ISO 12468-1:2003

(Main)External exposure of roofs to fire — Part 1: Test method

External exposure of roofs to fire — Part 1: Test method

ISO 12468-1:2003 specifies a test method to determine the resistance of roofs to external fire exposure. This method evaluates the behaviour of the roof when exposed to two types of burning brands combined with wind and with or without heat radiation, concerning the fire spread across the external surface of the roof, the fire spread within the roof, the fire penetration and the production of flaming droplets or debris falling through the roof, from the underside of the roof or from the exposed surface.

Exposition des toitures à un feu extérieur — Partie 1: Méthode d'essais

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 12468-1

First edition

2003-03-15

External exposure of roofs to fire —

Part 1:

Test method

Exposition des toitures à un feu extérieur —

Partie 1: Méthode d'essais

Reference number

ISO 12468-1:2003(E)

©

ISO 2003

---------------------- Page: 1 ----------------------

ISO 12468-1:2003(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2003

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2003 — All rights reserved

---------------------- Page: 2 ----------------------

ISO 12468-1:2003(E)

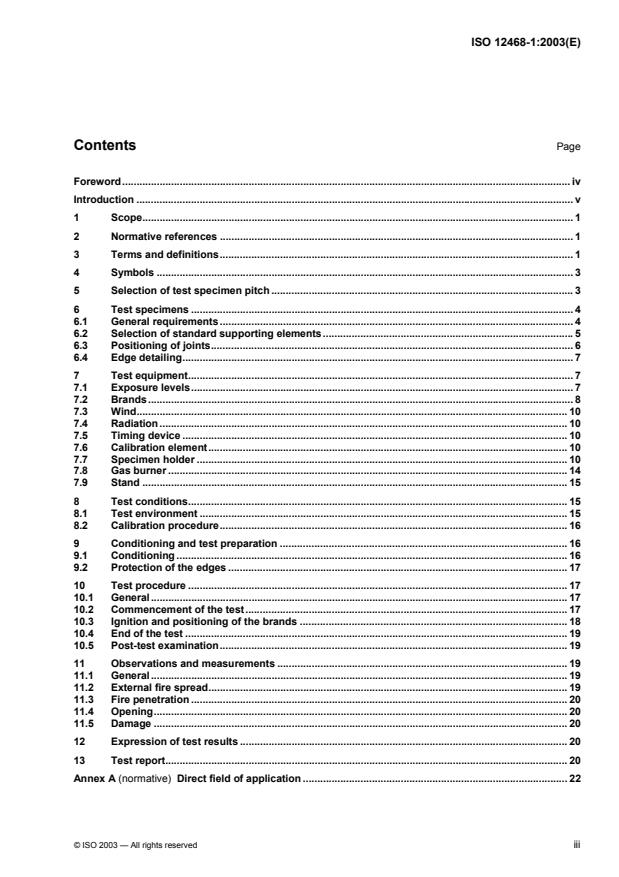

Contents Page

Foreword. iv

Introduction . v

1 Scope. 1

2 Normative references . 1

3 Terms and definitions. 1

4 Symbols . 3

5 Selection of test specimen pitch . 3

6 Test specimens . 4

6.1 General requirements . 4

6.2 Selection of standard supporting elements.5

6.3 Positioning of joints. 6

6.4 Edge detailing. 7

7 Test equipment. 7

7.1 Exposure levels. 7

7.2 Brands. 8

7.3 Wind. 10

7.4 Radiation. 10

7.5 Timing device . 10

7.6 Calibration element. 10

7.7 Specimen holder . 10

7.8 Gas burner . 14

7.9 Stand . 15

8 Test conditions. 15

8.1 Test environment . 15

8.2 Calibration procedure. 16

9 Conditioning and test preparation . 16

9.1 Conditioning . 16

9.2 Protection of the edges . 17

10 Test procedure . 17

10.1 General. 17

10.2 Commencement of the test. 17

10.3 Ignition and positioning of the brands . 18

10.4 End of the test . 19

10.5 Post-test examination. 19

11 Observations and measurements . 19

11.1 General. 19

11.2 External fire spread. 19

11.3 Fire penetration . 20

11.4 Opening. 20

11.5 Damage . 20

12 Expression of test results . 20

13 Test report. 20

Annex A (normative) Direct field of application . 22

© ISO 2003 — All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 12468-1:2003(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 12468-1 was prepared by Technical Committee ISO/TC 92, Fire safety, Subcommittee SC 2, Fire

containment.

