ISO 21036:2025

(Main)Plastics piping systems for industrial applications — Unplasticized polyamide (PA-U) — Metric series for specifications for components and system

Plastics piping systems for industrial applications — Unplasticized polyamide (PA-U) — Metric series for specifications for components and system

This document specifies the characteristics and requirements for a piping system and its components, made from unplasticized polyamide (PA-U) intended to be used for thermoplastics piping systems in industrial applications above and below ground. NOTE 1 Requirements applying to industrial valves are given in this document and in other standards. This document is applicable to PA-U pipes, fittings, valves and their joints, and to joints with components of other plastics and non-plastic materials, depending on their suitability, intended to be used for the conveyance of liquid and gaseous fluids as well as solid matter in fluids for industrial applications such as the following: — transport of oil, gaseous fuels and multiphase mixtures (exploration and production; general purpose hydrocarbon-based fluids); — transport of renewable gases (hydrogen, biomethane); — transport of contaminated sewer (e.g. contaminated with hydrocarbons); — transport of CO2 [carbon capture and utilisation or storage (CCUS)]. NOTE 2 National regulations can apply. NOTE 3 Other application areas are possible if the requirements of this document and/or applicable national requirements are fulfilled. Characteristics and requirements which are applicable for PA-U are covered by the relevant clauses of this document. Those characteristics and requirements which are dependent on the material are given in the relevant normative Annex A.

Systèmes de canalisations en matières plastiques pour les applications industrielles — Polyamide non plastifié (PA-U) — Séries métriques pour les spécifications pour les composants et le système

General Information

- Status

- Published

- Publication Date

- 28-Jan-2025

- Technical Committee

- ISO/TC 138/SC 3 - Plastics pipes and fittings for industrial applications

- Current Stage

- 6060 - International Standard published

- Start Date

- 29-Jan-2025

- Due Date

- 23-Jun-2026

- Completion Date

- 29-Jan-2025

Overview

ISO 21036:2025 - Plastics piping systems for industrial applications - Unplasticized polyamide (PA‑U) - Metric series for specifications for components and system - defines the characteristics and requirements for piping systems made from unplasticized polyamide (PA‑U). The standard applies to PA‑U pipes, fittings, valves and joints used above and below ground for industrial conveyance of liquids, gaseous fluids and solids-in-fluid (including hydrocarbons, renewable gases such as hydrogen and biomethane, contaminated sewer, and CO2 for CCUS).

This ISO standard is part of the metric series for industrial plastics piping and complements other standards addressing different polymer families.

Key topics and technical requirements

ISO 21036:2025 sets out comprehensive requirements and test criteria for PA‑U systems, including:

- Material requirements: definitions, material characteristics, long‑term hydrostatic strength, and provisions for virgin, reworkable and recyclable material. (See normative Annex A for material‑dependent requirements.)

- Geometrical characteristics: diameters, wall thickness tolerances, ovality, lengths, threads and joint dimensions.

- Mechanical characteristics: resistance to internal pressure, calculation of test pressures for pipes, fittings and valves, and resistance to rapid crack propagation (RCP).

- Physical, chemical and electrical characteristics: behaviour under service conditions, effects on fluids and components, and electrical properties where applicable.

- Performance and component requirements: fusion compatibility, component performance testing, classification, and conformity assessment.

- Design, installation and marking: installation guidance (informative Annex B), declaration of conformity and minimum marking requirements for pipes, fittings and valves.

- Joints and compatibility: joints with other plastics and non‑plastic materials depending on suitability for the intended service.

Note: some valve requirements are cross‑referenced to other standards; national regulations may also apply.

Practical applications and users

ISO 21036:2025 is intended for stakeholders involved in industrial piping systems where PA‑U offers performance advantages:

- Applications: oil and multiphase hydrocarbon transport (exploration/production), renewable gas distribution (hydrogen, biomethane), contaminated sewer lines, and CO2 transport for carbon capture, utilisation or storage (CCUS).

- Who uses it: design engineers, system specifiers, manufacturers of PA‑U pipes and fittings, valve makers, testing and certification bodies, installers, inspection bodies and end users/operators.

Related standards

- ISO 10931 (PVDF systems)

- ISO 15493 (ABS / PVC‑U / PVC‑C systems)

- ISO 15494 (PB, PE, PE‑RT, PE‑X, PP systems)

ISO 21036:2025 helps ensure consistent quality, safety and interoperability of PA‑U industrial piping systems and supports compliance, testing and procurement decisions.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

