ISO 7870-5:2014

(Main)Control charts — Part 5: Specialized control charts

Control charts — Part 5: Specialized control charts

ISO 7870-5:2014 establishes a guide to the use and understanding of specialized control charts in situations where commonly used Shewhart control chart approach to the methods of statistical control of a process may either be not applicable or less efficient in detecting unnatural patterns of variation of the process.

Cartes de contrôle — Partie 5: Cartes de contrôle particulières

General Information

- Status

- Published

- Publication Date

- 15-Jan-2014

- Technical Committee

- ISO/TC 69/SC 4 - Applications of statistical methods in product and process management

- Drafting Committee

- ISO/TC 69/SC 4/WG 10 - Control charts

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 10-Jan-2024

- Completion Date

- 14-Feb-2026

Overview

ISO 7870-5:2014 - Control charts: Part 5, Specialized control charts provides guidance on selecting, using and interpreting specialized control charts where standard Shewhart methods are inadequate or less efficient. The standard helps practitioners apply statistical process control (SPC) techniques in special situations such as widely spaced samples, changing process averages, non-normal data, large sample sizes, or when different types of nonconformities have different criticality. It focuses on practical use - when to choose a specialized chart, how control limits are determined, and the chart’s advantages and limitations.

Key Topics

- Scope and definitions tied to ISO 3534-2 (vocabulary and symbols for applied statistics).

- List of specialized charts for variables data, including:

- Moving average and moving range charts

- z-charts

- Group control charts

- High–low control charts

- Trend control charts

- Control charts for coefficient of variation

- Control charts for non-normal data

- Specialized charts for attributes data, including:

- Standardized p-charts

- Demerit control charts

- Control charts for inspection by gauging (go/no‑go)

- Guidance provided for each chart:

- When to use it (use cases)

- How control limits are established

- Interpretation rules

- Advantages and limitations

- Worked examples illustrating application

- Terminology and symbols to standardize interpretation and implementation.

Applications and Who Uses It

ISO 7870-5 is intended for professionals applying SPC where standard Shewhart charts are not optimal:

- Quality engineers and process control specialists

- Industrial statisticians and data analysts

- Six Sigma practitioners and continuous improvement teams

- Manufacturing engineers (assembly, gauging, long-cycle processes)

- Service industry analysts dealing with non-normal or sparse data

Typical applications:

- Processes with long production intervals or one-observation subgroups (use moving average/moving range)

- Situations with systematic shifts in mean (trend or z-charts)

- Multiple subgroup sources or large sample sizes (group control charts)

- Attribute-based inspections with weighted nonconformities (demerit charts, standardized p-charts)

- Non-normal measurement distributions (specialized control charts for non-normal data)

Related Standards

- ISO 7870 series (general guidance and other parts):

- Part 1: General guidelines

- Part 2: Shewhart control charts

- Part 3: Acceptance control charts

- Part 4: Cumulative sum (CUSUM) control charts

- Part 6: EWMA control charts

- ISO 3534-2 (Statistics - Vocabulary and symbols - Part 2: Applied statistics)

ISO 7870-5:2014 is practical, example-driven guidance for adapting SPC to complex or atypical monitoring scenarios where specialized control charts deliver better detection of unnatural process variation.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

ISO 7870-5:2014 is a standard published by the International Organization for Standardization (ISO). Its full title is "Control charts — Part 5: Specialized control charts". This standard covers: ISO 7870-5:2014 establishes a guide to the use and understanding of specialized control charts in situations where commonly used Shewhart control chart approach to the methods of statistical control of a process may either be not applicable or less efficient in detecting unnatural patterns of variation of the process.

ISO 7870-5:2014 establishes a guide to the use and understanding of specialized control charts in situations where commonly used Shewhart control chart approach to the methods of statistical control of a process may either be not applicable or less efficient in detecting unnatural patterns of variation of the process.