ISO 12468 consists of the following parts, under the general title External exposure of roofs to fire

Part 1: Test method

Part 2: Classification

iv © ISO 2003 — All rights reserved

---------------------- Page: 4 ----------------------

ISO 12468-1:2003(E)

Introduction

This part of ISO 12468 specifies a test method that relates to the effects of fires on roofs. The test method

described in this part of ISO 12468 represents the effect of two levels of fire exposure.

Level A: A large burning brand coming from a nearby building and falling onto the roof. Level A considers

the effects of wind and additional radiant heat.

Level B: A small burning brand transported by the wind from a remote fire and falling onto the roof.

Level B considers the effect of wind but without additional radiant heat.

Any national regulation may refer to only one or both of the two levels of fire exposure.

© ISO 2003 — All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 12468-1:2003(E)

External exposure of roofs to fire —

Part 1:

Test method

CAUTION — The attention of all persons concerned with managing and carrying out this fire test is

drawn to the fact that fire testing may be hazardous and that there is a possibility that toxic and/or

harmful smoke and gases may be evolved during the test. Mechanical and operational hazards may

also arise during the construction of the test elements or structures, their testing and disposal of test

residues.

An assessment of all potential hazards and risks to health shall be made and safety precautions shall

be identified and provided. Written safety instructions shall be issued. Appropriate training shall be

given to relevant personnel. Laboratory personnel shall ensure that they follow written safety

instructions at all times.

1 Scope

This part of ISO 12468 specifies a test method to determine the resistance of roofs to external exposure to fire.

This method evaluates the behaviour of the roof when exposed to two types of burning brands combined with

wind and with or without heat radiation, concerning:

a) the fire spread across the external surface of the roof;

b) the fire spread within the roof;

c) the fire penetration;

d) the production of flaming droplets or debris falling through the roof, from the underside of the roof or from

the exposed surface.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 13943, Fire safety — Vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 13943 and the following apply.

3.1

assembly

fabrication of materials and/or composites

EXAMPLE Sandwich panels.

© ISO 2003 — All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 12468-1:2003(E)

3.2

burned material

material that has been destroyed by combustion or pyrolysis

3.3

composite

combination of materials which are generally recognized in building construction as discrete entities

EXAMPLE Coated or laminated product such as roofing felt.

3.4

continuous deck

deck supporting the roof covering in which the gap between adjacent elements is not greater than 0,5 mm

(5,0 mm in the case of wooden planks with plain edges)

3.5

damaged material

material that has been burned, melted or otherwise visually changed by heat but does not include

discoloration and soot deposits

3.6

exposed surface

external surface of the calibration element or of the specimen which is subject to the heat conditions

3.7

external fire spread

progression and extent of sustained flaming across the exposed surface of the specimen

3.8

fire penetration

any opening, sustained flaming or glowing due to combustion on the underside that appears during the test

and/or the occurrence of any flaming droplets or debris falling through the specimen or from the underside

NOTE Charring or discoloration is not be regarded as fire penetration.

3.9

fire spread within the roof

extent of burned material in each functional layer inside the specimen

3.10

flaming droplets or debris

burning material falling from or through the specimen that continues to burn on the floor for at least 5 s

3.11

internal damage

extent of damaged material in each functional layer inside the specimen

3.12

material

basic single substance or a uniformly dispersed mixture of substances

EXAMPLE Metal, stone, wood, bitumen, concrete or mineral wool.

3.13

measuring zone

area of the specimen within which measurements are made

2 © ISO 2003 — All rights reserved

---------------------- Page: 7 ----------------------

ISO 12468-1:2003(E)

3.14

opening

any hole greater than 10 mm × 10 mm that appears during the test which penetrates completely through the

specimen

3.15

product

material (3.12), composite (3.3) or assembly (3.1) about which information is required

3.16

profile pitch

repeating length between sections of a uniformly corrugated or undulating roof deck

3.17

roof

covering and sealing systems including any insulating layers or vapour barriers with their supporting elements

and roof lights or other closures for roof apertures that are intended to provide a weatherproof surface

NOTE Elements with a slope greater than 70° are not considered as roofs in this part of ISO 12468.

3.18

roof covering

material (3.12) attached to the deck

3.19

specimen

representative section of the roof prepared for the purpose of test

3.20

sustained flaming

flaming arising from an observed location, which persists for 5 s or longer

3.21

underside

bottom surface of the specimen

4 Symbols

Symbol Description Unit

v , v , v , v , v , v v Velocity of the air at the measuring points metres per second (m/s)

1 2 3 4 5 6, 7

Pitch (slope)

α degrees (°)

5 Selection of test specimen pitch

Roof systems designed for only one pitch shall be tested at the actual design pitch.

