ISO/PAS 21448:2019

(Main)Road vehicles — Safety of the intended functionality

Road vehicles — Safety of the intended functionality

The absence of unreasonable risk due to hazards resulting from functional insufficiencies of the intended functionality or by reasonably foreseeable misuse by persons is referred to as the Safety Of The Intended Functionality (SOTIF). This document provides guidance on the applicable design, verification and validation measures needed to achieve the SOTIF. This document does not apply to faults covered by the ISO 26262 series or to hazards directly caused by the system technology (e.g. eye damage from a laser sensor). This document is intended to be applied to intended functionality where proper situational awareness is critical to safety, and where that situational awareness is derived from complex sensors and processing algorithms; especially emergency intervention systems (e.g. emergency braking systems) and Advanced Driver Assistance Systems (ADAS) with levels 1 and 2 on the OICA/SAE standard J3016 automation scales. This edition of the document can be considered for higher levels of automation, however additional measures might be necessary. This document is not intended for functions of existing systems for which well-established and well-trusted design, verification and validation (V&V) measures exist at the time of publication (e.g. Dynamic Stability Control (DSC) systems, airbag, etc.). Some measures described in this document are applicable to innovative functions of such systems, if situational awareness derived from complex sensors and processing algorithms is part of the innovation. Intended use and reasonably foreseeable misuse are considered in combination with potentially hazardous system behaviour when identifying hazardous events. Reasonably foreseeable misuse, which could lead directly to potentially hazardous system behaviour, is also considered as a possible event that could directly trigger a SOTIF-related hazardous event. Intentional alteration to the system operation is considered feature abuse. Feature abuse is not in scope of this document.

Véhicules routiers - Sécurité de la fonction attendue

General Information

Relations

Standards Content (Sample)

