ISO 10303-240:2005

(Main)Industrial automation systems and integration — Product data representation and exchange — Part 240: Application protocol: Process plans for machined products

Industrial automation systems and integration — Product data representation and exchange — Part 240: Application protocol: Process plans for machined products

ISO 10303-240:2005 specifies the use of the integrated resources necessary for the scope and information requirements for the exchange, sharing and long term data retention of computer-interpretable process plan information for both numerical control (NC) and manually operated applications and associated product definition data. The following are within the scope of ISO 10303-240:2005: information out of the planning activity that is contained in the process plans for machined parts which includes: numerical controlled machines; manual operations. the manufacture of a single piece mechanical part, and assemblies of single piece parts for manufacturing purpose which includes: process data for part routing which includes manufacturing process and setup sequencing; process data for operation. interface for capturing technical data out of the upstream application protocols which includes: product definition data, including tracking a design exception notice of a part; initial material definition data. technical data for and/or out of the process planning for machined pats which includes: machining features for defining shapes necessary for manufacturing; machining feature classification structure; geometric and dimensional tolerances of the parts being manufactured; materials, and properties of the parts being manufactured. references to standards and specifications declared in the process plan; work instructions for the tasks required to manufacture a part, using which include: references to the resources required to perform the work; the sequences of the work instructions; relationships of the work to the part geometry. information required to support NC programming of processes specified in the process plan; shop floor information specified in the process plan; information for production planning specified in the process plan;

Systèmes d'automatisation industrielle et intégration — Représentation et échange de données de produits — Partie 240: Protocole d'application: Plan des processus pour produits usinés

General Information

- Status

- Published

- Publication Date

- 08-Dec-2005

- Technical Committee

- ISO/TC 184/SC 4 - Industrial data

- Drafting Committee

- ISO/TC 184/SC 4/WG 12 - STEP product modelling and resources

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 28-Jun-2024

- Completion Date

- 14-Feb-2026

Overview

ISO 10303-240:2005 is an Application Protocol (AP) in the ISO 10303 series for product data representation and exchange. It defines the information requirements, context and integrated resources needed to exchange, share and retain computer-interpretable process plans for machined products. The standard covers both numerical control (NC) and manually operated manufacturing processes and links process plan data with associated product definition data (geometry, tolerances, materials).

Key topics and technical requirements

- Scope of data: process plans for single-piece mechanical parts and assemblies used for manufacturing; part routing, operation sequencing, and setup sequencing.

- Process planning content: machining features and classification, geometric and dimensional tolerances, material definitions and properties, and references to applicable standards.

- Work instructions & resources: task-level instructions, sequences, and references to required resources (tools, fixtures, machines).

- NC programming support: information required to support NC program generation and machine tool control.

- Shop floor & production planning data: manufacturing status, shop-floor instructions, and production planning attributes embedded in process plans.

- Data interoperability constructs: information requirements mapped to an Application Interpreted Model (AIM) and AIM EXPRESS representations to enable implementation and conformance testing.

- Conformance & implementation: conformance requirements, protocol implementation conformance statement (PICS) proforma, and annexes for implementation guidance and test suites.

- Traceability to upstream design: interfaces to capture product definition data (e.g., design exception notices, initial material data) from CAD/CAM or design systems.

Applications and who uses it

ISO 10303-240 is used to improve interoperability and data consistency across manufacturing IT and engineering systems. Typical users include:

- Manufacturing/process planners and CAPP (Computer-Aided Process Planning) vendors

- CAD/CAM and PLM integrators implementing product data exchange between design and manufacturing systems

- NC programmers and CAM engineers requiring standardized process plan inputs for toolpath generation

- Production planners, shop-floor systems, and MES integrators needing consistent manufacturing instructions and resource references

- Archives and data management teams focused on long-term retention of process plan data

Related standards

- ISO 10303 series (product data representation and exchange) - see other parts such as ISO 10303-1, ISO 10303-21, and ISO 10303-31 for foundational constructs and file/representation methods.

- The AP documents include mappings to AIM/AIM EXPRESS and normative annexes to support implementation and conformance testing.

By standardizing how process plans for machined products are represented, ISO 10303-240 enables reliable CAD/CAM, CAPP and NC toolchain integration, better production planning, and long-term archival of manufacturing intent.

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

ISO 10303-240:2005 is a standard published by the International Organization for Standardization (ISO). Its full title is "Industrial automation systems and integration — Product data representation and exchange — Part 240: Application protocol: Process plans for machined products". This standard covers: ISO 10303-240:2005 specifies the use of the integrated resources necessary for the scope and information requirements for the exchange, sharing and long term data retention of computer-interpretable process plan information for both numerical control (NC) and manually operated applications and associated product definition data. The following are within the scope of ISO 10303-240:2005: information out of the planning activity that is contained in the process plans for machined parts which includes: numerical controlled machines; manual operations. the manufacture of a single piece mechanical part, and assemblies of single piece parts for manufacturing purpose which includes: process data for part routing which includes manufacturing process and setup sequencing; process data for operation. interface for capturing technical data out of the upstream application protocols which includes: product definition data, including tracking a design exception notice of a part; initial material definition data. technical data for and/or out of the process planning for machined pats which includes: machining features for defining shapes necessary for manufacturing; machining feature classification structure; geometric and dimensional tolerances of the parts being manufactured; materials, and properties of the parts being manufactured. references to standards and specifications declared in the process plan; work instructions for the tasks required to manufacture a part, using which include: references to the resources required to perform the work; the sequences of the work instructions; relationships of the work to the part geometry. information required to support NC programming of processes specified in the process plan; shop floor information specified in the process plan; information for production planning specified in the process plan;

