ISO 16895:2016

(Main)Wood-based panels — Dry-process fibreboard

Wood-based panels — Dry-process fibreboard

ISO 16895:2016 specifies a classification matrix, related mandatory tests and thickness ranges for ultra-low-, low-, medium- and high-density dry process wood-based fibreboard. It then provides the manufacturing property requirements for these types of uncoated fibreboard. The values listed in this International Standard relate to product properties used to classify fibreboards into one of four types (UDF, LDF, MDF and HDF, see Clause 3), one of four grades (GP, FN, BL and LB), for use in one of four service conditions (REG, MR1, MR2, and HMR). The values are not characteristic values to be used for design purposes. NOTE Fibreboards are broadly divided into two groups based on the manufacturing process, namely the dry process group and the wet process group (see Clause 3). Wet process fibreboards lie outside the scope of this International Standard.

Panneaux à base de bois — Panneaux de fibres obtenus par procédé à sec

General Information

- Status

- Published

- Publication Date

- 27-Jan-2016

- Technical Committee

- ISO/TC 89/SC 1 - Fibre boards

- Drafting Committee

- ISO/TC 89/SC 1 - Fibre boards

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 29-Jun-2021

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 16-Jul-2011

- Effective Date

- 16-Jul-2011

Overview

ISO 16895:2016 - Wood-based panels - Dry-process fibreboard defines classification, testing and manufacturing property requirements for dry-process fibreboard. It covers four density types (Ultra-low UDF, Low LDF, Medium MDF, and High HDF), four product grades (GP, FN, BL, LB) and four service conditions (REG, MR1, MR2, HMR). The standard sets classification matrices, mandatory tests and thickness ranges for uncoated fibreboard and provides the property limits used to assign product type and grade. NOTE: wet-process fibreboards are outside the scope. Values in ISO 16895:2016 are for classification and quality-control purposes, not for structural design calculations.

Key topics and technical requirements

- Classification by density and grade: UDF, LDF, MDF, HDF with grade designations for intended use (general purpose, furniture, building, load-bearing).

- Service conditions: Definitions for normal (REG), temperate humid (MR1), high humid (MR2) and high-moisture resistant (HMR) applications.

- Mandatory and optional tests: Specifies which properties are required for each grade/type and service condition (e.g., density, dimensional stability, surface soundness, tensile strength perpendicular to plane).

- Thickness ranges: Acceptable thickness bands for each fibreboard type to guide product specification and production control.

- Expression of specification limits: How to set lower/upper specification limits, and statistical percentiles (5th/95th) for lot evaluation.

- Formaldehyde and moisture requirements: Requires compliance with established test methods for formaldehyde emission and moisture resistance; values are classification-related, not design parameters.

- Marking and coding: Guidance for product designation and marking to indicate type, grade and service class.

Practical applications - who uses ISO 16895:2016

- Manufacturers - to classify products, set production tolerances, define thickness ranges and prepare internal QC/testing schedules.

- Quality and compliance labs - to perform mandatory tests and report conformity to grade/service classes.

- Specifiers, architects and product purchasers - to select appropriate uncoated fibreboard (MDF/HDF/LDF/UDF) for intended service conditions.

- Regulators and certification bodies - for defining product labelling and market surveillance criteria.

- R&D and product development teams - to benchmark new dry-process fibreboard products.

Related standards (selection)

ISO 16895 references and aligns with several test standards, for example:

- ISO 12460 series - formaldehyde emission test methods (chamber, desiccator, perforator)

- ISO 16978 - modulus of elasticity and bending strength

- ISO 16979 - moisture content determination

- ISO 16981 - surface soundness

- ISO 16983 / ISO 16998 / ISO 16987 - swelling, boil and cyclic moisture resistance tests

- ISO 27528 - axial withdrawal resistance of screws

Keywords: ISO 16895:2016, dry-process fibreboard, MDF, HDF, LDF, UDF, wood-based panels, fibreboard classification, formaldehyde emission, moisture resistance, thickness ranges, manufacturing property requirements.

Get Certified

Connect with accredited certification bodies for this standard

Gozdarski inštitut Slovenije

Slovenian Forestry Institute. Forest management certification support, timber testing.

Sponsored listings

Frequently Asked Questions

ISO 16895:2016 is a standard published by the International Organization for Standardization (ISO). Its full title is "Wood-based panels — Dry-process fibreboard". This standard covers: ISO 16895:2016 specifies a classification matrix, related mandatory tests and thickness ranges for ultra-low-, low-, medium- and high-density dry process wood-based fibreboard. It then provides the manufacturing property requirements for these types of uncoated fibreboard. The values listed in this International Standard relate to product properties used to classify fibreboards into one of four types (UDF, LDF, MDF and HDF, see Clause 3), one of four grades (GP, FN, BL and LB), for use in one of four service conditions (REG, MR1, MR2, and HMR). The values are not characteristic values to be used for design purposes. NOTE Fibreboards are broadly divided into two groups based on the manufacturing process, namely the dry process group and the wet process group (see Clause 3). Wet process fibreboards lie outside the scope of this International Standard.

