ISO 22181:2021

(Main)Aerospace fluid systems and components — Variable displacement hydraulic motors — General specifications

Aerospace fluid systems and components — Variable displacement hydraulic motors — General specifications

This document establishes the general requirements for variable displacement uni-directional and bi-directional hydraulic motors, suitable for use in aircraft hydraulic systems at pressures up to 35 000 kPa (5 000 psi). These requirements include: — design requirements; — test requirements. Primary and secondary function motors (see Clause 4) are covered in this document; however, actuators with internal rotation angle limits and low-speed motors are not covered. This document is intended to be used in conjunction with the detail specification that is particular to each application.

Titre manque

General Information

- Status

- Published

- Publication Date

- 08-Feb-2021

- Technical Committee

- ISO/TC 20/SC 10 - Aerospace fluid systems and components

- Drafting Committee

- ISO/TC 20/SC 10/WG 9 - Hydraulic power and actuation equipment

- Current Stage

- 9020 - International Standard under periodical review

- Start Date

- 15-Jan-2026

- Completion Date

- 15-Jan-2026

Overview

ISO 22181:2021 - Aerospace fluid systems and components - Variable displacement hydraulic motors - General specifications - defines the general requirements for variable displacement uni-directional and bi-directional hydraulic motors intended for aircraft hydraulic systems at pressures up to 35 000 kPa (5 000 psi). The standard covers design and test requirements for primary and secondary function motors but explicitly excludes actuators with internal rotation angle limits and low-speed motors. ISO 22181:2021 is intended to be used together with a project-specific detail specification for each application.

Key topics and technical requirements

ISO 22181:2021 organizes comprehensive technical requirements, including:

Functional requirements

- Hydraulic fluid compatibility and rated operating pressures (supply, differential, case drain, return)

- Flow specifications (rated consumption, case drain flow, leakage limits)

- Speed, direction of rotation and dynamic characteristics (braking, reversals)

- Torque definitions (rated, break-out, stalling, torque pulsations)

- Efficiency, response time, stability and passive operation limits

- Temperature and acoustic noise constraints

Design and construction

- Dimensionally critical components, maintainability and lubrication

- Seals, balance, safety-wire provisions, electro-conductive bonding

- Marking and nameplate information, fluid identification and port labelling

Strength and durability

- Proof and ultimate pressures for motor case and ports

- Pressure impulse (fatigue) requirements and port strength

- Rated endurance, environmental and corrosion protection expectations

Installation, maintenance and quality

- Dimensional, mass, mounting, orientation and drive-shaft interface requirements

- Service life limitations, storage, reliability requirements and quality assurance provisions

- Requirement to meet applicable airworthiness regulations and qualification procedures

Practical applications and who uses it

ISO 22181:2021 is essential for:

- Aerospace OEMs specifying variable displacement hydraulic motors for flight control, landing gear, flight actuation and utility systems.

- Hydraulic motor manufacturers and suppliers designing, testing and certifying motors for aircraft use.

- Systems and mechanical engineers integrating motors into aircraft hydraulic systems to ensure compatibility and airworthiness.

- Test laboratories and certification bodies conducting prototype qualification, endurance and environmental testing.

- Maintenance and procurement teams using the standard for acceptance, overhaul criteria and supplier evaluation.

Using ISO 22181 helps ensure consistent safety, performance and interoperability of hydraulic motors across the aerospace supply chain.

Related standards

ISO 22181:2021 is intended to be used alongside project-specific detail specifications and other aerospace fluid systems and airworthiness standards (system-level, material and testing standards and relevant regulatory guidance). These complementary documents establish application-specific tests, certification and integration requirements.

Buy Documents

ISO 22181:2021 - Aerospace fluid systems and components -- Variable displacement hydraulic motors -- General specifications

ISO 22181:2021 - Aerospace fluid systems and components — Variable displacement hydraulic motors — General specifications Released:2/9/2021

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

ISO 22181:2021 is a standard published by the International Organization for Standardization (ISO). Its full title is "Aerospace fluid systems and components — Variable displacement hydraulic motors — General specifications". This standard covers: This document establishes the general requirements for variable displacement uni-directional and bi-directional hydraulic motors, suitable for use in aircraft hydraulic systems at pressures up to 35 000 kPa (5 000 psi). These requirements include: — design requirements; — test requirements. Primary and secondary function motors (see Clause 4) are covered in this document; however, actuators with internal rotation angle limits and low-speed motors are not covered. This document is intended to be used in conjunction with the detail specification that is particular to each application.

This document establishes the general requirements for variable displacement uni-directional and bi-directional hydraulic motors, suitable for use in aircraft hydraulic systems at pressures up to 35 000 kPa (5 000 psi). These requirements include: — design requirements; — test requirements. Primary and secondary function motors (see Clause 4) are covered in this document; however, actuators with internal rotation angle limits and low-speed motors are not covered. This document is intended to be used in conjunction with the detail specification that is particular to each application.

