa = 10 Pa; 1 MPa = 1 N/mm

ISO 2507-2, Thermoplastics pipes and fittings — Vicat softening temperature — Part 2: Test conditions for

unplasticized poly(vinyl chloride) (PVC-U) or chlorinated poly(vinyl chloride) (PVC-C) pipes and fittings and

for high impact resistance poly (vinyl chloride) (PVC-HI) pipes

ISO 2531, Ductile iron pipes, fittings, accessories and their joints for water applications

ISO 3126, Plastics piping systems — Plastics components — Determination of dimensions

ISO 3127, Thermoplastics pipes — Determination of resistance to external blows — Round-the-clock method

ISO 4065, Thermoplastics pipes — Universal wall thickness table

ISO 4633, Rubber seals — Joint rings for water supply, drainage and sewerage pipelines — Specification for

materials

ISO 6259-2, Thermoplastics pipes — Determination of tensile properties — Part 2: Pipes made of

unplasticized poly(vinyl chloride) (PVC-U), chlorinated poly (vinyl chloride) (PVC-C) and high-impact poly

(vinyl chloride) (PVC-HI)

ISO 7686, Plastics pipes and fittings — Determination of opacity

ISO 9080, Plastics piping and ducting systems — Determination of the long-term hydrostatic strength of

thermoplastics materials in pipe form by extrapolation

ISO 9852, Unplasticized poly(vinyl chloride) (PVC-U) pipes — Dichloromethane resistance at specified

temperature (DCMT) — Test method

ISO 9969, Thermoplastics pipes — Determination of ring stiffness

ISO 11922-1:1997, Thermoplastics pipes for the conveyance of fluids — Dimensions and tolerances — Part 1:

Metric series

ISO 12162, Thermoplastics materials for pipes and fittings for pressure applications — Classification,

designation and design coefficient

ISO 13783, Plastics piping systems — Unplasticized poly(vinyl chloride) (PVC-U) end-load-bearing double-

socket joints — Test method for leaktightness and strength while subjected to bending and internal pressure

ISO 13844, Plastics piping systems — Elastomeric-sealing-ring-type socket joints for use with plastic

pipes — Test method for leaktightness under negative pressure, angular deflection and deformation

ISO 13845, Plastics piping systems — Elastomeric-sealing-ring-type socket joints for use with thermoplastic

pipes — Test method for leaktightness under internal pressure and with angular deflection

ISO 13846, Plastics piping systems — End-load-bearing and non-end-load-bearing assemblies and joints for

thermoplastics pressure piping — Test method for long-term leaktightness under internal water pressure

ISO 18373-1, Rigid PVC pipes — Differential scanning calorimetry (DSC) method — Part 1: Measurement of

the processing temperature

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

nominal outside diameter

d

n

numerical designation of size which is common to all components in a thermoplastics piping system

other than flanges and components designated by thread size

Note 1 to entry: It is a convenient round number for reference purposes.

2 © ISO 2014 – All rights reserved

Note 2 to entry: For pipe conforming to ISO 161-1, the nominal outside diameter, expressed in millimetres, is the

minimum mean outside diameter d .

em, min

3.2

nominal wall thickness

e

n

specified wall thickness, in millimetres

Note 1 to entry: It is identical to the specified minimum wall thickness at any point e .

y, min

3.3

nominal pressure

PN

alphanumeric designation related to the mechanical characteristics of the components of a piping

system and used for reference purposes

3.4

hydrostatic pressure

p

internal pressure applied to a piping system

3.5

working pressure

maximum pressure which a piping system can sustain in continuous use under given service conditions

without pressure surge

Note 1 to entry: For thermoplastics piping systems, the value of the nominal pressure is equal to the working

pressure at a temperature of 20 °C, expressed in bar.

3.6

hydrostatic stress

σ

stress, expressed in megapascals, induced in the wall of a pipe when it is subjected to internal water

pressure

Note 1 to entry: It is calculated using the following approximate equation:

()de−

nn

σ =p

20e

n

where

p is the applied internal pressure, in bar;

d is the nominal outside diameter of the pipe, in millimetres;

n

e is the nominal wall thickness, in millimetres.

n

Note 2 to entry: If σ and p are given in the same units, the denominator becomes 2e

n

3.7

long-term hydrostatic strength for 50 years at 20 °C

σ

LTHS

quantity with the unit of stress, i.e. MPa, which can be considered to be a property of the material under

consideration

Note 1 to entry: It represents the 97,5 % lower confidence limit for the long-term hydrostatic strength and equals

the predicted average strength at a temperature of 20 °C and for a time of 50 years with internal water pressure.

3.8

lower confidence limit of the predicted hydrostatic strength

σ

LPL

quantity with the dimension of stress, which represents the 97,5 % lower confidence limit of the

predicted hydrostatic strength for a single value at a temperature T and a time t

Note 1 to entry: It is denoted as σ = σ(T,t,0,975).

LPL

Note 2 to entry: The value of this quantity is determined by the method given in ISO 9080.

3.9

minimum required strength

MRS

required value of σ for a temperature T of 20 °C and a time t of 50 years

LPL

Note 1 to entry: For a particular material, its MRS is established from the value of σ rounded to the next lower

LPL

value of the R 10 series from ISO 3:1973, when σ is less than 10 MPa, or to the next lower value of the R 20 series

LPL

when σ is greater than 10 MPa.