ISO 16895:2016 specifies a classification matrix, related mandatory tests and thickness ranges for ultra-low-, low-, medium- and high-density dry process wood-based fibreboard. It then provides the manufacturing property requirements for these types of uncoated fibreboard. The values listed in this International Standard relate to product properties used to classify fibreboards into one of four types (UDF, LDF, MDF and HDF, see Clause 3), one of four grades (GP, FN, BL and LB), for use in one of four service conditions (REG, MR1, MR2, and HMR). The values are not characteristic values to be used for design purposes. NOTE Fibreboards are broadly divided into two groups based on the manufacturing process, namely the dry process group and the wet process group (see Clause 3). Wet process fibreboards lie outside the scope of this International Standard.

ISO 16895:2016 is classified under the following ICS (International Classification for Standards) categories: 79.060.20 - Fibre and particle boards. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 16895:2016 has the following relationships with other standards: It is inter standard links to ISO 16895-1:2008, ISO 16895-2:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 16895:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 16895

First edition

2016-02-01

Wood-based panels — Dry-process

fibreboard

Panneaux à base de bois — Panneaux de fibres obtenus par

procédé à sec

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

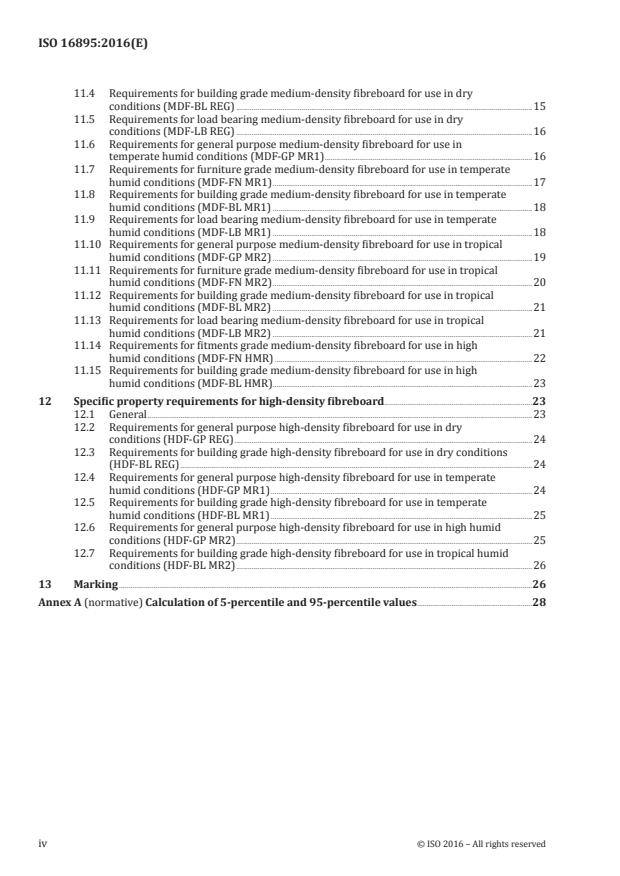

Contents Page

Foreword .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Symbols and abbreviated terms . 2