ISO 7870-5:2014 is classified under the following ICS (International Classification for Standards) categories: 03.120.30 - Application of statistical methods. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 7870-5:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 7870-5

First edition

2014-01-15

Control charts —

Part 5:

Specialized control charts

Cartes de contrôle —

Partie 5: Cartes de contrôle particulières

Reference number

©

ISO 2014

© ISO 2014

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2014 – All rights reserved

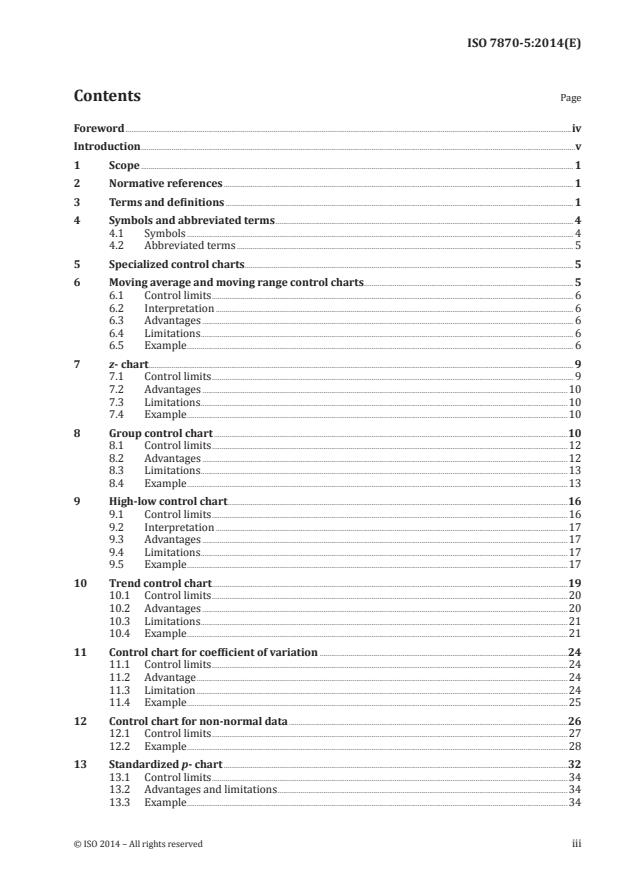

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols and abbreviated terms . 4

4.1 Symbols . 4

4.2 Abbreviated terms . 5

5 Specialized control charts . 5

6 Moving average and moving range control charts . 5

6.1 Control limits . 6

6.2 Interpretation . 6

6.3 Advantages . 6

6.4 Limitations . 6

6.5 Example . 6

7 z- chart. 9

7.1 Control limits . 9

7.2 Advantages .10

7.3 Limitations .10

7.4 Example .10

8 Group control chart .10

8.1 Control limits .12

8.2 Advantages .12

8.3 Limitations .13

8.4 Example .13

9 High-low control chart .16

9.1 Control limits .16

9.2 Interpretation .17

9.3 Advantages .17

9.4 Limitations .17

9.5 Example .17

10 Trend control chart .19

10.1 Control limits .20

10.2 Advantages .20

10.3 Limitations .21

10.4 Example .21

11 Control chart for coefficient of variation .24

11.1 Control limits .24

11.2 Advantage .24

11.3 Limitation .24

11.4 Example .25

12 Control chart for non-normal data .26

12.1 Control limits .27

12.2 Example .28

13 Standardized p- chart .32

13.1 Control limits .34

13.2 Advantages and limitations .34

13.3 Example .34

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 69, Applications of statistical methods,

Subcommittee SC 4, Applications of statistical methods in process management.

ISO 7870 consists of the following parts, under the general title Control charts:

— Part 1: General guidelines

— Part 2: Shewhart control charts

— Part 3: Acceptance control charts

— Part 4: Cumulative sum control charts

— Part 5: Specialized control charts

— Part 6: EWMA control charts

iv © ISO 2014 – All rights reserved

Introduction

The Shewhart control charts as given in ISO 7870-2 aid in detection of unnatural patterns of variations

in data from repetitive processes and provide criteria for detecting a lack of statistical control.

However, there may be several special situations for variables data where Shewhart control charts

may be inadequate, insufficient or less efficient in detecting the unnatural patterns of variation of the

process, particularly where:

a) it takes considerable time to produce an item and as such sample results are available at large

intervals;

b) there are several subgroup sources that have approximately the same production rate, process

average and process capability;

c) process average is changing systematically;

d) sample size is large and sequence of production is irrelevant;

e) process does not have a constant target value.

In such situations, specialized control charts are to be used.

Similarly, special situations may be encountered in dealing with attributes data. There may be situations

when criticality of an incidence in a subgroup (nonconformity) is a matter of concern, but different

nonconformities are having different criticality. As such, all types of nonconformities cannot be treated

alike. Depending upon criticality, different ratings (weights) are required to be given to each class of

nonconformity, and accordingly demerit scores are calculated. The control limits are calculated based

on such demerit scores and accordingly control charts are plotted to exercise process control.