ISO 21036:2025 is a standard published by the International Organization for Standardization (ISO). Its full title is "Plastics piping systems for industrial applications — Unplasticized polyamide (PA-U) — Metric series for specifications for components and system". This standard covers: This document specifies the characteristics and requirements for a piping system and its components, made from unplasticized polyamide (PA-U) intended to be used for thermoplastics piping systems in industrial applications above and below ground. NOTE 1 Requirements applying to industrial valves are given in this document and in other standards. This document is applicable to PA-U pipes, fittings, valves and their joints, and to joints with components of other plastics and non-plastic materials, depending on their suitability, intended to be used for the conveyance of liquid and gaseous fluids as well as solid matter in fluids for industrial applications such as the following: — transport of oil, gaseous fuels and multiphase mixtures (exploration and production; general purpose hydrocarbon-based fluids); — transport of renewable gases (hydrogen, biomethane); — transport of contaminated sewer (e.g. contaminated with hydrocarbons); — transport of CO2 [carbon capture and utilisation or storage (CCUS)]. NOTE 2 National regulations can apply. NOTE 3 Other application areas are possible if the requirements of this document and/or applicable national requirements are fulfilled. Characteristics and requirements which are applicable for PA-U are covered by the relevant clauses of this document. Those characteristics and requirements which are dependent on the material are given in the relevant normative Annex A.

This document specifies the characteristics and requirements for a piping system and its components, made from unplasticized polyamide (PA-U) intended to be used for thermoplastics piping systems in industrial applications above and below ground. NOTE 1 Requirements applying to industrial valves are given in this document and in other standards. This document is applicable to PA-U pipes, fittings, valves and their joints, and to joints with components of other plastics and non-plastic materials, depending on their suitability, intended to be used for the conveyance of liquid and gaseous fluids as well as solid matter in fluids for industrial applications such as the following: — transport of oil, gaseous fuels and multiphase mixtures (exploration and production; general purpose hydrocarbon-based fluids); — transport of renewable gases (hydrogen, biomethane); — transport of contaminated sewer (e.g. contaminated with hydrocarbons); — transport of CO2 [carbon capture and utilisation or storage (CCUS)]. NOTE 2 National regulations can apply. NOTE 3 Other application areas are possible if the requirements of this document and/or applicable national requirements are fulfilled. Characteristics and requirements which are applicable for PA-U are covered by the relevant clauses of this document. Those characteristics and requirements which are dependent on the material are given in the relevant normative Annex A.

ISO 21036:2025 is classified under the following ICS (International Classification for Standards) categories: 23.040.01 - Pipeline components and pipelines in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 21036:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

