ISO/TR 18159:2015

(Main)Document management — Environmental and work place safety regulations affecting microfilm processors

Document management — Environmental and work place safety regulations affecting microfilm processors

ISO/TR 18159:2015 provides information about environmental laws and regulations that can affect microfilm processing laboratories. These laws and regulations control the following microfilm processing activities: - storage and disposal of effluents; - storage and disposal of hazardous waste, employee safety training; - notification of the public regarding hazardous waste incidents. NOTE This Technical Report includes in an Annex, for information purposes, a discussion of The United States Environmental Protection Agency (EPA) Guidance Manual on the Development and Implementation of Local Discharge Limitations Under Pretreatment Programme and that guidance manual's relationship with state and local requirements in the United States. Also included in this Technical Report are examples of typical discharge limitations.

Gestion des documents — Réglementations relatives à la sécurité environnementale et du lieu de travail affectant les processeurs de microfilms

General Information

- Status

- Published

- Publication Date

- 21-Jul-2015

- Technical Committee

- ISO/TC 171/SC 1 - Quality, preservation and integrity of information

- Drafting Committee

- ISO/TC 171/SC 1 - Quality, preservation and integrity of information

- Current Stage

- 6060 - International Standard published

- Start Date

- 22-Jul-2015

- Due Date

- 31-May-2016

- Completion Date

- 31-May-2016

Overview

ISO/TR 18159:2015 - Document management - Environmental and work place safety regulations affecting microfilm processors - is a Technical Report published by ISO in 2015. It explains environmental laws and workplace-safety requirements that specifically affect microfilm and photographic processing laboratories. The report helps organizations understand effluent characteristics, hazardous-waste obligations, employee safety training, and public-notification duties so they can achieve regulatory compliance and reduce environmental risk.

Key topics

The Technical Report covers practical technical and regulatory topics relevant to microfilm processors, including:

- Effluent management: pretreatment requirements, stream standards, equalization and holding tanks, septic/leach-field considerations, and example discharge limitations.

- Effluent characteristics: temperature, BOD/COD (oxygen demand), suspended solids, chlorine demand, pH and heavy metals (notably silver, chromium, zinc, cadmium), phenols, cyano and thiocyanate complexes, hydroquinone, ammonium, phosphates, detergents, oils, colour and odour, VOCs and flammables.

- Sampling and analysis: sampling techniques (grab, composite, continuous), sample handling and laboratory analysis best practices.

- Pollution prevention and process controls: squeegees, replenishment rates, good housekeeping, dilution/ equalization strategies.

- Silver recovery and disposal: recovery techniques, regulatory compliance and options for commercial disposal services.

- Hazardous-waste management: container storage, labelling, emergency contingency planning, land-disposal criteria, stormwater and air-pollution considerations.

- Workplace safety: employee training, hazard communication, ventilation guidelines and control of air emissions.

- Annexes with regional guidance: includes a discussion of the U.S. EPA Guidance Manual on local discharge limitations, sample Hazard Communication Programme (OSHA), and country-specific information for France and the UK.

Practical applications and users

ISO/TR 18159:2015 is practical for:

- Microfilm and photographic processing laboratory managers seeking to implement environmental controls and compliance programs.

- Environmental, Health & Safety (EHS) officers responsible for hazardous-waste handling, employee training and emergency planning.

- Archivists and records-management professionals who operate in-house processing labs.

- Consultants and regulators evaluating discharge permits, silver recovery systems and air/waste controls. The report aids in designing sampling programs, selecting silver recovery or disposal strategies, writing safety programs, and aligning local permits with processing operations.

Related standards

- ISO/TC 171 series (Document management applications) - for broader document-management context.

- National and regional regulations (EPA, OSHA, EU directives) - Annexes reference U.S. EPA guidance and national regulatory examples relevant to discharge limits and workplace safety.

Keywords: ISO/TR 18159:2015, microfilm processors, environmental regulations, effluent management, silver recovery, workplace safety, hazardous waste, discharge limits.