There may be situations when inspection by attributes is preferred to that by variables, from practical

considerations, for controlling both the location and the variability parameters of a measureable

characteristic of a process (for example, inspection by gauging). The information is also available on the

number of items less than the lower specification limits (no-go gauge) as well as the number of items

above upper specification limit (go gauge) in assembly operations. In such situation, a specialized pair

of control charts may be used.

There may also be situations when data do not follow normal distribution. Such situations of non-normal

data are quite often encountered in service industry, besides in special processes of manufacturing. In

such a situation specialized control chart is to be used.

This part of ISO 7870 has been prepared to provide guidance on the use of specialized control charts to

address above typical, unusual situations.

INTERNATIONAL STANDARD ISO 7870-5:2014(E)

Control charts —

Part 5:

Specialized control charts

1 Scope

This part of ISO 7870 establishes a guide to the use and understanding of specialized control charts in

situations where commonly used Shewhart control chart approach to the methods of statistical control

of a process may either be not applicable or less efficient in detecting unnatural patterns of variation of

the process.

The specialized control charts included in this part of ISO 7870 for variables data are:

a) moving average and moving range charts;

b) z-charts;

c) group control charts;

d) high–low control charts;

e) trend control charts;

f) control charts for coefficient of variation;

g) control charts for non-normal data.

For attributes data, specialized control charts included in this part of ISO 7870 are:

a) standardized p-charts;

b) demerit control charts;

c) control charts for inspection by gauging.

This part of ISO 7870 also provides guidance as to when each of the above control charts should be used,

their control limits, advantages and limitations. Each control chart is illustrated with an example.

2 Normative references

The following referenced documents, in whole or in part, are normatively referenced in this document

and are indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 3534-2, Statistics — Vocabulary and symbols — Part 2: Applied statistics

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 3534-2 and the following

apply.

3.1

control chart

chart on which some statistical measure of a series of samples is plotted in a particular order to steer

the process with respect to that measure and to control and reduce variation

Note 1 to entry: The particular order is usually based on time or sample number order.

Note 2 to entry: The control chart operates most effectively when the measure is a process variable which is

correlated with an ultimate product or service characteristic.

[SOURCE: ISO 3534-2:2006, 2.3.1]

3.2

Shewhart control chart

control chart with Shewhart control limits intended primarily to distinguish between the variation in

the plotted measure due to random causes and that due to special causes

[SOURCE: ISO 3534-2:2006, 2.3.2]

3.3

variables control chart

Shewhart control chart in which the measure plotted represents data on a continuous scale

[SOURCE: ISO 3534-2:2006, 2.3.6]

3.4

attributes control chart

Shewhart control chart in which the measure plotted represents countable or categorized data

[SOURCE: ISO 3534-2:2006, 2.3.7]

3.5

Xbar control chart

average control chart

variables control chart for evaluating the process level in terms of subgroup averages

[SOURCE: ISO 3534-2:2006, 2.3.12]

3.6

R chart

range control chart

variables control chart for evaluating variation in terms of subgroup ranges

Note 1 to entry: The value of the subgroup range, given by the symbol R, is the difference between the largest and

smallest observation of a subgroup.

Note 2 to entry: The average of the range values for all subgroups is denoted by the symbol R

.

[SOURCE: ISO 3534-2:2006, 2.3.18]

3.7

moving average control chart

control chart for evaluating the process level in terms of the arithmetic average of each successive n

observations

Note 1 to entry: This chart is particularly useful when only one observation per subgroup is available. Examples

are process characteristics such as temperature, pressure and time.

Note 2 to entry: The current observation replaces the oldest of the latest n + 1 observations.

Note 3 to entry: It has the disadvantage of an unweighted carry-over effect lasting n points.

[SOURCE: ISO 3534-2:2006, 2.3.14]

2 © ISO 2014 – All rights reserved

3.8

moving range control chart

variables control chart for evaluating variation in terms of the range of each successive n observations

Note 1 to entry: The current observation replaces the oldest of the latest n +1 observations.