5 Classification, designation and coding . 3

5.1 General . 3

5.1.1 Classification matrices . 3

5.1.2 Uses . 3

5.1.3 Additional classifications . 3

5.1.4 Structural grades . 4

5.2 Ultra-low-density fibreboard (UDF) . 4

5.3 Low-density fibreboard (LDF). 4

5.4 Medium density fibreboard (MDF) . 4

5.5 High-density fibreboard (HDF) . 5

6 Tests related to each grade . 5

6.1 Mandatory tests . 5

6.2 Optional tests . 6

7 Thickness ranges . 8

8 Expression of specification limits and general requirements . 8

8.1 Expression of specification limits . 8

8.2 Lower specification limits . 8

8.3 Upper specification limits. 9

8.4 Moisture resistance requirement options . 9

8.5 Density variation, dimension and moisture content requirements . 9

8.6 Formaldehyde requirements .10

8.7 Load bearing fibreboard .10

9 Specific property requirements for ultra-low-density fibreboard (UDF-FN REG) .10

10 Specific property requirements for low-density fibreboard .11

10.1 General .11

10.2 Requirements for furniture grade low-density fibreboard for use in dry conditions

(LDF-FN REG) .11

10.3 Requirements for building grade low-density fibreboard for use in dry conditions

(LDF-BL REG) .11

10.4 Requirements for general purpose low-density fibreboard for use in temperate

humid conditions (LDF-GP MR1) .12

10.5 Requirements for furniture grade low-density fibreboard for use in temperate

humid conditions (LDF-FN MR1) .12

10.6 Requirements for building grade low-density fibreboard for use in temperate

humid conditions (LDF-BL MR1) .13

10.7 Requirements for general purpose low-density fibreboard for use in tropical

humid conditions (LDF-GP MR2) .13

10.8 Requirements for furniture grade low-density fibreboard for use in tropical humid

conditions (LDF-FN MR2) .14

11 Specific property requirements for medium-density fibreboard .14

11.1 General .14

11.2 Requirements for general purpose medium-density fibreboard for use in dry

conditions (MDF-GP REG) .15

11.3 Requirements for furniture grade medium-density fibreboard for use in dry

conditions (MDF-FN REG) .15

11.4 Requirements for building grade medium-density fibreboard for use in dry

conditions (MDF-BL REG) .15

11.5 Requirements for load bearing medium-density fibreboard for use in dry

conditions (MDF-LB REG) .16

11.6 Requirements for general purpose medium-density fibreboard for use in

temperate humid conditions (MDF-GP MR1) .16

11.7 Requirements for furniture grade medium-density fibreboard for use in temperate

humid conditions (MDF-FN MR1) .17

11.8 Requirements for building grade medium-density fibreboard for use in temperate

humid conditions (MDF-BL MR1) .18

11.9 Requirements for load bearing medium-density fibreboard for use in temperate

humid conditions (MDF-LB MR1) .18

11.10 Requirements for general purpose medium-density fibreboard for use in tropical

humid conditions (MDF-GP MR2) .19

11.11 Requirements for furniture grade medium-density fibreboard for use in tropical

humid conditions (MDF-FN MR2) .20

11.12 Requirements for building grade medium-density fibreboard for use in tropical

humid conditions (MDF-BL MR2) .21

11.13 Requirements for load bearing medium-density fibreboard for use in tropical

humid conditions (MDF-LB MR2) .21

11.14 Requirements for fitments grade medium-density fibreboard for use in high

humid conditions (MDF-FN HMR) .22

11.15 Requirements for building grade medium-density fibreboard for use in high

humid conditions (MDF-BL HMR) .23

12 Specific property requirements for high-density fibreboard .23

12.1 General .23

12.2 Requirements for general purpose high-density fibreboard for use in dry

conditions (HDF-GP REG) .24

12.3 Requirements for building grade high-density fibreboard for use in dry conditions

(HDF-BL REG) .24

12.4 Requirements for general purpose high-density fibreboard for use in temperate

humid conditions (HDF-GP MR1) .24

12.5 Requirements for building grade high-density fibreboard for use in temperate

humid conditions (HDF-BL MR1) .25

12.6 Requirements for general purpose high-density fibreboard for use in high humid

conditions (HDF-GP MR2) .25

12.7 Requirements for building grade high-density fibreboard for use in tropical humid

conditions (HDF-BL MR2) .26

13 Marking .26

Annex A (normative) Calculation of 5-percentile and 95-percentile values .28

iv © ISO 2016 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 89, Wood-based panels, Subcommittee SC 1,

Fibre boards.

This first edition cancels and replaces ISO 16895-1:2008 and ISO 16895-2:2010, of which the product

classification and specification have been technically revised.

INTERNATIONAL STANDARD ISO 16895:2016(E)

Wood-based panels — Dry-process fibreboard

1 Scope

This International Standard specifies a classification matrix, related mandatory tests and thickness

ranges for ultra-low-, low-, medium- and high-density dry process wood-based fibreboard. It then

provides the manufacturing property requirements for these types of uncoated fibreboard.

The values listed in this International Standard relate to product properties used to classify fibreboards

into one of four types (UDF, LDF, MDF and HDF, see Clause 3), one of four grades (GP, FN, BL and LB),

for use in one of four service conditions (REG, MR1, MR2, and HMR). The values are not characteristic

values to be used for design purposes.

NOTE Fibreboards are broadly divided into two groups based on the manufacturing process, namely the

dry process group and the wet process group (see Clause 3). Wet process fibreboards lie outside the scope of this

International Standard.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 3340, Fibre building boards — Determination of sand content

ISO 9426, Wood-based panels — Determination of dimensions of panels

ISO 9427, Wood-based panels — Determination of density

ISO 12460-1, Wood-based panels — Determination of formaldehyde release — Part 1: Formaldehyde

emission by the 1-cubic-metre chamber method

ISO 12460-2, Wood-based panels — Determination of formaldehyde release — Part 2: Small-scale

chamber method

ISO 12460-3, Wood-based panels — Determination of formaldehyde release — Part 3: Gas analysis method

ISO 12460-4, Wood-based panels — Determination of formaldehyde release — Part 4: Desiccator method

ISO 12460-5, Wood-based panels — Determination of formaldehyde release — Part 5: Perforator method

ISO 16572, Timber structures — Wood-based panels — Test methods for structural properties

ISO 16978, Wood-based panels — Determination of modulus of elasticity in bending and of bending strength

ISO 16979, Wood-based panels — Determination of moisture content

ISO 16981, Wood-based panels — Determination of surface soundness

ISO 16983, Wood-based panels — Determination of swelling in thickness after immersion in water

ISO 16984, Wood-based panels — Determination of tensile strength perpendicular to the plane of the panel

ISO 16985, Wood-based panels — Determination of dimensional changes associated with changes in

relative humidity

ISO 16987, Wood-based panels — Determination of moisture resistance under cyclic test conditions

ISO 16998, Wood-based panels — Determination of moisture resistance — Boil test

ISO 17064, Wood-based panels — Fibreboard, particleboard and oriented strand board (OSB) — Vocabulary

ISO 20585:2005, Wood-based panels — Determination of wet bending strength after immersion in water

at 70 degrees C or 100 degrees C (boiling temperature)

ISO 27528, Wood-based panels — Determination of resistance to axial withdrawal of screws

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 17064 and the following apply.

