ISO 19683:2017

(Main)Space systems — Design qualification and acceptance tests of small spacecraft and units

Space systems — Design qualification and acceptance tests of small spacecraft and units

ISO 19683:2017 provides test methods and test requirements for design qualification and/or acceptance of small spacecraft or units. It provides the minimum test requirements and test methods to qualify the design and manufacturing methods of commercial small spacecraft and their units and to accept the final products. ISO 19683:2017 places emphasis on achieving reliability against infant mortality after satellite launch to orbit while maintaining low cost and fast delivery. ISO 19683:2017 is applied to satellites whose development methods are different from the ones used for traditional satellites that have little room for risk tolerance, as shown in Figure 1. The scope of this document encompasses different categories of small spacecraft, so-called mini-, micro, nano-, pico- and femto-, as well as CubeSat, spacecraft. Therefore, for the sake of convenience, the term "small spacecraft" is used throughout this document as a generic term. ISO 19683:2017 includes CubeSat, as long as it is developed with the untraditional processes.

Systèmes spatiaux — Qualification de la conception et essais de réception des petits véhicules spatiaux

General Information

- Status

- Published

- Publication Date

- 13-Aug-2017

- Technical Committee

- ISO/TC 20/SC 14 - Space systems and operations

- Drafting Committee

- ISO/TC 20/SC 14/WG 1 - Design engineering and production

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 15-Feb-2023

- Completion Date

- 14-Feb-2026

Overview

ISO 19683:2017 – Space systems: Design qualification and acceptance tests of small spacecraft and units defines minimum test requirements and methods for the design qualification and acceptance of commercial small spacecraft and their units. It covers mini-, micro-, nano-, pico-, femto- and CubeSat-class vehicles developed with non‑traditional, low-cost, fast-delivery processes. The standard emphasizes reducing post‑launch infant mortality while retaining rapid development and low cost.

Key topics and technical requirements

- Test philosophy and tailoring: guidance on tailoring tests to mission risk, qualification vs acceptance vs proto‑flight approaches, and retest rules.

- Test documentation: mandatory test plan, test specification and procedures, test reports, and unit datasheets for traceable results.

- Functional and electrical interface tests: verifying operational behavior and electrical compatibility during environmental stress.

- Radiation testing: Total Ionizing Dose (TID) and Single Event Effect (SEE) test requirements and monitoring approaches.

- Spacecraft charging and ESD: methods to evaluate charging-induced electrostatic discharge susceptibility.

- Electromagnetic Compatibility (EMC): emission and susceptibility tests to ensure on-orbit electrical coexistence.

- Mechanical and deployment tests: deployment verification, launcher/spacecraft interface checks, quasi-static load, modal surveys, sinusoidal vibration and other dynamic tests.

- Environmental and mission tests: thermal, mission-profile functional tests, magnetic field and antenna pattern/alignment measurements, and physical property measurements.

- Monitoring and configuration: requirements for test setup, instrumentation and in-test monitoring to ensure repeatable and valid results.

Practical applications and users

ISO 19683:2017 is intended for:

- Small satellite developers and CubeSat teams seeking an auditable test program for design verification and product acceptance.

- Manufacturers and subcontractors validating units (power, communications, payloads) before delivery.

- Test facilities and labs implementing standardized procedures for environmental, vibration, EMC and radiation testing.

- Mission integrators, quality assurance and procurement teams requiring consistent acceptance criteria for low-cost spacecraft.

- Launch providers and system engineers who need clear interface and mechanical qualification evidence.

Typical uses include establishing qualification campaigns, performing acceptance testing for flight hardware, proto‑flight certification, and documenting conformity for customers or regulatory review.

Related standards

ISO 19683 complements other ISO and industry space-systems standards and launcher interface documents. For mission-specific detail, users should harmonize ISO 19683 requirements with applicable launcher, payload, and national space regulations.