[SOURCE: ISO 3534-2:2006, 2.3.20]

3.9

z-chart

variables control chart for evaluating the process in terms of subgroup standardized normal variates

3.10

group control chart for averages

variables control chart for evaluating the process level in terms of subgroup (with several sources)

highest and lowest averages with corresponding source identification

3.11

group control chart for ranges

variables control chart for evaluating the process variation in terms of subgroup (with several sources)

highest ranges with corresponding source identification

3.12

high – low control chart

variables control chart for evaluating the process level in terms of subgroup largest and smallest values

3.13

trend control chart

control chart for evaluating the process level with respect to the deviation of the subgroup averages

from an expected change in the process level

Note 1 to entry: The trend may be determined empirically or by regression techniques.

Note 2 to entry: A trend is an upward or downward tendency, after exclusion of the random variation and cyclical

effects, when observed values are plotted in the time order of the observations.

[SOURCE: ISO 3534-2:2006, 2.3.17]

3.14

control chart for coefficient of variation

variables control chart for evaluating variation in terms of subgroup coefficient of variation

3.15

p chart

proportion or percent categorized units control chart

attributes control chart for number of units of a given classification per total number of units in the

sample expressed either as a proportion or percent

Note 1 to entry: In the quality field, the classification usually takes the form of “nonconforming unit”.

Note 2 to entry: The “p” chart is applied particularly when the sample size is variable.

Note 3 to entry: The plotted measure can be expressed as a proportion or as a percentage.

[SOURCE: ISO 3534-2:2006, 2.3.11]

3.16

standardized p-chart

attributes control chart where proportions of given classification are expressed as standardized normal

variates

Note 1 to entry: In this chart, the centre line is zero, upper control limit is +3 and lower control limit is −3.

3.17

demerit control chart

quality score chart

multiple characteristic control chart for evaluating the process level where different weights are

apportioned to events depending on their perceived significance

[SOURCE: ISO 3534-2:2006, 2.3.23]

3.18

control chart for inspection by gauging

attributes control chart when the inspection is done by gauging and the information is available on the

number of units above upper gauge limit and below lower gauge limit

4 Symbols and abbreviated terms

4.1 Symbols

n subgroup sample size

k number of subgroups

x

individual measured value

average value of i-th subgroup

x

i

average of the subgroup average values

x

μ

true process mean value

σ

true process standard deviation value

R range

average range

R

s

sample standard deviation

s average of subgroup sample standard deviations

p

proportion or fraction of units

p

average value of the proportion or fraction of units

C centre line

L

upper control limit

U

CL

lower control limit

L

CL

average value of the variable X plotted on a control chart

X

x largest observation in a subgroup

H

smallest observation in a subgroup

x

L

4 © ISO 2014 – All rights reserved

average of largest observations for all subgroups

x

H

x average of smallest observations for all subgroups

L

z

variable that has a normal distribution with zero mean and unit standard deviation

v

coefficient of variation

v

average of coefficient of variation values

4.2 Abbreviated terms

BPO business process outsourcing

CV coefficient of variation

L lower gauge limit

GL

U upper gauge limit

GL

5 Specialized control charts

The following specialized control charts for variables have been included:

a) moving average and moving range control charts;

b) z-charts;

c) group control charts;

d) high–low control charts;

e) trend control charts;

f) control charts for coefficient of variation;

g) control charts for non-normal data.

The following specialized control charts for attributes have been included:

a) standardized p-chart;

b) demerit control chart;

c) control chart for inspection by gauging.

6 Moving average and moving range control charts

In certain cases of industrial production it takes considerable time to produce a new item or the tests

are destructive in nature. As a result, it is inconvenient to sample frequently to accumulate sample of

size n > 1. In the meantime process average or dispersion may have changed and this may incur some

appreciable loss. Under such situations subgroups, each consisting of individual observations, are used

for process monitoring.

In these situations, use of moving averages and moving ranges instead of Shewhart control charts has

been suggested. Moving averages of k subgroups (each of size one) are obtained as follows. Initially,

the values of first k subgroups are averaged. Then in the second step the value for the first subgroup

th

is dropped in favour of the value for (k+1) subgroup and an average obtained. Next, the value for the

th

second subgroup is dropped and the value for (k+2) subgroup is included and these values are averaged,

and so on. In a similar manner moving ranges are obtained. The rate of production helps to decide the

number of subgroups to be considered at a time for moving average and moving range. Additionally, the

lesser the magnitude of shift in process average and variation one wishes to detect, the higher will be

the value of k.