ISO 10303-240:2005 specifies the use of the integrated resources necessary for the scope and information requirements for the exchange, sharing and long term data retention of computer-interpretable process plan information for both numerical control (NC) and manually operated applications and associated product definition data. The following are within the scope of ISO 10303-240:2005: information out of the planning activity that is contained in the process plans for machined parts which includes: numerical controlled machines; manual operations. the manufacture of a single piece mechanical part, and assemblies of single piece parts for manufacturing purpose which includes: process data for part routing which includes manufacturing process and setup sequencing; process data for operation. interface for capturing technical data out of the upstream application protocols which includes: product definition data, including tracking a design exception notice of a part; initial material definition data. technical data for and/or out of the process planning for machined pats which includes: machining features for defining shapes necessary for manufacturing; machining feature classification structure; geometric and dimensional tolerances of the parts being manufactured; materials, and properties of the parts being manufactured. references to standards and specifications declared in the process plan; work instructions for the tasks required to manufacture a part, using which include: references to the resources required to perform the work; the sequences of the work instructions; relationships of the work to the part geometry. information required to support NC programming of processes specified in the process plan; shop floor information specified in the process plan; information for production planning specified in the process plan;

ISO 10303-240:2005 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 10303-240:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 10303-240

First edition

2005-12-15

Industrial automation systems and

integration — Product data

representation and exchange —

Part 240:

Application protocol: Process plans for

machined products

Systèmes d'automatisation industrielle et intégration — Représentation

et échange de données de produits —

Partie 240: Protocole d'application: Plan des processus pour produits

usinés

Reference number

©

ISO 2005

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2005

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2005 – All rights reserved

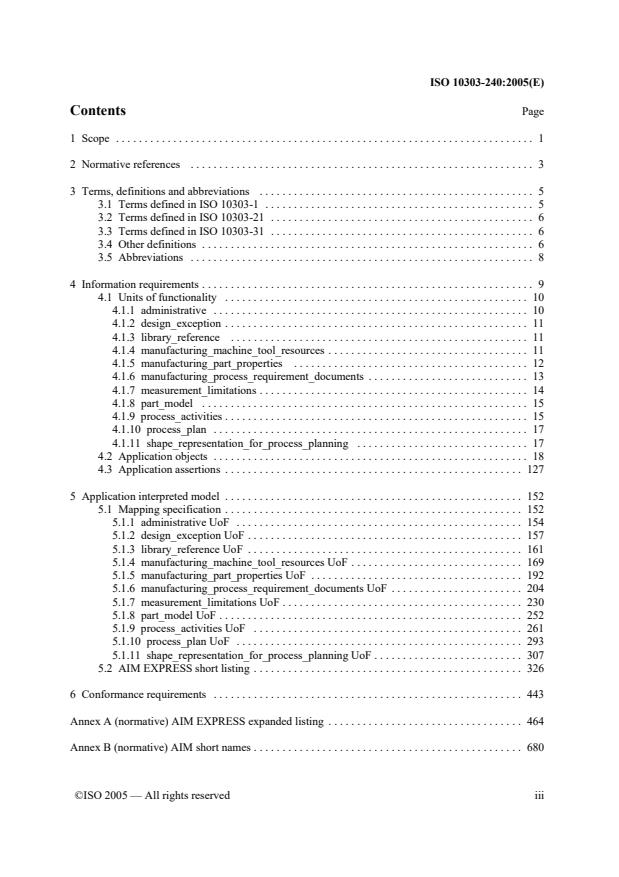

Contents Page

1 Scope . 1

2 Normative references . 3

3 Terms, definitions and abbreviations . 5

3.1 Terms defined in ISO 10303-1 . 5

3.2 Terms defined in ISO 10303-21 . 6

3.3 Terms defined in ISO 10303-31 . 6

3.4 Other definitions . 6

3.5 Abbreviations . 8

4 Information requirements . 9

4.1 Units of functionality . 10

4.1.1 administrative . 10

4.1.2 design_exception . 11

4.1.3 library_reference . 11

4.1.4 manufacturing_machine_tool_resources . 11

4.1.5 manufacturing_part_properties . 12

4.1.6 manufacturing_process_requirement_documents . 13

4.1.7 measurement_limitations . 14

4.1.8 part_model . 15

4.1.9 process_activities . 15

4.1.10 process_plan . 17

4.1.11 shape_representation_for_process_planning . 17

4.2 Application objects . 18

4.3 Application assertions . 127

5 Application interpreted model . 152

5.1 Mapping specification . 152

5.1.1 administrative UoF . 154

5.1.2 design_exception UoF . 157

5.1.3 library_reference UoF . 161

5.1.4 manufacturing_machine_tool_resources UoF . 169

5.1.5 manufacturing_part_properties UoF . 192

5.1.6 manufacturing_process_requirement_documents UoF . 204

5.1.7 measurement_limitations UoF . 230

5.1.8 part_model UoF . 252

5.1.9 process_activities UoF . 261

5.1.10 process_plan UoF . 293

5.1.11 shape_representation_for_process_planning UoF . 307

5.2 AIM EXPRESS short listing . 326

6 Conformance requirements . 443

Annex A (normative) AIM EXPRESS expanded listing . 464

Annex B (normative) AIM short names . 680

©ISO 2005 — All rights reserved iii

Annex C (normative) Implementation method specific requirements . 698

Annex D (normative) Protocol Implementation Conformance Statement (PICS) proforma . 699