ISO 22181:2021 is classified under the following ICS (International Classification for Standards) categories: 49.080 - Aerospace fluid systems and components. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 22181:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 22181

First edition

2021-02

Aerospace fluid systems and

components — Variable displacement

hydraulic motors — General

specifications

Reference number

©

ISO 2021

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

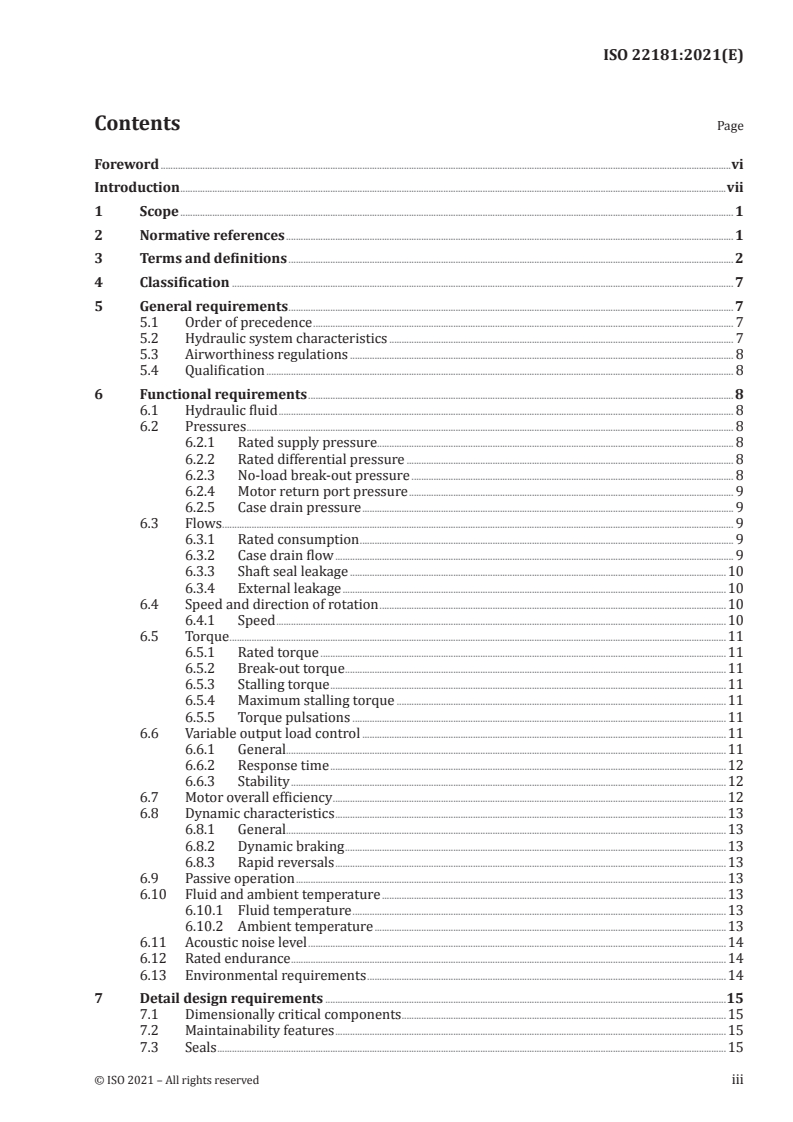

Contents Page

Foreword .vi

Introduction .vii

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Classification . 7

5 General requirements . 7

5.1 Order of precedence . 7

5.2 Hydraulic system characteristics . 7

5.3 Airworthiness regulations . 8

5.4 Qualification . 8

6 Functional requirements . 8

6.1 Hydraulic fluid . 8

6.2 Pressures . 8

6.2.1 Rated supply pressure. 8

6.2.2 Rated differential pressure . 8

6.2.3 No-load break-out pressure . 8

6.2.4 Motor return port pressure . 9

6.2.5 Case drain pressure . 9

6.3 Flows . 9

6.3.1 Rated consumption . 9

6.3.2 Case drain flow . 9

6.3.3 Shaft seal leakage .10

6.3.4 External leakage .10

6.4 Speed and direction of rotation .10

6.4.1 Speed .10

6.5 Torque .11

6.5.1 Rated torque .11

6.5.2 Break-out torque .11

6.5.3 Stalling torque .11

6.5.4 Maximum stalling torque .11

6.5.5 Torque pulsations .11

6.6 Variable output load control .11

6.6.1 General.11

6.6.2 Response time .12

6.6.3 Stability .12

6.7 Motor overall efficiency .12

6.8 Dynamic characteristics .13

6.8.1 General.13

6.8.2 Dynamic braking .13

6.8.3 Rapid reversals .13

6.9 Passive operation .13

6.10 Fluid and ambient temperature .13

6.10.1 Fluid temperature .13

6.10.2 Ambient temperature .13

6.11 Acoustic noise level .14

6.12 Rated endurance .14

6.13 Environmental requirements .14

7 Detail design requirements .15

7.1 Dimensionally critical components .15

7.2 Maintainability features .15

7.3 Seals .15

7.4 Lubrication .15

7.5 Balance .15

7.6 Self-contained failure .16

7.7 Safety wire sealing .16

7.8 Electro-conductive bonding .16

7.9 Marking .16

7.9.1 Nameplate .16

7.9.2 Modification standard .16

7.9.3 Fluid identification .16

7.9.4 Ports .16

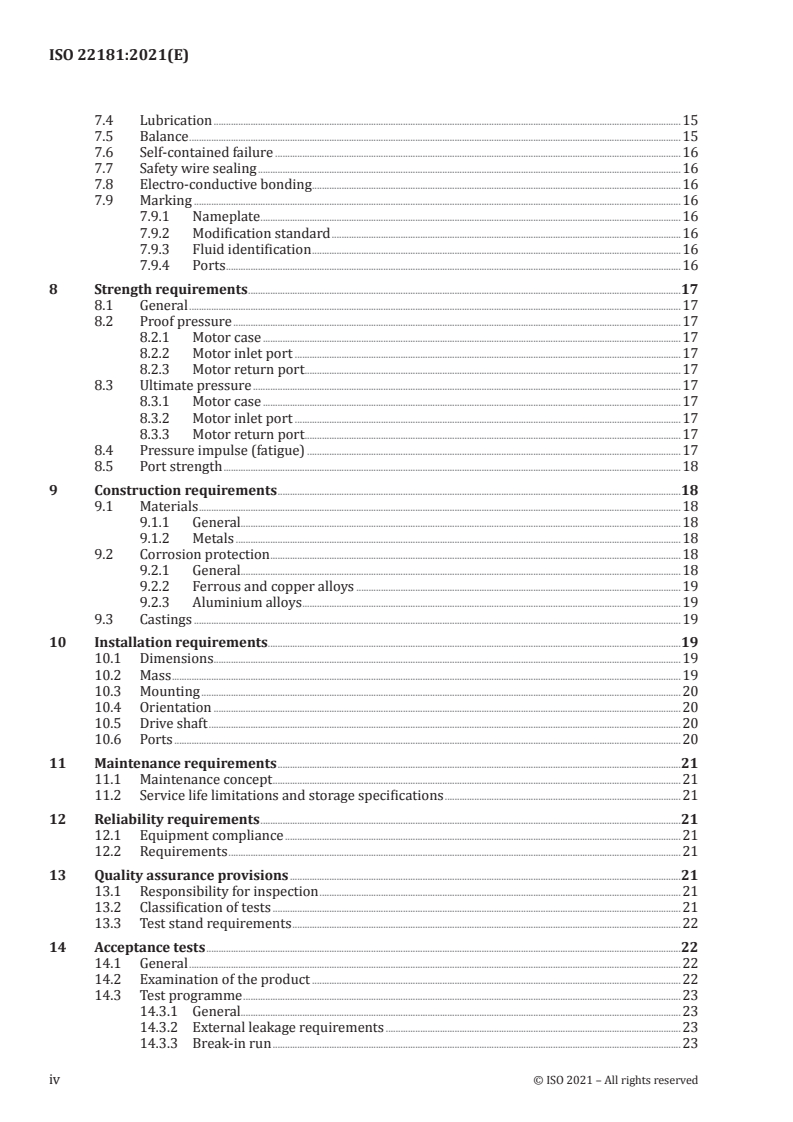

8 Strength requirements .17

8.1 General .17

8.2 Proof pressure .17

8.2.1 Motor case .17

8.2.2 Motor inlet port .17

8.2.3 Motor return port .17

8.3 Ultimate pressure .17

8.3.1 Motor case .17

8.3.2 Motor inlet port .17

8.3.3 Motor return port .17

8.4 Pressure impulse (fatigue) .17

8.5 Port strength .18

9 Construction requirements .18

9.1 Materials .18

9.1.1 General.18

9.1.2 Metals .18

9.2 Corrosion protection .18

9.2.1 General.18

9.2.2 Ferrous and copper alloys .19

9.2.3 Aluminium alloys .19

9.3 Castings .19

10 Installation requirements.19

10.1 Dimensions .19

10.2 Mass .19

10.3 Mounting .20

10.4 Orientation .20

10.5 Drive shaft .20

10.6 Ports .20

11 Maintenance requirements .21

11.1 Maintenance concept .21