6.1 Control limits

6.1.1 Moving range chart

C = R

L

UD= R

CL 4

LD= R

CL 3

6.1.2 Moving average chart

C = x

L

U =+xRA

CL 2

L =−xRA

CL 2

where, R is the homogenized range. The values of A , D and D are given in Annex A for various sample

2 3 4

sizes (n) = k.

6.2 Interpretation

Unlike the case of Shewhart control charts, here successive moving averages and moving ranges are

not independent. Hence, in moving average and moving range control charts, runs on either side of

the centre line do not have the same interpretation as is given by Shewhart control chart. However, a

point beyond control limits here has the same significance as in case of Shewhart control chart. Cyclic

pattern and/or increasing or decreasing trend in the moving range chart is indicative of potential for

improvement. However, the assignable causes for the moving average chart and those for moving range

chart may be different.

6.3 Advantages

In some situations a control chart for moving average and moving range is more efficient. It gives a

warning signal earlier than with usual (,XR) charts. It is not necessary to wait until an entire new

sample is accumulated. This may be important if the product is either expensive or the rate of output is

small.

6.4 Limitations

Successive points are not independent. Since the probability of obtaining a run of any kind is much larger

with control chart for moving average or moving range as compared to the Shewhart control charts, the

traditional interpretation of runs is not valid for these control charts.

6.5 Example

The crown of the watchcase is used to adjust the time. The pin of the crown is fitted through a hole in the

watch case. The diameter of the hole has to be maintained at 0,005 ± 0,001mm. Table 1 gives the data in

6 © ISO 2014 – All rights reserved

order of production, where reaming operation is done to make the hole for the pin of crown to fit in the

watchcase. It is decided to plot control charts for the moving average and moving range by averaging

diameter values from 3 consecutive subgroups.

Table 1 — Subgroup results from diameter of the hole for the pin of crown

Sub Hole diameter Sum of 3 mov- Moving average Moving range Remarks

ing observa-

group

tions

number

1 0,003

2 0,005

3 0,001 0,009 0,0030 0,004

4 0,003 0,009 0,0030 0,004

5 0,002 0,006 0,0020 0,002

6 0,005 0,010 0,0033 0,003

7 0,006 0,013 0,0043 0,004 Shift change

8 0,003 0,014 0,0047 0,003

9 0,004 0,013 0,0043 0,003

10 0,005 0,012 0,0040 0,002

11 0,005 0,014 0,0047 0,001

12 0,006 0,016 0,0053 0,001

13 0,001 0,012 0,0040 0,005

14 0,002 0,009 0,0030 0,005 Tool changed

15 0,007 0,010 0,0033 0,006

16 0,001 0,010 0,0033 0,006

17 0,003 0,011 0,0037 0,006

18 0,004 0,008 0,0027 0,003

19 0,003 0,010 0,0033 0,001

20 0,001 0,008 0,0027 0,003

21 0,006 0,010 0,0033 0,005

22 0,005 0,012 0,0040 0,005

23 0,004 0,015 0,0050 0,002

24 0,002 0,011 0,0037 0,003

25 0,001 0,007 0,0023 0,003

Total 0,0829 0,080

6.5.1 Control limits for moving range control chart

0,080

C ==R =0,0035

L

U ==D R 2,575×0,0035=0,0090

CL 4

L ==D R 0×0,0035=0

CL 3

The above values of D and D are taken from Annex A for n = 3. As all range values are less than U ,

3 4 CL

the value of average homogenized range is taken as 0,0035 for computation of control limits for moving

average control chart.

6.5.2 Control limits for moving average control chart

0,0829

C ==x =0,0036

L

U =+xRA =+0,,0036 1023×=0,,0035 00072

CL 2

L =−xRA =−0,,0036 1023×=0,0035 0

CL 2

The value of A is taken as 1,023 from Annex A for n = 3. The control chart is plotted in Figure 1.

0.0100

0.0090

0.0080

U

CL

0.0070

0.0060

0.0050

0.0040

C

L

0.0030

0.0020

0.0010

0.0000 L

CL

0123456789 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Subgroup number

8 © ISO 2014 – All rights reserved

Moving average

0.01

0.009 U

CL

0.008

0.007

0.006

0.005

0.004

C

L

0.003

0.002

0.001

L

0 CL

012345678 910111213141516171819202122232425

Subgroup number

Figure 1 — Moving average and moving range control charts

6.5.3 Interpretation

Process appears to be in state of statistical control.