Frequently Asked Questions

ISO/TR 18159:2015 is a technical report published by the International Organization for Standardization (ISO). Its full title is "Document management — Environmental and work place safety regulations affecting microfilm processors". This standard covers: ISO/TR 18159:2015 provides information about environmental laws and regulations that can affect microfilm processing laboratories. These laws and regulations control the following microfilm processing activities: - storage and disposal of effluents; - storage and disposal of hazardous waste, employee safety training; - notification of the public regarding hazardous waste incidents. NOTE This Technical Report includes in an Annex, for information purposes, a discussion of The United States Environmental Protection Agency (EPA) Guidance Manual on the Development and Implementation of Local Discharge Limitations Under Pretreatment Programme and that guidance manual's relationship with state and local requirements in the United States. Also included in this Technical Report are examples of typical discharge limitations.

ISO/TR 18159:2015 provides information about environmental laws and regulations that can affect microfilm processing laboratories. These laws and regulations control the following microfilm processing activities: - storage and disposal of effluents; - storage and disposal of hazardous waste, employee safety training; - notification of the public regarding hazardous waste incidents. NOTE This Technical Report includes in an Annex, for information purposes, a discussion of The United States Environmental Protection Agency (EPA) Guidance Manual on the Development and Implementation of Local Discharge Limitations Under Pretreatment Programme and that guidance manual's relationship with state and local requirements in the United States. Also included in this Technical Report are examples of typical discharge limitations.

ISO/TR 18159:2015 is classified under the following ICS (International Classification for Standards) categories: 37.080 - Document imaging applications. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/TR 18159:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 18159