Annex E (normative) Information object registration . 701

Annex F (informative) Application activity model . 702

Annex G (informative) Application reference model . 723

Annex H (informative) AIM EXPRESS-G . 744

Annex J (informative) Computer interpretable listings . 781

Annex K (informative) Technical discussions . 782

Bibliography . 783

Index . 784

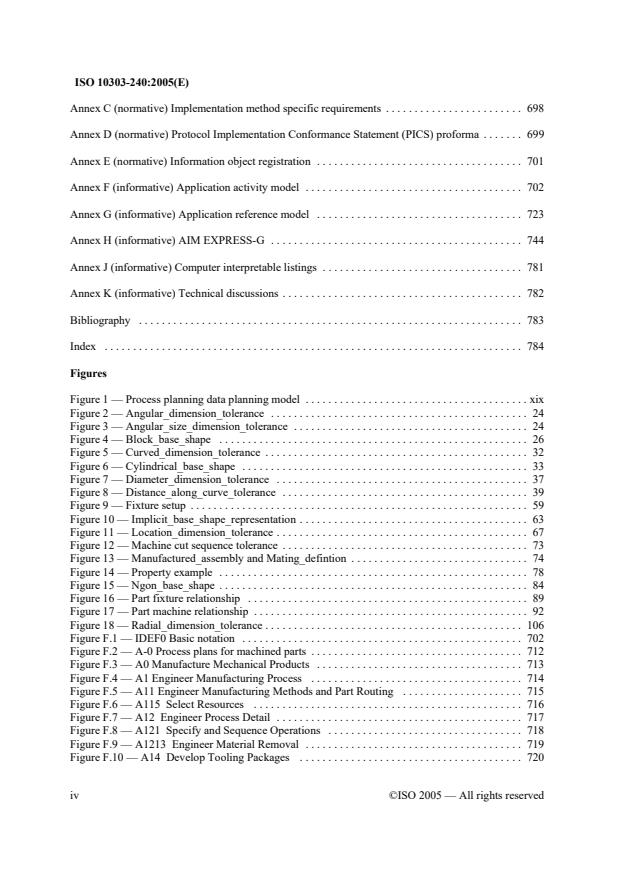

Figures

Figure 1 — Process planning data planning model . xix

Figure 2 — Angular_dimension_tolerance . 24

Figure 3 — Angular_size_dimension_tolerance . 24

Figure 4 — Block_base_shape . 26

Figure 5 — Curved_dimension_tolerance . 32

Figure 6 — Cylindrical_base_shape . 33

Figure 7 — Diameter_dimension_tolerance . 37

Figure 8 — Distance_along_curve_tolerance . 39

Figure 9 — Fixture setup . 59

Figure 10 — Implicit_base_shape_representation . 63

Figure 11 — Location_dimension_tolerance . 67

Figure 12 — Machine cut sequence tolerance . 73

Figure 13 — Manufactured_assembly and Mating_defintion . 74

Figure 14 — Property example . 78

Figure 15 — Ngon_base_shape . 84

Figure 16 — Part fixture relationship . 89

Figure 17 — Part machine relationship . 92

Figure 18 — Radial_dimension_tolerance . 106

Figure F.1 — IDEF0 Basic notation . 702

Figure F.2 — A-0 Process plans for machined parts . 712

Figure F.3 — A0 Manufacture Mechanical Products . 713

Figure F.4 — A1 Engineer Manufacturing Process . 714

Figure F.5 — A11 Engineer Manufacturing Methods and Part Routing . 715

Figure F.6 — A115 Select Resources . 716

Figure F.7 — A12 Engineer Process Detail . 717

Figure F.8 — A121 Specify and Sequence Operations . 718

Figure F.9 — A1213 Engineer Material Removal . 719

Figure F.10 — A14 Develop Tooling Packages . 720

iv ©ISO 2005 — All rights reserved

Figure F.11 — A15 Develop Equipment Instructions . 721

Figure F.12 — A16 Finalize Manufacturing Data Package . 722

Figure G.1 — ARM EXPRESS-G diagram 1 of 20 . 724

Figure G.2 — ARM EXPRESS-G diagram 2 of 20 . 725

Figure G.3 — ARM EXPRESS-G diagram 3 of 20 . 726

Figure G.4 — ARM EXPRESS-G diagram 4 of 20 . 727

Figure G.5 — ARM EXPRESS-G diagram 5 of 20 . 728

Figure G.6 — ARM EXPRESS-G diagram 6 of 20 . 729

Figure G.7 — ARM EXPRESS-G diagram 7 of 20 . 730

Figure G.8 — ARM EXPRESS-G diagram 8 of 20 . 731

Figure G.9 — ARM EXPRESS-G diagram 9 of 20 . 732

Figure G.10 — ARM EXPRESS-G diagram 10 of 20 . 733

Figure G.11 — ARM EXPRESS-G diagram 11 of 20 . 734

Figure G.12 — ARM EXPRESS-G diagram 12 of 20 . 735

Figure G.13 — ARM EXPRESS-G diagram 13 of 20 . 736

Figure G.14 — ARM EXPRESS-G diagram 14 of 20 . 737

Figure G.15 — ARM EXPRESS-G diagram 15 of 20 . 738

Figure G.16 — ARM EXPRESS-G diagram 16 of 20 . 739

Figure G.17 — ARM EXPRESS-G diagram 17 of 20 . 740

Figure G.18 — ARM EXPRESS-G diagram 18 of 20 . 741

Figure G.19 — ARM EXPRESS-G diagram 19 of 20 . 742

Figure G.20 — ARM EXPRESS-G diagram 20 of 20 . 743

Figure H.1 — action - AIM EXPRESS-G diagram 1 of 36 . 745

Figure H.2 — action_method - AIM EXPRESS-G diagram 2 of 36 . 746

Figure H.3 — action_property - AIM EXPRESS-G diagram 3 of 36 . 747

Figure H.4 — action_resource - AIM EXPRESS-G diagram 4 of 36 . 748

