ISO 16069:2017

(Main)Graphical symbols — Safety signs — Safety way guidance systems (SWGS)

Graphical symbols — Safety signs — Safety way guidance systems (SWGS)

ISO 16069:2017 describes the principles governing the design and application of visual components used to create a safety way guidance system (SWGS). ISO 16069:2017 contains general principles valid both for electrically powered and for phosphorescent components. Special information which is related to the type of component is given to assist in defining the environment of use, choice of material, layout, installation and maintenance of SWGS. ISO 16069:2017 does not cover risk assessment. Applications with different risks to the occupants typically require different layouts and types of SWGS. The specific application and exact final design of SWGS is entrusted to those persons responsible for this task. ISO 16069:2017 also does not include the special considerations of possible tactile or audible components of SWGS, nor does it include requirements for high mounted components of the emergency escape route lighting, especially the design and application of emergency escape route lighting. ISO 16069:2017 is intended, by collaboration and coordination, to be used by all other Technical Committees within ISO and IEC charged with developing SWGS for their specific requirements. ISO 16069:2017 is not to be used for ships falling under regulations of the International Maritime Organization (IMO).

Symboles graphiques — Signaux de sécurité — Systèmes de guidage pour cheminement d'évacuation de sécurité

General Information

- Status

- Published

- Publication Date

- 09-Nov-2017

- Technical Committee

- ISO/TC 145/SC 2 - Safety identification, signs, shapes, symbols and colours

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 14-Mar-2023

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 21-Jun-2014

Overview

ISO 16069:2017 - "Graphical symbols - Safety signs - Safety way guidance systems (SWGS)" defines the principles for designing and applying visual components that form a Safety Way Guidance System. The standard covers general design principles valid for both electrically powered and phosphorescent components, guidance on environment of use, material choice, layout, installation, documentation, inspection and maintenance. It does not cover risk assessment, tactile/audible components, high-mounted emergency escape route lighting, or ships regulated by the IMO.

Key topics and technical requirements

- Planning a SWGS: system objectives, continuity, visual reinforcement and avoidance of confusing information at decision points.

- Design principles: consistent use of graphical symbols and arrows (referencing ISO 7010 and ISO 3864-3) to ensure rapid recognition across language barriers.

- Guidance lines and escape route signs: placement, continuity, and consistency for directional information.

- Marking requirements: stairs, ramps, ladders, emergency exits, hazards, firefighting and safety equipment, assembly/safe areas and provisions for multi-level buildings and disabled persons.

- Component-specific requirements:

- Electrically powered components: luminaire requirements, emergency power supply considerations, installation, documentation and maintenance.

- Phosphorescent components: luminance properties, installed luminance verification, illumination and on-site measurement procedures.

- Verification & maintenance: documentation, logbooks, inspection intervals and procedures.

- Measurement annexes: laboratory and on-site measurement methods for photopic luminance (Annex A & B) and guidance on visibility/identifiability and sizing (Annex C).

Note: the 2017 (second) edition updated luminance requirements, clarified dimensions for phosphorescent systems, and simplified requirements to improve usability.

Practical applications

ISO 16069 is applied when designing visual evacuation aids to improve occupant egress during fires, power failures or smoke conditions where traditional escape lighting may be ineffective. Typical uses include:

- Design and specification of floor-level guidance lines and low-mounted escape signage

- Selection of phosphorescent or electrically lit components based on environment and power-backup needs

- Creating inspection, testing and maintenance programs for SWGS installations

- Integrating SWGS into building evacuation strategies and safety audits

Who uses this standard

- Fire safety engineers and building designers

- Facility managers, building services and maintenance teams

- Manufacturers and installers of SWGS components (electrical and phosphorescent)

- Emergency planners and consultants

- ISO/IEC technical committees developing related guidance

Related standards

- ISO 7010 (graphical symbols for safety signs)

- ISO 3864-3 and ISO 3864-4 (colour and safety sign specifications and colourimetric properties)

Keywords: ISO 16069, SWGS, safety way guidance systems, phosphorescent guidance, electrically powered escape signs, escape route signage, luminance measurement, emergency evacuation.