First edition

2015-08-15

Document management —

Environmental and work place safety

regulations affecting microfilm

processors

Gestion des documents — Réglementations relatives à la sécurité

environnementale et du lieu de travail affectant les processeurs de

microfilms

Reference number

©

ISO 2015

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

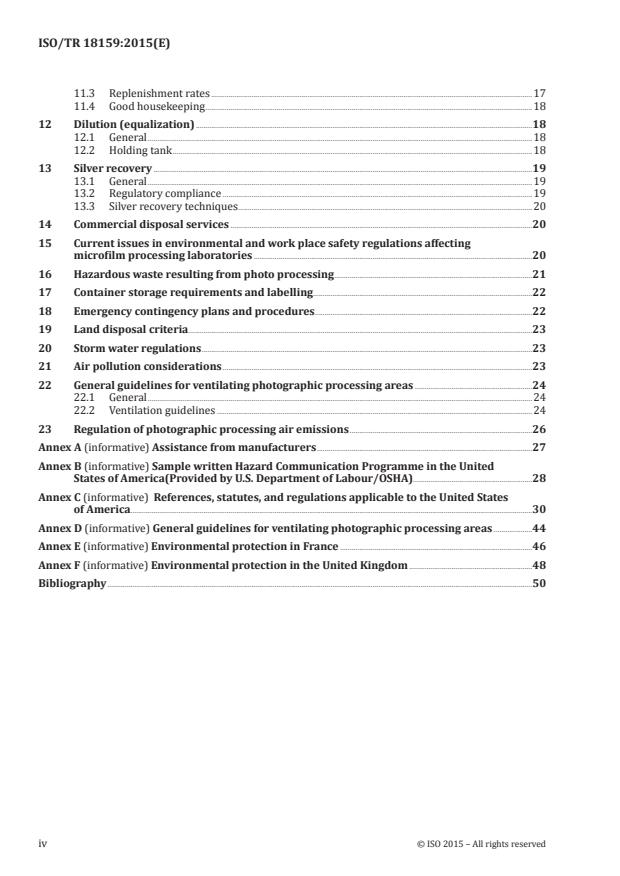

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Terms and definitions . 1

3 International standard industrial classification . 4

4 Effluent pretreatment requirements . 4

5 Stream standards . 5

6 Disposal of photo processing effluents using septic tanks and leach fields .5

7 Trade effluents consents . 5

8 Photographic processing effluent characteristics . 6

8.1 General . 6

8.2 Temperature . 9

8.3 Oxygen demand . 9

8.3.1 General. 9

8.3.2 BOD .

5 9

8.3.3 COD .10

8.4 Suspended solids .10

8.5 Chlorine demand .10

8.6 pH .10

8.7 Heavy metals .10

8.7.1 General.10

8.7.2 Silver .11

8.7.3 Chromium compound .11

8.7.4 Iron complexes .11

8.7.5 Zinc .12

8.7.6 Cadmium .12

8.7.7 Other heavy metals .12

8.8 Phenols .12

8.9 Cyano complexes .12

8.10 Thiocyanate.13

8.11 Hydroquinone .13

8.12 Ammonium .13

8.13 Phosphates and nitrates .13

8.14 Detergents, oils, and tars .13

8.15 Colour and odour .13

8.16 Flammable and explosive materials .13

8.17 Volatile organic compounds (VOC) .14

9 Effluent sampling .14

9.1 General .14

9.2 Sampling techniques .15

9.2.1 General.15

9.2.2 Grab sampling .15

9.2.3 Composite sampling.16

9.2.4 Continuous sampling .16

10 Handling samples for analysis .16

11 Pollution prevention .16

11.1 General .16

11.2 Squeegees .17

11.2.1 General.17

11.2.2 Types of squeegees .17

11.3 Replenishment rates .17

11.4 Good housekeeping .18

12 Dilution (equalization) .18

12.1 General .18

12.2 Holding tank .18

13 Silver recovery .19

13.1 General .19

13.2 Regulatory compliance .19

13.3 Silver recovery techniques .20

14 Commercial disposal services .20

15 Current issues in environmental and work place safety regulations affecting

microfilm processing laboratories .20

16 Hazardous waste resulting from photo processing .21

17 Container storage requirements and labelling.22

18 Emergency contingency plans and procedures .22

19 Land disposal criteria.23

20 Storm water regulations .23

21 Air pollution considerations .23

22 General guidelines for ventilating photographic processing areas .24

22.1 General .24

22.2 Ventilation guidelines .24

23 Regulation of photographic processing air emissions .26

Annex A (informative) Assistance from manufacturers .27

Annex B (informative) Sample written Hazard Communication Programme in the United

States of America(Provided by U.S. Department of Labour/OSHA).28

Annex C (informative) References, statutes, and regulations applicable to the United States

of America.30

Annex D (informative) General guidelines for ventilating photographic processing areas .44

Annex E (informative) Environmental protection in France .46

Annex F (informative) Environmental protection in the United Kingdom .48

Bibliography .50

iv © ISO 2015 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2. www.iso.org/directives

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received. www.iso.org/patents

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

ISO/TR 18159 was prepared by Technical Committee ISO/TC 171, Document Management Applications,

Subcommittee SC 1, Quality.

Introduction

This Technical Report was developed to help microfilm processing laboratories understand

characteristics of effluent resulting from film processing, regulations, comply with regulations, and

report on regulation compliance. The intended audience of this technical report includes those people

responsible for maintaining an organization’s awareness of environmental regulations and those

people responsible for implementing procedures for compliance (such as training and record keeping)

and reporting their implementations.

vi © ISO 2015 – All rights reserved

TECHNICAL REPORT ISO/TR 18159:2015(E)

Document management — Environmental and work place

safety regulations affecting microfilm processors

1 Scope

This Technical Report provides information about environmental laws and regulations that can

affect microfilm processing laboratories. These laws and regulations control the following microfilm

processing activities:

— storage and disposal of effluents;

— storage and disposal of hazardous waste, employee safety training;

— notification of the public regarding hazardous waste incidents.

NOTE This Technical Report includes in an Annex, for information purposes, a discussion of The United

States Environmental Protection Agency (EPA) Guidance Manual on the Development and Implementation of

Local Discharge Limitations Under Pretreatment Programme and that guidance manual’s relationship with

state and local requirements in the United States. Also included in this Technical Report are examples of typical

discharge limitations.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

bath

chemical solution in water used in wet processing

2.2

bleaching

converting the reduced silver of an image to soluble silver sulphate salts, in black-and-white reversal

processing, that will be removed by clearing in colour processing (reversal or negative)

Note 1 to entry: This is the step that converts the reduced silver of an image to silver halide that will be removed

by fixing and washing.