PUBLICLY ISO/PAS

AVAILABLE 21448

SPECIFICATION

First edition

2019-01

Road vehicles — Safety of the intended

functionality

Véhicules routiers - Sécurité de la fonction attendue

Reference number

©

ISO 2019

© ISO 2019

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2019 – All rights reserved

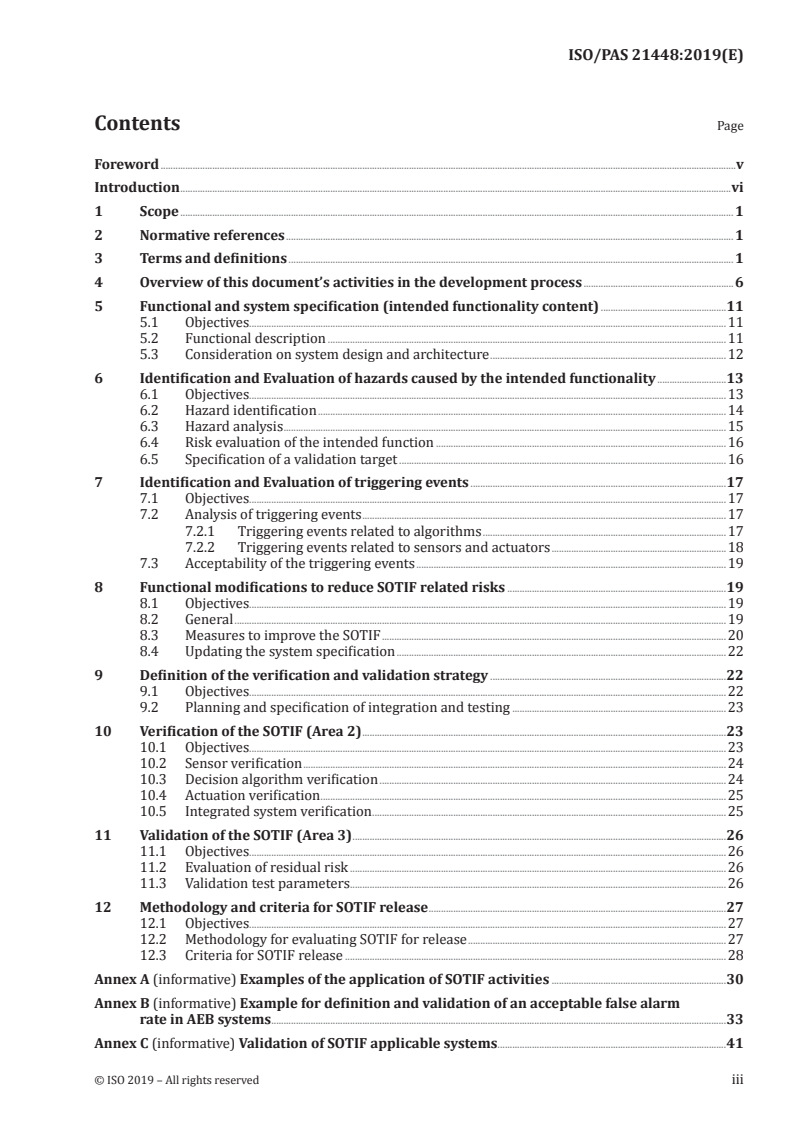

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Overview of this document’s activities in the development process .6

5 Functional and system specification (intended functionality content) .11

5.1 Objectives.11

5.2 Functional description .11

5.3 Consideration on system design and architecture .12

6 Identification and Evaluation of hazards caused by the intended functionality .13

6.1 Objectives.13

6.2 Hazard identification .14

6.3 Hazard analysis .15

6.4 Risk evaluation of the intended function .16

6.5 Specification of a validation target .16

7 Identification and Evaluation of triggering events .17

7.1 Objectives.17

7.2 Analysis of triggering events .17

7.2.1 Triggering events related to algorithms .17

7.2.2 Triggering events related to sensors and actuators .18

7.3 Acceptability of the triggering events .19

8 Functional modifications to reduce SOTIF related risks .19

8.1 Objectives.19

8.2 General .19

8.3 Measures to improve the SOTIF .20

8.4 Updating the system specification .22

9 Definition of the verification and validation strategy .22

9.1 Objectives.22

9.2 Planning and specification of integration and testing .23

10 Verification of the SOTIF (Area 2) .23

10.1 Objectives.23

10.2 Sensor verification .24

10.3 Decision algorithm verification .24

10.4 Actuation verification .25

10.5 Integrated system verification .25

11 Validation of the SOTIF (Area 3) .26

11.1 Objectives.26

11.2 Evaluation of residual risk .26

11.3 Validation test parameters.26

12 Methodology and criteria for SOTIF release .27

12.1 Objectives.27

12.2 Methodology for evaluating SOTIF for release .27

12.3 Criteria for SOTIF release .28

Annex A (informative) Examples of the application of SOTIF activities .30

Annex B (informative) Example for definition and validation of an acceptable false alarm

rate in AEB systems .33

Annex C (informative) Validation of SOTIF applicable systems .41

Annex D (informative) Automotive perception systems verification and validation.43

Annex E (informative) Method for deriving SOTIF misuse scenarios.46

Annex F (informative) Example construction of scenario for SOTIF safety analysis method .49

Annex G (informative) Implications for off-line training .52

Bibliography .54

iv © ISO 2019 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso

.org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 32,

Electrical and electronic components and general system aspects.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

Introduction

The safety of road vehicles during their operation phase is of paramount concern for the road vehicles

industry. Recent years have seen a large increase in the number of advanced functionalities included

in vehicles. These rely on sensing, processing of complex algorithms and actuation implemented by

electrical and/or electronic (E/E) systems.

An acceptable level of safety for road vehicles requires the avoidance of unreasonable risk caused by

every hazard associated with the intended functionality and its implementation, especially those not

due to failures, e.g. due to performance limitations. ISO 26262-1 defines the vehicle safety as the absence

of unreasonable risks that arise from malfunctions of the E/E system. ISO 26262-3 specifies a Hazard

Analysis and Risk Assessment to determine vehicle level hazards. This evaluates the potential risks due

to malfunctioning behaviour of the item and enables the definition of top-level safety requirements,

i.e. the safety goals, necessary to mitigate the risks. The other parts of the ISO 26262 series provide

requirements and recommendations to avoid and control random hardware failures and systematic

failures that could violate safety goals.