Roof systems designed for more than one pitch shall be tested as follows:

a) for pitch (α) less than 5°, test at zero pitch;

b) for pitch (α) from 5° to 20°, test at 15°;

c) for pitch (α) greater than 20°, test at 30°.

© ISO 2003 — All rights reserved 3

---------------------- Page: 8 ----------------------

ISO 12468-1:2003(E)

6 Test specimens

6.1 General requirements

For each level of fire exposure, two specimens shall be tested with dimensions measuring 1 200 mm ± 10 mm

in width × 2 000 mm ± 10 mm in length for each test pitch. (See Figures 1 and 2.) When this is not possible

due to the size of the roof light or other closure, a larger specimen shall be used.

NOTE Roof lights cause difficulties due to their size, shape, composition and fire behaviour. Further guidance on the

testing of roof lights will be presented in the next revision of this part of ISO 12468.

The specimens shall be representative in all details of the roof in practice.

Dimensions in millimetres with tolerances of ± 10 mm

Key

1 radiant panel position

2 A Brands

3 measuring zone

Figure 1 — Measuring zone and position of the brands for Level A

4 © ISO 2003 — All rights reserved

---------------------- Page: 9 ----------------------

ISO 12468-1:2003(E)

Dimensions in millimetres with tolerances of ± 10 mm

Key

1 measuring zone

2 B Brands

Figure 2 — Measuring zone and position of the brands for Level B

6.2 Selection of standard supporting elements

6.2.1 For continuous decks

6.2.1.1 General

The test deck shall be selected in accordance with the following.

a) In the case of roof coverings intended to be installed over a continuous deck other than a profiled metal

deck, a roof deck in accordance with 6.2.1.2 or 6.2.1.4 shall be used.

© ISO 2003 — All rights reserved 5

---------------------- Page: 10 ----------------------

ISO 12468-1:2003(E)

b) If the materials will only be laid over a profiled metal deck, then a trapezoidal profiled metal deck, in

accordance with 6.2.1.3, shall be used as the deck.

6.2.1.2 Wood particleboard decks

6.2.1.2.1 The wood particleboard shall consist of wood particles bonded with polymer adhesive (e.g. urea

3 3

formaldehyde). This particleboard shall have a density of 680 kg/m ± 50 kg/m and shall not be treated with

fire retardants.

6.2.1.2.2 A wood particleboard deck shall be constructed from planks 250 mm wide × 13 mm ± 1 mm thick

running parallel to the eaves with plain edges and tightly butt jointed so that the gaps between planks do not

exceed 0,5 mm.

6.2.1.2.3 If it is intended also to cover the case of decks made from wooden planks with plain edges, then

these gaps shall be 5 mm ± 0,5 mm.

6.2.1.3 Metal decks

The trapezoidal profiled metal deck shall be made of aluminium or steel (subject to the expected field of

application) and have the width of the crown approximately equal to 50 % of the profile pitch and a trough

depth of approximately 100 mm. The corrugations shall run parallel to the eaves and be open at the ends.

6.2.1.4 Other non-combustible decks

If roofing materials are intended to be laid only on continuous, non-combustible decks with a minimum

thickness of 10 mm, then the test roof deck shall consist of 12 mm ± 2 mm thick reinforced calcium silicate

3 3

board (oven dry density 900 kg/m ± 100 kg/m ).

6.2.2 For non-continuous decks

The spacing of roof supports of any type shall be in accordance with the maximum permissible spans

proposed by the manufacturer for the particular application but not exceeding the minimum dimensions

specified for the specimen in 6.1.

6.3 Positioning of joints

6.3.1 General

The joints shall be representative of practical application. In the case of overlapping layers, the position of the

joints shall be considered to be the edge of the upper layer.

6.3.2 Description of specimen types with respect to joints

Where the dimensions of the elements of any of the layers are such that it requires more than four pieces to

cover the specimen, or if any of the layers are without joints, then the specimens shall be fabricated such that

those layers are representative (see Figures 3 and 4).

Specimens are categorized by the following types.

Type 1: Single central vertical joint in the top layer. Single horizontal joint in the top layer under position of

left brand. Single vertical joint in layer next to top layer under position of right brand. Single vertical joint in

insulation under position of left brand [see Figure 4 a), Type 1].

