ISO 20501:2003

(Main)Fine ceramics (advanced ceramics, advanced technical ceramics) — Weibull statistics for strength data

Fine ceramics (advanced ceramics, advanced technical ceramics) — Weibull statistics for strength data

ISO 20501:2003 covers the reporting of uniaxial strength data and the estimation of probability distribution parameters for advanced ceramics which fail in a brittle fashion. The failure strength of advanced ceramics is treated as a continuous random variable. Typically, a number of test specimens with well-defined geometry are brought to failure under well-defined isothermal loading conditions. The load at which each specimen fails is recorded. The resulting failure stresses are used to obtain parameter estimates associated with the underlying population distribution. ISO 20501:2003 is restricted to the assumption that the distribution underlying the failure strengths is the two-parameter Weibull distribution with size scaling. Furthermore, this International Standard is restricted to test specimens (tensile, flexural, pressurized ring, etc.) that are primarily subjected to uniaxial stress states. Measurements of the strength at failure are taken for one of two reasons: either for a comparison of the relative quality of two materials, or the prediction of the probability of failure (or alternatively the fracture strength) for a structure of interest. ISO 20501:2003 permits estimates of the distribution parameters which are needed for either. In addition, this International Standard encourages the integration of mechanical property data and fractographic analysis.

Céramiques techniques — Statistiques Weibull des données de résistance

General Information

- Status

- Withdrawn

- Publication Date

- 24-Nov-2003

- Withdrawal Date

- 24-Nov-2003

- Technical Committee

- ISO/TC 206 - Fine ceramics

- Drafting Committee

- ISO/TC 206/WG 6 - Monolithic ceramics/Mechanical properties

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 05-Mar-2019

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 04-Nov-2015

Frequently Asked Questions

ISO 20501:2003 is a standard published by the International Organization for Standardization (ISO). Its full title is "Fine ceramics (advanced ceramics, advanced technical ceramics) — Weibull statistics for strength data". This standard covers: ISO 20501:2003 covers the reporting of uniaxial strength data and the estimation of probability distribution parameters for advanced ceramics which fail in a brittle fashion. The failure strength of advanced ceramics is treated as a continuous random variable. Typically, a number of test specimens with well-defined geometry are brought to failure under well-defined isothermal loading conditions. The load at which each specimen fails is recorded. The resulting failure stresses are used to obtain parameter estimates associated with the underlying population distribution. ISO 20501:2003 is restricted to the assumption that the distribution underlying the failure strengths is the two-parameter Weibull distribution with size scaling. Furthermore, this International Standard is restricted to test specimens (tensile, flexural, pressurized ring, etc.) that are primarily subjected to uniaxial stress states. Measurements of the strength at failure are taken for one of two reasons: either for a comparison of the relative quality of two materials, or the prediction of the probability of failure (or alternatively the fracture strength) for a structure of interest. ISO 20501:2003 permits estimates of the distribution parameters which are needed for either. In addition, this International Standard encourages the integration of mechanical property data and fractographic analysis.

ISO 20501:2003 covers the reporting of uniaxial strength data and the estimation of probability distribution parameters for advanced ceramics which fail in a brittle fashion. The failure strength of advanced ceramics is treated as a continuous random variable. Typically, a number of test specimens with well-defined geometry are brought to failure under well-defined isothermal loading conditions. The load at which each specimen fails is recorded. The resulting failure stresses are used to obtain parameter estimates associated with the underlying population distribution. ISO 20501:2003 is restricted to the assumption that the distribution underlying the failure strengths is the two-parameter Weibull distribution with size scaling. Furthermore, this International Standard is restricted to test specimens (tensile, flexural, pressurized ring, etc.) that are primarily subjected to uniaxial stress states. Measurements of the strength at failure are taken for one of two reasons: either for a comparison of the relative quality of two materials, or the prediction of the probability of failure (or alternatively the fracture strength) for a structure of interest. ISO 20501:2003 permits estimates of the distribution parameters which are needed for either. In addition, this International Standard encourages the integration of mechanical property data and fractographic analysis.

ISO 20501:2003 is classified under the following ICS (International Classification for Standards) categories: 81.060.30 - Advanced ceramics. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 20501:2003 has the following relationships with other standards: It is inter standard links to ISO 20501:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 20501:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 20501