For some systems, which rely on sensing the external or internal environment, there can be potentially

hazardous behaviour caused by the intended functionality or performance limitation of a system that is

free from the faults addressed in the ISO 26262 series. Examples of such limitations include:

— The inability of the function to correctly comprehend the situation and operate safely; this also

includes functions that use machine learning algorithms;

— Insufficient robustness of the function with respect to sensor input variations or diverse

environmental conditions.

The absence of unreasonable risk due to these potentially hazardous behaviours related to such

limitations is defined as the safety of the intended functionality (SOTIF). Functional safety (addressed

by the ISO 26262 series) and SOTIF are distinct and complementary aspects of safety.

To address the SOTIF, activities are implemented during the following phases:

— Measures in the design phase;

EXAMPLE Requirement on sensor performance.

— Measures in the verification phase;

EXAMPLE Technical Reviews, test cases with a high coverage of relevant scenarios, injection of

potential triggering events, in the loop testing (e.g. SIL/HIL/MIL) of selected SOTIF are relevant use cases.

— Measures in the Validation phase.

EXAMPLE Long term vehicle test, simulations.

A proper understanding of the function by the user, its behaviour and its limitations (including the

human/machine interface) is the key to ensuring safety.

In many instances, a triggering event is necessary to cause a potentially hazardous behaviour; hence

the importance of analysing hazards in the context of particular use cases.

In this document the hazards caused by a potentially hazardous system behaviour, due to a triggering

event, are considered both for use cases when the vehicle is correctly used and for use cases when it

is incorrectly used in a reasonably foreseeable way (this excludes intentional alterations made to the

system’s operation).

EXAMPLE Lack of driver attention while using a level 2 driving automation.

In addition, reasonably foreseeable misuse, which could lead directly to potentially hazardous system

behaviour, is also considered as a possible triggering event.

vi © ISO 2019 – All rights reserved

A successful attack exploiting vehicle security vulnerabilities can also have very serious consequences

(i.e. data or identity theft, privacy violation, etc.). Although security risks can also lead to potentially

hazardous behaviour that needs to be addressed, security is not addressed by this document.

It is assumed that the E/E random hardware faults and systematic faults of the E/E system are

addressed using the ISO 26262 series. The activities mentioned in this document are complementary to

those given in the ISO 26262 series.

Table 1 illustrates how the possible causes of hazardous event map to existing standards.

Table 1 — Overview of safety relevant topics addressed by different ISO standards

Source Cause of hazardous event Within scope of

E/E System failures ISO 26262 series

Performance limitations or insufficient situa-

tional awareness, with or without reasonably ISO/PAS 21448

foreseeable misuse

ISO/PAS 21448

System

ISO 26262 series

Reasonably foreseeable misuse, incorrect HMI

(e.g. user confusion, user overload) European statement of principal

on the design of human-ma-

chine-interface

Hazards caused by the system technology Specific standards

successful attack exploiting vehicle security

a

ISO 21434 or SAE J3061

vulnerabilities

Impact from active Infrastructure and/or vehi-

External cle to vehicle communication, external devices ISO 20077 series; ISO 26262 series

factor and cloud services.

Impact from car surroundings (other users,

ISO/PAS 21448

“passive” infrastructure, environmental condi-

ISO 26262 series

tions: weather, Electro-Magnetic Interference…)

a

Under preparation. Stage at the time of publication: ISO/SAE CD 21434.

NOTE Options for automated driving level definitions (from NHTSA, SAE and OICA, etc.) are discussed in the

ITS-Informal Group ECE/TRANS/WP29.