3.1

dry process fibreboard

wood fibreboard with a forming line moisture content, as a mass fraction, of less than or equal to 20 %

and whose primary bonding results from applied adhesives or resins

3.2

wet process fibreboard

wood fibreboard with a forming line moisture content, as a mass fraction, of greater than 20 % and

whose primary bonding results from felting of wood fibres and their inherent adhesive properties

4 Symbols and abbreviated terms

For the purposes of this document, the following symbols and abbreviated terms apply.

BL building

DIY do-it-yourself

EXT exterior

F fungi resistant

FN furniture

FR fire retardant

GP general purpose

HDF high-density fibreboard

HMR highly moisture resistant

I insect resistant

LB load bearing

LDF low-density fibreboard

MDF medium-density fibreboard

MR1 moisture resistant — temperate

MR2 moisture resistant — tropical

REG regular

UDF ultra-low-density fibreboard

2 © ISO 2016 – All rights reserved

δ thickness

5 Classification, designation and coding

5.1 General

5.1.1 Classification matrices

Overall classification matrices, which include all major classes available at the time of publication, are

shown in Tables 1 to 4. Tables 1 to 4 allow for future classes to be included as they become available on

international markets.

Not all products in the matrices shown in Tables 1 to 4 are currently available or under development.

Realistic property tables can only be developed for existing products. The remainder are potential

future products and property tables will be developed when necessary.

Density ranges given in product descriptions in 5.2 to 5.5 are a guide. Manufacturers may classify a

product as a particular type or grade if it meets all the property requirements of the nominated type or

grade. For example, a thin fibreboard of density 830 kg/m could be called MDF if it meets all property

requirements of the particular MDF grade nominated.

5.1.2 Uses

Products specified in this International Standard have the following applications.

regular REG dry conditions only

moisture resistant — temperate MR1 temperate humid conditions

moisture resistant — tropical MR2 tropical humid conditions

highly moisture resistant HMR high humid conditions

exterior EXT exposed to weather conditions, above ground

general purpose GP applications not requiring the specific properties of

furniture or load-bearing grades

furniture FN in furniture manufacture, cabinet making, fitments, joinery,

bases for surface decorative treatment

building BL building applications requiring high dimensional stability

load bearing LB structural or load bearing

do-it-yourself DIY home projects done by residents rather than professional

tradespersons

5.1.3 Additional classifications

If additional attribute classifications are used, such as fire retardant (FR), insect resistant (I) and

fungi resistant (F), claimed performance shall be confirmed by appropriate testing. Relevant tests and

performance requirements may be specified by national standards and regulations.

5.1.4 Structural grades

When a product is used in a load-bearing or structural application, additional information shall

be available in the form of characteristic values derived from structural testing (see ISO 16572),

experimental test results or history of use to validate its performance under the proposed conditions.

It should be noted that engineering design methods do not provide for design for high humid or exterior

service conditions. The inclusion of the MDF-LB grade in the “high humid” section of the classification

matrix (see Table 3) is on the basis that performance is validated by experimental test results or

history of use.

5.2 Ultra-low-density fibreboard (UDF)

UDF has a nominal density less than 550 kg/m and is classified according to Table 1.

Table 1 — UDF classification matrix

Service conditions

UDF type

Humid

Dry Humid temperate High humid Exterior

tropical

UDF-FN REG furniture grade

No existing No existing No existing No existing

product product product product

Application examples Light-duty partitions

5.3 Low-density fibreboard (LDF)

3 3

LDF has a nominal density in the range 550 kg/m to 650 kg/m and is classified according to Table 2.

Table 2 — LDF classification matrix

Service conditions

LDF type

Dry Humid temperate Humid tropical High humid Exterior

LDF-GP MR1 general purpose MR2 general purpose

No

No existing

Roof Roof

No existing product existing

Application

product

underlay/sheathing, underlay/sheathing,

product

examples

wall sheathing wall sheathing

REG furniture

LDF-FN MR1 furniture grade MR2 furniture grade

grade

No

No existing

existing

Furniture, DIY uses,

product

Application Furniture, DIY uses, Furniture, DIY uses,

product

general uses,

examples general uses general uses

light-duty partitions

LDF-BL REG building grade MR1 building grade

No

No existing

No existing product existing

Application Window frames, Window frames,

product

product

examples door backs door backs

5.4 Medium density fibreboard (MDF)

3 3

MDF has a nominal density in the range 650 kg/m to 800 kg/m and is classified according to Table 3.