International

Standard

ISO 21036

First edition

Plastics piping systems for

2025-01

industrial applications —

Unplasticized polyamide (PA-U) —

Metric series for specifications for

components and system

Systèmes de canalisations en matières plastiques pour les

applications industrielles — Polyamide non plastifié (PA-U) —

Séries métriques pour les spécifications pour les composants et le

système

Reference number

© ISO 2025

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

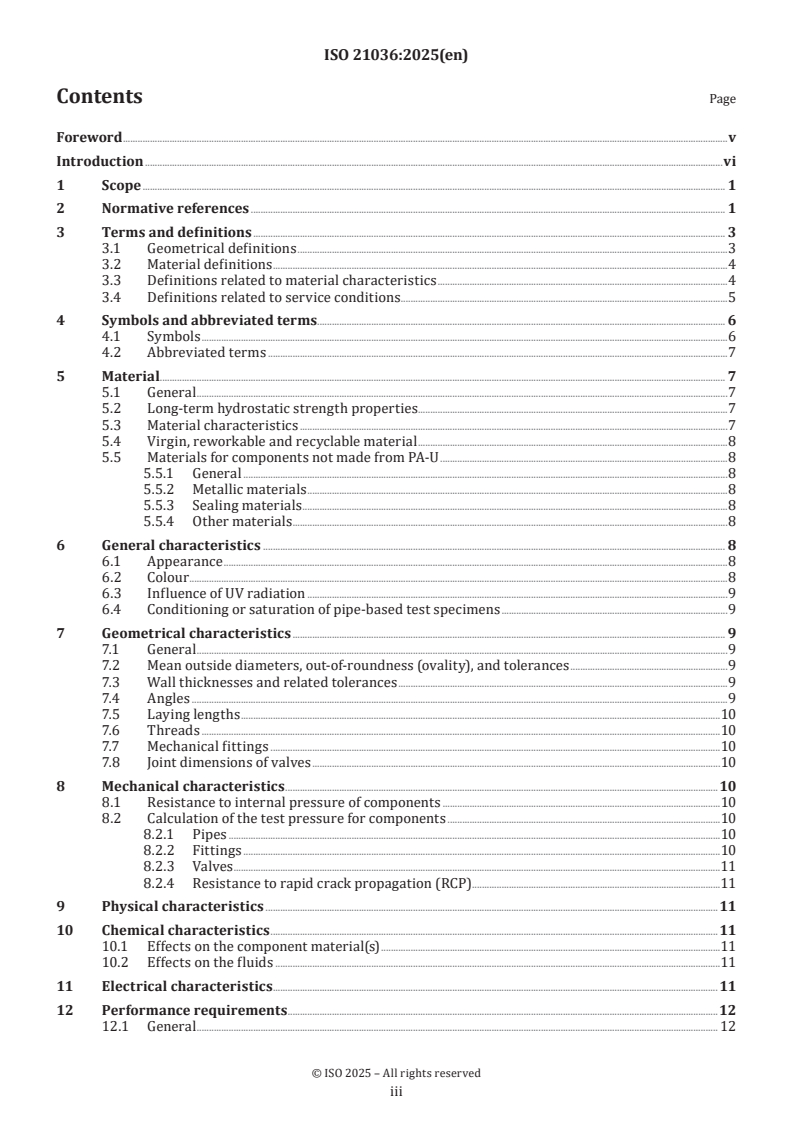

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 3

3.1 Geometrical definitions .3

3.2 Material definitions .4

3.3 Definitions related to material characteristics .4

3.4 Definitions related to service conditions .5

4 Symbols and abbreviated terms. 6

4.1 Symbols .6

4.2 Abbreviated terms .7

5 Material. 7

5.1 General .7

5.2 Long-term hydrostatic strength properties.7

5.3 Material characteristics .7

5.4 Virgin, reworkable and recyclable material .8

5.5 Materials for components not made from PA-U .8

5.5.1 General .8

5.5.2 Metallic materials .8

5.5.3 Sealing materials .8

5.5.4 Other materials .8

6 General characteristics . 8

6.1 Appearance .8

6.2 Colour .8

6.3 Influence of UV radiation .9

6.4 Conditioning or saturation of pipe-based test specimens .9

7 Geometrical characteristics . 9

7.1 General .9

7.2 Mean outside diameters, out-of-roundness (ovality), and tolerances .9

7.3 Wall thicknesses and related tolerances .9

7.4 Angles .9

7.5 Laying lengths .10

7.6 Threads .10

7.7 Mechanical fittings .10

7.8 Joint dimensions of valves .10

8 Mechanical characteristics .10

8.1 Resistance to internal pressure of components .10

8.2 Calculation of the test pressure for components .10

8.2.1 Pipes .10

8.2.2 Fittings .10

8.2.3 Valves .11

8.2.4 Resistance to rapid crack propagation (RCP) .11

9 Physical characteristics .11

10 Chemical characteristics .11

10.1 Effects on the component material(s) .11

10.2 Effects on the fluids .11

11 Electrical characteristics .11

12 Performance requirements . .12

12.1 General . 12

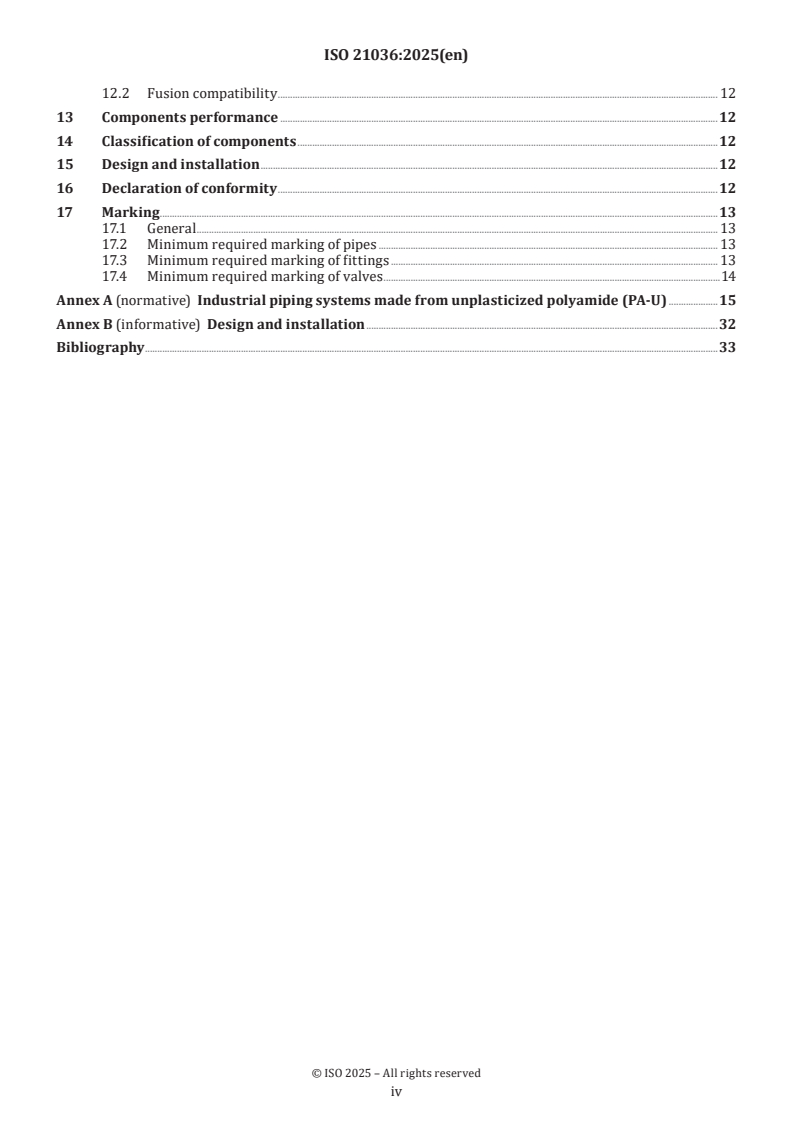

iii

12.2 Fusion compatibility . 12

13 Components performance .12

14 Classification of components .12

15 Design and installation .12

16 Declaration of conformity .12

17 Marking . .13

17.1 General . 13

17.2 Minimum required marking of pipes . 13

17.3 Minimum required marking of fittings . 13

17.4 Minimum required marking of valves .14

Annex A (normative) Industrial piping systems made from unplasticized polyamide (PA-U) .15

Annex B (informative) Design and installation .32

Bibliography .33

iv

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee

has been established has the right to be represented on that committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely

with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types

of ISO document should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent

rights in respect thereof. As of the date of publication of this document, ISO had not received notice of (a)

patent(s) which may be required to implement this document. However, implementers are cautioned that

this may not represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents. ISO shall not be held responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 138, Plastics pipes, fittings and valves for the

transport of fluids, Subcommittee SC 3, Plastics pipes and fittings for industrial applications.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

Introduction

This document specifies the characteristics and requirements for a piping system and its components made