Figure H.5 — contract and security_classification - AIM EXPRESS-G diagram 5 of 36 . 749

Figure H.6 — document- AIM EXPRESS-G diagram 6 of 36 . 750

Figure H.7 — document reference - AIM EXPRESS-G diagram 7 of 36 . 751

Figure H.8 — identification assignment - AIM EXPRESS-G diagram 8 of 36 . 752

Figure H.9 — group - AIM EXPRESS-G diagram 9 of 36 . 753

Figure H.10 — approval- AIM EXPRESS-G diagram 10 of 36 . 754

Figure H.11 — date - AIM EXPRESS-G diagram 11 of 36 . 755

Figure H.12 — person and organization - AIM EXPRESS-G diagram 12 of 36 . 756

Figure H.13 — application context - AIM EXPRESS-G diagram 13 of 36 . 757

Figure H.14 — product - AIM EXPRESS-G diagram 14 of 36 . 758

Figure H.15 — property definition - AIM EXPRESS-G diagram 15 of 36 . 759

Figure H.16 — representation - AIM EXPRESS-G diagram 16 of 36 . 760

Figure H.17 — shape representation - AIM EXPRESS-G diagram 17 of 36 . 761

Figure H.18 — characterized object - AIM EXPRESS-G diagram 18 of 36 . 762

Figure H.19 — shape aspect- AIM EXPRESS-G diagram 19 of 36 . 763

Figure H.20 — geometry topology - AIM EXPRESS-G diagram 20 of 36 . 764

Figure H.21 — point - AIM EXPRESS-G diagram 21 of 36 . 765

Figure H.22 — position - AIM EXPRESS-G diagram 22 of 36 . 766

Figure H.23 — curve - AIM EXPRESS-G diagram 23 of 36 . 767

Figure H.24 — bounded curve - AIM EXPRESS-G diagram 24 of 36 . 768

Figure H.25 — b_spline curve - AIM EXPRESS-G diagram 25 of 36 . 769

Figure H.26 — surface - AIM EXPRESS-G diagram 26 of 36 . 770

Figure H.27 — bounded surface - AIM EXPRESS-G diagram 27 of 36 . 771

Figure H.28 — topology - AIM EXPRESS-G diagram 28 of 36 . 772

©ISO 2005 — All rights reserved v

Figure H.29 — face and shell - AIM EXPRESS-G diagram 29 of 36 . 773

Figure H.30 — geometric tolerance - AIM EXPRESS-G diagram 30 of 36 . 774

Figure H.31 — dimensional tolerance - AIM EXPRESS-G diagram 31 of 36 . 775

Figure H.32 — datum - AIM EXPRESS-G diagram 32 of 36 . 776

Figure H.33 — unit - AIM EXPRESS-G diagram 33 of 36 . 777

Figure H.34 — measure with unit - AIM EXPRESS-G diagram 34 of 36 . 778

Figure H.35 — attributes - AIM EXPRESS-G diagram 35 of 36 . 779

Figure H.36 — description attribute - AIM EXPRESS-G diagram 36 of 36 . 780

Tables

Table 1 — Conformance class elements . 444

Table 2 — AIM short names . 680

vi ©ISO 2005 — All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work. ISO

collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 10303-240 was prepared by Technical Committee ISO TC184/SC4, Industrial automation systems

and integration, Subcommittee SC4 Industrial data.

This International Standard is organized as a series of parts, each published separately. The structure of

this International Standard is described in ISO 10303-1.

Each part of this International Standard is a member of one of the following series: description methods,

implementation methods, conformance testing methodology and framework, integrated generic resources,

integrated application resources, application protocols, abstract test suites, application interpreted

constructs, and application modules. This part is a member of the 200 series.