11.2 Service life limitations and storage specifications .21

12 Reliability requirements .21

12.1 Equipment compliance .21

12.2 Requirements .21

13 Quality assurance provisions .21

13.1 Responsibility for inspection .21

13.2 Classification of tests .21

13.3 Test stand requirements .22

14 Acceptance tests .22

14.1 General .22

14.2 Examination of the product .22

14.3 Test programme .23

14.3.1 General.23

14.3.2 External leakage requirements .23

14.3.3 Break-in run .23

iv © ISO 2021 – All rights reserved

14.3.4 Proof pressure and overspeed tests .23

14.3.5 Operational tests at rated conditions .24

14.3.6 Break-out torque test .24

14.3.7 Teardown inspection examination .24

14.3.8 Run-in .25

14.3.9 Speed control test .25

14.3.10 Performance data .25

14.3.11 Fluid contamination test .26

14.4 Storage and packaging .27

15 Qualification procedures .27

15.1 General .27

15.2 Qualification procedure .27

15.2.1 Qualification by analogy .27

15.2.2 Motor qualification test report .27

15.2.3 Samples and program of qualification tests .27

15.3 Qualification testing .28

15.3.1 Dimensional check .28

15.3.2 Expanded envelope acceptance tests .28

15.3.3 Overspeed test .28

15.3.4 Operational test at overpressure .29

15.3.5 Calibration .29

15.3.6 Endurance testing .31

15.3.7 Environmental tests .34

15.3.8 Structural tests .35

15.3.9 Combination tests .37

15.3.10 Supplementary tests .37

Bibliography .38

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 20, Aircraft and space vehicles,

Subcommittee SC 10, Aerospace fluid systems and components.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

vi © ISO 2021 – All rights reserved

Introduction

It is noted that, while ISO standards refer to SI units, large segments of the aerospace industry refer

to other measurement systems as a matter of common working practice. All dimensions used in this

document are in SI units with the non-SI units given in addition for the convenience of those users more

familiar with these.

It is further noted that the standard ISO decimal symbol “,” (comma) is not used as common working

practice for inch dimensions. A decimal point is used in the inch dimensions in this document as in

many other aerospace standards.

NOTE The use of non-SI units and the decimal point in this document does not constitute general acceptance

of measurement systems other than SI within International Standards.

INTERNATIONAL STANDARD ISO 22181:2021(E)

Aerospace fluid systems and components — Variable

displacement hydraulic motors — General specifications

1 Scope

This document establishes the general requirements for variable displacement uni-directional and

bi-directional hydraulic motors, suitable for use in aircraft hydraulic systems at pressures up to

35 000 kPa (5 000 psi).

These requirements include:

— design requirements;

— test requirements.

Primary and secondary function motors (see Clause 4) are covered in this document; however, actuators

with internal rotation angle limits and low-speed motors are not covered.