2.3

bleaching/fixing

combining, in a single bath, the bleaching and fixing steps

Note 1 to entry: This is a step in colour processing.

2.4

clearing

removing the soluble silver sulphate salts and the stains, in black-and-white reversal processing,

resulting from bleaching action in colour processing (reversal or negative)

Note 1 to entry: This is the step that removes the stains resulting from bleaching action.

2.5

coupler

chemical compound (e.g. phenols, naphthols, pyrazolones) that combines during

colour development with the oxidation products of the developing agent to form a dye

2.6

coupler

compound that combines with the unexposed diazonium salts to form dyes

2.7

developing agent

active agent of the developer

2.8

development

processing step in which the latent image is made visible

2.9

developer

chemical solution used in the development process

2.10

diazo film

photographic film containing one or more photosensitive layers composed of diazonium salts in a

polymeric material which react with coupler(s), contained either in photosensitive layer(s) or in the

processing solution, to form an azo dye image after film processing

2.11

drying

removing unwanted moisture from photographic materials

Note 1 to entry: This is a step in processing.

2.12

effluent

fluid discharged from a given source into the external environment

[SOURCE: ISO 29464:2011, 3.2.32]

2.13

fixer

chemical used in fixing

2.14

fixing

converting the residual light sensitive silver halides into soluble salts removed by washing to make the

developed image stable

Note 1 to entry: This is a step in processing.

2.15

International Standard Industrial Classification

ISIC

International Standard Industrial Classification of all economic activities

Note 1 to entry: ISIC is the international reference classification of productive activities. Its main purpose is to

provide a set of activity categories that can be utilized for the collection and reporting of statistics according to

such activities (United Nations Statistics Division).

2.16

leach field

leaching field

filter that consists of layers of coarse gravel, fine gravel, coarse sand, and fine sand arranged over one

another so that a liquid flowing through one material does not carry it into the next to clog it

[SOURCE: ISO 6707-1:2014, 5.4.45, modified.]

2 © ISO 2015 – All rights reserved

2.17

micrographics

techniques associated with the production, handling, and use of microforms

2.18.1

microfilm processing

treatment of exposed photographic material by chemical or physical means to make the latent image

clearly visible and ultimately usable

2.18.2

conventional processing

processing, including development, fixing, washing, and drying of silver film in which the polarity of

the original is reversed in the image

2.18.3

reversal processing

processing of silver film in which the polarity of the original is maintained in the image

2.18.4

full reversal processing

reversal processing that requires secondary exposure and development, or a secondary development

using fogging agents

2.18.5

colour processing

processing in which the oxidation products of the developing agent react with a coupler incorporated in

the developer or film to produce a dye close to each silver grain

2.18.6

dry processing

processing in which chemicals incorporated in the film react to heat or gas or both

2.18.7

wet processing

processing using chemicals in liquid form

2.18.8

deep-tank processor

deep-tank microfilm photoprocessor

developing machine containing 30 litres to 60 litres of liquid in each bath, wherein the chemicals are

automatically replenished, and with a built-in hot air dryer

2.19

replenishment

replacing exhausted chemistry, in photographic film and paper processing, in a continuous or per-batch

fashion using fresh chemistry

Note 1 to entry: This is a process used in chemical processing.

2.20

sludge

accumulated settled solids separated from various types of water as a result of natural or artificial

processes

[SOURCE: ISO 6707-1:2014, 10.27]

2.21

squeegee

device for scraping the excess water from the film, consisting e.g. of a holder and a blade

2.22

toxicity characteristic leaching procedure

TCLP

soil sample extraction method for chemical analysis employed as an analytical method to simulate

leaching through a landfill

2.23

TSDF

Treatment, Storage, and Disposal Facility

facility that is permitted to treat, store, and/or dispose hazardous waste in special units

Note 1 to entry: These units are commonly called hazardous waste management units. A facility may be permitted

to accept hazardous wastes for treatment, storage, and/or disposal from outside generators (a commercial TSDF)

or be permitted to treat, store, or dispose of its own hazardous waste (a private TSDF).