A complete list of parts of ISO 10303 is available from the Internet:

©ISO 2005 — All rights reserved vii

Introduction

ISO 10303 is an International Standard for the computer-interpretable representation of product

information and for the exchange of product data. The objective is to provide a neutral mechanism capable

of describing products throughout their life cycle. This mechanism is suitable not only for neutral file

exchange, but also as a basis for implementing and sharing product databases, and as a basis for archiving.

This part of ISO 10303 is a member of the application protocol series. This part of ISO 10303 specifies

an application protocol (AP) for the exchange, archiving and sharing of computer-interpretable process

plans for numerical control and manually machined parts. The intent of this AP is to allow for the

exchange, archiving and sharing of data between dissimilar Computer-Aided Process Planning (CAPP)

systems.

A process plan is a set of instructions. These instructions are used by programmers to generate machine

tool controller programs which, when executed, drive the tool motion to remove material. Process planning

takes place after the preliminary engineering design is completed but before the manufacturing process has

begun, and the process plan effort requires feedback for design completeness. Design information is

communicated to a process planner who identifies the manufacturing steps necessary to transform the

material specified by the design into a product.

This AP specifies the data contained within a process plan as opposed to the data necessary to perform

process planning functions. Included in this AP are the relationships that exist between the different

process plan data items as well as the relationships that exist between these data items and the product

definition data. Product definition data includes data items from design process such as geometry, surface

finish and machining tolerance.

This application protocol defines the context, scope, and information requirements for digitally represented

process plans for numerical control and manually machined parts and specifies the integrated resources

necessary to satisfy these requirements.

Application protocols provide the basis for developing implementations of ISO 10303 and abstract test

suites for the conformance testing of AP implementations.

Clause 1 defines the scope of the application protocol and summarizes the functionality and data covered

by the AP. Clause 3 lists the words defined in this part of ISO 10303 and gives pointers to words defined

elsewhere. An application activity model that is the basis for the definition of the scope is provided in

Annex F. The information requirements of the application are specified in clause 4 using terminology

appropriate to the application. A graphical representation of the information requirements, referred to as

the application reference model, is given in Annex G.

Resource constructs are interpreted to meet the information requirements. This interpretation produces the

application interpreted model (AIM). This interpretation, given in 5.1, shows the correspondence between

the information requirements and the AIM. The short listing of the AIM specifies the interface to the

integrated resources and is given in 5.2. Note that the definitions and EXPRESS provided in the integrated

resources for constructs used in the AIM may include select list items and subtypes which are not imported

into the AIM. The expanded listing given in Annex A contains the complete EXPRESS for the AIM

without annotation. A graphical representation of the AIM is given in Annex H. Additional requirements

for specific implementation methods are given in Annex C.

viii ©ISO 2005 — All rights reserved

Figure 1 contains the data planning model that provides a high-level description of the requirements for

this application protocol, as well as identifying that some relationship exists between the basic data

components.

The planning model illustrates that an process plan is composed of one or more sequenced activities. The

activities can be broken into several closely related sub-activities. Activities are associated with the

product definition data and will be used in the production of the product shape data. Each activity

describes in detail the associated processing and the type and amount of resource required with additional

special instructions, if necessary. An process plan also includes administrative data pertinent to the

management of the process plan.

©ISO 2005 — All rights reserved ix

Figure 1 — Process planning data planning model

x ©ISO 2005 — All rights reserved

INTERNATIONAL STANDARD ISO 10303-240:2005(E)

Industrial automation systems and integration —

Product data representation and exchange —

Part 240:

Application protocol: Process plans for machined products

1 Scope

This part of ISO 10303 specifies the use of the integrated resources necessary for the scope and

information requirements for the exchange, sharing and long term data retention of computer-interpretable

process plan information for both numerical control (NC) and manually operated applications, and

associated product definition data.

NOTE 1 The application activity model in Annex F provides a graphical representation of the processes and

information flows which are the basis for the definition of the scope of this part of ISO 10303.

The following are within the scope of this part of ISO 10303:

— information out of the planning activity that is contained in the process plans for machined parts which

includes:

— numerical controlled machines;

— manual operations.

— the manufacture of a single piece mechanical part, and assemblies of single piece parts for

manufacturing purpose which includes:

— process data for part routing which includes manufacturing process and setup sequencing;

— process data for operation.

— interface for capturing technical data out of the upstream application protocols which includes:

— product definition data, including tracking a design exception notice of a part;

— initial material definition data.

— technical data for and/or out of the process planning for machined pats which includes:

— machining features for defining shapes necessary for manufacturing;

— machining feature classification structure;

— geometric and dimensional tolerances of the parts being manufactured;

©ISO 2005 — All rights reserved 1

— materials, and properties of the parts being manufactured.

— references to standards and specifications declared in the process plan;

— work instructions for the tasks required to manufacture a part, using which include:

— references to the resources required to perform the work;

— the sequences of the work instructions;

— relationships of the work to the part geometry.

— information required to support NC programming of processes specified in the process plan;

NOTE 2 This includes product definition, administrative data, machine, tooling, and material requirements.

— information required to support in-process inspection specified in the process plan;

NOTE 3 In-process inspection includes such tasks as using gauge blocks or performing a probing operation to verify

the dimensional constraints placed upon the part.

— shop floor information specified in the process plan;

— information for production planning specified in the process plan;

NOTE 4 Information for production planning contains items such as process data for part routing and required

resource to perform the planned activity.