7 z- chart

There are situations where processes are needed to be controlled when there are large varieties of

products with different specifications, production runs are small and varying sample/lot sizes. When

there are substantial differences in the variance of these products, using the deviation from the process

target becomes problematic. There may also be situations when the process does not have a constant

target value; instead, the target value keeps on changing with time.

In such cases the commonly used charts like X,R or Xs, fail to provide a basis for viewing and validly

() ()

interpreting control chart and appropriate decision making. A suitable chart to see the pattern and take

decisions is the z-chart. The idea is to standardize the data to compensate for the different product

parameters in terms of averages and variability and transform each point to a standard normal variate

by using the transformationzx=−()μσ/ , provided the expected value of the standard deviation is

known at that time point. If process is under control then standard normal variates will lie between +3

and –3. These types of charts are referred to as z-charts.

7.1 Control limits

C =0

L

U =+3

CL

L =−3

CL

Moving range

7.2 Advantages

The z-chart has the advantage of simplified calculation, presentation and most important it facilitates

usual interpretation of Shewhart control charts to control the processes and decision-making.

7.3 Limitations

When there is no historical data, this chart may be difficult to apply because it requires past data for

estimating variability.

7.4 Example

Graphite rods used in steel manufacturing are baked in furnaces. At different time points (subgroups),

the temperature inside the furnace differs. The target values of temperature and the estimates of the

inherent standard deviation of the furnace temperature at different times are also given in Table 2.

Standard normal variate (z) values for different subgroups have been calculated and are given in Table 2.

It is then seen whether they lie between +3 and –3. If it is above +3 or below −3, then it is out of control

situation. The control chart is plotted in Figure 2.

8 Group control chart

In industrial production it may happen that the data presented for the purpose of controlling the quality

comes from a number of sources, say from multi-spindle machine with same standard output, or several

workers or several machines. In such cases, unless proper steps are taken in choosing the sample, it is

difficult for the quality engineer to single out the problem when the control chart shows lack of control.

One obvious way is to maintain a separate chart for each possible source of variation, which is rather

uneconomical and time-consuming. A group control chart, first devised with a view to controlling

the dimensions on multiple-spindle automatics, having wide applicability, provides an answer to the

problem.

The group control charts are valid only when there are enough reasons to presume that the averages of

each source of data, and also the variability of each source are uniform. Instead of maintaining a pair of

average and range charts for each possible source, (such as machine or worker) only one pair of average

and range charts is maintained. In the average chart, the highest and lowest average values are plotted

along with suitable source identifications (such as serial number of spindles/machines/workers) and the

largest range is plotted on the range chart. In the average chart, the highest values are connected by a

line, so also, the lowest values in order to avoid confusion. The underlying idea is that if corresponding to

a particular sample the highest value is below the Upper Control Limit (U ), the others are necessarily

CL

so. Similarly, if the lowest value is above the Lower Control Limit (L ), others are necessarily so. The

CL

identifying number attached to the highest value that is beyond the U or to a lowest value that is below

CL

the L at once detects the trouble-yielding source. It calls for an attention if a particular identifying

CL

number is appearing more frequently either in the high value or in low value. If high and the low values

together show a cyclic pattern for the same identifying number, this provides vital clue for attention.

Table 2 — Subgroup results from the temperature in side furnace

Subgroup Time Target Standard devia- Observed Remarks

x−μ

()

z=

number (h) value(μ) tion from past value (x)

σ

data (σ)

1 2 205 2,12 200 −2,36

2 4 210 7,07 200 −1,41

3 6 210 8,48 210 0,00

4 8 220 6,36 215 −0,79

5 10 220 7,07 215 −0,71

6 12 230 7,07 220 −1,41

10 © ISO 2014 – All rights reserved

Table 2 (continued)

Subgroup Time Target Standard devia- Observed Remarks

x−μ

()

z=

number (h) value(μ) tion from past value (x)

σ

data (σ)