from unplasticized polyamide (PA-U), as applicable, intended to be used for industrial applications above

ground or below ground by authorities, design engineers, certification bodies, inspection bodies, testing

laboratories, manufacturers, and users.

At the date of publication of this document, standards for piping systems of other plastics used for industrial

applications include the following:

ISO 10931, Plastics piping systems for industrial applications — Poly(vinylidene fluoride) (PVDF) —

Specifications for components and the system

ISO 15493, Plastics piping systems for industrial applications — Acrylonitrile-butadiene-styrene (ABS),

unplasticized poly(vinyl chloride) (PVC-U) and chlorinated poly(vinyl chloride) (PVC-C) — Specifications for

components and the system — Metric series

ISO 15494, Plastics piping systems for industrial applications — Polybutene (PB), polyethylene (PE), polyethylene

of raised temperature resistance (PE-RT), crosslinked polyethylene (PE-X), polypropylene (PP) — Metric series

for specifications for components and the system

vi

International Standard ISO 21036:2025(en)

Plastics piping systems for industrial applications —

Unplasticized polyamide (PA-U) — Metric series for

specifications for components and system

1 Scope

This document specifies the characteristics and requirements for a piping system and its components, made

from unplasticized polyamide (PA-U) intended to be used for thermoplastics piping systems in industrial

applications above and below ground.

NOTE 1 Requirements applying to industrial valves are given in this document and in other standards.

This document is applicable to PA-U pipes, fittings, valves and their joints, and to joints with components

of other plastics and non-plastic materials, depending on their suitability, intended to be used for the

conveyance of liquid and gaseous fluids as well as solid matter in fluids for industrial applications such as

the following:

— transport of oil, gaseous fuels and multiphase mixtures (exploration and production; general purpose

hydrocarbon-based fluids);

— transport of renewable gases (hydrogen, biomethane);

— transport of contaminated sewer (e.g. contaminated with hydrocarbons);

— transport of CO [carbon capture and utilisation or storage (CCUS)].

NOTE 2 National regulations can apply.

NOTE 3 Other application areas are possible if the requirements of this document and/or applicable national

requirements are fulfilled.

Characteristics and requirements which are applicable for PA-U are covered by the relevant clauses of this

document. Those characteristics and requirements which are dependent on the material are given in the

relevant normative Annex A.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

ISO 7-1, Pipe threads where pressure-tight joints are made on the threads — Part 1: Dimensions, tolerances and

designation

ISO 228-1, Pipe threads where pressure-tight joints are not made on the threads — Part 1: Dimensions, tolerances

and designation

ISO 291, Plastics — Standard atmospheres for conditioning and testing

ISO 307, Plastics — Polyamides — Determination of viscosity number

ISO 472, Plastics — Vocabulary

ISO 1043-1, Plastics — Symbols and abbreviated terms — Part 1: Basic polymers and their special characteristics

ISO 1110, Plastics — Polyamides — Accelerated conditioning of test specimens

ISO 1133-2, Plastics — Determination of the melt mass-flow rate (MFR) and melt volume-flow rate (MVR) of

thermoplastics — Part 2: Method for materials sensitive to time-temperature history and/or moisture