4 © ISO 2016 – All rights reserved

Table 3 — MDF classification matrix

Service conditions

MDF type

Dry Humid temperate Humid tropical High humid Exterior

REG general MR1 general

MDF-GP MR2 general purpose

purpose purpose

No

No existing

existing

DIY uses, DIY uses,

product

Application DIY uses, general

product

general uses, general uses,

examples uses, overlay floors

veneer grade overlay floors

MR1 MR2 HMR

REG furniture

MDF-FN furniture/fitments furniture/fitments furniture/fitments

grade

grade grade grade

No

Carcase, furniture, Carcase, furniture,

existing

Carcase, furniture, Fascias, window

cabinets for kitchen cabinets for kitchen

product

Application cabinets, substrate joinery, protected

and bathroom, and bathroom,

examples for any decorative exterior

substrate for any substrate for any

finish construction

decorative finish decorative finish

MDF-LB REG load bearing MR1 load bearing MR2 load bearing

Domestic or

No

Domestic or

industrial flooring,

No existing

Domestic flooring,

existing

Application industrial flooring,

wall and roof

product

shelving, general

product

examples shelving, general

sheathing, beams,

construction

construction

toilet partitions

MDF-BL REG building grade MR1 building grade MR2 building grade HMR building grade

Window frames,

No

Window frames, door linings,

Window frames, Window frames,

existing

Application door linings, bearing bearing

door linings, door linings,

product

examples walls, floor and roof walls, floor and

bearing walls bearing walls

sheathing, underlay roof sheathing,

underlay

5.5 High-density fibreboard (HDF)

HDF has a nominal density greater than 800 kg/m and is classified according to Table 4.

Table 4 — HDF classification matrix

Service conditions

HDF type

Dry Humid temperate Humid tropical High humid Exterior

HDF-GP REG general purpose MR1 general purpose MR2 general purpose

No

No existing

Composite flooring, Composite flooring, Composite flooring,

existing

Application

product

machined articles, wall panelling in public wall panelling in

product

examples

patterns, packaging amenities, packaging public amenities

HDF-BL REG building grade MR1 building grade MR2 building grade

No

No existing

existing

Application

product

Composite flooring Composite flooring Bearing walls

product

examples

6 Tests related to each grade

6.1 Mandatory tests

The mandatory tests shown in Tables 5 to 8 shall be applied to the various fibreboard grades identified

in Tables 1 to 4, respectively. All property requirements shall be met at dispatch from the factory.

6.2 Optional tests

If information on additional properties is agreed between user and manufacturer, it shall be determined

using the test method(s) nominated from ISO 3340, ISO 16985 and/or ISO 27528.

Table 5 — Tests relating to each UDF grade

Property Method UDF-FN

Dimensions ISO 9426 REG

Density variation ISO 9427 REG

Formaldehyde emission ISO 12460-1 REG

Moisture content ISO 16979 REG

Internal bond strength ISO 16984 REG

Bending strength — Modulus of rupture (MOR) ISO 16978 REG

Table 6 — Tests relating to each LDF grade

Property Method LDF-GP LDF-FN LDF-BL

Dimensions ISO 9426 MR1 MR2 REG MR1 MR2 REG MR1

Density variation ISO 9427 MR1 MR2 REG MR1 MR2 REG MR1

Formaldehyde emission ISO 12460-1 MR1 MR2 REG MR1 MR2 REG MR1

Moisture content ISO 16979 MR1 MR2 REG MR1 MR2 REG MR1

Internal bond strength ISO 16984 MR1 MR2 REG MR1 MR2 REG MR1

Bending strength —

ISO 16978 MR1 MR2 REG MR1 MR2 REG MR1

Modulus of rupture (MOR)

Bending stiffness —

ISO 16978 MR1 MR2 REG MR1 MR2 REG MR1

Modulus of elasticity (MOE)

Thickness swelling ISO 16983 MR1 MR2 REG MR1 MR2 REG MR1

Surface soundness ISO 16981 — MR1 MR2 —

ISO 16987

Moisture resistance ISO 16998 MR1 MR2 MR1 MR2 —

ISO 20585

Moisture resistance —

ISO 20585 — — MR1

Wet bending strength

Table 7 — Tests relating to each MDF grade

Property Method MDF-GP MDF-FN MDF-BL MDF-LB

ISO REG MR1 MR2 REG MR1 MR2

Dimensions REG MR1 MR2 REG MR1 MR2

9426 HMR HMR

ISO REG MR1 MR2 REG MR1 MR2

Density variation REG MR1 MR2 REG MR1 MR2

9427 HMR HMR

ISO REG MR1 MR2 REG MR1 MR2

Formaldehyde emission REG MR1 MR2 REG MR1 MR2

12460–1 HMR HMR

ISO REG MR1 MR2 REG MR1 MR2

Moisture content REG MR1 MR2 REG MR1 MR2

16979 HMR HMR

ISO REG MR1 MR2 REG MR1 MR2

Internal bond strength REG MR1 MR2 REG MR1 MR2

16984 HMR HMR

Bending strength —

ISO REG MR1 MR2 REG MR1 MR2

Modulus of rupture REG MR1 MR2 REG MR1 MR2

16978 HMR HMR

(MOR)

6 © ISO 2016 – All rights reserved

Table 7 (continued)