2.24

UN number

UN ID four-digit number that identifies hazardous substances and articles (such as explosives,

flammable liquids, toxic substances, etc.) in the framework of international transport

Note 1 to entry: Some hazardous substances have their own UN numbers (e.g. acrylamide has UN2074), while

sometimes groups of chemicals or products with similar properties receive a common UN number (e.g. flammable

liquids, not otherwise specified, have UN1993). A chemical in its solid state may receive a different UN number

than the liquid phase if their hazardous properties differ significantly; substances with different levels of purity

(or concentration in solution) may also receive different UN numbers.

Note 2 to entry: UN numbers range from UN0001 to about UN3506 and are assigned by the United Nations

Committee of Experts on the Transport of Dangerous Goods. They are published as part of their Recommendations

on the Transport of Dangerous Goods, also known as the Orange Book. These recommendations are adopted by

the regulatory organization responsible for the different modes of transport.

Note 3 to entry: There is no UN number allocated to non-hazardous substances. These will simply not have a UN

number.

2.25

washing

removing unwanted soluble chemicals from photographic materials using water

Note 1 to entry: This is a step in processing.

3 International standard industrial classification

Microfilm processing falls under International Standard Industrial Classification, Rev. Four (ISIC)

M 7420 — Photographic activities. This ISIC number is often requested for permits and survey forms.

4 Effluent pretreatment requirements

Although microfilm processing laboratories may not be specifically regulated, guidelines exist

for water discharge. The applicable regulation is for silver and affects those microfilm processing

laboratories that directly discharge to a receiving body of water. One can determine the amount of

silver discharged from a specific microfilm processing laboratory by collecting a representative sample

of the photo processing waste water and having it analysed by a certified analytical laboratory. Because

most microfilm processing laboratories do not discharge directly to surface water but discharge to a

municipal treatment system instead, they are not directly affected by these limits.

Microfilm processing laboratories which discharge to receiving bodies of water may be required to

have a permit. If the microfilm processing laboratory discharges directly to a surface stream, contact

the local water pollution control agency.

4 © ISO 2015 – All rights reserved

5 Stream standards

Discharge permits are required by regulatory agencies. Water quality standards regulate direct

discharges into receiving bodies of water. These standards are usually stricter than sewer codes

because they reflect the quality of water after treatment. Nearly all standards include a clause that

prohibits discharging any substance that will injure fish or other aquatic life.

6 Disposal of photo processing effluents using septic tanks and leach fields

Most locations specifically prohibit the use of septic tanks for anything other than domestic waste, and

most manufacturers of photographic materials and chemistries do not recommend discharge to a septic

system. Septic tanks are used for the disposal of domestic waste primarily in areas where municipal

sewers are unavailable. Septic tanks operate with anaerobic biological action; that is, the wastes are

broken down by living organisms in the absence of an adequate oxygen supply.

One of the concerns about using a septic tank/leach field system is that, photographic effluents can

adversely affect the anaerobic digestion system unless the effluents are heavily diluted with domestic

wastes. Another concern is that, the soil may not have adequate capacity to absorb the leach field runoff.

With a septic tank/leach field system, care needs to be taken to prevent contamination of ground water.

Most governments have regulations governing industrial discharges (for example, photo processing

effluent) to ground waters. In addition, many governments have regulations on the design, installation,

and testing of septic tank systems.

Microfilm processing laboratories using septic tank/leach field systems or spray irrigation systems

should be aware of permit requirements and potential limitations on discharges from such systems.

Contact the appropriate environmental regulatory agency for additional information.

7 Trade effluents consents

A permit to discharge photo processing waste to a municipal sewer system can be required. Trade

effluent consents to discharge can specify limits for concentrations of some parameters, such as the

following:

— biochemical oxygen demand (BOD);

— chemical oxygen demand (COD);

— suspended solids;

— metals.

Because most microfilm processing laboratories are located in urban areas and discharge their effluent

directly to public sewers, municipal sewer code regulations are of high concern. Pollutants most

frequently regulated and their typical limits are shown in Table 1. The consent issued will set limits

for pollutants likely to be in the discharge and the limits will be set to prevent adverse impacts on the

sewers and treatment processes and the people operating them. The rate of discharge and maximum

volume discharged per day is also likely to be specified in the consent.