PUBLICLY AVAILABLE SPECIFICATION ISO/PAS 21448:2019(E)

Road vehicles — Safety of the intended functionality

1 Scope

The absence of unreasonable risk due to hazards resulting from functional insufficiencies of the

intended functionality or by reasonably foreseeable misuse by persons is referred to as the Safety

Of The Intended Functionality (SOTIF). This document provides guidance on the applicable design,

verification and validation measures needed to achieve the SOTIF. This document does not apply to

faults covered by the ISO 26262 series or to hazards directly caused by the system technology (e.g. eye

damage from a laser sensor).

This document is intended to be applied to intended functionality where proper situational awareness

is critical to safety, and where that situational awareness is derived from complex sensors and

processing algorithms; especially emergency intervention systems (e.g. emergency braking systems)

and Advanced Driver Assistance Systems (ADAS) with levels 1 and 2 on the OICA/SAE standard J3016

automation scales. This edition of the document can be considered for higher levels of automation,

however additional measures might be necessary. This document is not intended for functions of

existing systems for which well-established and well-trusted design, verification and validation (V&V)

measures exist at the time of publication (e.g. Dynamic Stability Control (DSC) systems, airbag, etc.).

Some measures described in this document are applicable to innovative functions of such systems,

if situational awareness derived from complex sensors and processing algorithms is part of the

innovation.

Intended use and reasonably foreseeable misuse are considered in combination with potentially

hazardous system behaviour when identifying hazardous events.

Reasonably foreseeable misuse, which could lead directly to potentially hazardous system behaviour, is

also considered as a possible event that could directly trigger a SOTIF-related hazardous event.

Intentional alteration to the system operation is considered feature abuse. Feature abuse is not in scope

of this document.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 26262-1:2018, Road vehicles — Functional Safety Part 1: Vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 26262-1:2018 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at http: //www .electropedia .org/

3.1

action

atomic behaviour that is executed by any actor in a scene

Note 1 to entry: The temporal sequence of actions/events and scenes specify a scenario.

EXAMPLE Ego vehicle activates the hazard warning lights.

3.2

erroneous pattern

input that can trigger unintended behaviour

3.3

event

occurrence at a certain place and at a particular point in time

Note 1 to entry: The temporal sequence of actions/events and scenes specify a scenario.

Note 2 to entry: In particular this document addresses triggering events (3.15) and hazardous events. A hazardous

event is the combination of a hazard (caused by malfunctioning behaviour) and a specific operational situation.

Refer to Figure 12 for details.

EXAMPLE 1 Tree falling on a street 50 m ahead of a vehicle XY.

EXAMPLE 2 Traffic light turning green at time XX:XX.

3.4

functional improvement

modification to a function, system or element specification to reduce risk

3.5

intended behaviour

specified behaviour of the intended functionality including interaction with items

Note 1 to entry: See Clause 5 for additional information about the specification of intended behaviour.

Note 2 to entry: The specified behaviour is the behaviour that the developer of the item considers to be the

nominal (i.e. fault-free) functionality, with its capability limitations due to inherent characteristics of the

components and technology used.

3.6

intended functionality

behaviour specified for a system

3.7

misuse

usage of the system by a human in a way not intended by the manufacturer of the system

Note 1 to entry: Misuse can result from overconfidence in the performance of the system.

Note 2 to entry: Misuse includes human behaviour that is not specified but does not include deliberate system

alterations.

3.8

misuse scenario

scenario in which misuse occurs

3.9

performance limitation

insufficiencies in the implementation of the intended functionality

EXAMPLE Incomplete perception of the scene, insufficiency of the decision algorithm, insufficient

performance of actuation.

2 © ISO 2019 – All rights reserved

3.10

Safety Of The Intended Functionality

SOTIF

absence of unreasonable risk due to hazards resulting from functional insufficiencies of the intended

functionality or from reasonably foreseeable misuse by persons

Note 1 to entry: Nominal performance includes intended functionality and the implementation of intended

functionality that can be affected by performance limitations or by foreseeable misuse by persons.