Buy Documents

ISO 16069:2017 - Graphical symbols -- Safety signs -- Safety way guidance systems (SWGS)

ISO 16069:2017 - Graphical symbols — Safety signs — Safety way guidance systems (SWGS) Released:11/10/2017

Frequently Asked Questions

ISO 16069:2017 is a standard published by the International Organization for Standardization (ISO). Its full title is "Graphical symbols — Safety signs — Safety way guidance systems (SWGS)". This standard covers: ISO 16069:2017 describes the principles governing the design and application of visual components used to create a safety way guidance system (SWGS). ISO 16069:2017 contains general principles valid both for electrically powered and for phosphorescent components. Special information which is related to the type of component is given to assist in defining the environment of use, choice of material, layout, installation and maintenance of SWGS. ISO 16069:2017 does not cover risk assessment. Applications with different risks to the occupants typically require different layouts and types of SWGS. The specific application and exact final design of SWGS is entrusted to those persons responsible for this task. ISO 16069:2017 also does not include the special considerations of possible tactile or audible components of SWGS, nor does it include requirements for high mounted components of the emergency escape route lighting, especially the design and application of emergency escape route lighting. ISO 16069:2017 is intended, by collaboration and coordination, to be used by all other Technical Committees within ISO and IEC charged with developing SWGS for their specific requirements. ISO 16069:2017 is not to be used for ships falling under regulations of the International Maritime Organization (IMO).

ISO 16069:2017 describes the principles governing the design and application of visual components used to create a safety way guidance system (SWGS). ISO 16069:2017 contains general principles valid both for electrically powered and for phosphorescent components. Special information which is related to the type of component is given to assist in defining the environment of use, choice of material, layout, installation and maintenance of SWGS. ISO 16069:2017 does not cover risk assessment. Applications with different risks to the occupants typically require different layouts and types of SWGS. The specific application and exact final design of SWGS is entrusted to those persons responsible for this task. ISO 16069:2017 also does not include the special considerations of possible tactile or audible components of SWGS, nor does it include requirements for high mounted components of the emergency escape route lighting, especially the design and application of emergency escape route lighting. ISO 16069:2017 is intended, by collaboration and coordination, to be used by all other Technical Committees within ISO and IEC charged with developing SWGS for their specific requirements. ISO 16069:2017 is not to be used for ships falling under regulations of the International Maritime Organization (IMO).

ISO 16069:2017 is classified under the following ICS (International Classification for Standards) categories: 01.080.10 - Public information symbols. Signs. Plates. Labels; 01.080.20 - Graphical symbols for use on specific equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 16069:2017 has the following relationships with other standards: It is inter standard links to ISO 16069:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 16069:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 16069

Second edition

2017-11

Graphical symbols — Safety signs —

Safety way guidance systems (SWGS)