ISO 1167-1, Thermoplastics pipes, fittings and assemblies for the conveyance of fluids — Determination of the

resistance to internal pressure — Part 1: General method

ISO 1167-2, Thermoplastics pipes, fittings and assemblies for the conveyance of fluids — Determination of the

resistance to internal pressure — Part 2: Preparation of pipe test pieces

ISO 1167-3, Thermoplastics pipes, fittings and assemblies for the conveyance of fluids — Determination of the

resistance to internal pressure — Part 3: Preparation of components

ISO 1167-4, Thermoplastics pipes, fittings and assemblies for the conveyance of fluids — Determination of the

resistance to internal pressure — Part 4: Preparation of assemblies

ISO 1183-1, Plastics — Methods for determining the density of non-cellular plastics — Part 1: Immersion method,

liquid pyknometer method and titration method

ISO 1183-2, Plastics — Methods for determining the density of non-cellular plastics — Part 2: Density gradient

column method

ISO 2505, Thermoplastics pipes — Longitudinal reversion — Test method and parameters

ISO 3126, Plastics piping systems — Plastics components — Determination of dimensions

ISO 6964, Polyolefin pipes and fittings — Determination of carbon black content by calcination and pyrolysis —

Test method

ISO 9080, Plastics piping and ducting systems — Determination of the long-term hydrostatic strength of

thermoplastics materials in pipe form by extrapolation

ISO 11922-1, Thermoplastics pipes for the conveyance of fluids — Dimensions and tolerances — Part 1: Metric series

ISO 12162, Thermoplastics materials for pipes and fittings for pressure applications — Classification, designation

and design coefficient

ISO 13478, Thermoplastics pipes for the conveyance of fluids — Determination of resistance to rapid crack

propagation (RCP) — Full-scale test (FST)

ISO 13479, Polyolefin pipes for the conveyance of fluids — Determination of resistance to crack propagation —

Test method for slow crack growth on notched pipes

ISO 15512:2019, Plastics — Determination of water content

ISO 15853, Thermoplastics materials — Preparation of tubular test pieces for the determination of the

hydrostatic strength of materials used for injection moulding

ISO 16135, Industrial valves — Ball valves of thermoplastics materials

ISO 16486-4, Plastics piping systems for the supply of gaseous fuels — Unplasticized polyamide (PA-U) piping

systems with fusion jointing and mechanical jointing — Part 4: Valves

ISO 18553, Method for the assessment of the degree of pigment or carbon black dispersion in polyolefin pipes,

fittings and compounds

IEC 60529, Degrees of protection provided by enclosures (IP-code)

EN 12099, Plastics piping systems — Polyethylene piping materials and components — Determination of

volatile content

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 472, ISO 1043-1, and the

following apply.

3.1 Geometrical definitions

3.1.1

nominal outside diameter

d

n

specified outside diameter assigned to a nominal size, DN/OD

Note 1 to entry: The nominal inside diameter of a socket is equal to the nominal outside diameter of the corresponding pipe.

Note 2 to entry: It is expressed in millimetres.

3.1.2

outside diameter

d

e

value of the measurement of the outside diameter through its cross-section at any point of the pipe, rounded

to the next greater 0,1 mm

Note 1 to entry: The symbol d corresponds to d given in other International Standards such as ISO 11922-1.

e ey

3.1.3

mean outside diameter

d

em

value of the measurement of the outer circumference of the pipe or spigot end of a fitting in any cross-section

divided by π (= 3,142), rounded to the next greater 0,1 mm

3.1.4

nominal size

DN/OD

numerical designation of the size of a component, other than a component designated by thread size, which

is a convenient round number, approximately equal to the manufacturing dimension in millimetres (mm)

and related to the outside diameter

3.1.5

nominal size of flange

DN

numerical designation of the size of a flange for reference purposes and related to the manufacturing

dimension in millimetres

3.1.6

out-of-roundness

ovality

difference between the maximum and the minimum outside diameter in the same cross-section of a pipe

or spigot

3.1.7

nominal wall thickness

e

n

numerical designation of the wall thickness of a component, which is a convenient round number,

approximately equal to the manufacturing dimension in millimetres (mm)

Note 1 to entry: For thermoplastics components conforming to Annexes A and B, the value of the nominal wall

thickness, e , is identical to the specified minimum wall thickness at any point, e .

n min

Note 2 to entry: The symbol e corresponds to e given in other International Standards, such as ISO 11922-1.

n ey

3.1.8

wall thickness at any point

e

wall thickness at any point around the circumference of a component, rounded to the next greater 0,1 mm

3.1.9

minimum wall thickness at any point

e

min

minimum value for the wall thickness at any point around the circumference of a component, as specified

3.1.10

pipe series

S

dimensionless number for pipe designation

Note 1 to entry: The pipe series, S, conforms to ISO 4065.

Note 2 to entry: The relationship between the pipe series, S, and the standard dimension ratio, SDR, is given by the

following formula as specified in ISO 4065:

SDR1−

S =

Note 3 to entry: Flanges are designated on the basis of nominal pressure, PN.