3.11

scenario

description of the temporal development between several scenes in a sequence of scenes

Figure 1 — Scenario (dashed) as a temporal sequence of actions/events (edges) and scenes

(nodes)

Note 1 to entry: Every scenario starts with an initial scene. Actions and events, as well as goals and values, may

be specified to characterise this temporal development within a scenario. In contrast to a scene, a scenario spans

a certain amount of time.

[1]

Note 2 to entry: See Figures 1, 2 and 3 .

Figure 2 — Taxonomy of use case, scene and scenario

Figure 3 — Temporal view of scenes, events, actions and situations in a scenario

3.12

scene

snapshot of the environment including the scenery, dynamic elements, and all actor and observer self-

representations, and the relationships between those entities

Note 1 to entry: See Figure 4.

Note 2 to entry: Only a scene representation in a simulated world can be all-encompassing (i.e. an objective

scene, or ground truth). In the real world the scene is incomplete, incorrect, uncertain, and from one or several

observers’ points of view (i.e. a subjective scene).

[1]

Note 3 to entry: Refer to Reference .

Figure 4 — Characteristics of a scene

4 © ISO 2019 – All rights reserved

3.13

situation

selection of an appropriate behaviour pattern at a particular point of time

Note 1 to entry: A situation entails all relevant conditions, options and determinants for the behaviour. A situation

is derived from the scene, by an information selection and augmentation process that is based on transient (e.g.

mission-specific) as well as permanent goals and values. Hence, a situation is always subjective as it represents

an element’s point of view.

[1]

Note 2 to entry: See Figure 5 and Reference .

Figure 5 — Characteristics of a situation

3.14

test case

set of conditions to determine if a system is working according to its intended functionality

Note 1 to entry: A test case entails a (logical) scenario with a specific set of parametric values for each aspect of

the scenario, together with the pass-fail criteria on which to evaluate it.

[2]

Note 2 to entry: Refer to Reference .

3.15

triggering event

specific conditions of a driving scenario that serve as an initiator for a subsequent system reaction

possibly leading to a hazardous event

EXAMPLE While operating on a highway, a vehicle’s automated emergency braking (AEB) system

misidentifies a road sign as a lead vehicle resulting in braking at X g for Y seconds.

3.16

use case

specification of a generalized field of application, possibly entailing the following information about

the system:

— one or several scenarios;

— the functional range;

— the desired behaviour; and

— the system boundaries

Note 1 to entry: The use case description typically does not include a detailed list of all relevant scenarios for this

use case. Instead a more abstract description of these scenarios is used.

3.17

unexpected item behaviour

unintended behaviour not specified

Note 1 to entry: The unintended behaviour might be discovered during validation.

3.18

validation

set of activities gaining confidence that an item is able to accomplish its expected functionalities and

missions

Note 1 to entry: Verification activities address mainly Area 2 of Figures 7, 8 and 9 including the verification

of known use cases, whereas Validation activities address mainly Area 3 of Figures 7, 8 and 9, including the

validation of SOTIF in unknown use cases.

4 Overview of this document’s activities in the development process

The objective sub-clauses of this document (5.1, 6.1, 7.1, 8.1, 9.1, 10.1, 11.1 and 12.1) are normative. All

other content is informative. Compliance to this document can be claimed by listing the objectives and

providing an argument that the objectives have been achieved.

A development interface agreement can be defined between all development parties when applicable

for a distributed product development. The goal of an agreement is to confirm in the early stages of a

project all responsibilities of the SOTIF activities.

Achieving SOTIF requires some activities which are complementary to the ISO 26262:2018 series. One

of the main objectives of this document is to outline the process and rationale used to ensure that the

likelihood of a hazardous event is sufficiently low. Furthermore, this document also seeks to assess that

the remaining residual risk from:

i) a system not able to process a given scenario in a safe manner, and

ii) the involved persons (driver, other vehicle occupants, or bystanders) are not capable of mitigating

the hazardous event, is acceptable (see Figure 6).

The functional and system specification includes relevant use cases and those use cases are comprised

of several relevant scenarios. These scenarios could contain triggering events (see Clause 3 definitions)

that lead to harm (see Figure 6).