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

ISO 19683:2017 is a standard published by the International Organization for Standardization (ISO). Its full title is "Space systems — Design qualification and acceptance tests of small spacecraft and units". This standard covers: ISO 19683:2017 provides test methods and test requirements for design qualification and/or acceptance of small spacecraft or units. It provides the minimum test requirements and test methods to qualify the design and manufacturing methods of commercial small spacecraft and their units and to accept the final products. ISO 19683:2017 places emphasis on achieving reliability against infant mortality after satellite launch to orbit while maintaining low cost and fast delivery. ISO 19683:2017 is applied to satellites whose development methods are different from the ones used for traditional satellites that have little room for risk tolerance, as shown in Figure 1. The scope of this document encompasses different categories of small spacecraft, so-called mini-, micro, nano-, pico- and femto-, as well as CubeSat, spacecraft. Therefore, for the sake of convenience, the term "small spacecraft" is used throughout this document as a generic term. ISO 19683:2017 includes CubeSat, as long as it is developed with the untraditional processes.

ISO 19683:2017 provides test methods and test requirements for design qualification and/or acceptance of small spacecraft or units. It provides the minimum test requirements and test methods to qualify the design and manufacturing methods of commercial small spacecraft and their units and to accept the final products. ISO 19683:2017 places emphasis on achieving reliability against infant mortality after satellite launch to orbit while maintaining low cost and fast delivery. ISO 19683:2017 is applied to satellites whose development methods are different from the ones used for traditional satellites that have little room for risk tolerance, as shown in Figure 1. The scope of this document encompasses different categories of small spacecraft, so-called mini-, micro, nano-, pico- and femto-, as well as CubeSat, spacecraft. Therefore, for the sake of convenience, the term "small spacecraft" is used throughout this document as a generic term. ISO 19683:2017 includes CubeSat, as long as it is developed with the untraditional processes.

ISO 19683:2017 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 19683:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 19683