Table 1 — Typical trade effluent limits

Parameter Range of regulations

pH 6 to 10

Temperature (Maximum) 43 °C

Biochemical oxygen demand (BOD) (Maximum) 1 000

Chemical oxygen demand (COD) 2 000

Total suspended solids (TSS) 1 000

Total dissolved solids (TDS) 2 000

Phenols 10

Total cyanide 2

Oil and grease 200

Chromium 3

Iron 50

Silver 1

Zinc 3

NOTE All units except temperature and pH are specified in mg/L (ppm).

8 Photographic processing effluent characteristics

8.1 General

Photographic processing effluents vary in composition among microfilm processing laboratories

because of the different processes available and the laboratories’ operating differences, such as

— daily operating time of each process,

— number of processes,

— chemical replenishment rates,

— amount of wash water used,

— volume of effluent,

— ratio of processing wastes to non-processing wastes, and

— recycling, reuse, and regeneration.

The general characteristics that are typical of conventional processing effluents are shown in Table 2.

Table 3 to Table 4 show effluent characteristics for conventional process deep-tank microfilm photo

processing, replenishment rates for conventional process deep-tank microfilm photo processing,

effluent characteristics for full-reversal deep-tank microfilm photo processing, and replenishment

rates for full-reversal deep-tank microfilm photo processing.

6 © ISO 2015 – All rights reserved

Table 2 — General characteristics of microfilm effluent

Characteristic Typical concentrations

Temperature 27 °C to 43 °C

Biochemical oxygen demand (BOD ) 200 to 3 000

Chemical oxygen demand (COD) 400 to 5 000

Suspended solids (Total) <50

pH 6,5 to 9,0

Flammable; explosive None

Detergents Minimal

Oils and grease 0 to 50

Phenol 0 to 10

Odour Scarcely detectable

a

Silver 0,5 to 100

Cadmium <0,02

b

Chromium <0,5 to 50

Copper <0,5

Iron <0,5

Lead <0,05

Lithium <0,5

Mercury <0,002

Nickel <0,5

Zinc <0,5

Barium <0,5

TKN - nitrogen 200 - 500

NH - nitrogen 150 - 400

Total phosphorus <0,5

NOTE All units expressed in mg/L unless otherwise noted.

a

A notification requirement exists for discharge of hazardous waste down the sewer, e.g.

greater than 5,0 parts per million (ppm) of silver. Silver content depends upon processing

system and silver recovery technique.

b

Depends upon process solutions used.

Table 3 — Conventional process deep-tank microfilm photo processing effluent characteristics

Parameter Concentration

pH 7,6

Temperature 30 °C

Biochemical oxygen demand (BOD ) 350

NOTE All units are in mg/L unless otherwise specified.

a

ND = Not detected (detection limit).

b

Before silver recovery.

c Estimated concentration mg/L after silver recovery.

Table 3 (continued)

Parameter Concentration

Chemical oxygen demand (COD) 1 900

Total suspended solids <2

Total dissolved solids (TDS) 1 660

Ammonia - nitrogen 380

Total Kjeldahl Nitrogen (TKN) 410

Sulphite 250

Thiosulphite 1 600

Sulfate 135

Phenol None

Colour 25 Hazen units

Flammable; explosive None

Detergents Minimal

Odour Scarcely detectable

Chloride demand 940 to 1100

Total phosphorous <0,03

Total metals

Aluminium 11

a

Boron ND < 0,1

a

Barium ND < 0,2

a

Cadmium ND < 0,4

a

Chromium ND < 0,5

a

Copper ND < 0,5

a

Iron ND < 0,5

a

Lead ND < 2

a

Lithium ND < 0,5

Manganese 0,18

Magnesium 9,4

a

Mercury ND < 0,2 ng/L

Nickel < 1

a

Selenium ND < 50 ng/L

b c

Silver 72 < 5

Sodium 110

a

Tin ND < 4

a

Zinc ND < 0,5

NOTE All units are in mg/L unless otherwise specified.

a

ND = Not detected (detection limit).

b

Before silver recovery.

c Estimated concentration mg/L after silver recovery.