Property Method MDF-GP MDF-FN MDF-BL MDF-LB

Bending stiffness —

ISO REG MR1 MR2 REG MR1 MR2

Modulus of elasticity REG MR1 MR2 REG MR1 MR2

16978 HMR HMR

(MOE)

ISO REG MR1 MR2 REG MR1 MR2

Thickness swelling REG MR1 MR2 REG MR1 MR2

16983 HMR HMR

ISO REG MR1 MR2

Surface soundness — — —

16981 HMR

ISO

ISO

Moisture resistance MR1 MR2 MR1 MR2 HMR — MR1 MR2

ISO

Moisture resistance —

20585 — — MR1 MR2 HMR —

Wet bending strength

Table 8 — Tests relating to each HDF grade

Property Method HDF-GP HDF-BL

Dimensions ISO 9426 REG MR1 MR2 REG MR1

Density variation ISO 9427 REG MR1 MR2 REG MR1

Formaldehyde emission ISO 12460-1 REG MR1 MR2 REG MR1

Moisture content ISO 16979 REG MR1 MR2 REG MR1

Internal bond strength ISO 16984 REG MR1 MR2 REG MR1

Bending strength —

ISO 16978 REG MR1 MR2 REG MR1

Modulus of rupture (MOR)

Bending stiffness —

ISO 16978 REG MR1 MR2 REG MR1

Modulus of elasticity (MOE)

Thickness swelling ISO 16983 MR1 MR2 REG MR1

Surface soundness ISO 16981 REG MR1 MR2 —

ISO 16987

Moisture resistance ISO 16998 MR1 MR2 —

ISO 20585

Moisture resistance —

ISO 20585 — MR1 MR2

Wet bending strength

7 Thickness ranges

Specification values shall be related to the ranges of thickness, δ, shown. The specification of a particular

thickness of product shall be determined by consulting the correct thickness range.

0 mm <δ ≤ 2,5 mm

>2,5 mm <δ ≤ 4,0 mm

>4,0 mm <δ ≤ 6,0 mm

>6,0 mm <δ ≤ 9,0 mm

>9,0 mm <δ ≤ 12 mm

>12 mm <δ ≤ 19 mm

>19 mm <δ ≤ 30 mm

>30 mm <δ ≤ 45 mm

δ > 45 mm

8 Expression of specification limits and general requirements

8.1 Expression of specification limits

This International Standard may be used to evaluate groups of panels or production batches. To

evaluate a group of panels, this requires that

a) the mandatory tests of Tables 5 to 8 be applied to samples of the group. Conditioning of test

specimens is required and is specified in each test method, and

b) the results of the tests be evaluated against the appropriate specification limits in Tables 9 to 38

according to the product types, grades and thickness ranges. Tables 9 and 10 apply to all product

types and thickness ranges of panels.

For density variation and dimensions (see Table 9), specification limits are based on the mean values

for individual panels (calculated in accordance with Annex A) and are maximum tolerances. For

formaldehyde emission, Table 10 gives upper specification limits for individual panel results.

Specification limits in Tables 11 to 38 are based on 5 (lower) or 95 (upper) percentile expressions,

according to 8.2 and 8.3.

8.2 Lower specification limits

The requirements in Tables 11 to 38 are the lower specification limits for the following properties:

a) bending strength — modulus of rupture (MOR);

b) bending stiffness — modulus of elasticity (MOE);

c) internal bond strength;

d) surface soundness;

e) internal bond strength after cyclic test;

f) internal bond strength after boil test;

g) wet bending strength.

8 © ISO 2016 – All rights reserved

The 5-percentile values based on the mean values for individual panels and calculated in accordance

with Annex A shall be equal to or greater than the lower specification limits in Tables 11 to 38.

8.3 Upper specification limits

The requirements in Tables 11 to 38 are the upper specification limits for the following properties:

a) thickness swelling after 24 h;

b) thickness swelling after cyclic test.

The 95-percentile values based on the mean values for individual panels and calculated in accordance

with Annex A shall be equal to or less than the upper specification limits in Tables 11 to 38.

8.4 Moisture resistance requirement options

There are no moisture resistant test requirements for dry condition products (REG).

Requirements for moisture resistant products are dependent on the test method employed to assess

this property. Three alternative sets of requirements (Option 1, Option 2 and Option 3) apply to MR1,

MR2 and HMR products as indicated in the relevant tables.

It is necessary to show compliance with only one of these three options, as follows.

— Option 1: Requirements apply to those fibreboards subjected to a cyclic accelerated ageing test,

followed by the determination of thickness swelling and internal bond, as described in ISO 16987.

— Option 2: Requirements apply to those fibreboards subjected to an accelerated ageing test,

consisting of immersion in boiling water followed by determination of internal bond, as described

in ISO 16998.

— Option 3: Requirements apply to those fibreboards subjected to an accelerated ageing test consisting

of determination of the wet bending strength following immersion in water at 70 °C or immersion in

boiling water for exterior grade products, as described in ISO 20585, Method A or Method B.

BL product types have only Option 3 specified.