First edition

2017-07

Space systems — Design qualification

and acceptance tests of small

spacecraft and units

Systèmes spatiaux — Qualification de la conception et essais de

réception des petits véhicules spatiaux

Reference number

©

ISO 2017

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

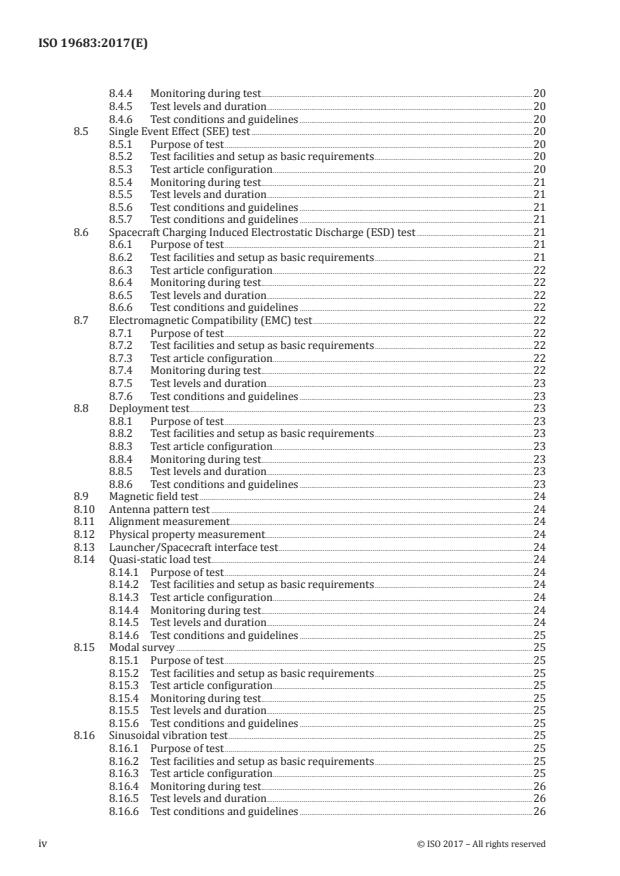

Contents Page

Foreword .vii

Introduction .viii

1 Scope . 1

2 Normative references . 2

3 Terms and definitions . 2

4 Abbreviated terms . 3

5 General requirements . 4

5.1 Tailoring . 4

5.2 Qualification test . 4

5.3 Acceptance test . 4

5.4 Proto-flight test . 4

5.5 Retest . 4

5.6 Test documentation . 4

5.6.1 Test plan, specification and procedure . 5

5.6.2 Test report . 5

5.6.3 Datasheet for unit test results . 6

5.7 Test conditions, tolerances and accuracies. 6

5.8 Functional test . 6

5.9 Design, verification and testing philosophy . 6

6 Satellite system tests . 7

6.1 Test items . 7

6.2 Test level and duration . 8

7 Unit tests . 8

7.1 Test items . 8

7.2 Test levels and duration .14

8 Test requirements .17

8.1 Electrical interface .17

8.1.1 Purpose of test .17

8.1.2 Test facilities and setup as basic requirements .18

8.1.3 Test article configuration .18

8.1.4 Monitoring during test . .18

8.1.5 Test levels and duration .18

8.1.6 Test conditions and guidelines .18

8.2 Functional test .18

8.2.1 Purpose of test .18

8.2.2 Test facilities and setup as basic requirements .18

8.2.3 Test article configuration .18

8.2.4 Monitoring during test . .18

8.2.5 Test levels and duration .18

8.2.6 Test conditions and guidelines .19

8.3 Mission test .19

8.3.1 Purpose of test .19

8.3.2 Test facilities and setup as basic requirements .19

8.3.3 Test article configuration .19

8.3.4 Monitoring during test . .19

8.3.5 Test levels and duration .19

8.3.6 Test conditions and guidelines .19

8.4 Total Ionization Dose (TID) test .19

8.4.1 Purpose of test .19

8.4.2 Test facilities and setup as basic requirements .20

8.4.3 Test article configuration .20

8.4.4 Monitoring during test . .20

8.4.5 Test levels and duration .20

8.4.6 Test conditions and guidelines .20

8.5 Single Event Effect (SEE) test .20

8.5.1 Purpose of test .20

8.5.2 Test facilities and setup as basic requirements .20

8.5.3 Test article configuration .20

8.5.4 Monitoring during test . .21

8.5.5 Test levels and duration .21

8.5.6 Test conditions and guidelines .21

8.5.7 Test conditions and guidelines .21

8.6 Spacecraft Charging Induced Electrostatic Discharge (ESD) test .21

8.6.1 Purpose of test .21

8.6.2 Test facilities and setup as basic requirements .21

8.6.3 Test article configuration .22

8.6.4 Monitoring during test . .22

8.6.5 Test levels and duration .22

8.6.6 Test conditions and guidelines .22

8.7 Electromagnetic Compatibility (EMC) test .22

8.7.1 Purpose of test .22

8.7.2 Test facilities and setup as basic requirements .22

8.7.3 Test article configuration .22

8.7.4 Monitoring during test . .22

8.7.5 Test levels and duration .23

8.7.6 Test conditions and guidelines .23

8.8 Deployment test .23

8.8.1 Purpose of test .23

8.8.2 Test facilities and setup as basic requirements .23

8.8.3 Test article configuration .23

8.8.4 Monitoring during test . .23

8.8.5 Test levels and duration .23

8.8.6 Test conditions and guidelines .23

8.9 Magnetic field test .24

8.10 Antenna pattern test .24

8.11 Alignment measurement .24

8.12 Physical property measurement.24

8.13 Launcher/Spacecraft interface test .24

8.14 Quasi-static load test.24

8.14.1 Purpose of test .24

8.14.2 Test facilities and setup as basic requirements .24

8.14.3 Test article configuration .24

8.14.4 Monitoring during test . .24

8.14.5 Test levels and duration .24

8.14.6 Test conditions and guidelines .25

8.15 Modal survey .25

8.15.1 Purpose of test .25

8.15.2 Test facilities and setup as basic requirements .25

8.15.3 Test article configuration .25

8.15.4 Monitoring during test . .25

8.15.5 Test levels and duration .25

8.15.6 Test conditions and guidelines .25

8.16 Sinusoidal vibration test .25

8.16.1 Purpose of test .25

8.16.2 Test facilities and setup as basic requirements .25

8.16.3 Test article configuration .25

8.16.4 Monitoring during test . .26