Type 2: Single vertical joint in the top layer under position of right brand. Single vertical joint in layer next

to insulation under position of left brand [see Figure 4 b), Type 2].

6 © ISO 2003 — All rights reserved

---------------------- Page: 11 ----------------------

ISO 12468-1:2003(E)

Type 3: One cross joint of the top layer under position of the right brand and, where possible according to

the design of the product, a vertical joint in layer under top under the left brand [see Figure 4 c), Type 3].

Type 4: Centre of one element of the top layer and, where possible according to the design of the product,

a vertical joint of supporting deck, under position of the right brand and in insulation under the left brand

[see Figure 4 d), Type 4].

6.3.3 Selection of the specimen types

Either specimen types, Types 1 and 2 or Types 3 and 4, shall be used for each test pitch and for each level of

fire exposure.

6.4 Edge detailing

No special measures shall be taken by the sponsor to protect the edges of the specimen.

Key

1 vertical joint in top layer 6 vertical joint in supporting deck

2 horizontal joint in top layer 7 weathering layer

3 joint in layer next to insulation 8 insulation

4 joint in layer next to top layer 9 roof deck

5 joint in insulation

Figure 3 — Identification of joints in a multilayer roof

7 Test equipment

7.1 Exposure levels

Two levels are defined.

a) Level A consists of Brand A combined with wind and additional radiant heat.

b) Level B consists of Brand B combined with wind and without any additional radiant heat.

The wind is identical for the Levels A and B. The measuring zone, position of the brands and position of the

radiant panel are shown in Figures 1 and 2.

© ISO 2003 — All rights reserved 7

---------------------- Page: 12 ----------------------

ISO 12468-1:2003(E)

a) Type 1 b) Type 2

c) Type 3 d) Type 4

Key

1 vertical joint in top layer 4 joint in layer next to top layer

2 horizontal joint in top layer 5 joint in insulation

3 joint in layer next to insulation 6 vertical joint in supporting deck

Figure 4 — Position of joints and types of specimens

7.2 Brands

7.2.1 General

Two brands are utilized for each specimen. The test brands shall be constructed from Beech (Fagus salvatica

3 3

or Fagus grandifolia) having an oven-dry density of 560 kg/m ± 50 kg/m .

The mass of the finished brand following conditioning in an oven at 40 °C to 50 °C for at least 24 h shall be

33 g ± 5 g at the time of the test for Brand B and 550 g ± 50 g (less fasteners) at the time of the test for

Brand A.

8 © ISO 2003 — All rights reserved

---------------------- Page: 13 ----------------------

ISO 12468-1:2003(E)

7.2.2 Brands A

The Brands A shall consist of a grid of approximately 150 mm square and 57 mm deep, using nominally

19 mm × 19 mm × 150 mm strips of lumber, placed in three layers of six strips each, placed at right angles to

adjacent layers and spaced equidistant from each other within the brand envelope. The strips shall be

fastened to this configuration using light nails or staples (see Figure 5).

Dimensions in millimetres with tolerances of ± 2 mm

Figure 5 — Brand A

7.2.3 Brands B

The Brands B shall consist of a piece of lumber 40 mm × 40 mm × 40 mm with a saw cut 3 mm wide, half the

thickness of the brand across the centre of the top and bottom faces. The saw cuts on opposite face shall be

at right angles to each other (see Figure 6).

Dimensions in millimetres with tolerances of ± 2 mm

Figure 6 — Brand B

© ISO 2003 — All rights reserved 9

---------------------- Page: 14 ----------------------

ISO 12468-1:2003(E)

7.3 Wind

7.3.1 Apparatus

A wind generating apparatus capable of applying air across the surface of the calibration element at a

temperature of 20 °C ± 15 °C and a velocity as defined in 8.2.3 shall be used. The apparatus shall have a

control for the volume rate. The wind outlet section of the tube shall have minimum dimension of 250 mm in

height and 1 000 mm in width. The minimum length of the duct shall be 1 200 mm. Baffles and flow smoothers

shall be used to avoid turbulence of the flow pattern.

7.3.2 Air velocity

A vane anemometer with a diameter no greater than 25 mm shall be used to measure the air velocity. The

instrument shall integrate the average value of the air velocity for a period of 10 s to 30 s at the respective

positions (see Figure 7). The air velocity shall be established, parallel to the surface and in the direction of the

longitudinal axis of the calibration element.

So as to minimize the disturbance of the flow pattern in the region of the measuring zone, a supporting device

shall be used.