7 14 230 6,36 225 −0,79

8 16 230 17,68 240 0,57

9 18 240 11,31 245 0,44

10 20 240 10,61 260 1,89

11 22 240 7,07 265 3,54 Heating system mal-

functioned

12 24 240 3,53 245 1,42

13 26 240 5,53 255 2,71

14 28 250 8,08 260 1,24

15 30 250 12,65 270 1,58

16 32 250 13,62 285 2,57

17 34 260 10,5 285 2,38

18 36 260 10,07 285 2,48

19 38 270 8,48 285 1,77

20 40 270 6,36 285 2,36

21 42 270 7,07 285 2,12

22 44 270 7,07 285 2,12

23 46 280 6,36 300 3,14

24 48 280 7,67 300 2,61

25 50 320 4,95 330 2,02

26 52 380 4,95 350 −6,06

27 54 460 5,15 430 −5,83

28 56 480 6,7 460 −2,99

29 58 550 8,1 530 −2,47

30 60 550 5,1 545 −0,98

31 62 550 4,8 555 1,04

32 64 550 5,25 550 0,00

33 66 550 4,5 545 −1,11

34 68 550 6,02 540 −1,66

35 70 550 8,07 530 −2,48

36 72 460 7,8 450 −1,28

37 74 340 10,2 350 0,98

38 76 300 8,76 310 1,14

NOTE Events such as change in raw material, shift, operator, etc. may be recorded in “Remarks” to facilitate

traceability of assignable cause at that stage.

6.00

4.00

U

CL

2.00

0.00

C

L

-2.00

L

CL

-4.00

-6.00

-8.00

1357 91113151719212325272931333537

Subgroup number

Figure 2 — z chart

8.1 Control limits

8.1.1 Group control chart for range

C = R

L

UD= R

CL 4

LD= R

CL 3

8.1.2 For group control chart for averages

k

C ==xx

L ∑ i

i=1

U =+xRA

CL 2

L =−xRA

CL 2

The values of the factors A , D , and D are given in Annex A for various sample sizes

2 3 4

8.2 Advantages

The advantages are:

a) It involves less work in plotting.

12 © ISO 2014 – All rights reserved

z value

b) A compact presentation of all information from a group of machines on a single chart makes the

interpretation easier.

c) It is easier to find out whether a particular source is giving consistently high or low values on

average or range chart. If there is no real difference among the sources, the numbers corresponding

to the various sources should occur on the charts almost equally in the long run.

8.3 Limitations

The limitations are:

a) The group control charts requires that there should be several subgroup sources that yield

approximately equal number of subgroups at approximately the same rate, such as different

spindles on one automatic machine, several identical machines, or several operators each doing

the same operation. There should be consistency among the averages or dispersions of various

subgroups which can be sustained. For example, if there are 10 machines on the same job but two

of the machines have different process capability, then the group control chart cannot be applied

for all the 10 machines and should not include these two machines. The two machines, which give

different process capability, should be treated separately.

b) Experience and skill are needed for interpretation.

c) Conventional interpretation of runs above or below the centre line is not applicable.

8.4 Example

Table 3 gives two measurements of the diameters of two pieces produced on each of six spindles of an

automatic screw machine. The values given are in units of 0,001 mm in excess of 12 mm. The highest

and lowest average values are indicated in Table 3 as H and L respectively. The highest ranges are also

indicated by H in Table 3. It is decided to plot group control chart.

8.4.1 Control limits for group control chart for range

Cm==R =09, 7 icrons=0,00097mm

L

UD==R 3,,267×0973= ,17microns=0,00317mm

CL 4

LD==R 00× ,97=0microns

CL 3

The values of D and D for sample size (n) = 2 from Annex A are 0 and 3,267 respectively. Since all range

3 4

values are less than U , the ranges are homogeneous. The average range can therefore be used for

CL

computing control limits for group control chart for average.

8.4.2 Control limits for group control chart for average

195,5

Cm==x ==54,,30icrons 00543mm

L

UA=+xR=+54,,31 88×09,,77==25micronsm0,00725 m

CL 2

LA=−xR=−54,,31 88×09,,73==61micronsm0,00361 m

CL 2

The value of A from Annex A for sample size 2 is 1,880.

As the values are in excess of 12 mm, the actual control limits for the group control chart for average are:

C = 12,0054 mm

L

U = 12,0072 mm

CL

L = 12,0036 mm

CL

Table 3 — Subgroup results from diameter measurements (microns in excess of 12 mm)