8.16.5 Test levels and duration .26

8.16.6 Test conditions and guidelines .26

iv © ISO 2017 – All rights reserved

8.17 Random vibration test .26

8.17.1 Purpose of test .26

8.17.2 Test facilities and setup as basic requirements .26

8.17.3 Test article configuration .26

8.17.4 Monitoring during test . .26

8.17.5 Test levels and duration .26

8.17.6 Test conditions and guidelines .26

8.18 Acoustic test .27

8.18.1 Purpose of test .27

8.18.2 Test facilities and setup as basic requirements .27

8.18.3 Test article configuration .27

8.18.4 Monitoring during test . .27

8.18.5 Test levels and duration .27

8.18.6 Test conditions and guidelines .27

8.19 Shock test .27

8.19.1 Purpose of test .27

8.19.2 Test facilities and setup as basic requirements .27

8.19.3 Test article configuration .27

8.19.4 Monitoring during test . .27

8.19.5 Test levels and duration .28

8.19.6 Test conditions and guidelines .28

8.20 Thermal balance test .28

8.20.1 Purpose of test .28

8.20.2 Test facilities and setup as basic requirements .28

8.20.3 Test article configuration .28

8.20.4 Monitoring during test . .28

8.20.5 Test levels and duration .28

8.20.6 Test conditions and guidelines .28

8.21 Thermal vacuum test .29

8.21.1 Purpose of test .29

8.21.2 Test facilities and setup as basic requirements .29

8.21.3 Test article configuration .29

8.21.4 Monitoring during test . .29

8.21.5 Test levels and duration .29

8.21.6 Test conditions and guidelines .29

8.22 Functional test in vacuum .30

8.22.1 Purpose of test .30

8.22.2 Test facilities and setup as basic requirements .30

8.22.3 Test article configuration .30

8.22.4 Monitoring during test . .30

8.22.5 Test levels and duration .30

8.22.6 Test conditions and guidelines .30

8.23 Cold/Hot start test .30

8.23.1 Purpose of test .30

8.23.2 Test facilities and setup as basic requirements .30

8.23.3 Test article configuration .31

8.23.4 Monitoring during test . .31

8.23.5 Test levels and duration .31

8.23.6 Test conditions and guidelines .31

8.24 Thermal cycle functional test .31

8.24.1 Purpose of test .31

8.24.2 Test facilities and setup as basic requirements .31

8.24.3 Test article configuration .31

8.24.4 Monitoring during test . .32

8.24.5 Test levels and duration .32

8.24.6 Test conditions and guidelines .32

8.25 Thermal cycle endurance test .32

8.25.1 Purpose of test .32

8.25.2 Test facilities and setup as basic requirements .32

8.25.3 Test article configuration .32

8.25.4 Monitoring during test . .32

8.25.5 Test levels and duration .33

8.25.6 Test conditions and guidelines .33

8.26 Pressure test .33

8.27 Leakage test .33

8.28 Microvibration test .33

8.28.1 Purpose of test .33

8.28.2 Test facilities and setup as basic requirements .33

8.28.3 Test article configuration .33

8.28.4 Monitoring during test . .33

8.28.5 Test levels and duration .33

8.28.6 Test conditions and guidelines .34

8.29 Burn-in and wear-in test .34

8.30 End-to-end mission simulation .34

8.30.1 Purpose of test .34

8.30.2 Test facilities and setup as basic requirements .34

8.30.3 Test article configuration .34

8.30.4 Monitoring during test . .34

8.30.5 Test levels and duration .34

8.30.6 Test conditions and guidelines .34

8.31 Bake out and outgas test .35

8.31.1 Purpose of test .35

8.31.2 Test facilities and setup as basic requirements .35

8.31.3 Test article configuration .35

8.31.4 Monitoring during test . .35

8.31.5 Test levels and duration .35

8.31.6 Test conditions and guidelines .35

8.32 Tailoring and waiver guides.36

Annex A (normative) Tailoring and waiver guides .37

Annex B (informative) Basis of test levels and duration .42

Annex C (informative) Design, verification and testing philosophy for small spacecrafts .45

Annex D (informative) Test selection logic flow .68

Annex E (informative) Environment stress screening and burn-in .80

Annex F (informative) Thermal vacuum or thermal cycle? .81

Bibliography .84

vi © ISO 2017 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO’s adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see the following

URL: w w w . i s o .org/ iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 20, Aircraft and space vehicles,

Subcommittee SC 14, Space systems and operations.