7.3.3 Eave

A simulated eave shall be installed in front of the test specimen to prevent air from flowing underneath the test

specimen.

This shall be done in a way so as not to interfere with or obstruct material flowing or falling from the roof

surface (see Figures 8 and 9).

7.4 Radiation

A radiant panel of 600 mm ± 10 mm by 600 mm ± 10 mm capable of being mounted in a plane parallel to the

surface of the specimen and at a distance of 500 mm ± 10 mm above it shall be provided.

The radiant panel shall be capable of providing a heat flux distribution on the surface of the specimen as

defined in 8.2.4, with wind. A flux meter having accuracy equal to or better than 5 % of the target value shall

measure the total heat flux.

7.5 Timing device

A timing device with an accuracy better than or equal to 5 s over 1 h shall be provided for the recording of the

sequence of events during each test.

7.6 Calibration element

The calibration element consists of a smooth, flat 12 mm ± 2 mm thick sheet of calcium silicate material

3 3

having the dimension 1 200 mm × 2 000 mm and a density of 900 kg/m ± 100 kg/m .

7.7 Specimen holder

The specimen holder shall be capable of presenting the specimen to the airflow at the required pitch.

10 © ISO 2003 — All rights reserved

---------------------- Page: 15 ----------------------

ISO 12468-1:2003(E)

Dimensions in millimetres

Key

1 calibration element

a

2 anemometer location (side view)

a

3 anemometer location (plan view)

a

All dimensions specifying the positions of the anemometer are in millimetres with tolerances of ± 5 mm. See 8.2.3.

b

Air flow

Figure 7 — Positions for air velocity measurement

© ISO 2003 — All rights reserved 11

---------------------- Page: 16 ----------------------

ISO 12468-1:2003(E)

Dimensions in millimetres

Key

1 eave

2 wind apparatus

3 filter

Figure 8 — Examples for general test arrangement for Level A

12 © ISO 2003 — All rights reserved

---------------------- Page: 17 ----------------------

ISO 12468-1:2003(E)

Dimensions in millimetres

Key

1 eave 2 wind apparatus 3 filter

Figure 9 — Examples for general test arrangement for Level B

Dimensions in millimetres with tolerances of ± 5 mm

Key

a

X Positions for heat flux measurement Air flow.

Figure 10 — Positions for heat flux measurements during calibration FIX dimensions

© ISO 2003 — All rights reserved 13

---------------------- Page: 18 ----------------------

ISO 12468-1:2003(E)

7.8 Gas burner

A gas burner of such size that during the procedure of ignition, the brands are enveloped in the burner flame.

The burner shall be shielded from draughts. The flame temperature of the igniting flame shall be

900 °C ± 50 °C measured 60 mm ± 5 mm above the top of the burner. An example of a suitable burner is

shown in Figures 11 and 12.

a) Stand

b) Burner

Key

1 wire bars

2 valve

3 gas supply

Figure 11 — Example of suitable stand and burner

14 © ISO 2003 — All rights reserved

---------------------- Page: 19 ----------------------

ISO 12468-1:2003(E)

Key

1 thermocouple

2 flame

3 burner

4 stand

5 stacked thermocouple 3 mm off centre

6 inner ring

a

General tolerances ± 5 mm

b

Thermocouple is directly over the inner ring, just 3 mm off centre. The thermocouple is 63 mm ± 2 mm above the inner

ring

Figure 12 — Example of suitable installation of stand and burner with thermocouple

7.9 Stand

A stand designed to support the brand during the period of ignition at a distance of 60 mm ± 5 mm above the

top of the burner shall be provided. An example of a suitable stand is shown in Figures 11 and 12.

8 Test conditions

8.1 Test environment

3

Tests shall be carried out in a draught free enclosure of no less than 150 m in volume. The lower edge of the

specimen shall be 750 mm ± 250 mm above the floor. The floor can be simulated by a horizontal platform of

non-combustible material located at the correct height with respect to the lower edge of the specimen. The

temperature in the enclosure shall be 20 °C ± 15 °C prior to the fire test. If any measures are taken to remove

products of combustion from the test laboratory, they shall be in operation during the calibration period and

maintained during the test.

© ISO 2003 — All rights reserved 15

---------------------- Page: 20 ----------------------

ISO 12468-1:2003(E)

8.2 Calibration procedure

8.2.1 Frequency

The interval between calibration and test shall not exceed seven days. A new calibration shall be done each

time the pitch is changed

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.