6 © ISO 2019 – All rights reserved

a

These scenarios can also be caused by reasonably foreseeable misuse, e.g. activating a functionality intended for

the highway in an urban setting causes the vehicle to be in a scenario in which it does not detect a red traffic light.

b

Reasonably foreseeable misuse can lead directly to a hazard, e.g. in case of mode confusion where the driver

assumes that the system is active even though it is deactivated.

c

The inability to control the hazardous event can also be the result of a reasonably foreseeable misuse, e.g. the

driver does not supervise the system as he is supposed to do.

Figure 6 — Visualisation of a Potential SOTIF-related Hazardous Event Model

Within this document, the scenarios which are part of the relevant use cases are therefore classified

into four areas (see Figure 7).

Key

1 known safe scenarios (Area 1)

2 known unsafe scenarios (Area 2)

3 unknown unsafe scenarios (Area 3)

4 unknown safe scenarios (Area 4)

Figure 7 — Visualisation of the Known/Unknown and Safe/Unsafe Scenario categories

Areas 1, 2 and 3 are used as a mental model to structure this document. Area 4 is referenced for

completeness but is not needed for the purposes of this document and therefore not used further. When

considering the areas in the model, it can be useful to imagine their size as representing the proportion

of each type of scenario that falls within each respective area.

A given use case can include known as well as unknown scenarios.

At the beginning of the development Areas 2 and Area 3 might be too large, resulting in unacceptable

residual risk. The ultimate goal of the SOTIF activities to evaluate the SOTIF in Area 2 and Area 3 and to

provide an argument that these areas are sufficiently small and therefore that the resulting residual risk

is acceptable. While the known scenarios and the corresponding use cases of Area 2 can be explicitly

evaluated, the scenarios and corresponding use cases of Area 3 are evaluated by industry best practice

or by other approaches such as design measures, systematic analyses, or dedicated experiments. The

results of these evaluations provide an argument that Area 3 is sufficiently small and Area 2 is managed

through SOTIF improvements and therefore the probability of encountering these kinds of scenarios is

sufficiently low.

It is expected that Areas 2 and Area 3 will be reduced and Area 1 will grow during development

(see Figure 8).

Key

1 known safe scenarios (Area 1)

2 known unsafe scenarios (Area 2)

3 unknown unsafe scenarios (Area 3)

4 unknown safe scenarios (Area 4)

Figure 8 — Evolution of the scenario categories resulting from the ISO/PAS 21448 activities

The goals of the SOTIF process with respect to Area 1, Area 2, and Area 3 and relevant scenarios are:

— Area 1: Maximize or maintain area, while minimizing Areas 2 & 3. This retains or improves safe

functionality.

— Area 2: Minimize area with technical measures to an acceptably small level, with statistical

significance of that level appropriate to the relative impact of the technical measure; evaluate the

potential risk and, if necessary, move hazardous scenarios into Area 1 by improving the function or

by restricting the use/performance of the function.

— Area 3: Minimize area (the risk of the unknown) as much as possible with an acceptable level of

effort (every detected hazardous scenario is moved into Area 2).

8 © ISO 2019 – All rights reserved

Figure 9 describes a flowchart for the improvement of the intended functionality to ensure its safety.

The circled numbers denote the corresponding clauses within this document.

Figure 9 — Flowchart of this document’s activities

In Figure 9, the process starts with a definition of the functional and system specification (see Clause 5).

The possible hazardous behaviours of the intended function are subjected to a Hazard Identification

and Risk Evaluation (see Clause 6) that identifies potential hazardous events. If it is shown that these

potentially hazardous events do not lead to harm, then no improvement is necessary and the intended

functionality can be considered free from unreasonable risk.

If it is shown that harm is possible, then an analysis of the possible hazardous triggering events (e.g.

misdetection of certain objects under certain environmental conditions or driver misuse) is conducted

(see Clause 7).