NOTE Moisture resistance testing is not intended to prove durability of a new resin system, but to confirm

the correct processing of panels made from a resin system proven to provide the required durability.

8.5 Density variation, dimension and moisture content requirements

At least 95 % of the mean values of the individual panels shall be within the maximum tolerances

stated in Table 9.

Density ranges given for each product type in Clause 5 are a guide only and not a mandatory

specification. Products may be designated as a particular type if they meet the specified requirements

for that type.

Table 9 — Requirements for density variation, dimensions and moisture content

Property Test method Requirement

Density variation within panel ISO 9427 ±10 % max from mean

Length and width ISO 9426 ±2 mm/m, max. ±5 mm

Squareness ISO 9426 <2 mm/m

Thickness range

mm, nominal

Thickness

<8 ≥8 to ≤12 >12

ISO 9426

−0,3 −0,3 −0,5

—Unsanded panel

+1,5 +1,5 +1,7

—Sanded panel ±0,2 ±0,3 ±0,3

Moisture content (advisory only) ISO 16979 5 % to 14 % (see Note)

NOTE This International Standard applies internationally. Wood products attain a moisture content according to the

temperature and relative humidity of their environment. The upper limits of this moisture content range will only apply in

hot, humid areas.

8.6 Formaldehyde requirements

Compliance with formaldehyde requirements can be confirmed by applying one test method only

of those listed in Table 10. The reference chamber method can take up to four weeks for each test to

be completed. The other tests are designated production control methods because one test can be

completed within 24 h. Each individual panel result shall comply with the specification limits stated in

Table 10 for the selected method.

Table 10 — Maximum limits of formaldehyde emission/content

a

Property Method Unit Requirement

Emission ISO 12460-1 mg/m 0,124

3 a

Emission ISO 12460-2 mg/m

Emission ISO 12460-3 mg/m /h 3,5

Emission ISO 12460-4 mg/L 0,7

Content ISO 12460-5 mg/100 g 8,0

NOTE National regulations may impose restrictions on the use of panels of particular formaldehyde emission levels.

a

If this or any other method is used for production control, correlations should be established with the reference

chamber method to determine the emission value that is equivalent to the chamber method limit value stated in this table.

Correlations may be regional, national, company or plant specific as appropriate.

8.7 Load bearing fibreboard

When fibreboard is classified as “load bearing” (LB) and nominated for structural applications,

characteristic strength and stiffness values shall be established based upon testing in accordance with

ISO 16572 or equivalent ASTM or EN standards. Alternatively, for specific load bearing applications

(e.g. walls, roofs, floors, I-joist webs), the load bearing fibreboard shall meet the specific performance

requirements for that intended application.

9 Specific property requirements for ultra-low-density fibreboard (UDF-FN REG)

Ultra low-density fibreboards have a nominal density of less than 550 kg/m .

Requirements for UDF-FN REG fibreboard are listed in Table 11.

10 © ISO 2016 – All rights reserved

Table 11 — Requirements for UDF-FN REG

Requirement

Thickness ranges

Property Test method Units

mm, nominal

>9,0 to ≤12 >12 to ≤19 >19 to ≤30 >30 to ≤45 >45

Bending strength

ISO 16978 MPa 18 14 13 12 12

(MOR)

Internal bond strength ISO 16984 MPa 0,35 0,35 0,30 0,30 0,30

24 h thickness swelling ISO 16983 % 18 16 14 12 12

10 Specific property requirements for low-density fibreboard

10.1 General

3 3

Low-density fibreboards have a nominal density of 550 kg/m to 650 kg/m .

10.2 Requirements for furniture grade low-density fibreboard for use in dry

conditions (LDF-FN REG)

Requirements for LDF-FN REG fibreboard are listed in Table 12.

Table 12 — Requirements for LDF-FN REG fibreboard

Requirement

Thickness ranges

Test mm, nominal

Property Units

method

>6,0 >9,0 >12 >19 >30

to to to to to >45

≤9,0 ≤12 ≤19 ≤30 ≤45

Bending strength (MOR) ISO 16978 MPa 20 20 18 15 14 14

Modulus of elasticity ISO 16987 MPa 1 700 1 700 1 600 1 500 1 400 1 200

(MOE)

Internal bond strength ISO 16984 MPa 0,45 0,45 0,45 0,45 0,40 0,40

24 h thickness swelling ISO 16983 % 20 16 14 12 11 11

10.3 Requirements for building grade low-density fibreboard for use in dry

conditions (LDF-BL REG)

Requirements for LDF-BL REG fibreboard are listed in Table 13.

Table 13 — Requirements for LDF-BL REG fibreboard

Requirement

Thickness ranges

Property Test method Units mm, nominal

>6,0 >9,0

>12 to ≤19 >19 to ≤30 >30

to ≤9,0 to ≤12

Bending strength (MOR) ISO 16978 MPa 15 15 15 15 —

Modulus of elasticity ISO 16987 MPa 1 500 1 500 1 500 1 400 —

(MOE)

Internal bond strength ISO 16984 MPa 0,30 0,30 0,30 0,30 —

24 h thickness swelling ISO 16983 % 20 13 12 8 —

10.4 Requirements for general purpose low-density fibreboard for use in temperate

humid conditions (LDF-GP MR1)

Requirements for LDF-GP MR1 fibreboard are listed in Table 14.