LPL

Note 2 to entry: See also ISO 1452-2:2009, Clause 7.

3.10

design coefficient

C

coefficient with a value greater than one, which takes into consideration service conditions as well as

properties of the components of a piping system other than those represented in σ .

LPL

3.11

pipe series

S

dimensionless number for pipe designation

Note 1 to entry: See ISO 4065

3.12

standard dimension ratio

SDR

numerical designation of a pipe series which is a convenient round number approximately equal to the

dimension ratio of the nominal outside diameter, d , and the nominal wall thickness e

n n

Note 1 to entry: According to ISO 4065, the standard dimension ratio, SDR, and the pipe series S are related, as

expressed in the following equation:

SDR =2S + 1

3.13

orientation factor

factor related to the stretch ratio used in orientation processing

4 © ISO 2014 – All rights reserved

4 Symbols and abbreviated terms

4.1 Symbols

C overall service (design) coefficient

d outside diameter (at any point)

e

d mean outside diameter

em

d inside diameter (at any point)

i

d mean inside diameter of socket

im

d nominal (outside or inside) diameter

n

e wall thickness (at any point)

e mean wall thickness

m

e nominal wall thickness

n

f derating (or uprating) factor for application

A

f derating factor for temperatures

T

K K-value

p internal hydrostatic pressure

p test pressure

T

PN nominal pressure

δ material density

σ hydrostatic stress

σ design stress

s

λ axial orientation factor

a

λ circumferential orientation factor

c

σ Lower predicted confidence limit

LPL

4.2 Abbreviations

DN nominal size

MRS minimum required strength

PFA allowable operating pressure

PVC-O oriented unplasticized poly(vinyl chloride)

PVC-U unplasticized poly(vinyl chloride)

S pipe series

S calc calculated value of the pipe series

SDR standard dimension ratio

5 Material

5.1 General

The material from which the pipes are made shall be PVC-U compound/formulation. This

compound/formulation shall consist substantially of PVC-U resin/powder to which shall be added

only those additives necessary to facilitate the production of pipes and fittings in accordance with this

International Standard. All additives shall be uniformly dispersed.

5.2 Rework material

The use of the manufacturer’s own reprocessed material, produced during the manufacture and works

testing of products and conforming to the material requirements of this International Standard, is

permitted. Reprocessed or recycled material obtained from external sources shall not be used.

6 Effect of materials on water quality

All plastics and non-plastic materials for components of the PVC piping system, e.g. pipes, fittings,

valves, elastomeric sealing rings, solvent cement, and lubricants, when in permanent or in temporary

contact with water which is intended for human consumption, shall not adversely affect the quality of

the drinking water. Where applicable, all materials for components shall conform to the current national

regulations concerning materials in contact with drinking water.

7 Material classification

7.1 MRS value

Oriented pipes made from a defined PVC-U compound and with a well-defined orientation level in

circumferential and axial direction, shall be evaluated according to the procedures of Annex A. The

minimum required strength (MRS) values shall be classified in accordance with 7.3 and Table 1.

7.2 Design coefficient

The design coefficient of oriented PVC-U pipes shall be a minimum of 1,6. Alternatively, 1,4 is permitted

for MRS 450 and MRS 500, provided that axial contraction of the pipe (due to higher design stress) does

not result in pull-out of the joints. In this case, evidence shall be given according to Annex B.

6 © ISO 2014 – All rights reserved

7.3 Design stress

The design stress shall be based on the value of the lower confidence limit σ of the long term hydrostatic

LPL

strength for the resistance to internal pressure as determined in accordance with ISO 9080. This σ

LPL

value shall be converted into a minimum required strength (MRS) in accordance with ISO 12162. The

MRS shall be divided by an overall service (design) coefficient C to give the design stress σ , which is

s

expressed by the following equation:

MRS

σ = (1)

s

C

Table 1 — Material classification

Pipe material classification

315 355 400 450 500

number

a

MRS MPa 31,5 35,5 40 45 50

C 1,6 2 1,6 2 1,6 2 1,4 1,6 2 1,4 1,6 2

σ MPa 20 16 22 18 25 20 32 28 23 36 32 25

s

a

Higher MRS classes can be chosen, provided they fall in the R20 range of ISO 3:1973.

8 Classification and selection of pipes

8.1 Classification

Pipes shall be classified to their nominal pressure PN.

The nominal pressure PN, the pipe series S and the design stress, σ , are connected by the following

s

relationship.

10σ

s

PN≅ (2)

S

SDR−1

S= (3)

d

n

SDR= (4)

e

n

MRS

σ = (5)

s

C

where

e is expressed in millimetres (mm);

n

PN is expressed in megapascals (MPa);

MRS is expressed in megapascals (MPa);

C is nondimensional.

8.2 Calculation of wall thickness

The relationship between the nominal wall thickness e and the nominal outside diameter d is specified

n n

in ISO 4065. The values for nominal pipe wall thickness e for nominal pressure ratings PN, can be

n

calculated by substituting the values for MRS, C, and d in the formula

n

d

n

e = (6)

n

21S +

o

where

S is the calculated preferred value of the nominal S series number of the pipe from 8.1.

o

Values shall be rounded to one decimal place according to the rules of ISO 4065.

NOTE Nominal S numbers and their calculated values are given in ISO 4065 for the R10 series of preferred

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...