Clause 6 and Clause 7 address different aspects of the SOTIF. Clause 6 does not consider the causes of

possible hazardous intended behaviour of the function, but only their consequences for safety. Clause 6

is, therefore, focused on evaluating hazardous events that could result from hazardous intended

behaviour, and on defining the verification and validation targets to be met. Clause 7 addresses the

analysis of the causes of potentially hazardous behaviour. These are mitigated in Clause 8 and verified

and validated in Clause 9, Clause 10 and Clause 11.

Functional improvement or restrictions of the use cases are applied to avoid these hazards or to further

reduce the resulting risk (see Clause 8).

A verification and validation strategy is developed to provide an argument that the residual risk is below

an acceptable level (see Clause 9). This includes enforcement of the resulting strategy. Corresponding

verification and validation test cases can be derived from this analysis (see Clauses 10 & 11).

Finally, the residual risk is evaluated (Clause 12) considering the results from verification and validation.

If the risk is determined to be unacceptable, further functional improvement or restrictions of the use

cases can be necessary (Clause 8). This verification and validation strategy can include model-in-the-

loop (MIL), software-in-the-loop (SIL), hardware-in-the-loop (HIL), test track experiments, dedicated

analyses, long-term endurance tests, or other approaches.

Possible causes of unintended behaviour considered in this document are closely related to the

performance of sensing, processing of algorithms, actuation, and their implementation for the

functionality under development. Therefore, this document’s activities are applicable to the vehicle,

system, and component levels.

Similarly, the selection of a capable, overall system architecture becomes a primary concern to ensure

the SOTIF, and, to ensure that overall capability, corresponding activities take place both at early stages

and throughout the overall functional development lifecycle.

It can be necessary to include specific mechanisms to ensure the SOTIF. For instance, a dedicated

Human-Machine Interface (HMI) can be defined to prevent/mitigate some reasonably foreseeable

misuses by the driver (see Annex E). During the product development, both this document’s activities

and activities specified in the ISO 26262:2018 series activities are carried out and the measures for

SOTIF are evaluated.

Figure 10 — Possible interactions of product development activities between this document

and the ISO 26262 series processes

Figure 10 describes possible interactions between this document and the ISO 26262:2018 series

activities. The product development phases will typically require several iterations to produce a final

functional and system specification. These iterations are not represented in the figure.

10 © ISO 2019 – All rights reserved

A set of methods and measures are selected in order to:

— Identify and evaluate the SOTIF related hazards associated with the intended functionality

(Clause 6);

— Identify and evaluate hazardous triggering events (Clause 7);

— Improve the system design as necessary through functional modifications or use case restriction to

reduce SOTIF risk (Clause 8); and

— Verify and validate the appropriateness of the design with respect to the SOTIF (Clause 9–11).

NOTE The hazard identification process is similar to the process described in ISO 26262-3:2018, because

the vehicle-level effects of SOTIF related potentially hazardous behaviour and the system failures covered by the

ISO 26262 series can be identical.

Annex A presents an example of application of the SOTIF activities.

This document provides a non-exhaustive collection of methods and measures, from which the

development team can select the appropriate combination. Other equivalent methods can also be

applied.

5 Functional and system specification (intended functionality content)

5.1 Objectives

The functional and system specification activity shall:

— Compile and create evidence containing the information sufficient to initiate the SOTIF related

activities;

— Update the evidence as necessary after each iteration of the SOTIF related activities (see Figure 9).

5.2 Functional description

The functional and system specification includes (where applicable):

Function related:

— The goals of the intended functionality;

— The use cases in which the intended functionality is activated, deactivated and active;

— The description of the intended functionality;

— The level of automation/authority over the vehicle dynamics; and

— The dependencies on, and interaction with:

— the car driver, passengers, pedestrians and other road users;

— relevant environmental conditions; and

— the interfaces with the road infrastructure.

System related:

— The description of the system and elements implementing the intended functionality.

— The description and behaviour of the installed sensors, controllers and actuators used by the

intended functionality.

— The assumptions about how the intended functionality makes use of inputs from other elements.