3.1.11

standard dimension ratio

SDR

numerical designation of a pipe series, which is a convenient round number, approximately equal to the

dimension ratio of the nominal outside diameter, d , and the nominal wall thickness, e

n n

3.2 Material definitions

3.2.1

virgin material

material in a form such as granules or powder that has not been subjected to use or processing other than

that required for its manufacture and to which no reprocessable or recyclable materials have been added

3.2.2

reworked material

plastics material from rejected unused products or trimmings capable of being reclaimed within the same

process that generated it

Note 1 to entry: Previously referred to as “own reprocessed material”.

3.3 Definitions related to material characteristics

3.3.1

lower confidence limit of the predicted hydrostatic strength

σ

LPL

quantity with the dimensions of stress, which represents the 97,5 % lower confidence limit of the predicted

hydrostatic strength at a temperature, T, and time, t

Note 1 to entry: It is expressed in megapascals.

3.3.2

minimum required strength

MRS

value of σ (lower confidence limit of the predicted hydrostatic strength) at 20 °C and 50 years, rounded

LPL

down to the next smaller value of the R10 series or the R20 series

Note 1 to entry: The R10 series conforms to ISO 3 and the R20 series conforms to ISO 497.

3.3.3

design stress

σ

s

allowable stress for a given application at 20 °C that is derived from the minimum required strength (MRS)

by dividing it by the coefficient C

Note 1 to entry: Design stress can be calculated using the following formula:

MRS

σ =

s

C

Note 2 to entry: It is expressed in megapascals.

3.3.4

design coefficient

C

coefficient with a value greater than one which takes into consideration service conditions as well as the

properties of the components of a piping system other than those represented in the lower confidence limit

3.4 Definitions related to service conditions

3.4.1

nominal pressure

PN

numerical designation used for reference purposes related to the mechanical characteristics of the

components of a piping system

Note 1 to entry: A pressure, in bar, with the numerical value of PN is identical with the pressure, PS, as defined by

Reference [19] if both pressures are taken at 20 °C.

Note 2 to entry: For plastics piping systems conveying water, PN corresponds to the maximum continuous operating

pressure in bar, which can be sustained for water at 20 °C for 50 years, based on the following minimum design

coefficient:

10σσ20

ss

PN= =

S SDR−1

[]

where

σ is expressed in MPa;

s

PN is expressed in bar.

5 2

Note 3 to entry: 1 bar = 0,1 MPa = 10 Pa; 1 MPa= 1 N/mm .

3.4.2

hydrostatic stress

σ

stress induced in the wall of a pipe when an internal hydrostatic pressure is applied

Note 1 to entry: The hydrostatic stress is related to the applied internal hydrostatic pressure (in bar), p, the wall

thickness at any point, e, and the mean outside diameter, d , of a pipe. It is calculated using the following formula:

em

de−

em min

σ =p

20e

min

Note 2 to entry: This formula is applicable for pipes only.

Note 3 to entry: The value is expressed in megapascals.

4 Symbols and abbreviated terms

4.1 Symbols

C design coefficient (design factor)

D mean inside diameter in the fusion zone

D minimum diameter of the flow channel through the body of the fitting

d outside diameter (at any point)

e

d mean outside diameter

em

d nominal outside diameter

n

D outside diameter of chamfer on shoulder

f1

D outside diameter of flange adaptor

f2

DN nominal size of flange

e wall thickness (at any point)

e nominal wall thickness

n

h height of the service pipe

H height of the saddle

L width of the tapping tee

L depth of penetration of the pipe or male end of a spigot end fitting

L nominal length of the fusion zone

L nominal unheated entrance length of the fitting

L outside tubular length

b2

p internal hydrostatic pressure

p critical pressure

c

p critical reference pressure

c,REF

p maximum allowable pressure

s

r radius of chamfer on shoulder

f

T temperature

t time

σ hydrostatic stress

4.2 Abbreviated terms

MOP maximum operating pressure

MRS minimum required strength

PA-U unplasticized polyamide (PA-U11 or PA-U12)

PN nominal pressure

RCP rapid crack propagation

S pipe series S

SDR standard dimension ratio

5 Material

5.1 General

The PA-U material from which the components are made shall either be PA-U 11 or PA-U 12, to which are

added those additives that are needed to facilitate the manufacture of pipes, fittings, and valves conforming

to this document.

If additives are used, they shall be uniformly dispersed.

The additives shall not be used separately or together in quantities sufficient to impair the fabrication or

fusion characteristics of the component or to impair the chemical, physical, or mechanical characteristics as

specified in this document.

5.2 Long-term hydrostatic strength properties

The material shall be evaluated in accordance with ISO 9080 by analysis of pressure tests carried out in

accordance with ISO 1167-1 and ISO 1167-2 to classify the material in accordance with ISO 12162.

EXAMPLE PA-U12 180 or PA-U11 180 compounds are classified for MRS 18 MPa.

Conformity of the relevant material to the reference curves given for PA-U 180 shall be proven according to

Annex A, Formula (A.1) and Formula (A.2) or corresponding Figure A.1. At least 97,5 % of the data points

shall be on or above the reference curves. For design, these reference curves shall be used as a basis.

The material shall be classified by the raw material producer.