NOTE 5 Shop floor information contains such items as part routing, machine setup, and part loading instructions.

The following are outside the scope of this part of ISO 10303:

— NC program, source programs, and specific machine tool controller codes;

— NC process information derived from, or required for, manufacturing preplanning activities;

NOTE 6 This includes information from activities such as factory capacity planning, scheduling, producibility

analysis, and statistical process control.

— continuous processes;

NOTE 7 Continuous process is the control of a process that requires feedback to determine new parameters such as

those in adaptive control, real-time inspection and automatic corrections and in the manufacture of chemical and

plating products.

— inspection processes that require an inspection plan;

NOTE 8 Inspection processes refer to inspection that occurs outside the context of the NC machining process, such

as removing the part and remounting it on a Coordinate Measuring Machine (CMM).

— drawing and production illustration contents;

2 ©ISO 2005 — All rights reserved

— make or buy analysis activities;

— actual costing data;

— production control and scheduling analysis;

— production planning functions;

— actual execution of the process plan or associated NC programs.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 8824-1, Information Technology — Abstract Syntax Notation One (ASN.1) — Specification of Basic

Notation — Part 1.

ISO 10303-1, Industrial automation systems and integration — Product data representation and exchange

— Part 1: Overview and fundamental principles.

ISO 10303-11, Industrial automation systems and integration — Product data representation and

exchange — Part 11: Description methods: The EXPRESS language reference manual.

ISO 10303-21, Industrial automation systems and integration — Product data representation and

exchange — Part 21: Implementation methods: Clear text encoding of the exchange structure.

ISO 10303-31, Industrial automation systems and integration — Product data representation and

exchange — Part 31: Conformance testing methodology and framework: General concepts.

ISO 10303-41, Industrial automation systems and integration — Product data representation and

exchange — Part 41: Integrated generic resources: Fundamentals of product description and support.

ISO 10303-42, Industrial automation systems and integration — Product data representation and

exchange — Part 42: Integrated generic resources: Geometric and topological representation.

ISO 10303-43, Industrial automation systems and integration — Product data representation and

exchange — Part 43: Integrated generic resources: Representation structures.

ISO 10303-44, Industrial automation systems and integration — Product data representation and

exchange — Part 44: Integrated generic resources: Product structure configuration.

ISO 10303-45, Industrial automation systems and integration — Product data representation and

exchange — Part 45: Integrated generic resources: Materials.

©ISO 2005 — All rights reserved 3

ISO 10303-47, Industrial automation systems and integration — Product data representation and

exchange — Part 47: Integrated generic resources: Shape variation tolerances.

ISO 10303-49, Industrial automation systems and integration — Product data representation and

exchange — Part 49: Integrated generic resources: Process structure and properties.

ISO 10303-501, Industrial automation systems and integration — Product data representation and

exchange — Part 501: Application interpreted construct: Edge-based wireframe.

ISO 10303-502, Industrial automation systems and integration — Product data representation and

exchange — Part 502: Application interpreted construct: Shell-based wireframe.

ISO 10303-507, Industrial automation systems and integration — Product data representation and

exchange — Part 507: Application interpreted construct: Geometrically bounded surface.

ISO 10303-509, Industrial automation systems and integration — Product data representation and

exchange — Part 509: Application interpreted construct: Manifold surface.

ISO 10303-510, Industrial automation systems and integration — Product data representation and

exchange — Part 510: Application interpreted construct: Geometrically bounded wireframe.

ISO 10303-511, Industrial automation systems and integration — Product data representation and

exchange — Part 511: Application interpreted construct: Topologically bounded surface.

ISO 10303-512, Industrial automation systems and integration — Product data representation and

exchange — Part 512: Application interpreted construct: Faceted boundary representation.

ISO 10303-514, Industrial automation systems and integration — Product data representation and

exchange — Part 514: Application interpreted construct: Advanced boundary representation.

ISO 10303-519, Industrial automation systems and integration — Product data representation and

exchange — Part 519: Application interpreted construct: Geometric tolerances.

ISO 10303-522, Industrial automation systems and integration — Product data representation and

exchange — Part 522: Application interpreted construct: Machining features.

ISO 13584-26, Industrial automation systems and integration — Parts library — Part 26: Logical

resource: Information supplier identification.

ISO 13584-42, Industrial automation systems and integration — Parts library — Part 42: Description

methodology: Methodology for structuring part families.

IEC/ISO Directives, Part 2, Rules for the structure and drafting of International Standards, Fourth edition,

2001.

4 ©ISO 2005 — All rights reserved

3 Terms, definitions and abbreviations

3.1 Terms defined in ISO 10303-1

For the purpose of this part of ISO 10303, the following terms defined in ISO 10303-1 apply.

— abstract test suite (ATS);

— application;

— application activity model (AAM);

— application context;

— application interpreted model (AIM);

— application object;

— application protocol (AP);

— application reference model (ARM);

— computer aided design (CAD);

— computer aided manufacture (CAM);

— conformance class;

— conformance requirement;

— data;

— data exchange;

— generic resource;

— information;

— integrated generic resource;

— integrated resource;

— interpretation;

— model;

— PICS proforma;

— product;

©ISO 2005 — All rights reserved 5

— product data;

— product information model;

— resource construct;

— test purpose;

— unit of functionality (UoF);

— validation.