8 © ISO 2015 – All rights reserved

Table 4 — Conventional process deep-tank microfilm photo processing effluent

characteristics — Replenishment rates

Product Replenishment rate

(metric equivalents)

Microfilm developer 187,3 mLs/m

Microfilm fixer 233,6 mLs/m

Wash rate 12,9 L/m

Machine speed 7,7 M/min

8.2 Temperature

The temperature of some of the most widely used photographic processes is in the 26,7 °C to 43,3 °C

range. This temperature range from a microfilm processing laboratory is unlikely to present a problem

to a municipal sewer system.

8.3 Oxygen demand

8.3.1 General

BOD and COD are procedures used to determine the amount of oxygen that will be consumed by

effluent.

8.3.2 BOD

The BOD test measures the quantity of oxygen that the effluent, chemical, or solution will consume

over a five-day period through biological degradation. It is important to know the oxygen demand of

discharged waste because the waste can overload the aeration capacity of a municipal secondary waste

water treatment plant if the waste demands too much oxygen. Discharging improperly treated wastes

could deplete the amount of dissolved oxygen in a receiving body of water.

Normally, water contains 7 mg/L to 9 mg/L of dissolved oxygen at 21 °C. (This concentration decreases

as the temperature increases.) Most fish and other aquatic life require 5 mg/L to 7 mg/L of dissolved

oxygen for survival. Amounts of dissolved oxygen below these levels can affect aquatic life and can also

result in the production of strong smelling gases. A BOD of 400 mg/L or 400 parts per million (ppm)

means that 1 l of the effluent would consume 400 mg of oxygen in five days in a natural body of water.

The BOD analysis attempts to duplicate in the laboratory the environmental conditions in a receiving

body of water and to measure the oxygen demand that the discharged material places on the body of

water. The test is highly dependent on several variables, including the following:

— temperature;

— appropriate microorganisms being present;

— sample dilution;

— storage condition for the sample;

— toxicity;

— length of time between sampling and analysis.

Despite the dependency on these variables, a BOD analysis can be included as a consent requirement.

The oxygen demand of photographic effluent, as measured by a BOD test, will also vary widely

depending on the amount of wash water used, the composition of the processing solutions, and the

varying combinations of processing and non-processing waste. The BOD of effluent from various

photographic processing laboratories typically has been found to be in the range of 300 mg/L to 3

000 mg/L.

8.3.3 COD

In the Chemical Oxygen Demand (COD) test, the photographic effluent in question is subjected to a

strong oxidizing chemical which oxidizes not only the biodegradable organic material but also non-

biodegradable material.

The COD value will be larger or similar to the BOD ; the ratio of the two values gives an indication of the

biodegradability of the sample. The COD test does not suffer from the many variables of the BOD, so it is

more reproducible, hence, it is generally used for trade effluent consents.

8.4 Suspended solids

Suspended solids are undissolved matter carried in effluent. These solids are removed during primary

and secondary waste water treatment. Left untreated, they can build up sufficient sediment over a

period of time to fill stream channels and reservoirs, erode power turbines and pumping equipment,

plug water filters, and reduce available sunlight to aquatic plants. Photographic processing effluent is

typically very low in suspended solids (less than 50 mg/L) and therefore should not present a problem

to municipal treatment plants.

8.5 Chlorine demand

One operation a sewage treatment plant may perform is to chlorinate the effluent after the other

treatment stages used in the plant. Chlorination can be used to destroy any pathogenic organisms and

disinfect the effluent after treatment, thus, providing an additional measure of health protection.

Chlorine demand is the amount of chlorine needed to provide a certain residual chlorine content

(usually 0,5 mg/L) after a specific time (often 15 min). The chlorine demand test is no longer widely

used because water-quality experts have begun to recognize that excessive chlorination can produce

chloramines and other harmful, persistent products from wastes that were originally less harmful by

themselves.