This document is intended to be used in conjunction with the detail specification that is particular to

each application.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 2093, Electroplated coatings of tin — Specification and test methods

ISO 2669, Environmental tests for aircraft equipment — Steady-state acceleration

ISO 2671, Environmental tests for aircraft equipment — Part 3.4 : Acoustic vibration

ISO 2685, Aircraft — Environmental test procedure for airborne equipment — Resistance to fire in

designated fire zones

ISO 3323, Aircraft — Hydraulic components — Marking to indicate fluid for which component is approved

ISO 3601-1, Fluid power systems — O-rings — Part 1: Inside diameters, cross-sections, tolerances and

designation codes

ISO 7137, Aircraft — Environmental conditions and test procedures for airborne equipment

ISO 7320, Aerospace — Couplings, threaded and sealed, for fluid systems — Dimensions

ISO 8078, Aerospace process — Anodic treatment of aluminium alloys — Sulfuric acid process, undyed coating

ISO 8079, Aerospace process — Anodic treatment of aluminium alloys — Sulfuric acid process, dyed coating

ISO 8399-1, Aerospace — Accessory drives and mounting flanges (Metric series) — Part 1: Design criteria

ISO 8399-2, Aerospace — Accessory drives and mounting flanges (Metric series) — Part 2: Dimensions

ISO 8625-1, Aerospace — Fluid systems — Vocabulary — Part 1: General terms and definitions related to

pressure

ISO 8625-2, Aerospace — Fluid systems — Vocabulary — Part 2: General terms and definitions relating to

flow

ISO 8625-3, Aerospace — Fluid systems — Vocabulary — Part 3: General terms and definitions relating to

temperature

ISO 11218, Aerospace — Cleanliness classification for hydraulic fluids

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 8625-1, ISO 8625-2, ISO 8625-3,

and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

variable displacement hydraulic motor

mechanical actuator that converts hydraulic pressure and flow into torque and angular velocity

(rotation) and whose speed is controlled by varying the displacement of the hydraulic motor

Note 1 to entry: The use of a variable displacement hydraulic motor permits the optimization of hydraulic

flow demand.

Note 2 to entry: The motor’s output torque, direction of rotation (if bi-directional) and associated operating

speed and resultant flow consumption is controlled by a servo valve which varies the motor’s displacement

which is typically operated in closed loop control.

Note 3 to entry: The specifications, design, manufacture and qualification of the servo valve is outside the scope

of this document.

3.1.1

uni-directional hydraulic motor

variable displacement hydraulic motor (3.1) that generates output torque via the drive shaft in only one

direction

3.1.2

bi-directional hydraulic motor

variable displacement hydraulic motor (3.1) that generates output torque via the drive shaft to both

clockwise and anti-clockwise directions

Note 1 to entry: Except for bi-directional over-centre hydraulic motors (3.1.3), bi-directional operation is typically

achieved by reversing the differential pressure across the inlet/outlet ports, thus reversing the output torque.

Note 2 to entry: Except for bi-directional over-centre hydraulic motors (3.1.3), the position of the swashplate is

controlled in each direction by a dedicated controller.

3.1.3

bi-directional over-centre hydraulic motor

bi-directional hydraulic motor (3.1.2) whose direction of rotation of the output drive shaft is controlled

by the angle of the motor swashplate which can go over centre

Note 1 to entry: This may be accomplished by controlling the position of the swashplate in each direction by a

single controller.

2 © ISO 2021 – All rights reserved

3.2

purchaser

organization that has the engineering responsibility for the system that includes the motor

Note 1 to entry: Typically, the purchaser is a system supplier (3.4), an aircraft manufacturer or a contractor.

3.3

detail specification

document compiled by the purchaser (3.2) that specifies the following:

a) technical requirements;

b) acceptance and qualification test requirements;

c) reliability, testability and maintainability requirements;

d) quality requirements;

e) packaging requirements;

f) other requirements

Note 1 to entry: Technical requirements include performance requirements and design requirements.

3.4

supplier

organization that provides the motor

Note 1 to entry: Typically, the supplier is the manufacturer of the motor who will be responsible for the design,

production, and qualification of the motor.

3.5.1

motor inlet port

port that receives flow from the hydraulic system to supply the motor

3.5.2

motor return port

port that returns flow back to the system reservoir

3.5.3

motor case drain port

port that drains internal leakage flow to the system reservoir

Note 1 to entry: Not all motors have a case drain port; instead the case drain fluid is supplied to the motor

outlet port.

3.5.4

shaft seal leakage port

port that routes any shaft seal leakage from the motor to an overboard drain, collector tank, ecology

bottle, etc.

3.6.1

rated temperature

maximum continuous temperature of the fluid to be supplied at the inlet port of the motor

3.6.2

normal operating temperature

temperature of the fluid to be supplied at the inlet port of the motor at which full performance of the

motor is required

3.6.3

minimum continuous temperature

minimum temperature of the fluid at the supply port of the motor at which the motor is able to function

Note 1 to entry: This temperature is generally higher than the minimum survival temperature (3.6.5).

3.6.4

extreme operating temperature

temperature of the fluid to be supplied at the inlet port of the motor at which the motor runs with an

agreed degraded performance

3.6.5

survival temperature

ambient temperature at which the motor is not required to run, but runs without degradation at the

normal operating temperature (3.6.2)

3.7.1

design operating pressure

normal maximum steady pressure

Note 1 to entry: Excluded are reasonable tolerances, transient pressure effects such as may arise from the

following:

— pressure ripple;

— reactions to system functioning;

— demands that may affect fatigue.