Table 14 — Requirements for LDF-GP MR1 fibreboard

Requirement

Thickness ranges

Test mm, nominal

Property Units

method

>6,0 >9,0 >12 >19 >30

to to to to to >45

≤9,0 ≤12 ≤19 ≤30 ≤45

Bending strength (MOR) ISO 16978 MPa 20 20 18 16 16 14

Modulus of elasticity ISO 16987 MPa 1 700 1 700 1 600 1 500 1 400 1200

(MOE)

Internal bond strength ISO 16984 MPa 0,45 0,45 0,45 0,45 0,40 0,40

24 h thickness swelling ISO 16983 % 18 16 13 12 11 10

Moisture resistance

Option 1: Cyclic test

Internal bond strength ISO 16987 MPa 0,25 0,18 0,16 0,13 0,10 0,10

Thickness swelling % 19 16 15 15 15 15

Option 2: Boil test ISO 16998 MPa 0,12 0,09 0,09 0,09 0,08 0,07

Internal bond strength

Option 3: ISO 20585, MPa 6,0 5,5 4,5 3,5 3,0 3,0

Wet bending strength Method A

10.5 Requirements for furniture grade low-density fibreboard for use in temperate

humid conditions (LDF-FN MR1)

Requirements for LDF-FN MR1 fibreboard are listed in Table 15.

12 © ISO 2016 – All rights reserved

Table 15 — Requirements for LDF-FN MR1 fibreboard

Requirement

Thickness ranges

Test mm, nominal

Property Units

method

>6,0 >9,0 >12 >19 >30

to to to to to >45

≤9,0 ≤12 ≤19 ≤30 ≤45

Bending strength (MOR) ISO 16978 MPa 22 22 20 17 15 15

Modulus of elasticity ISO 16987 MPa 1 800 1 800 1 700 1 500 1 400 1 400

(MOE)

Internal bond strength ISO 16984 MPa 0,50 0,50 0,45 0,40 0,38 0,38

24 h thickness swelling ISO 16983 % 16 13 11 10 10 10

Surface soundness ISO 16981 MPa 0,7 0,7 0,8 0,8 0,8 0,8

Moisture resistance

Option 1: Cyclic test

Internal bond strength ISO 16987 MPa 0,30 0,25 0,20 0,15 0,10 0,10

Thickness swelling % 19 16 15 15 15 15

Option 2: Boil test ISO 16998 MPa 0,15 0,15 0,12 0,12 0,10 0,10

Internal bond strength

Option 3: ISO 20585, MPa 6,5 6,0 5,0 4,0 3,5 3,5

Wet bending strength Method A

10.6 Requirements for building grade low-density fibreboard for use in temperate

humid conditions (LDF-BL MR1)

Requirements for LDF-BL MR1 fibreboard are listed in Table 16.

Table 16 — Requirements for LDF-BL MR1 fibreboard

Requirement

Thickness ranges

Property Test method Units mm, nominal

>9,0 to >19 to

>6,0 to ≤9,0 >12 to ≤19 >30

≤12 ≤30

Bending strength (MOR) ISO 16978 MPa 22 22 22 21 —

Modulus of elasticity ISO 16987 MPa 1 800 1 800 1 800 1 700 —

(MOE)

Internal bond strength ISO 16984 MPa 0,30 0,30 0,30 0,30 —

24 h thickness swelling ISO 16983 % 14,0 9,0 8,0 5,5 —

Moisture resistance — ISO 20585,

Wet bending strength Method A MPa 10,0 10,0 10,0 9,0 —

10.7 Requirements for general purpose low-density fibreboard for use in tropical humid

conditions (LDF-GP MR2)

Requirements for LDF-GP MR2 fibreboard are listed in Table 17.

Table 17 — Requirements for LDF-GP MR2 fibreboard

Requirement

Thickness ranges

Property Test method Units

mm, nominal

>9,0 to ≤12 >12 to ≤19 >19 to ≤30

Bending strength (MOR) ISO 16978 MPa 20 18 17

Modulus of elasticity (MOE) ISO 16987 MPa 1 700 1 600 1 550

Internal bond strength ISO 16984 MPa 0,45 0,45 0,45

24 h thickness swelling ISO 16983 % 12 10 9

Moisture resistance

Option 1: Cyclic test

Internal bond strength MPa 0,20 0,20 0,20

ISO 16987

Thickness swell % 15 15 15

Option 2: Boil test

ISO 16998 MPa 0,10 0,10 0,10

Internal bond strength

Option 3: Wet bending strength ISO 20585, Method A MPa 10 9 8

10.8 Requirements for furniture grade low-density fibreboard for use in tropical humid

conditions (LDF-FN MR2)

Requirements for LDF-FN MR2 fibreboard are listed in Table 18.

Table 18 — Requirements for LDF-FN MR2 fibreboard

Requireme

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...