3.2 Terms defined in ISO 10303-21

For the purpose of this part of ISO 10303, the following terms defined in ISO 10303-21 apply.

— implementation method.

3.3 Terms defined in ISO 10303-31

For the purpose of this part of ISO 10303, the following terms defined in ISO 10303-31 apply.

— conformance class;

— conformance testing;

— postprocessor;

— preprocessor.

3.4 Other definitions

For the purposes of this part of ISO 10303, the following definitions apply:

3.4.1

computer-aided process planning (CAPP) system

a commercial or proprietary software application used to assist process planners in making a process plan.

3.4.2

direct numerical control (DNC) system

a computer system that transmits machine-tool controller codes directly from a host computer to the

machine-tool controller. The machine-tool controller transmits back its status to the host system.

3.4.3

engineering bill of materials (EBOM)

the list of part numbers and assemblies that make up the design engineering configuration that contains

the raw stock size and the material specification.

6 ©ISO 2005 — All rights reserved

3.4.4

engineering change notice (ECN)

a document released by design engineering to production that informs production of pending changes to

a specific design.

3.4.5

engineering change order (ECO)

an authorization to implement changes to a specific engineering design.

3.4.6

fixture coordinate system

a coordinate system on a fixture for the location and orientation of the fixture in a machine tool coordinate

system.

3.4.7

group technology (GT)

a manufacturing philosophy in which similar parts are identified and grouped together to take advantage

of their similarities in manufacturing and design.

3.4.8

inventory item

a tangible object that must be accounted for on an inventory manifest.

3.4.9

machine coordinate system

three mutually perpendicular planes which define the axis and origin for a machine location.

3.4.10

machined part (MP)

a product shaped by removing material using one or more machine tools.

3.4.11

manufacturing bill of materials

a list of materials required for the machining process plan.

EXAMPLE A product has an engineering bill of materials of: left hinge, right holder, bolt, washer, locknut, bearing

washer. The left hinge, right holder, and bearing washer need to have a hole machined as a loose assembly, they are

then separated. The bearing washer is returned to stores and the left hinge, right holder have other machining work

done prior to being sent off to another site for heat treatment and plating. The engineering and product build will

show six items but our machining process plan needs a separate bill of materials with just left hinge, right holder, and

bearing washer.

3.4.12

material resource planning (MRP) system

a software application that controls and schedules the flow of materials as required by production.

3.4.13

numerical control (NC)

a machine tool controlled by a programmable computerized system.

©ISO 2005 — All rights reserved 7

3.4.14

part coordinate system

three mutually perpendicular planes which define the axis and origin for a part location.

3.4.15

part program

a set of instructions used to transform the part specification from an engineering drawing or 3D model to

a sequence of processing steps to be performed on an NC machine.

3.4.16

process plan (PP)

the detailed method for the machining of a part. It includes a sequence of steps to be executed that call out

the selected machines, fabrication, operation steps, setups, routings, and in-process inspection requirements

for the manufacturing of a machined part.

3.4.17

product definition data (PDD)

the data that pertains to the design description

3.5 Abbreviations

For purposes of this part of ISO 10303, the following abbreviations apply:

AAM application activity model

AIC application interpreted construct

AIM application interpreted model

AP application protocol

ARM application reference model

ATS abstract test suite

B-rep boundary representation

CAD computer aided design

CAPP computer-aided process planning

DBMS database management system

DNC direct numerical control

EBOM engineering bill of materials

ECN engineering change notice

ECO engineering change order

8 ©ISO 2005 — All rights reserved

GT group technology

ID identification

IDEF0 ICAM definition language 0

IDEF1X ICAM definition language 1 - extended

MP machined part

MRP material resource planning

NC numerical control

PDD product definition data

PICS protocol implementation conformance statement

PP process plan

UoF units of functionality

4 Information requirements

This clause specifies the information required for manual or numerical control process plans for machined

parts.

The information requirements are specified as a set of units of functionality, application objects, and

application assertions. These assertions pertain to individual application objects and to relationships

between application objects. The information requirements are defined using the terminology of the subject

area of this application protocol.

NOTE 1 A graphical representation of the information requirements is given in Annex G.

NOTE 2 The information requirements correspond to those of the activities identified as being within the scope of

this application protocol in Annex F.

NOTE 3 The mapping table specified in 5.1 shows how the integrated resources and application interpreted constructs

are used to meet the information requirements of this application protocol.

©ISO 2005 — All rights reserved 9

4.1 Units of functionality

This subclause specifies the units of functionality for the process planning application protocol. This part

of ISO 10303 specifies the following units of functionality:

— administrative;

— design_exception;

— library_reference;

— manufacturing_machine_tool_resources;

— manufacturing_process_requirement_documents;

— manufacturing_part_properties;

— measurement_limitations;

— part_model;

— process_activities;

— process_plan;

— shape_representation_for_process_planning.

The units of functionality and a description of the functions that each UoF supports are given below. The

application objects included in the UoFs are defined in 4.2.

4.1.1 administrative

The administrative UoF contains the information required for the management of process plan. This

information contains sufficient detail to allow for the identification, release and revision of the process

plan.

The following application objects are used by the administrative UoF:

— Company;

— Company_contract_assignment;

— Organization;

— Planning_group_member;

— Status_authority.