3.7.2

rated supply pressure

system rated pressure, which is normally the hydraulic power generation system design operating

pressure (3.7.1)

3.7.3

rated differential pressure

differential pressure measured between the motor inlet and outlet ports required to produce the rated

torque (3.11.1)

3.7.4

no-load break-out pressure

differential pressure required for starting the output shaft, without interruption, with the case drain

port at the rated case drain pressure (3.7.6.1) and the return port at the nominal motor return pressure

(3.7.5.1)

Note 1 to entry: This corresponds to break-out torque (3.11.2).

3.7.5.1

nominal motor return pressure

pressure generated at the return port as the motor returns flow back to the system

3.7.5.2

rated motor return pressure

maximum pressure at the return port

Note 1 to entry: This is applicable to uni-directional motors only.

Note 2 to entry: This is a stressing term only as the nominal motor return pressure (3.7.5.1) is generally

considerably less than the rated motor return pressure.

3.7.6.1

rated case drain pressure

nominal pressure at which the motor case is required to operate continuously in the system

4 © ISO 2021 – All rights reserved

3.7.6.2

maximum case pressure

maximum of either

— the maximum pressure peak that may be imposed by the hydraulic system on the motor case drain

port (3.5.3), or

— the pressure resulting from the internal bypassing of the rated flow towards the return and drain

ports in order to take into account the accidental transitory separation of the components

3.8

rated consumption

maximum flow rate measured at the motor inlet port (3.5.1) under the following conditions:

— rated fluid temperature;

— rated differential pressure (3.7.3);

— rated speed (3.10);

— using the hydraulic fluid specified in the detail specification (3.3)

3.9

maximum displacement

theoretical volume of fluid consumed by one revolution of the motor drive shaft at full stroke

Note 1 to entry: It is expressed in cubic centimetres per revolution (cubic inches per revolution).

Note 2 to entry: The maximum displacement is calculated from the geometrical configuration of the motor,

without allowing for the following effects:

— permissible manufacturing tolerances;

— distortions of the motor structure;

— the compressibility of the hydraulic fluid;

— internal leakage;

— temperature.

Note 3 to entry: The maximum displacement is used to indicate the size of the motor rather than its performance.

3.10

rated speed

maximum speed at which the motor is required to operate continuously at rated temperature (3.6.1)

and at rated differential pressure (3.7.3)

Note 1 to entry: The rated speed is expressed as the number of revolutions of the motor output shaft per minute.

3.11.1

rated torque

minimum torque value at rated operating conditions

3.11.2

break-out torque

minimum torque against which the motor will start at operating conditions specified in the detail

specification (3.3)

Note 1 to entry: This corresponds to no-load break-out pressure (3.7.4)

3.11.3

stalling torque

minimum opposing torque which stops the rotation of the outlet shaft at the rated supply pressure (3.7.2)

and for the outlet port and case drain port pressures specified in the detail specification (3.3)

3.11.4

maximum stalling torque

stalling torque (3.11.3) which can be generated at rated operating conditions

Note 1 to entry: This shall be specified to ensure that the motor’s torque capability in a stall (high efficiency)

condition does not overload the system’s capability (e.g. the shafts and gears, as applicable).

3.12

motor overall efficiency

e

value obtained from the formula

e = (o/i) × 100

where

o is the output shaft power (3.12.1);

i is the input fluid power (3.12.2)

Note 1 to entry: e is expressed in per cent.

Note 2 to entry: Calculating hydraulic power and mechanical power can be problematic unless the correct units

and associated equations are used:

— Metric units (torque – Nm; flow – L/min)

— Imperial units (torque – lb.in; flow – gpm)

3.12.1

output shaft power

o

value obtained from the formula

o = t × s

where

t is the shaft torque;

s is the shaft speed

3.12.2

input fluid power

i

value obtained from the formula

i = (p − r) × f

where

6 © ISO 2021 – All rights reserved

p is the inlet pressure;

r is the return pressure;

f is the rated flow

Note 1 to entry: This formula ignores compressibility effects. If this formula is to be used, the flow rate

measurement should be made on the compressed flow stream.

3.13

rated endurance

total number of hours and cycles of operation to be included in the endurance phase of its

qualification testing

3.14

first article inspection

FAI

process that conducts the following:

— verifies that the parts of a component comply with the drawings;

— verifies that the manufacturing processes have been compiled and are adhered to;

— verifies that the assembly processes have been compiled and are adhered to;

— verifies that the acceptance test of the component is in accordance with the test procedure, and that

the results of the test are in agreement with the test requirements

4 Classification

The hydraulic motors covered by this document are classified in two categories.

— Category A: Primary function motors, for example, flight controls, slats, flaps, adjustable planes,

power transfer units, constant speed drives, nosewheel steering.

NOTE ISO 22089 provides the variable displacement motor requirements for power transfer units.

— Category B: Secondary function motors, for example, hoists, guns, radars, doors.

In addition, the motor can be a uni-directional motor or a bi-directional motor.

The motor category and type (uni-directional or bi-directional or bi-directional over-centre) shall be

specified in the detail specification.

5 General requirements

5.1 Order of precedence

The detail specification shall take precedence in the case of a conflict between the requirements of this

document and the detail specification.

5.2 Hydraulic system characteristics

The hydraulic motor shall be designed to be operated by the hydraulic system as defined in the detail

specification.

The detail specification shall include the characteristics of the hydraulic system in which the motor

is to be used. This shall include the flow versus pressure curves for the supply, return, and case drain

lines for the following hydraulic fluid temperatures:

— normal operating temperature (e.g. +20 °C);

— rated temperature;

— minimum continuous temperature.

5.3 Airworthiness regulations

It is assumed that the hydraulic motor meets the applicable airworthiness requirements, whi

...