First edition

2003-12-01

Fine ceramics (advanced ceramics,

advanced technical ceramics) — Weibull

statistics for strength data

Céramiques techniques — Statistiques Weibull des données de

résistance

Reference number

©

ISO 2003

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2003

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2003 — All rights reserved

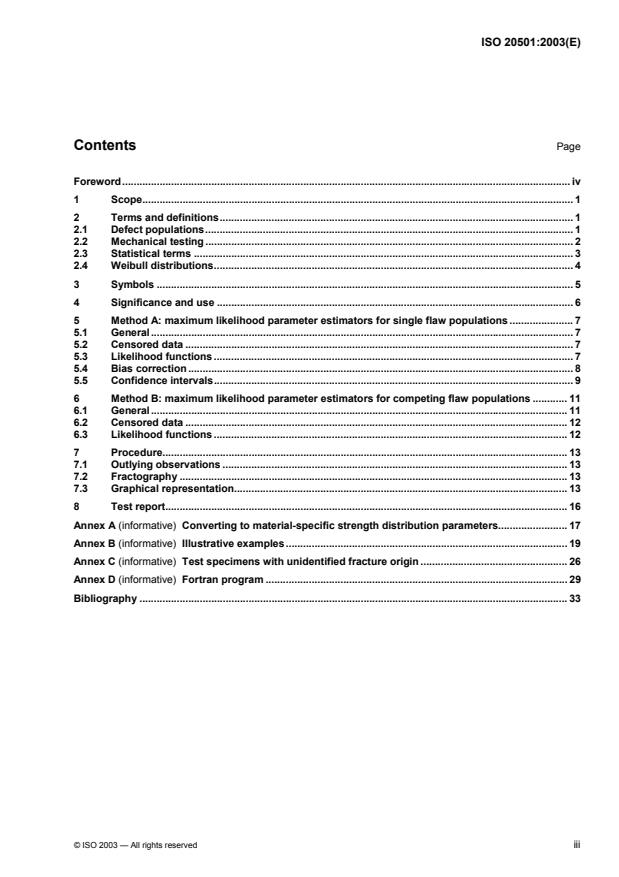

Contents Page

Foreword. iv

1 Scope. 1

2 Terms and definitions. 1

2.1 Defect populations. 1

2.2 Mechanical testing . 2

2.3 Statistical terms . 3

2.4 Weibull distributions. 4

3 Symbols . 5

4 Significance and use . 6

5 Method A: maximum likelihood parameter estimators for single flaw populations . 7

5.1 General. 7

5.2 Censored data . 7

5.3 Likelihood functions . 7

5.4 Bias correction . 8

5.5 Confidence intervals. 9

6 Method B: maximum likelihood parameter estimators for competing flaw populations . 11

6.1 General. 11

6.2 Censored data . 12

6.3 Likelihood functions . 12

7 Procedure. 13

7.1 Outlying observations . 13

7.2 Fractography . 13

7.3 Graphical representation. 13

8 Test report. 16

Annex A (informative) Converting to material-specific strength distribution parameters. 17

Annex B (informative) Illustrative examples . 19

Annex C (informative) Test specimens with unidentified fracture origin . 26

Annex D (informative) Fortran program . 29

Bibliography . 33

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 20501 was prepared by Technical Committee ISO/TC 206, Fine ceramics.

iv © ISO 2003 — All rights reserved

INTERNATIONAL STANDARD ISO 20501:2003(E)

Fine ceramics (advanced ceramics, advanced technical

ceramics) — Weibull statistics for strength data

1 Scope

This International Standard covers the reporting of uniaxial strength data and the estimation of probability

distribution parameters for advanced ceramics which fail in a brittle fashion. The failure strength of advanced

ceramics is treated as a continuous random variable. Typically, a number of test specimens with well-defined

geometry are brought to failure under well-defined isothermal loading conditions. The load at which each

specimen fails is recorded. The resulting failure stresses are used to obtain parameter estimates associated

with the underlying population distribution.

This International Standard is restricted to the assumption that the distribution underlying the failure strengths

is the two-parameter Weibull distribution with size scaling. Furthermore, this International Standard is

restricted to test specimens (tensile, flexural, pressurized ring, etc.) that are primarily subjected to uniaxial

stress states. Subclauses 5.4 and 5.5 outline methods of correcting for bias errors in the estimated Weibull

parameters, and to calculate confidence bounds on those estimates from data sets where all failures originate

from a single flaw population (i.e., a single failure mode). In samples where failures originate from multiple

independent flaw populations (e.g., competing failure modes), the methods outlined in 5.4 and 5.5 for bias

correction and confidence bounds are not applicable.

Measurements of the strength at failure are taken for one of two reasons: either for a comparison of the

relative quality of two materials, or the prediction of the probability of failure (or alternatively the fracture

strength) for a structure of interest. This International Standard permits estimates of the distribution

parameters which are needed for either. In addition, this International Standard encourages the integration of

mechanical property data and fractographic analysis.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1 Defect populations

2.1.1

censored strength data

strength measurements (i.e., a sample) containing suspended observations such as that produced by multiple

competing or concurrent flaw populations

NOTE Consider a sample where fractography clearly established the existence of three concurrent flaw distributions

(although this discussion is applicable to a sample with any number of concurrent flaw distributions). The three concurrent

flaw distributions are referred to here as distributions A, B, and C. Based on fractographic analyses, each specimen

strength is assigned to a flaw distribution that initiated failure. In estimating parameters that characterize the strength

distribution associated with flaw distribution A, all specimens (and not just those that failed from type-A flaws) must be

incorporated in the analysis to assure efficiency and accuracy of the resulting parameter estimates. The strength of a

specimen that failed by a type-B (or type-C) flaw is treated as a right censored observation relative to the A flaw

distribution. Failure due to a type-B (or type-C) flaw restricts, or censors, the information concerning type-A flaws in a

specimen by suspending the test before failure occurs by a type-A flaw [2]. The strength from the most severe type-A flaw

in those specimens that failed from type-B (or type-C) flaws is higher than (and thus to the right of) the observed strength.