Symboles graphiques — Signaux de sécurité — Systèmes de guidage

pour cheminement d'évacuation de sécurité

Reference number

©

ISO 2017

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

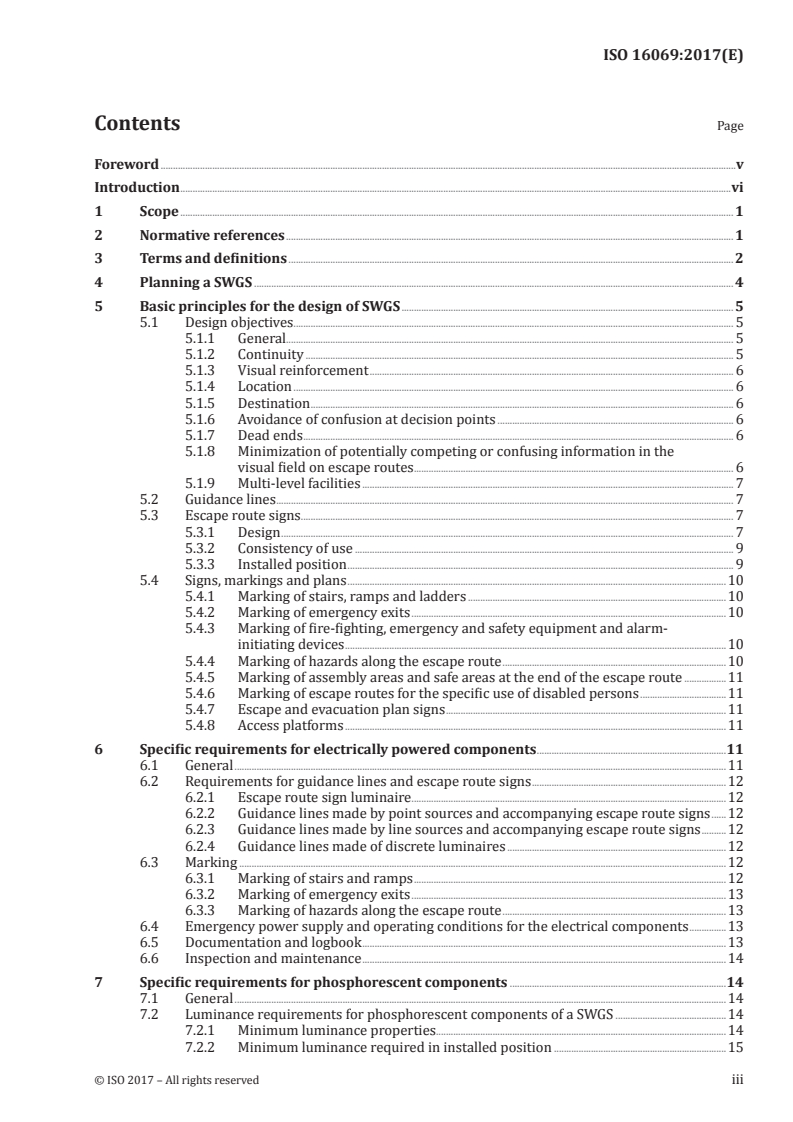

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Planning a SWGS . 4

5 Basic principles for the design of SWGS . 5

5.1 Design objectives . 5

5.1.1 General. 5

5.1.2 Continuity . 5

5.1.3 Visual reinforcement . 6

5.1.4 Location . 6

5.1.5 Destination . 6

5.1.6 Avoidance of confusion at decision points . 6

5.1.7 Dead ends . 6

5.1.8 Minimization of potentially competing or confusing information in the

visual field on escape routes . 6

5.1.9 Multi-level facilities . 7

5.2 Guidance lines . 7

5.3 Escape route signs . 7

5.3.1 Design . 7

5.3.2 Consistency of use . 9

5.3.3 Installed position . 9

5.4 Signs, markings and plans .10

5.4.1 Marking of stairs, ramps and ladders .10

5.4.2 Marking of emergency exits .10

5.4.3 Marking of fire-fighting, emergency and safety equipment and alarm-

initiating devices .10

5.4.4 Marking of hazards along the escape route .10

5.4.5 Marking of assembly areas and safe areas at the end of the escape route .11

5.4.6 Marking of escape routes for the specific use of disabled persons .11

5.4.7 Escape and evacuation plan signs .11

5.4.8 Access platforms .11

6 Specific requirements for electrically powered components .11

6.1 General .11

6.2 Requirements for guidance lines and escape route signs .12

6.2.1 Escape route sign luminaire .12

6.2.2 Guidance lines made by point sources and accompanying escape route signs .12

6.2.3 Guidance lines made by line sources and accompanying escape route signs .12

6.2.4 Guidance lines made of discrete luminaires .12

6.3 Marking .12

6.3.1 Marking of stairs and ramps .12

6.3.2 Marking of emergency exits .13

6.3.3 Marking of hazards along the escape route .13

6.4 Emergency power supply and operating conditions for the electrical components .13

6.5 Documentation and logbook .13

6.6 Inspection and maintenance .14

7 Specific requirements for phosphorescent components .14

7.1 General .14

7.2 Luminance requirements for phosphorescent components of a SWGS .14

7.2.1 Minimum luminance properties . .14

7.2.2 Minimum luminance required in installed position .15

7.3 Guidance lines and escape route signs and their location within a SWGS .15

7.3.1 Guidance lines .15

7.3.2 Escape route signs .15

7.4 Marking .16

7.4.1 Marking of stairs, ramps and ladders .16

7.4.2 Marking of door frames of emergency exits . .16

7.4.3 Marking of hazards along the route .16

7.4.4 Marking of fire-fighting, emergency and safety equipment along the

escape route .16

7.4.5 Floor numbering and stairwell identification for multi-storey building.16

7.5 Illumination requirements .17

7.6 Verification of illumination and luminance .17

7.7 Documentation and logbook .17

7.8 Inspection and maintenance .17

Annex A (normative) Measurement of photopic luminance of phosphorescent components