Introduction

There is an increasing demand for small/micro/nano/pico satellite development and utilization

worldwide; yet, there is no clear and globally accepted definition of what is considered “small”, “micro”,

“nano” or “pico” satellites. These satellites are often built with emphasis on low cost and fast delivery.

They are characterized by extensive use of non-space-qualified commercial-off-the-shelf (COTS) units.

For the sake of convenience, the term “small spacecraft” is used throughout this document as a generic

term to refer to these satellites.

A small spacecraft is a satellite that utilizes non-traditional risk-taking development and management

approaches to achieve low cost and fast delivery with a small number of team. To achieve these two

points, low cost and fast delivery, satellite design relies on the use of non-space-qualified commercial-

off-the-shelf (COTS) units, making satellite size inherently smaller. The design accepts a certain level of

risk associated with the use of COTS.

A certain set of tests is necessary to ensure the mission success of small spacecraft. Applying the same

test requirements and methods as those applied to traditional large/medium satellites, however, will

nullify the low-cost and fast-delivery advantages possessed by small spacecraft.

This document is meant to improve the reliability of small spacecraft, especially those with commercial

purpose, while maintaining the low-cost and fast-delivery nature of small spacecraft. This document

intends to promote worldwide trade of small spacecraft products by providing a minimum level of

assurance that a product made of non-space-qualified commercial-off-the-shelf parts and units can

work in space. This document also aims to serve as a testing guideline for those who intend to enter

satellite manufacturing through development of small spacecraft products.

viii © ISO 2017 – All rights reserved

INTERNATIONAL STANDARD ISO 19683:2017(E)

Space systems — Design qualification and acceptance tests

of small spacecraft and units

1 Scope

This document provides test methods and test requirements for design qualification and/or acceptance

of small spacecraft or units. It provides the minimum test requirements and test methods to qualify the

design and manufacturing methods of commercial small spacecraft and their units and to accept the

final products.

This document places emphasis on achieving reliability against infant mortality after satellite launch to

orbit while maintaining low cost and fast delivery.

This document is applied to satellites whose development methods are different from the ones used

for traditional satellites that have little room for risk tolerance, as shown in Figure 1. The scope of this

document encompasses different categories of small spacecraft, so-called mini-, micro, nano-, pico-

and femto-, as well as CubeSat, spacecraft. Therefore, for the sake of convenience, the term “small

spacecraft” is used throughout this document as a generic term.

This document includes CubeSat, as long as it is developed with the untraditional processes.

Figure 1 — Applicability of this document

This document does not cover satellite deployment mechanisms, such as POD, as the verification

requirements are defined in the Interface Control Document (ICD) with the launcher, such as ISO 26869.

This document does not cover software testing, although some tests such as functional test, mission

test and end-to-end test are inherently used to test the software installed in the hardware being tested.

General requirements and processes of satellite software testing can be found in various references,

such as ECSS-E-ST40.

This document does not cover requirements regarding safety nor debris mitigation. Appropriate

documents such as ISO 14620–1 or ISO 24113 can be referred to. Other common requirements for small

spacecraft can be found in Reference [14].

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 11221:2011, Space systems — Space solar panels — Spacecraft charging induced electrostatic

discharge test methods

ISO 14302, Space systems — Electromagnetic compatibility requirements

ISO 15864:2004, Space systems — General test methods for space craft, subsystems and units

ISO 17566:2011, Space systems — General test documentation

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http:// www .electropedia .org/

— ISO Online browsing platform: available at http:// www .iso .org/ obp

3.1

flat-sat

table-sat

configuration where only units (3.4), sometimes bare circuit boards only, are laid out in atmosphere on

a table while not being mounted to the satellite structure

3.2

flight model

satelli

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...