However, no information is provided regarding the magnitude of that difference. Censored data analysis techniques

incorporated in this International Standard utilize this incomplete information to provide efficient and relatively unbiased

estimates of the distribution parameters.

2.1.2

competing failure modes

distinguishably different types of fracture initiation events that result from concurrent (competing) flaw

distributions

2.1.3

compound flaw distributions

any form of multiple flaw distribution that is neither pure concurrent, nor pure exclusive

NOTE A simple example is where every specimen contains the flaw distribution A, while some fraction of the

specimens also contains a second independent flaw distribution B.

2.1.4

concurrent flaw distributions

a type of multiple flaw distribution in a homogeneous material where every specimen of that material contains

representative flaws from each independent flaw population

NOTE Within a given specimen, all flaw populations are then present concurrently and are competing with each other

to cause failure. This term is synonymous with “competing flaw distributions”.

2.1.5

exclusive flaw distributions

a type of multiple flaw distribution created by mixing and randomizing specimens from two or more versions of

a material where each version contains a different single flaw population

NOTE Thus, each specimen contains flaws exclusively from a single distribution, but the total data set reflects more

than one type of strength-controlling flaw. This term is synonymous with “mixture flaw distributions”.

2.1.6

extraneous flaws

strength-controlling flaws observed in some fraction of test specimens that cannot be present in the

component being designed

NOTE An example is machining flaws in ground bend specimens that will not be present in as-sintered components

of the same material.

2.2 Mechanical testing

2.2.1

effective gauge section

that portion of the test specimen geometry included within the limits of integration (volume, area or edge

length) of the Weibull distribution function

NOTE In tensile specimens, the integration may be restricted to the uniformly stressed central gauge section, or it

may be extended to include transition and shank regions.

2.2.2

fractography

the analysis and characterization of patterns generated on the fracture surface of a test specimen

NOTE Fractography can be used to determine the nature and location of the critical fracture origin causing

catastrophic failure in an advanced ceramic test specimen or component.

2.2.3

proof testing

applying a predetermined load to every test specimen (or component) in a batch or a lot over a short period of

time to ascertain if the specimen fails due to a serious strength limiting defect

NOTE This procedure, when applied to all specimens in the sample, removes potentially weak specimens and

modifies the statistical characteristics of the surviving samples.

2 © ISO 2003 — All rights reserved

2.3 Statistical terms

2.3.1

confidence interval

interval within which one would expect to find the true population parameter

NOTE Confidence intervals are functionally dependent on the type of estimator utilized and the sample size. The

level of expectation is associated with a given confidence level. When confidence bounds are compared to the parameter

estimate one can quantify the uncertainty associated with a point estimate of a population parameter.

2.3.2

confidence level

probability that the true population parameter falls within a specified confidence interval

2.3.3

estimator

well-defined function that is dependent on the observations in a sample

NOTE The resulting value for a given sample may be an estimate of a distribution parameter (a point estimate)

associated with the underlying population. The arithmetic average of a sample is, e.g., an estimator of the distribution

mean.

2.3.4

population

totality of potential observations about which inferences are made

2.3.5

population mean

the average of all potential measurements in a given population weighted by their relative frequencies in the

population

2.3.6

probability density function

function f (x) is a probability density function for the continuous random variable X if

f (x) W 0 (1)

and

∞

fxdx= 1 (2)

()

∫

−∞

NOTE The probability that the random variable X assumes a value between a and b is given by

b

Pr a<

() ()

∫

a

2.3.7

ranking estimator

function that estimates the probability of failure to a particular strength measurement within a ranked sample

2.3.8

sample

collection of measurements or observations taken from a specified population

2.3.9

skewness

term relating to the asymmetry of a probability density function

NOTE The distribution of failure strength for advanced ceramics is not symmetric with respect to the maximum value

of the distribution function but has one tail longer than the other.

2.3.10

statistical bias

inherent to most estimates, this is a type of consistent numerical offset in an estimate relative to the true

underlying value

NOTE The magnitude of the bias error typically decreases as the sample size increases.