in the laboratory .19

Annex B (normative) On-site measurement of luminance performance of phosphorescent

components of a SWGS .25

Annex C (informative) Visibility and identifiability of phosphorescent safety way guidance

components and their sizing and location .29

Bibliography .39

iv © ISO 2017 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see the following

URL: www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 145, Graphical symbols, Subcommittee

SC 2, Safety identifications, signs, shapes, symbols, and colours.

This second edition cancels and replaces the first edition (ISO 16069:2004) which has been technically

revised.

The main changes compared with the previous edition are as follows:

a) the component luminance requirements of the electrical systems have been updated;

b) the component luminance and dimensions of non-electrical phosphorescent systems have been

updated;

c) the document and its requirements have been simplified to improve ease of use and eliminate

ambiguity;

d) all example figures which by definition could not cover all arrangements have been removed;

e) an informative annex for designers of non-electrical phosphorescent systems regarding observation

distances has been added.

Introduction

Safety way guidance systems need to be standardized so that they communicate the information

necessary to allow people to be able to evacuate a building efficiently and, if necessary, to assemble in

designated safe areas in cases of fire or other emergencies.

Through the consistent and uniform international application of common SWGS design principles,

persons in all countries will be better able to recognize and follow the directional information provided

by such systems to assist in providing a safe evacuation. As an additional benefit, a standardized SWGS

will assist fire fighters and other rescue teams to evacuate occupied areas during emergency situations.

In order to communicate safety way guidance information efficiently across language barriers, the

systems defined in this document incorporate the use of graphical symbols and markings such as

arrows, conforming to ISO 7010 and ISO 3864-3.

Illumination of escape routes is not part of the SWGS and is therefore not covered by this document;

a SWGS is not intended to replace emergency escape lighting. There will be certain situations where

emergency escape lighting is not needed, and other situations, for example where smoke is present,

where emergency escape lighting can lose its efficiency and a SWGS will be more effective in assisting

emergency evacuation, but it is generally recommended that SWGS be used in combination with the

illumination of escape routes to provide additional benefits for the whole system.

The principles given in this document are intended to provide consistent design elements irrespective

of whether they use electrically powered or phosphorescent components. Consistent use will improve

public awareness of the systems and assist rapid recognition and effectiveness in the case of an

emergency.

vi © ISO 2017 – All rights reserved

INTERNATIONAL STANDARD ISO 16069:2017(E)

Graphical symbols — Safety signs — Safety way guidance

systems (SWGS)

IMPORTANT — The colours represented in the electronic file of this document can be neither

viewed on screen nor printed as true representations. For the purposes of colour matching,

see ISO 3864-4 which provides colorimetric and photometric properties together with, as a

guideline, references from colour order systems.

1 Scope

This document describes the principles governing the design and application of visual components

used to create a safety way guidance system (SWGS).

This document contains general principles valid both for electrically powered and for phosphorescent

components. Special information which is related to the type of component is given to assist in defining

the environment of use, choice of material, layout, installation and maintenance of SWGS.

This document does not cover risk assessment. Applications with different risks to the occupants

typically require different layouts and types of SWGS. The specific application and exact final design of

SWGS is entrusted to those persons responsible for this task.

This document also does not include the special considerations of possible tactile or audible components

of SWGS, nor does it include requirements for high mounted components of the emergency escape route

lighting, especially the design and application of emergency escape route lighting.