INTERNATIONAL ISO

STANDARD 22181

First edition

2021-02

Aerospace fluid systems and

components — Variable displacement

hydraulic motors — General

specifications

Reference number

©

ISO 2021

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

Contents Page

Foreword .vi

Introduction .vii

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Classification . 7

5 General requirements . 7

5.1 Order of precedence . 7

5.2 Hydraulic system characteristics . 7

5.3 Airworthiness regulations . 8

5.4 Qualification . 8

6 Functional requirements . 8

6.1 Hydraulic fluid . 8

6.2 Pressures . 8

6.2.1 Rated supply pressure. 8

6.2.2 Rated differential pressure . 8

6.2.3 No-load break-out pressure . 8

6.2.4 Motor return port pressure . 9

6.2.5 Case drain pressure . 9

6.3 Flows . 9

6.3.1 Rated consumption . 9

6.3.2 Case drain flow . 9

6.3.3 Shaft seal leakage .10

6.3.4 External leakage .10

6.4 Speed and direction of rotation .10

6.4.1 Speed .10

6.5 Torque .11

6.5.1 Rated torque .11

6.5.2 Break-out torque .11

6.5.3 Stalling torque .11

6.5.4 Maximum stalling torque .11

6.5.5 Torque pulsations .11

6.6 Variable output load control .11

6.6.1 General.11

6.6.2 Response time .12

6.6.3 Stability .12

6.7 Motor overall efficiency .12

6.8 Dynamic characteristics .13

6.8.1 General.13

6.8.2 Dynamic braking .13

6.8.3 Rapid reversals .13

6.9 Passive operation .13

6.10 Fluid and ambient temperature .13

6.10.1 Fluid temperature .13

6.10.2 Ambient temperature .13

6.11 Acoustic noise level .14

6.12 Rated endurance .14

6.13 Environmental requirements .14

7 Detail design requirements .15

7.1 Dimensionally critical components .15

7.2 Maintainability features .15

7.3 Seals .15

7.4 Lubrication .15

7.5 Balance .15

7.6 Self-contained failure .16

7.7 Safety wire sealing .16

7.8 Electro-conductive bonding .16

7.9 Marking .16

7.9.1 Nameplate .16

7.9.2 Modification standard .16

7.9.3 Fluid identification .16

7.9.4 Ports .16

8 Strength requirements .17

8.1 General .17

8.2 Proof pressure .17

8.2.1 Motor case .17

8.2.2 Motor inlet port .17

8.2.3 Motor return port .17

8.3 Ultimate pressure .17

8.3.1 Motor case .17

8.3.2 Motor inlet port .17

8.3.3 Motor return port .17

8.4 Pressure impulse (fatigue) .17

8.5 Port strength .18

9 Construction requirements .18

9.1 Materials .18

9.1.1 General.18

9.1.2 Metals .18

9.2 Corrosion protection .18

9.2.1 General.18

9.2.2 Ferrous and copper alloys .19

9.2.3 Aluminium alloys .19

9.3 Castings .19

10 Installation requirements.19

10.1 Dimensions .19

10.2 Mass .19

10.3 Mounting .20

10.4 Orientation .20

10.5 Drive shaft .20

10.6 Ports .20

11 Maintenance requirements .21

11.1 Maintenance concept .21

11.2 Service life limitations and storage specifications .21

12 Reliability requirements .21

12.1 Equipment compliance .21

12.2 Requirements .21

13 Quality assurance provisions .21

13.1 Responsibility for inspection .21

13.2 Classification of tests .21

13.3 Test stand requirements .22

14 Acceptance tests .22

14.1 General .22

14.2 Examination of the product .22

14.3 Test programme .23

14.3.1 General.23

14.3.2 External leakage requirements .23

14.3.3 Break-in run .23

iv © ISO 2021 – All rights reserved

14.3.4 Proof pressure and overspeed tests .23

14.3.5 Operational tests at rated conditions .24

14.3.6 Break-out torque test .24

14.3.7 Teardown inspection examination .24

14.3.8 Run-in .25

14.3.9 Speed control test .25

14.3.10 Performance data .25

14.3.11 Fluid contamination test .26

14.4 Storage and packaging .27

15 Qualification procedures .27

15.1 General .27

15.2 Qualification procedure .27

15.2.1 Qualification by analogy .27

15.2.2 Motor qualification test report .27

15.2.3 Samples and program of qualification tests .27

15.3 Qualification testing .28

15.3.1 Dimensional check .28

15.3.2 Expanded envelope acceptance tests .28

15.3.3 Overspeed test .28

15.3.4 Operational test at overpressure .29

15.3.5 Calibration .29

15.3.6 Endurance testing .31

15.3.7 Environmental tests .34

15.3.8 Structural tests .35

15.3.9 Combination tests .37

15.3.10 Supplementary tests .37

Bibliography .38

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 20, Aircraft and space vehicles,

Subcommittee SC 10, Aerospace fluid systems and components.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

vi © ISO 2021 – All rights reserved

Introduction

It is noted that, while ISO standards refer to SI units, large segments of the aerospace industry refer

to other measurement systems as a matter of common working practice. All dimensions used in this

document are in SI units with the non-SI units given in addition for the convenience of those users more

familiar with these.

It is further noted that the standard ISO decimal symbol “,” (comma) is not used as common working

practice for inch dimensions. A decimal point is used in the inch dimensions in this document as in

many other aerospace standards.

NOTE The use of non-SI units and the decimal point in this document does not constitute general acceptance

of measurement systems other than SI within International Standards.

INTERNATIONAL STANDARD ISO 22181:2021(E)

Aerospace fluid systems and components — Variable

displacement hydraulic motors — General specifications

1 Scope

This document establishes the general requirements for variable displacement uni-directional and

bi-directional hydraulic motors, suitable for use in aircraft hydraulic systems at pressures up to

35 000 kPa (5 000 psi).

These requirements include:

— design requirements;

— test requirements.