2.3.11

unbiased estimator

estimator that has been corrected for statistical bias error

2.4 Weibull distributions

2.4.1

Weibull distribution

continuous random variable X has a two-parameter Weibull distribution if the probability density function is

given by

mm−1

mx x

fx()=−exp whenx> 0 (4)

ββ β

or

f (x) = 0 when x u 0 (5)

and the cumulative distribution function is given by

m

x

Fx=−1exp− whenx>0 (6)

()

β

or

F(x) = 0 when x u 0 (7)

where

m is the Weibull modulus (or the shape parameter) (> 0);

β is the Weibull scale parameter (> 0)

NOTE 1 The random variable representing uniaxial tensile strength of an advanced ceramic will assume only positive

values, and the distribution is asymmetrical about the mean. These characteristics rule out the use of the normal

distribution (as well as others) and point to the use of the Weibull and similar skewed distributions. If the random variable

representing uniaxial tensile strength of an advanced ceramic is characterized by Equations 4 to 7, then the probability

that this advanced ceramic will fail under an applied uniaxial tensile stress σ is given by the cumulative distribution function

m

σ

P=−1exp− whenσ>0 (8)

f

σ

θ

P = 0 when σ u 0 (9)

f

where

P is the probability of failure;

f

σ is the Weibull characteristic strength.

θ

4 © ISO 2003 — All rights reserved

NOTE 2 The Weibull characteristic strength is dependent on the uniaxial test specimen (tensile, flexural, or pressurized

ring) and will change with specimen geometry. In addition, the Weibull characteristic strength has units of stress, and

should be reported using units of MPa or GPa.

NOTE 3 An alternative expression for the probability of failure is given by

m

σ

Pd=−1exp−V whenσ>0 (10)

f

∫

V

σ

P = 0 when σ u 0 (11)

f

The integration in the exponential is performed over all tensile regions of the specimen volume if the strength-controlling

flaws are randomly distributed through the volume of the material, or over all tensile regions of the specimen area if flaws

are restricted to the specimen surface. The integration is sometimes carried out over an effective gauge section instead of

over the total volume or area. In Equation 10, σ is the Weibull material scale parameter and can be described as the

Weibull characteristic strength of a specimen with unit volume or area loaded in uniform uniaxial tension. The Weibull

1/m 3/m 3/m

material scale parameter has units of stress⋅(volume) , and should be reported using units of MPa⋅m or GPa⋅m if

the strength-controlling flaws are distributed through the volume of the material. If the strength-controlling flaws are

restricted to the surface of the specimens in a sample, then the Weibull material scale parameter should be reported using

2/m 2/m

units of MPa⋅m or GPa⋅m . For a given specimen geometry, Equations 8 and 10 can be combined, to yield an

expression relating σ and σ . Further discussion related to this issue can be found in Annex A.

0 θ

3 Symbols

A specimen area

b gauge section dimension, base of bend test specimen

d gauge section dimension, depth of bend test specimen

f (x) probability density function

F(x) cumulative distribution function

L likelihood function

L length of the inner load span for a bend test specimen

i

L length of the outer load span for a bend test specimen

o

m Weibull modulus

mˆ estimate of the WeibuII modulus

ˆ

m unbiased estimate of the WeibuII modulus

U

N number of specimens in a sample

P probability of failure

f

r number of specimens that failed from the flaw population for which the WeibuII estimators are

being calculated

t intermediate quantity defined by Equation 15, used in calculation of confidence bounds

V specimen volume

x realization of a random variable X

X random variable

β Weibull scale parameter

σ uniaxial tensile stress

ˆ

σ estimate of mean strength

σ maximum stress in the j th test specimen at failure

j

σ Weibull material scale parameter (strength relative to unit size) defined in Equation 10

σˆ � estimate of the WeibuII material scale parameter

σ Weibull characteristic strength (associated with a test specimen) defined in Equation 8

θ

σˆ estimate of the Weibull characteristic strength

θ

4 Significance and use

4.1 This International Standard enables the experimentalist to estimate Weibull distribution parameters from

failure data. These parameters permit a description of the statistical nature of fracture of fine ceramic

materials for a variety of purposes, particularly as a measure of reliability as it relates to strength data utilized

for mechanical design purposes. The observed strength values are dependent on specimen size and

geometry. Parameter estimates can be computed for a given specimen geometry (,mˆˆσ ), but it is suggested

θ

ˆˆ

that the parameter estimates be transformed and reported as material-specific parameters (,mσ ). In addition,

different flaw distributions (e.g., failures due to inclusions or machining damage) may be observed, and each

will have its own strength distribution parameters. The procedure for transforming parameter estimates for

typical specimen geometries and flaw distributions is outlined in Annex A.

4.2 This International Standard provides two approaches, Method A and Method B, which are appropriate

for different purposes.

Method A provides a simple analysis for circumstances in which the nature of strength-defining flaws is either

known or assumed to be from a single population. Fractography to identify and group test items with given

flaw types is thus not required. This method is suitable for use for simple material screening.

Method B provides an analysis for the general case in which competing flaw populations exist. This method is

appropriate for final component design and analysis. The method requires that fractography be undertaken to

identify the nature of strength-limiting flaws and assign failure data to given flaw population types.