NOTE In some cases, the component manufacturer can be regarded as the raw material producer.

Where fittings and valves are manufactured from the same material as pipes, the material classification

shall be the same as for pipes.

For the classification of a material intended only for the manufacture of fittings and valves, the test piece

shall be an injection-moulded or extruded test piece in the form of a pipe where a test pressure is applied

according to ISO 1167-1. The free length shall be 3d , as defined in ISO 1167-2 or ISO 15853.

n

5.3 Material characteristics

The details of the material characteristics of PA-U mechanical and physical properties with requirements

are given in Annex A.

5.4 Virgin, reworkable and recyclable material

Stress-bearing parts shall only be made from virgin material in accordance with Annex A. Non-stress-

bearing parts shall be made from virgin material or reworked material from a compound with the same

MRS or a mixture of both, virgin and reworked material.

The use of reworkable material obtained during the production and testing of components according to this

document is not permitted.

Reprocessable material obtained from external sources and recyclable material shall not be used.

5.5 Materials for components not made from PA-U

5.5.1 General

All components shall conform to the relevant International Standard(s). Alternative standards may be

applied in cases where suitable International Standard(s) do not exist. In all cases, fitness for purpose of the

components shall be demonstrated.

Materials and constituent elements used in making the relevant component (including rubber, greases, and

any metal parts used) shall have comparable resistance to the external and internal environments as all

other elements of the piping system according to this document.

Materials other than PA-U in contact with components conforming to this document shall not adversely

affect the performance of the components or initiate stress cracking.

5.5.2 Metallic materials

All metal parts susceptible to corrosion shall be adequately protected.

When dissimilar metallic materials are used which can be in contact with moisture, steps shall be taken to

avoid the possibility of galvanic corrosion.

5.5.3 Sealing materials

Sealing materials shall have no detrimental effects on the properties of the components, joints, and

assemblies.

5.5.4 Other materials

Greases or lubricants shall not exude onto fusion areas and shall not affect the long-term performance of

materials conforming to this document.

6 General characteristics

6.1 Appearance

When viewed without magnification, the internal and external surfaces of the components shall be smooth,

clean, and free from scoring, cavities, and other surface defects to an extent that would prevent conformity

to this document. The components shall not contain visible impurities.

Each end of a component shall be square to its axis and shall be deburred.

6.2 Colour

The colour of the components shall be as given in Clause A.2 of this document.

NOTE National or regional legislation relating to the colour coding of piping in respect of its purpose or contents

for the location in which the components are intended to be used can apply.

6.3 Influence of UV radiation

Components for external above ground installations shall be adequately protected against UV radiation or

the material shall be resistant to UV radiation for the intended application. For products which are usually

stored outside in direct sunlight prior to installation, the effect of UV radiation shall be taken into account.

To assess materials for resistance to UV radiation for storage purposes, pipe shall subject to a cumulative

radiant exposure of ≥7,0 GJ/m in accordance with ISO 16871. Following this exposure, the pipe is assessed

for any significant change in mechanical properties.

6.4 Conditioning or saturation of pipe-based test specimens

Unless otherwise specified in the applicable test method, test pieces shall be conditioned for at least 16 h at

23 °C and 50 % relative humidity in accordance with ISO 291 before testing.

The test pieces shall not be tested within the period of 48 h after their manufacture.

Long-term hydrostatic strength data shall be generated on saturated polyamide pipe specimens representing

the most severe case to prevent rising humidity content of the pipe over test duration and resulting effects

on the analysis of time to failure test results. The saturation process in water shall be accelerated according

to ISO 1110. Data shall show the uptake of water until saturation over time according to ISO 15512.

NOTE In ISO 16486-2:2024 Annex B, information is given about the saturation performance of pipes in water.

7 Geometrical characteristics

7.1 General

The measurement shall not be made less than 24 h after manufacture.

Dimensions shall be measured in accordance with ISO 3126 at (23 ± 2) °C after being conditioned for at least

4 h unless specified otherwise in Annex A.

Indirect measurement during the stage of production is allowed at shorter time periods providing that

evidence is shown of correlation.

The figures provided in Annex A are schematic sketches only, to indicate the relevant dimensions. They do

not necessarily represent the manufactured component(s). The given dimensions shall be followed.

Dimensions not given shall be specified by the manufacturer.

7.2 Mean outside diameters, out-of-roundness (ovality), and tolerances

For components made from PA-U the diameters, out-of-roundness (ovality) and related tolerances shall

conform to Clause A.3.

The out-of-roundness (ovality) shall be measured at the point of manufacture.

7.3 Wall thicknesses and related tolerances

For components made from PA-U, the wall thicknesses and related tolerances shall conform to Clause A.3.

7.4 Angles

The permitted deviations from the nominal or declared angle for a nonlinear fitting shall be ±2° where the

angle comprises the relevant change of axis of the flow through the fitting.

The recommended nominal angles for a nonlinear fitting are 45° or 90°.