10 ©ISO 2005 — All rights reserved

4.1.2 design_exception

The design_exception UoF contains the application objects used for documentation required for issuing

an error report for a problem that was discovered in the creation of a process plan, and a solution to the

problem as it pertains to the regeneration of input data for further process planning.

The following application objects are used by the design_exception UoF:

— Design_exception_notice;

— Engineering_change_order;

— Engineering_change_proposal.

4.1.3 library_reference

The library_reference UoF provides the capability and mechanisms by which references can be made to

information in external libraries.

NOTE A supplier library of part information is a type of library that may be referenced.

The following application objects are used by the library_reference UoF:

— BSU;

— Class_BSU;

— Externally_defined_representation;

— Library_part_assignment;

— Property_BSU;

— Property_value;

— Supplier_BSU.

4.1.4 manufacturing_machine_tool_resources

The manufacturing_machine_tool_resources UoF contains the definitions of tools, fixtures, and jigs used

to accomplish the fabrication of a part.

The following application objects are used by the manufacturing_machine_tool_resources UoF:

— Controller;

— Fixture_assembly;

— Fixture_assembly_element;

©ISO 2005 — All rights reserved 11

— Generic_manufacturing_resource;

— In_facility_location;

— Machine;

— Pallet;

— Part_holding_position;

— Resource_with_material;

— Resource_with_representation;

— Tool_assembly;

— Tool_assembly_element;

— Tool_body;

— Tool_magazine_turret_carousel;

— Work_cell;

— Workstation.

4.1.5 manufacturing_part_properties

The manufacturing_part_properties UoF contains the description of characteristics of the part that is being

defined. These characteristics specify requirements for manufacturing that apply to either the state of the

part at a particular time prior to or after the manufacture of the part, or a process that is required to be

executed during the manufacture of the part.

The following application objects are used by the manufacturing_part_properties UoF:

— Alternate_material;

— Descriptive_parameter;

— Hardness;

— Material;

— Material_property;

— Numeric_parameter;

— Numeric_parameter_with_tolerance;

— Part_property;

12 ©ISO 2005 — All rights reserved

— Process_property;

— Property;

— Property_parameter;

— Surface_property.

4.1.6 manufacturing_process_requirement_documents

The manufacturing_process_requirement_documents UoF contains information that identifies product data

for control documents. These documents include contracts, drawings, additional data for process plans,

and other supporting documentation for process plans. These documents may be in either digital or

hardcopy format.

The following application objects are used by the manufacturing_process_requirement_documents UoF:

— Contract;

— Controller_program;

— Digital_file;

— Document_assignment;

— Document_file;

— Document_file_properties;

— Document_file_relationship;

— Design_reference;

— Executable;

— External_file_identification;

— External_schema_definition;

— Fixture_contract;

— Hardcopy;

— Illustration;

— Material_specification;

— Partial_document_assignment;

©ISO 2005 — All rights reserved 13

— Part_dimensioning_standard;

— Special_capability;

— Special_instruction;

— Specification;

— Supplemental_document;

— Tool_contract;

— Tool_placement_instruction;

— View_reference.

4.1.7 measurement_limitations

The measurement_limitations UoF contains the information necessary to identify the important sizes of

the measured relationships between aspects of a part's shape or between an aspect of a part's shape and a

reference shape that does not comprise the shape of the part, and the acceptable deviation from that size

or relationship for the purpose of manufacturing.

The following application objects are used by the measurement_limitations UoF:

— Angular_dimension_tolerance;

— Angular_size_dimension_tolerance;

— Curved_dimension_tolerance;

— Diameter_dimension_tolerance;

— Dimensional_tolerance;

— Distance_along_curve_tolerance;

— Externally_defined_size_dimension;

— Height_dimension;

— Geometric_tolerance;

— Length_dimension;

— Limits_and_fits;

— Location_dimension_tolerance;

— Location_tolerance;

14 ©ISO 2005 — All rights reserved

— Machining_tolerance;

— Plus_minus_value;

— Radial_dimension_tolerance;

— Size_tolerance;

— Thickness_tolerance;

— Tolerance_limit;

— Tolerance_range;

— Tolerance_value.

— Width_dimension.

4.1.8 part_model

The part_model UoF contains the information necessary to identify the part that is to be input to the

process planning function and identify the association of properties with that part. Additionally,

information pertaining to feedback about the quality or necessary revisions to the product data is

represented by this UoF.

The following application objects are used by the part_model UoF:

— Manufactured_assembly;

— Manufactured_assembly_relationship;

— Mating_definition;

— Mating_definition_relationship;

— Mating_relationship;

— Part_version;

— Single_piece_part.

4.1.9 process_activities

The process_activities UoF contains the information which defines a specific manufacturing action.

Manufacturing actions deal with the transformation and inspection that takes place in the sequential

process of machining a source material into a final part. These manufacturing actions include processes,

operations and tasks associated with material removal by numerically controlled machine tools.

©ISO 2005 — All rights reserved 15

The following application objects are used by the process_activities UoF:

— Activity;

— Allowed_time;

— Alternate_activity;

— Ancillary_activity;

— Ancillary_setup;

— Continuous_process;

— Fixture_machine_mounti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...