4.3 In method A, a strength data set can be analysed and values of the Weibull modulus and characteristic

strength (,mˆˆσ ) are produced, together with confidence bounds on these parameters. If necessary the

θ

estimate of the mean strength can be computed. Finally, a graphical representation of the failure data along

with a test report can be prepared. It should be noted that the confidence bounds are frequently widely spaced,

which indicates that the results of the analysis should not be used to extrapolate far beyond the existing

bounds of probability of failure.

6 © ISO 2003 — All rights reserved

4.4 In method B, begin by performing a fractographic examination of each failed specimen in order to

characterize fracture origins. Screen the data associated with each flaw distribution for outliers. If all failures

originate from a single flaw distribution compute an unbiased estimate of the Weibull modulus, and compute

confidence bounds for both the estimated Weibull modulus and the estimated Weibull characteristic strength.

If the failures originate from more than one flaw type, separate the data sets associated with each flaw type,

and subject these individually to the censored analysis. Finally, prepare a graphical representation of the

failure data along with a test report. When using the results of the analysis for design purposes it should be

noted that there is an implicit assumption that the flaw populations in the strength test pieces and the

components are of the same types.

5 Method A: maximum likelihood parameter estimators for single flaw populations

5.1 General

This International Standard outlines the application of parameter estimation methods based on the maximum

likelihood technique. This technique has certain advantages. The parameter estimates obtained using the

maximum likelihood technique are unique (for a two-parameter Weibull distribution), and as the size of the

sample increases, the estimates statistically approach the true values of the population more efficiently than

other parameter estimation techniques.

5.2 Censored data

The application of the techniques presented in this International Standard can be complicated by the presence

of test specimens that fail from extraneous flaws, fractures that originate outside the effective gauge section,

and unidentified fracture origins. If these complications arise, the strength data from these specimens should

generally not be discarded. Strength data from specimens with fracture origins outside the effective gauge

section [3] and from specimens with fractures that originate from extraneous flaws should be censored, and

the maximum likelihood methods presented later in Method B (Clause 6) of this International Standard are

applicable. It is imperative that the number of unidentified fracture origins, and how they were classified, be

stated in the test report. A discussion of the appropriateness of each option can be found in 6.2.2.

5.3 Likelihood functions

The likelihood function for the two-parameter Weibull distribution of a sample with a single flaw population [4]

is defined by the expression:

mmˆˆ−1

N

mˆσσ

ii

L=−exp (12)

∏

σσˆˆ σˆ

θθ θ

i=1

NOTE σ is the maximum stress in the i th test specimen at failure and N is the number of test specimens in the

i

sample being analysed. The parameter estimates (the Weibull modulus, mˆ, and the characteristic strength, σˆ ) are

θ

ˆ ˆ

determined by taking the partial derivatives of the logarithm of the likelihood function with respect to m and σ and

θ

equating the resulting expressions to zero.

The system of equations obtained by differentiating the log likelihood function for a sample with a single flaw

population [5] is given by

N

mˆ

σσln

() ()

ii

∑

N

i=1

−−lnσ= 0 (13)

()

∑ i

N

Nmˆ

mˆ

i=1

σ

()

∑ i

i=1

and

mˆ

N

ˆ 1

m

σσˆ = (14)

()

θ ∑ i

N

i=1

ˆ ˆ

Equation 13 is solved first for m . Subsequently σ is computed from Equation 14. Obtaining a closed form

θ

solution of Equation 13 for mˆ is not possible. This expression must be solved numerically.

Since the characteristic strength also reflects specimen geometry and stress gradients, this International

Standard suggests reporting the estimated Weibull material scale parameter, σˆ . Expressions that relate σˆ

0 θ

to the Weibull material scale parameter σ for typical specimen geometries are given in Annex A.

5.4 Bias correction

5.4.1 The procedures described herein, to correct for statistical bias errors and to compute confidence

bounds, are appropriate only for data sets where all failures originate from a single population (i.e., an

uncensored sample). Procedures for bias correction and confidence bounds in the presence of multiple active

flaw populations are not currently well developed. The statistical bias associated with the estimator σˆ is

θ

ˆ

minimal (< 0,3 % for 20 test specimens, as opposed to ≈ 7 % bias for m with the same number of specimens).

Therefore, this International Standard allows the assumption that σˆ is an unbiased estimator of the true

θ

ˆ

population parameter. The parameter estimate of the Weibull modulus, m, generally exhibits statistical bias.

The amount of statistical bias depends on the number of specimens in the sample. An unbiased estimate of

ˆ ˆ

m shall be obtained by multiplying m by unbiasing factors [6]. This procedure is discussed in 5.4.2. Statistical

bias associated with the maximum likelihood estimators presented in this International Standard can be

reduced by increasing the sample size.