8.6 pH

The pH level is an indication of how acidic or alkaline (basic) the solution is. It is a measurement of

the hydrogen ion concentration and is expressed as the negative logarithm of the hydrogen ion

concentration. The pH values run from 0 to 14,0, with the lower numbers indicating acidic materials,

higher numbers indicating basic materials, and 7,0 representing neutrality. Almost every sewer code

contains restrictions on the minimum and maximum pH of mixed effluent discharge. Most are in the

range of 6 to 10. The pH of photographic effluent does not present a problem to waste treatment systems

because it is generally in the range of 6 to 10.

8.7 Heavy metals

8.7.1 General

Materials classified as heavy metals are commonly regulated by local sewer authorities. These metals

include cadmium, chromium, cobalt, copper, gold, iron, lead, manganese, mercury, molybdenum, nickel,

silver, and zinc.

The concentration of heavy metals in the effluent is regulated because of the toxicity of these metals

or their compounds. The toxicity can vary with the particular metal or compound and with the form

in which the metal exists (for example, as a free ion, a complex, or a precipitate). Some photosensitive

photographic products do contain small amounts of metals that may appear in the effluent. Heavy

10 © ISO 2015 – All rights reserved

metals frequently found in photographic processing effluent and commonly regulated include the

following:

— silver;

— iron complexes, zinc.

8.7.2 Silver

Silver compounds are the light-sensitive material used in most of today’s photographic films and papers.

Neither elemental silver nor silver compounds are packaged components of processing solutions. Many

silver compounds are toxic to some extent.

During processing, primarily in the fixing bath, silver is removed from the film or paper and is carried

out in the solution or wash overflow, usually in the form of a silver thiosulphate complex.

Recovering the silver before discharge is recommended as a practice that is sound both environmentally

and economically. Not only does silver recovery have environmental benefits and conserve a natural

resource, but selling the recovered silver becomes a source of revenue to a microfilm processing

laboratories.

Local sewer authorities regulate the compound because they cannot distinguish between toxic and

non-toxic forms of silver. In some locations, the discharge standards for silver can be lower than

conventional silver recovery equipment can achieve.

8.7.3 Chromium compound

Some process systems cleaners contain chromium compounds. However, many microfilm processing

+6

laboratories do not use any products that contain chromium. Hexavalent chromium (Cr ) as present in

chromates, etc., can be harmful to treatment systems and requires tight control. Some municipal sewer

+6 +3

codes have specific limits for Cr , Cr (trivalent chromium), and total chromium. Non-chromium

systems cleaners are quite prevalent in today’s market, thus, the use of chromium containing solutions

is avoidable.

+6 +3

Cr can be reduced to Cr , which is less hazardous. When a dichromate bleach is mixed with other

alkaline processing solutions and with solutions that contain reducing agents, such as thiosulphate,

±6 +3

the Cr is reduced to Cr and precipitated as chromium hydroxide. Chromium hydroxide would be

removed during primary or secondary clarification at the waste water treatment plant in sludge; since

sludge is often intended to go to agriculture, sewage treatment plants limits the amount of chromium

allowed in trade effluent. Remove chromium before discharge by collecting the chromium-bearing

liquid in tanks and reducing the hexavalent chromium to the trivalent form by adding bisulphate.

By adding an alkaline material to adjust the solution to pH 8, the chromium can be precipitated as

chromium hydroxide. This chromium hydroxide sludge may have to be managed as a hazardous

waste under local government regulations. Microfilm processing laboratories currently using a bleach

containing chromium should check with their supplier for an alternative non-chromium process.

8.7.4 Iron complexes

Iron complexes are commonly used in colour photographic processing bleaches or bleach-fixers.

Also, the use of cartridges (steel wool metallic replacement cartridges) for silver recovery results in

photographic effluents containing iron. Iron is not a typical component of processing solutions for

microfilm processing.

Iron concentration in effluent is commonly regulated because it affects the appearance and taste of

+3

water and it readily oxidizes to the reddish ferric (Fe ) form, which precipitates and causes rust stains.

Iron can also clog the gills of fish. The iron in photographic effluent is not generally a problem be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...