7.5 Laying lengths

The laying lengths for fittings and valves shall be declared by the manufacturer.

The laying lengths are intended to assist in the design of moulds and are not intended to be used for quality

control purposes. ISO 265-1 may be used as a guideline.

7.6 Threads

Joints made pressure-tight by the mating of the threads shall conform to ISO 7-1 and fastening pipe threads

to ISO 228-1

International Standard with the same content as ISO 7-1 exist, e.g. EN 10226-1 and EN 10226-2.

7.7 Mechanical fittings

Mechanical fittings such as adaptors, unions, compression fittings, and reducing bushes may be used,

provided that their joint dimensions are in accordance with the applicable dimensions of components

conforming to this document.

7.8 Joint dimensions of valves

The joint dimensions of valves shall conform to the relevant dimensions of pipes and fittings conforming to

this document.

8 Mechanical characteristics

8.1 Resistance to internal pressure of components

Components shall withstand the hydrostatic stress induced by internal hydrostatic pressure without

bursting or leaking when tested in accordance with ISO 1167-1, ISO 1167-2, and ISO 1167-3 and the test

conditions specified for PA-U in Annex A.

8.2 Calculation of the test pressure for components

8.2.1 Pipes

For pipes, the relation between hoop stress, σ, expressed in MPa, and internal hydrostatic pressure, p,

expressed in bar, is given by Formula (1):

de−

em min

σ =p (1)

20e

min

For tests the internal hydrostatic pressure, p, expressed in bar, shall be determined for pipes using

Formula (2):

10σσ20

p= = (2)

[]S SDR−1

where σ is the hoop stress for PA-U conforming to the A.1.2.

8.2.2 Fittings

For tests the internal hydrostatic pressure, p, expressed in bar, shall be determined for fittings using

Formula (2). For S and SDR respectively, the value of the corresponding pipe shall be taken.

8.2.3 Valves

For tests the hydrostatic pressure, p, expressed in bar, is defined for valves in ISO 16486-4.

8.2.4 Resistance to rapid crack propagation (RCP)

For a pipeline system carrying air or a compressible gas, for design purposes, the resistance of the material

to the phenomenon known as rapid crack propagation shall be taken into account (see ISO 16486-1,

ISO 16486-2 and ISO 16486-5). The critical pressure p is dependent on the material, pipe diameter, and

c

operating temperature.

The critical reference pressure p measured in accordance with ISO 13478 shall be greater than 1,5 times

c,REF

the maximum operating pressure of the pipeline system.

Information provided by the pipe or material supplier should be taken into account when designing an

industrial pipeline system for the transport of air or a compressible gas. The maximal wall thickness for RCP

resistance shall be provided by the compound manufacturer.

NOTE For unplasticized polyamide (PA-U) SDR 11 pipe produced in accordance with ISO 16486-2 for natural gas

[9]

applications, the KRV listing show an RCP resistance for a wall thickness up to including 14,6 mm that allows an

operation at 18 bar (for CEN limited to 16 bar) for temperatures above 0 °C with diameters up to including 160 mm.

9 Physical characteristics

The physical characteristics of components made from PA-U shall conform to Annex A.

10 Chemical characteristics

10.1 Effects on the component material(s)

Where fluids other than water are to be conveyed, the effect of the fluid on the component material should

be considered.

NOTE Guidance is available in ISO/TR 10358 or from the component manufacturer.

The chemical resistance of the pipe shall be evaluated for a particular application. Then the pipe can be

classified in accordance with ISO 4433-1.

The influence of chemical fluids on the long-term hydrostatic strength of PA-U pressure pipes may be

determined by DIN 16463 or, if applicable, by long-term, in situ creep rupture tests as described in Reference

[13], where the results are used for ASTM F 3524.

10.2 Effects on the fluids

Where fluids other than water are to be conveyed, the effect of the component material on the fluid should

be considered.

11 Electrical characteristics

The electrical protection that shall be provided by the fusion process depends on the characteristics of the

electricity power source.

NOTE The relevant component during the fusion process is part of an electrical system, see Reference [21] or

Reference [15].

Protection against direct contacts with active parts (live conductors) shall be in accordance with IEC 60529.

This protection is a function of the work site conditions.

The surface finish of the terminal pins shall allow a minimum contact resistance.

12 Performance requirements

12.1 General

When components made from the same material conforming to this document are jointed to each other, the

pipes, fittings, valves, and the joints shall conform to the requirements of Clause A.6.

NOTE If test pressures defined for pipes are used for assemblies made from components of dissimilar materials

(e.g. screwed joints, flanged joints), the resulting strain exceeds the strain occurring under service conditions. These

strains unavoidably cause leakage. Therefore, in this document, the time related strain behaviour of the assemblies is

taken into account and the test pressures derived from the isochronous stress-strain-diagram are used.

12.2 Fusion compatibility

Pipes made from PA-U 11 shall be heat fusion jointed only to either pipes or component

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...