5.4.2 An unbiased estimator produces nearly zero statistical bias between the value of the true parameter

and the point estimate. The amount of deviation can be quantified either as a percent difference or with

unbiasing factors. In keeping with the accepted practice in the open literature, this International Standard

quantifies statistical bias through the use of unbiasing factors, denoted here as UF. Depending on the number

of specimens in a given sample, the point estimate of the Weibull modulus, mˆ, may exhibit significant

ˆ

statistical bias. An unbiased estimate of the Weibull modulus (denoted as m ) is obtained by multiplying the

U

biased estimate with an appropriate unbiasing factor. Unbiasing factors for mˆ are listed in Table 1. An

example in Annex B demonstrates the use of Table 1 in correcting a biased estimate of the Weibull modulus.

8 © ISO 2003 — All rights reserved

Table 1 — Unbiasing factor for the maximum likelihood estimate of the Weibull modulus

Number of Unbiasing factor, Number of Unbiasing factor,

specimens, N UF specimens, N UF

5 0,700 42 0,968

6 0,752 44 0,970

7 0,792 46 0,971

8 0,820 48 0,972

9 0,842 50 0,973

10 0,859 52 0,974

11 0,872 54 0,975

12 0,883 56 0,976

13 0,893 58 0,977

14 0,901 60 0,978

15 0,908 62 0,979

16 0,914 64 0,980

18 0,923 66 0,980

20 0,931 68 0,981

22 0,938 70 0,981

24 0,943 72 0,982

26 0,947 74 0,982

28 0,951 76 0,983

30 0,955 78 0,983

32 0,958 80 0,984

34 0,960 85 0,985

36 0,962 90 0,986

38 0,964 100 0,987

40 0,966 120 0,990

5.5 Confidence intervals

5.5.1 Confidence bounds quantify the uncertainty associated with a point estimate of a population

parameter. The size of the confidence bounds for maximum likelihood estimates of both Weibull parameters

will diminish with increasing sample size. The values used to construct confidence bounds are based on

percentile distributions obtained by Monte Carlo simulation; e.g., the 90 % confidence bound on the Weibull

modulus is obtained from the 5 and 95 percentile distributions of the ratio of mˆ to the true population value m.

ˆ

For a point estimate of the Weibull modulus, the normalized values (/mm) necessary to construct the 90 %

confidence bounds are listed in Table 2. The example in Annex B demonstrates the use of Table 2 in

constructing the upper and lower bounds. Note that the statistically biased estimate of the Weibull modulus

shall be used here. Again, this procedure is not appropriate for censored statistics.

5.5.2 Confidence bounds can be constructed for the estimated Weibull characteristic strength. However, the

percentile distributions needed to construct the bounds do not involve the same normalized ratios or the same

tables as those used for the Weibull modulus. Define the function:

σˆ

θ

tm= ˆ ln (15)

σ

θ

The 90 % confidence bound on the characteristic strength is obtained from the 5 and 95 percentile

distributions of t. For the point estimate of the characteristic strength, these percentile distributions are listed in

Table 3. An example in Annex B demonstrates the use of Table 3 in constructing upper and lower bounds on

ˆ

σ . Note that the biased estimate of the Weibull modulus shall be used here. Again, this procedure is not

θ

appropriate for censored statistics. Note that Equation 15 is not applicable for developing confidence bounds

ˆ ˆ

on σ , therefore the confidence bounds on σ should not be converted through the use of Equations 8

0 θ

and 10.

Table 2 — Normalized upper and lower bounds on the maximum likelihood estimate

of the Weibull modulus — 90 % confidence interval

Number of q q Number of q q

0,05 0,95 0,05 0,95

specimens, N specimens, N

5 0,683 2,779 42 0,842 1,265

6 0,697 2,436 44 0,845 1,256

7 0,709 2,183 46 0,847 1,249

8 0,720 2,015 48 0,850 1,242

9 0,729 1,896 50 0,852 1,235

10 0,738 1,807 52 0,854 1,229

11 0,745 1,738 54 0,857 1,224

12 0,752 1,682 56 0,859 1,218

13 0,759 1,636 58 0,861 1,213

14 0,764 1,597 60 0,863 1,208

15 0,770 1,564 62 0,864 1,204

16 0,775 1,535 64 0,866 1,200

17 0,779 1,510 66 0,868 1,196

18 0,784 1,487 68 0,869 1,192

19 0,788 1,467 70 0,871 1,188

20 0,791 1,449 72 0,872 1,185

22 0,798 1,418 74 0,874 1,182

24 0,805 1,392 76 0,875 1,179

26 0,810 1,370 78 0,876 1,176

28 0,815 1,351 80 0,878 1,173

30 0,820 1,334 85 0,881 1,166

32 0,824 1,319 90 0,883 1,160

34 0,828 1,306 95 0,886 1,155

36 0,832 1,294 100 0,888 1,150

38 0,835 1,283 110 0,893 1,141

40 0,839 1,273 120 0,897 1,133

10 © ISO 2003 — All rights reserved

Table 3 — Normalized upper and lower bounds on the function t — 90 % confidence interval