This document is intended, by collaboration and coordination, to be used by all other Technical Committees

within ISO and IEC charged with developing SWGS for their specific requirements. This document is not to

be used for ships falling under regulations of the International Maritime Organization (IMO).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3864-1, Graphical symbols — Safety colours and safety signs — Part 1: Design principles for safety

signs and safety markings

ISO 3864-3, Graphical symbols — Safety colours and safety signs — Part 3: Design principles for graphical

symbols for use in safety signs

ISO 3864-4:2011, Graphical symbols — Safety colours and safety signs — Part 4: Colorimetric and

photometric properties of safety sign materials

ISO 7010:2011, Graphical symbols — Safety colours and safety signs — Registered safety signs

ISO 23601, Safety identification — Escape and evacuation plan signs

IEC 60364-5-56, Low-Voltage electrical Installations — Part 5-56: Selection and erection of electrical

equipment — Safety services

IEC 60598-2-22, Luminaires — Part 2-22: Particular requirements — Luminaires for emergency lighting

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at http://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

3.1

assembly area

designated safe area outside the occupied area where occupants are expected to assemble

3.2

dead end

corridor, or part of a corridor whose depth is greater than its width from which there is only one

escape route

[SOURCE: ISO 15370:2010, 3.5]

3.3

emergency escape lighting

that part of emergency lighting (3.4) that provides illumination for the safety of people leaving a location

or attempting to terminate a potentially dangerous process before doing so

3.4

emergency lighting

lighting provided for use when the supply to the normal lighting fails

3.5

factor of distance

z

relationship between the height (h) of a sign and observation distance (l), used to determine observation

distances of signs

l

z =

h

[SOURCE: ISO 3864-1:2011, 3.2]

3.6

guidance line

line of luminous material on or close to the floor provided to clearly delineate an escape route or define

an escape path through an open area

3.7

high location

installation position above doors or at or close to ceiling level for safety signs and other safety way

guidance components

3.8

intermediate location

installation position between a low location (3.9) and a high location (3.7) especially at eye level for

safety signs and other safety way guidance components

3.9

low location

installation position at or close to floor level for safety signs and other safety way guidance components

2 © ISO 2017 – All rights reserved

3.10

luminance contrast

luminance of the brightest element of the safety way guidance component divided by the

luminance of the surrounding environment

3.11

marking

method of highlighting and identifying specific building components or equipment

3.12

observation distance

l

distance from which a sign is identifiable and conspicuous

3.13

observation distance

l

distance from which guidance lines (3.6) and door frames are visible

3.14

period of use

time over which the safety way guidance system is expected to be operational

3.15

phosphorescent material

material incorporating phosphors that, if excited by UV or visible radiation, store energy, which is

emitted as light over a period of time

Note 1 to entry: A phosphorescent sign is the same as “photoluminescent” commonly used in the literature of the

photoluminescent safety sign industry.

[SOURCE: ISO 3864-4:2011, 3.12, modified — Note 1 to entry has been added.]

3.16

safety sign

sign which gives a general safety message, obtained by a combination of colour and geometric shape

and which, by the addition of a graphical symbol, gives a particular safety message

[SOURCE: ISO 3864-1:2011, 3.12]

3.17

safety way guidance system

SWGS

system that provides luminous markings and direction information for the safety of people leaving a

location

3.18

sign height

diameter of a circular geometric shape or height of a rectangular or triangular geometric shape

Note 1 to entry: Registered safety sign originals in ISO 7010 are in a uniform 70 mm size with corner marks to

enable accurate enlargement and reduction scaling. A border is not shown.

[SOURCE: ISO 3864-1:2011, 3.13, modified — Note 1 to entry has been added.]

3.19

supplementary sign

sign that is supportive of a safety sign and the main purpose of which is to provide additional

clarification

[SOURCE: ISO 3864-1:2011, 3.14]

4 Planning a SWGS

This document provides guidelines for the installation of the guidance system in buildings where it has

been decided as the result of risk assessment to install a luminous safety way guidance system.

Since SWGS can consist of a variety of possible components, steps shall be taken at the planning stage to

determine appropriate designs.