Average

Subgroup Spindle Diameter Range Remarks

number number

x

Piece 1 Piece 2 R

1 6 7 6,5 H 1

2 4 6 5,0 2 H

3 6 4 5,0 2 H

4 5 4 4,5 L 1

5 6 5 5,5 1

6 4 5 4,5 L 1

1 6 6 6,0 H 0

2 6 6 6,0 H 0

3 5 6 5,5 1

4 5 5 5,0 L 0

5 5 6 5,5 1

6 7 5 6,0 H 2 H

1 5 6 5,5 1 H

2 6 6 6,0 H 0

3 5 5 5,0 L 0

4 6 5 5,5 1 H

5 5 5 5,0 L 0

6 6 6 6,0 H 0

1 5 6 5,5 1

2 6 5 5,5 1

3 5 5 5,0 0

4 4 4 4,0 L 0

5 5 7 6,0 H 2 H

6 6 4 5,0 2 H

1 5 6 5,5 1

2 5 4 4,5 L 1

3 6 5 5,5 1

4 7 4 5,5 3 H

5 7 6 6,5 H 1

6 5 7 6,0 2

14 © ISO 2014 – All rights reserved

Table 3 (continued)

Average

Subgroup Spindle Diameter Range Remarks

number number

x

Piece 1 Piece 2

R

1 5 5 5,0 L 0

2 6 5 5,5 1

3 4 7 5,5 3 H

4 7 6 6,5 H 1

5 5 5 5,0 L 0

6 6 5 5,5 1

Total 195,5 35

The group control chart for average and range are plotted in Figure 3. In this figure, in the group

control chart for average, the highest and lowest average values along with suitable source identifying

indications (spindle number) are plotted. Similarly in the group control chart for range, the highest

range along with suitable source identifying indications of spindle number is plotted.

8.4.3 Interpretation

There is no evidence of any out of control situation

12.008

UUU

CLCLCL

12.007

(1) (5) (4)

(2,6)

(5)

(1,2,6)

12.006

C

L

12.005

(4)

(3,5) (1,5)

(4)

(2)

12.004

(4,6)

L

CL

12.003

12.002

12.001

Subgroup number

Average

0.0035

U

CL

0.003

(4)

(3)

0.0025

(5,6)

0.002 (6)

0.0015

0.001

C

L

(1,4)

0.0005

L

C

L

Subgroup number

Figure 3 — Group control chart for averages and ranges

9 High-low control chart

There may be situations when sample size is large and the sequence of production is not traceable. For

example, in batch production (e.g. zinc coating, heat treatment for annealing) the sequence of production

is lost. Also, since several batches get mixed up, the systematic variation becomes an inherent part of

further processing. In such situations, it is desirable to use a control chart for largest and smallest values

or the high-low control chart, as it is popularly called, in place of the conventional Shewhart control

charts.

9.1 Control limits

9.1.1 Average and standard deviation not known

When the values of the process average and dispersion are not known from the past data, they are

estimated with the help of the initial data collected and the control limits are computed as follows:

()xx+

HL

CM= =

L

UM=+ H R

CL 2

LM=− H R

CL 2

where Rx=−x where,x and x denote the largest (high) and smallest (low) values respectively in

HL H L

each subgroup, and x and x are the average of largest and smallest values respectively for all

H L

subgroups. The values of H are given in Annex A.

16 © ISO 2014 – All rights reserved

Range

9.1.2 Average and standard deviation known

If the values of process mean and standard deviation are known as μ and σ respectively, the control

limits are:

C = μ

L

U = μ + H σ

CL

L = μ – H σ

CL

The values of H are given in Annex A.

9.2 Interpretation

Although an upper control limit for x and a lower control limit for x are usually drawn, it is possible

H L

to have an upper and a lower control limit for each x and x separately. The control limits forx and

H L H

1 1

x are given by xR±−Η and xR±−Η respectively. In such a case, shift in the process is

L H 2 L 2

2 2

indicated if both x and x are above the respective upper control limits or below the lower control

H L

limits. On the other hand, if x is above the relevant upper control limit and x is below the relevant

H L

lower control limit, this is enough evidence to conclude the increase in process variability.

A run of 6 or 7 points of high as well as low points closer to the centre line shows improvement in the

process. Control limits for the subsequent process may be consequentially changed. If there is a trend in

both x andx , dip or rise simultaneously, then it shows a shift in the average. Likewise, any increasing

H L

or decreasing trends and cyclic patterns should be investigated for special causes. If x and x points

H L

are very close to centre line, then either sampling method is not appropriate or the data are not authentic.

9.3 Advantages

This type of chart is extremely simple since no calculations are needed for plotting the points on control

chart. Besides, only one chart needs to be maintained in this case in place of the two conventional charts

since information concerning both process level and variation are provided on the single chart.

It has been found that under most conditions, high-low control charts are nearly as good as the XR,

()

charts for detecting lack of control

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...