Primary and secondary function motors (see Clause 4) are covered in this document; however, actuators

with internal rotation angle limits and low-speed motors are not covered.

This document is intended to be used in conjunction with the detail specification that is particular to

each application.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 2093, Electroplated coatings of tin — Specification and test methods

ISO 2669, Environmental tests for aircraft equipment — Steady-state acceleration

ISO 2671, Environmental tests for aircraft equipment — Part 3.4 : Acoustic vibration

ISO 2685, Aircraft — Environmental test procedure for airborne equipment — Resistance to fire in

designated fire zones

ISO 3323, Aircraft — Hydraulic components — Marking to indicate fluid for which component is approved

ISO 3601-1, Fluid power systems — O-rings — Part 1: Inside diameters, cross-sections, tolerances and

designation codes

ISO 7137, Aircraft — Environmental conditions and test procedures for airborne equipment

ISO 7320, Aerospace — Couplings, threaded and sealed, for fluid systems — Dimensions

ISO 8078, Aerospace process — Anodic treatment of aluminium alloys — Sulfuric acid process, undyed coating

ISO 8079, Aerospace process — Anodic treatment of aluminium alloys — Sulfuric acid process, dyed coating

ISO 8399-1, Aerospace — Accessory drives and mounting flanges (Metric series) — Part 1: Design criteria

ISO 8399-2, Aerospace — Accessory drives and mounting flanges (Metric series) — Part 2: Dimensions

ISO 8625-1, Aerospace — Fluid systems — Vocabulary — Part 1: General terms and definitions related to

pressure

ISO 8625-2, Aerospace — Fluid systems — Vocabulary — Part 2: General terms and definitions relating to

flow

ISO 8625-3, Aerospace — Fluid systems — Vocabulary — Part 3: General terms and definitions relating to

temperature

ISO 11218, Aerospace — Cleanliness classification for hydraulic fluids

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 8625-1, ISO 8625-2, ISO 8625-3,

and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

variable displacement hydraulic motor

mechanical actuator that converts hydraulic pressure and flow into torque and angular velocity

(rotation) and whose speed is controlled by varying the displacement of the hydraulic motor

Note 1 to entry: The use of a variable displacement hydraulic motor permits the optimization of hydraulic

flow demand.

Note 2 to entry: The motor’s output torque, direction of rotation (if bi-directional) and associated operating

speed and resultant flow consumption is controlled by a servo valve which varies the motor’s displacement

which is typically operated in closed loop control.

Note 3 to entry: The specifications, design, manufacture and qualification of the servo valve is outside the scope

of this document.

3.1.1

uni-directional hydraulic motor

variable displacement hydraulic motor (3.1) that generates output torque via the drive shaft in only one

direction

3.1.2

bi-directional hydraulic motor

variable displacement hydraulic motor (3.1) that generates output torque via the drive shaft to both

clockwise and anti-clockwise directions

Note 1 to entry: Except for bi-directional over-centre hydraulic motors (3.1.3), bi-directional operation is typically

achieved by reversing the differential pressure across the inlet/outlet ports, thus reversing the output torque.

Note 2 to entry: Except for bi-directional over-centre hydraulic motors (3.1.3), the position of the swashplate is

controlled in each direction by a dedicated controller.

3.1.3

bi-directional over-centre hydraulic motor

bi-directional hydraulic motor (3.1.2) whose direction of rotation of the output drive shaft is controlled

by the angle of the motor swashplate which can go over centre

Note 1 to entry: This may be accomplished by controlling the position of the swashplate in each direction by a

single controller.

2 © ISO 2021 – All rights reserved

3.2

purchaser

organization that has the engineering responsibility for the system that includes the motor

Note 1 to entry: Typically, the purchaser is a system supplier (3.4), an aircraft manufacturer or a contractor.

3.3

detail specification

document compiled by the purchaser (3.2) that specifies the following:

a) technical requirements;

b) acceptance and qualification test requirements;

c) reliability, testability and maintainability requirements;

d) quality requirements;

e) packaging requirements;

f) other requirements

Note 1 to entry: Technical requirements include performance requirements and design requirements.

3.4

supplier

organization that provides the motor

Note 1 to entry: Typically, the supplier is the manufacturer of the motor who will be responsible for the design,

production, and qualification of the motor.

3.5.1

motor inlet port

port that receives flow from the hydraulic system to supply the motor

3.5.2

motor return port

port that returns flow back to the system reservoir

3.5.3

motor case drain port

port that drains internal leakage flow to the system reservoir

Note 1 to entry: Not all motors have a case drain port; instead the case drain fluid is supplied to the motor

outlet port.

3.5.4

shaft seal leakage port

port that routes any shaft seal leakage from the motor to an overboard drain, collector tank, ecology

bottle, etc.

3.6.1

rated temperature

maximum continuous temperature of the fluid to be supplied at the inlet port of the motor

3.6.2

normal operating temperature

temperature of the fluid to be supplied at the inlet port of the motor at which full performance of the

motor is required

3.6.3

minimum continuous temperature

minimum temperature of the fluid at the supply port of the motor at which the motor is able to function

Note 1 to entry: This temperature is generally higher than the minimum survival temperature (3.6.5).

3.6.4

extreme operating temperature

temperature of the fluid to be supplied at the inlet port of the motor at which the motor runs with an

agreed degraded performance

3.6.5

survival temperature

ambient temperature at which the motor is not required to run, but runs without degradation at the

normal operating temperature (3.6.2)

3.7.1

design operating pressure

normal maximum steady pressure

Note 1 to entry: Excluded are reasonable tolerances, transient pressure effects such as may arise from the

following:

— pressure ripple;

— reactions to system functioning;

— demands that may affect fatigue.