Number of t t Number of t t

0,05 0,95 0,05 0,95

specimens, N specimens, N

5 − 1,247 1,107 42 − 0,280 0,278

6 − 1,007 0,939 44 − 0,273 0,271

7 − 0,874 0,829 46 − 0,266 0,264

8 − 0,784 0,751 48 − 0,260 0,258

9 − 0,717 0,691 50 − 0,254 0,253

10 − 0,665 0,644 52 − 0,249 0,247

11 − 0,622 0,605 54 − 0,244 0,243

12 − 0,587 0,572 56 − 0,239 0,238

13 − 0,557 0,544 58 − 0,234 0,233

14 − 0,532 0,520 60 − 0,230 0,229

15 − 0,509 0,499 62 − 0,226 0,225

16 − 0,489 0,480 64 − 0,222 0,221

17 − 0,471 0,463 66 − 0,218 0,218

18 − 0,455 0,447 68 − 0,215 0,214

19 − 0,441 0,433 70 − 0,211 0,211

20 − 0,428 0,421 72 − 0,208 0,208

22 − 0,404 0,398 74 − 0,205 0,205

24 − 0,384 0,379 76 − 0,202 0,202

26 − 0,367 0,362 78 − 0,199 0,199

28 − 0,352 0,347 80 − 0,197 0,197

30 − 0,338 0,334 85 − 0,190 0,190

32 − 0,326 0,323 90 − 0,184 0,185

34 − 0,315 0,312 95 − 0,179 0,179

36 − 0,305 0,302 100 − 0,174 0,175

38 − 0,296 0,293 110 − 0,165 0,166

40 − 0,288 0,285 120 − 0,158 0,159

6 Method B: maximum likelihood parameter estimators for competing flaw

populations

6.1 General

This International Standard outlines the application of parameter estimation methods based on the maximum

likelihood technique. This technique has certain advantages, especially when parameters must be determined

from censored failure populations. When a sample of test specimens yields two or more distinct flaw

distributions, the sample is said to contain censored data, and the associated methods for censored data must

be used. The methods described in this International Standard include censoring techniques that apply to

multiple concurrent flaw distributions. However, the techniques for parameter estimation presented in this

International Standard are not directly applicable to data sets that contain exclusive or compound multiple flaw

distributions [7].

The estimation techniques for censored data presented herein require positive confirmation of multiple flaw

distributions, which necessitates fractographic examination in order to characterize the fracture origin in each

specimen. Multiple flaw distributions may be further evidenced by deviation from the linearity of the data from

a single Weibull distribution. However, since there are many exceptions, observations of approximately linear

behaviour should not be considered sufficient reason to conclude that only a single flaw distribution is active.

For data sets with multiple active flaw distributions where one flaw distribution (identified by fractographic

analysis) occurs in a small number of specimens, it is sufficient to report the existence of this flaw distribution

(and the number of occurrences), but it is not necessary to estimate Weibull parameters. Estimates of the

Weibull parameters for this flaw distribution would be potentially biased with wide confidence bounds (neither

of which could be quantified). However, special note should be made in the report if the occurrences of this

flaw distribution take place in the upper or lower tail of the sample strength distribution.

6.2 Censored data

6.2.1 The application of the censoring techniques presented in this International Standard can be

complicated by the presence of test specimens that fail from extraneous flaws, fractures that originate outside

the effective gauge section, and unidentified fracture origins. If these complications arise, the strength data

from these specimens should generally not be discarded. Strength data from specimens with fracture origins

outside the effective gauge section [3] as well as from specimens with fractures that originate from extraneous

flaws should be censored, and the maximum likelihood methods presented in this International Standard are

applicable.

6.2.2 This International Standard recognizes four options the experimentalist can pursue when unidentified

fracture origins are encountered during fractographic examinations. Specimens with unidentified fracture

origins can be:

a) assigned a previously identified flaw distribution using inferences based on all available fractographic

information;

b) assigned the same flaw distribution as that of the specimen closest in strength;

c) assigned a new and as yet unspecified flaw distribution;

d) be removed from the sample.

6.2.3 It is imperative that the number of unidentified fracture origins, and how they were classified, be stated

in the test report. A discussion of the appropriateness of each option appears in Annex C. If the strength data

and the resulting parameter estimates are used for component design, the engineer must consult with the

fractographer before and after performing the fractographic examination. Considerable judgement may be

needed to identify the correct option. Whenever partial fractographic information is available option a) is

strongly recommended, especially if the data are used for component design. Conversely, option d) is not

recommended by this International Standard unless there is overwhelming justification.