— The assumptions about how other elements make use of outputs from the intended functionality.

— The concepts and technologies for the system and sub systems.

— The limitations and their countermeasures.

— The system architecture supporting the countermeasures.

— The degradation concept.

— The warning strategies.

— The dependencies on, and interaction with other functions and systems of the vehicle.

NOTE This document and the ISO 26262-3:2018 item definition can contain common information.

5.3 Consideration on system design and architecture

The functional and system specification provides an adequate understanding of the system and its

functionality so that the activities in subsequent phases can be performed. This includes a list of all

performance limitations and their countermeasures. Some limitations and countermeasures are

known and documented before the SOTIF related process begins while others are revealed as a result

of the SOTIF activities.

Each iteration of the SOTIF related activity (Figure 9) can result in engineering activity and an update

to this specification. Each iteration relies on this specification being up to date, such that it reflects all

information discovered in previous iterations. Cooperation between all development parties (OEM, Tier1,

TierN) is used to discover limitations and develop countermeasures during all development phases.

The functional and system specification lists performance limitations of every individual mechanisms,

algorithms, or elements related to the safety of the intended functionality. The system is thus designed

considering such limitations and ensuring that countermeasures are taken to mitigate their effect on

the overall system if needed.

As the SOTIF activities identify new limitations and consequences (Clause 7), and define new mitigation

measures (Clause 8), the functional and system specification is updated. This will ensure that all the

required work is done both for closure of previous iterations, and at the beginning of the next iteration.

Specifically, the design includes considerations of system limitations that can result in erroneous

subsystem output values being reported with high confidence (low confidence values might be ignored

by design) and which can lead to potentially hazardous behaviour. Examples of limitations include

incorrect classification, incorrect measurements, incorrect tracking, misdetection, ghosts, incorrect

target selection, incorrect kinematic estimation, etc.

The final system architecture achieves robustness by considering every component, technology and

system limitation. The system development is based on the assumption made about the limitations in

design. Implementing measures to ensure SOTIF and integrating them into the functional and system

specification, decreases the sizes of Area 2 and Area 3, and increases overall robustness by increasing

the size of Area 1. Area 3 testing is used to uncover new issues only when the countermeasures, with

respect to the original system design, are incomplete or not applicable to newly introduced use cases.

NOTE 1 Methods such as qualitative fault tree, HAZOP, FMEA, STPA and event tree analysis can be used to

increase the confidence for the SOTIF.

NOTE 2 Performance limitations can be addressed by redundancy, diversity, functional restrictions or other

measures.

12 © ISO 2019 – All rights reserved

EXAMPLE 1 A highway lane boundary detection algorithm, for functions such as lane keeping, might

incorrectly determine the lane due to debris on the roadway. However, lane excursions that result in a collision can

be mitigated by other autonomous driving functionality such as: using a high definition map and localization to

confirm the lane, rationalizing the vehicle trajectory with the trajectory of preceding vehicles, collision avoidance

algorithms maintaining separation with other vehicles even if this implies leaving the perceived lane, etc.

EXAMPLE 2 An object detection algorithm detects a person on a skateboard as a pedestrian but rejects

the object as due to its speed being implausible. A collision with the skateboarder is mitigated by a collision

mitigation braking system which uses sensing and processing that is independent from that of the object

detection algorithm.

EXAMPLE 3 An optical illusion drawing of a child running into the road is used to alert drivers in some areas.

The image is drawn specifically to fool the human perception and can also fool a vision system into detecting a

non-existent object. In this case, an optical flow-based analysis mechanism can prevent false braking. Optical

flow analyses as well as radar-based environment recognition are alternative countermeasures for such cases, as

well as other common detection cases such as ghosts that result from classification errors.

Figure 11 — Example of optical illusion drawing that could fool a vision system

EXAMPLE 4 Using an automated parking system with a big item protruding from the open trunk can lead to

a hazardous event. A countermeasure in the system design can be to only permit automatic parking when the

trunk is closed.

6 Identification and Evaluation of hazards caused by the inte

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.