3.7.2

rated supply pressure

system rated pressure, which is normally the hydraulic power generation system design operating

pressure (3.7.1)

3.7.3

rated differential pressure

differential pressure measured between the motor inlet and outlet ports required to produce the rated

torque (3.11.1)

3.7.4

no-load break-out pressure

differential pressure required for starting the output shaft, without interruption, with the case drain

port at the rated case drain pressure (3.7.6.1) and the return port at the nominal motor return pressure

(3.7.5.1)

Note 1 to entry: This corresponds to break-out torque (3.11.2).

3.7.5.1

nominal motor return pressure

pressure generated at the return port as the motor returns flow back to the system

3.7.5.2

rated motor return pressure

maximum pressure at the return port

Note 1 to entry: This is applicable to uni-directional motors only.

Note 2 to entry: This is a stressing term only as the nominal motor return pressure (3.7.5.1) is generally

considerably less than the rated motor return pressure.

3.7.6.1

rated case drain pressure

nominal pressure at which the motor case is required to operate continuously in the system

4 © ISO 2021 – All rights reserved

3.7.6.2

maximum case pressure

maximum of either

— the maximum pressure peak that may be imposed by the hydraulic system on the motor case drain

port (3.5.3), or

— the pressure resulting from the internal bypassing of the rated flow towards the return and drain

ports in order to take into account the accidental transitory separation of the components

3.8

rated consumption

maximum flow rate measured at the motor inlet port (3.5.1) under the following conditions:

— rated fluid temperature;

— rated differential pressure (3.7.3);

— rated speed (3.10);

— using the hydraulic fluid specified in the detail specification (3.3)

3.9

maximum displacement

theoretical volume of fluid consumed by one revolution of the motor drive shaft at full stroke

Note 1 to entry: It is expressed in cubic centimetres per revolution (cubic inches per revolution).

Note 2 to entry: The maximum displacement is calculated from the geometrical configuration of the motor,

without allowing for the following effects:

— permissible manufacturing tolerances;

— distortions of the motor structure;

— the compressibility of the hydraulic fluid;

— internal leakage;

— temperature.

Note 3 to entry: The maximum displacement is used to indicate the size of the motor rather than its performance.

3.10

rated speed

maximum speed at which the motor is required to operate continuously at rated temperature (3.6.1)

and at rated differential pressure (3.7.3)

Note 1 to entry: The rated speed is expressed as the number of revolutions of the motor output shaft per minute.

3.11.1

rated torque

minimum torque value at rated operating conditions

3.11.2

break-out torque

minimum torque against which the motor will start at operating conditions specified in the detail

specification (3.3)

Note 1 to entry: This corresponds to no-load break-out pressure (3.7.4)

3.11.3

stalling torque

minimum opposing torque which stops the rotation of the outlet shaft at the rated supply pressure (3.7.2)

and for the outlet port and case drain port pressures specified in the detail specification (3.3)

3.11.4

maximum stalling torque

stalling torque (3.11.3) which can be generated at rated operating conditions

Note 1 to entry: This shall be specified to ensure that the motor’s torque capability in a stall (high efficiency)

condition does not overload the system’s capability (e.g. the shafts and gears, as applicable).

3.12

motor overall efficiency

e

value obtained from the formula

e = (o/i) × 100

where

o is the output shaft power (3.12.1);

i is the input fluid power (3.12.2)

Note 1 to entry: e is expressed in per cent.

Note 2 to entry: Calculating hydraulic power and mechanical power can be problematic unless the correct units

and associated equations are used:

— Metric units (torque – Nm; flow – L/min)

— Imperial units (torque – lb.in; flow – gpm)

3.12.1

output shaft power

o

value obtained from the formula

o = t × s

where

t is the shaft torque;

s is the shaft speed

3.12.2

input fluid power

i

value obtained from the formula

i = (p − r) × f

where

6 © ISO 2021 – All rights reserved

p is the inlet pressure;

r is the return pressure;

f is the rated flow

Note 1 to entry: This formula ignores compressibility effects. If this formula is to be used, the flow rate

measurement should be made on the compressed flow stream.

3.13

rated endurance

total number of hours and cycles of operation to be included in the endurance phase of its

qualification testing

3.14

first article inspection

FAI

process that conducts the following:

— verifies that the parts of a component comply with the drawings;

— verifies that the manufacturing processes have been compiled and are adhered to;

— verifies that the assembly processes have been compiled and are adhered to;

— verifies that the acceptance test of the component is in accordance with the test procedure, and that

the results of the test are in agreement with the test requirements

4 Classification

The hydraulic motors covered by this document are classified in two categories.

— Category A: Primary function motors, for example, flight controls, slats, flaps, adjustable planes,

power transfer units, constant speed drives, nosewheel steering.

NOTE ISO 22089 provides the variable displacement motor requirements for power transfer units.

— Category B: Secondary function motors, for example, hoists, guns, radars, doors.

In addition, the motor can be a uni-directional motor or a bi-directional motor.

The motor category and type (uni-directional or bi-directional or bi-directional over-centre) shall be

specified in the detail specification.

5 General requirements

5.1 Order of precedence

The detail specification shall take precedence in the case of a conflict between the requirements of this

document and the detail specification.

5.2 Hydraulic system characteristics

The hydraulic motor shall be designed to be operated by the hydraulic system as defined in the detail

specification.

The detail specification shall include the characteristics of the hydraulic system in which the motor

is to be used. This shall include the flow versus pressure curves for the supply, return, and case drain

lines for the following hydraulic fluid temperatures:

— normal operating temperature (e.g. +20 °C);

— rated temperature;

— minimum continuous temperature.

5.3 Airworthiness regulations

It is assumed that the hydraulic motor meets the applicable airworthiness requirements, whi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...