6.3 Likelihood functions

The likelihood function for the two-parameter Weibull distribution of a censored sample is defined by

equation [4]:

mmˆˆ−1 mˆ

rN

σ

mˆσσ

j

ii

L=−exp exp− (16)

∏∏

ˆˆ ˆ ˆ

σσ σ σ

θθ θ θ

ij==11r+

This expression is applied to a sample where two or more active concurrent flaw distributions have been

identified from fractographic inspection. For the purpose of the discussion here, the different distributions are

identified as flaw types A, B, C, etc. When Equation 16 is used to estimate the parameters associated with the

“A” flaw distribution, then r is the number of specimens where type-A flaws were found at the fracture origin,

and i is the associated index in the first product. The second product is carried out for all other specimens not

failing from type-A flaws (i.e., type-B flaws, type-C flaws, etc.). Therefore the product is carried out from

( j = r + 1) to N (the total number of specimens) where j is the index in the second product. Accordingly, σ and

i

σ are the maximum stress in the ith and jth test specimen at failure. The parameter estimates (the Weibull

j

modulus, mˆ,and the characteristic strength, σ ) are determined by taking the partial derivatives of the

θ

ˆ ˆ

logarithm of the likelihood function with respect to m and σ and equating the resulting expressions to zero.

θ

Note that σˆ is a function of specimen geometry and the estimate of the Weibull modulus mˆ. Expressions

θ

ˆ

that relate σ to the Weibull material scale parameter σ for typical specimen geometries are given in

θ 0

Annex A.

12 © ISO 2003 — All rights reserved

The system of equations obtained by differentiating the log likelihood function for a censored sample [5] is

given by:

N

mˆ

σσln

() ()

∑ii

r

i=1

−−lnσ = 0 (17)

()

i

∑

N

ˆ

rm

mˆ

i=1

()σ

i

∑

i=1

and

mˆ

N

ˆ 1

m

σσˆ = (18)

()

θ ∑ i

r

i=1

where r is the number of failed specimens from a particular group of a censored sample.

Equation 17 is solved first for mˆ. Subsequently σˆ is computed from Equation 18. Obtaining a closed form

θ

ˆ

solution of Equation 17 for m is not possible. This expression must be solved numerically.

7 Procedure

7.1 Outlying observations

Before computing the parameter estimates, the data should be screened for outlying observations (outliers).

An outlying observation is one that deviates significantly from other observations in the sample. It should be

understood that an apparent outlying observation may be an extreme manifestation of the variability of the

strength of an advanced ceramic. If this is the case, the data point should be retained and treated as any other

observation in the failure sample. However, the outlying observation may be the result of a gross deviation

from prescribed experimental procedure or an error in calculating or recording the numerical value of the data

point in question. When the experimentalist is clearly aware that a gross deviation from the prescribed

experimental procedure has occurred, the outlying observation may be discarded, unless the observation can

be corrected in a rational manner.

7.2 Fractography

7.2.1 Fractographic examination of each failed specimen is highly recommended in order to characterize

the fracture origins. The strength of advanced ceramics is often limited by discrete fracture origins which may

be intrinsic or extrinsic to the material. Porosity, agglomerates, inclusions, and atypical large grains are

considered intrinsic fracture origins. Extrinsic fracture origins are typically on the surface of the specimen and

are the result of contact stresses, impact events or adverse environment. When the means are available to

the experimentalist, fractographic methods should be used to locate, identify, and classify the strength-limiting

fracture origin causing catastrophic failure in an advanced ceramic test specimen. Moreover, for the purpose

of parameter estimation, each classification of fracture origin must be identified as a surface fracture origin or

a volume fracture origin in order to use the expressions given in Annex A. Thus, there may exist several

classifications of fracture origins within the volume (or surface area) of the test specimens in a sample. It

should be clearly indicated on the test report if a fractographic analysis is not performed.

7.2.2 Perform a fractographic analysis and label each datum with a symbol identifying the type of fracture

origin. This may be a word, an abbreviation, or a different symbol for each type of fracture origin.

7.3 Graphical representation

7.3.1 An objective of this International Standard is the consistent representation of strength data. To this

end, the following procedure is the recommended graphical representation of strength data. Begin by ranking

the strength data obtained from laboratory testing in ascending order, and assign to each a ranked probability

of failure P according to the estimator

f

i− 0,5

P()σ = (19a)

f i

N

or

i− 0,3

P σ = (19b)

()

f i

N+ 0,4

where

N is the number of specimens;

i is the ith datum.

Compute the natural logarithm of the ith failure stress, and the natural logarithm of the natural logarithm of

[1/(1 − P )] (i.e., the double logarithm of the quantity in square brackets), where P is associated with the ith

f f

failure stress.

7.3.2 Create a graph representing the data as shown in Figure 1. Plot ln{ln[1/(1 − P )]} as the ordinate, and

f

ln(s) as the abscissa. A typical ordinate scale assumes values from + 2 to − 6. This approximately corresponds

to a range in probability of failure from 0,25 % to 99,9 %. The ordinate axis must be labelled as probability of

failure P , as depicted in Figure 1. Similarly, the abscissa must be l

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...