The SWGS shall take into account the following factors:

a) the characteristics of the exit path of the horizontal and stairwell sections of the defined escape

route and exit paths to them, including through open areas;

b) the location of emergency exit doors and how the door frame can be marked and the placement of

escape route signs;

c) the location of assembly stations and refuge areas;

d) the location of all possible escape routes (emergency stairwell, escape windows, ladders);

e) the location of escape and evacuation plan signs at a prominent place;

f) the location of hazards such as machinery, dangerous goods, steps and obstacles;

g) the location of safety equipment and fire equipment;

h) the characteristics of the installed emergency lighting in terms of designed illuminance

performance and duration;

i) the location and type of high mounted emergency exit signs installed as part of the emergency

lighting system;

j) for phosphorescent systems, the type of light source of the normal and emergency lighting and

designed/in situ illuminance at potential placement of guidance lines and safety signs;

k) for phosphorescent systems, the time management of the normal light sources in the location

(occupancy floor and stairwells) for phosphorescent components to be sufficiently exposed to an

illumination source in order to function in dark surroundings;

l) for electrically powered systems, the potential locations for the independent power supply, the

potential locations for routing of the power cables and devices for detection of failure of power

supply and/or smoke;

m) the possible combinations of components in SWGS to assist evacuation under specific risk

conditions such as presence of diffused or stratified smoke, earthquakes, and presence of obstacles

or specific crowding conditions;

n) the fire compartmentalization provisions;

o) the location of opening devices for doors, e.g. sliding doors, door handle, push bars, emergency push

buttons;

p) the design of existing escape route signs.

4 © ISO 2017 – All rights reserved

5 Basic principles for the design of SWGS

5.1 Design objectives

5.1.1 General

Safety way guidance systems shall provide the users of the building with consistent, coherent

information so that they can be evacuated efficiently from any occupancy unit to a safe area.

Luminous safety way guidance systems can be installed in addition to high located emergency lighting

and its associated high located escape route signs. Safety way guidance systems shall be installed

and activated in all risk situations that have been defined by risk assessments. Examples of situations

include blackout of the exit path and escape route signs due to potential failure of the power supply to

the escape route lighting or the risk of smoke obscuring the exit path and emergency exit doors.

The approach of both phosphorescent or electrically powered safety way guidance systems is luminous

marking of the exit path and changes of level of the emergency exit path, not the illumination of the

floor or steps. Consequently, for the safety way guidance systems specified in this document there is

not a requirement to specify the horizontal illuminance on the centre line of the escape path or vertical

illuminance at safety equipment.

Activation/charging of phosphorescent components to produce light emission in dark surroundings

requires pre-exposure of the components to the installed light sources. The luminance performance

during the decay mode of the phosphorescent components depends upon the light spectral

characteristics of the light source, the excitation illuminance at the location of the phosphorescent

component and the duration of the excitation.

All the components of an activated safety way guidance system shall have a luminance contrast with

the surroundings of >3 when in use and for at least the time allocated for escape in clear air conditions.

For the same performance of luminous material, the observation distance for visibility of emergency

exit door marking is longer than the distance for identification of the escape route sign at the exit door.

In conditions of smoke on the emergency exit path, the light from luminous way guidance components

is attenuated exponentially with smoke density and light is scattered producing a luminous veil. As

the smoke density increases, an emergency exit door may no longer be visible but the guidance lines

and escape route signs in short distance from the evacuee can be visible to direct evacuees towards an

emergency exit door. In smoke conditions evacuees may bend forward or crawl, reducing their speed of

movement and increasing the evacuation time to a safe area.

The technical design of the different luminous safety way guidance systems is discussed in Clause 6 for

electrically powered systems and in Clause 7 for phosphorescent systems.

SWGS is intended to be installed throughout a building but may be restricted to certain parts of the

escape route where supported by a risk analysis.

5.1.2 Continuity

SWGS components shall be arranged as continuously and unbroken as possible from within the

occupied area to the assembly area. Way guidance lines shall be used to provide a visually continuous,

conspicuous line from within the building to a final point of the escape route and shall preferably be a

complete delineation of the boundaries of the escape route.

NOTE 1 Four dots or chevrons per linear metre with diameter of at least 100 mm can be accepted as

continuous line.

NOTE 2 The final point of the escape route can be inside or outside the building, depending on the evacuation

strategy.

5.1.3 Visual reinforcement

Escape route signs shall be placed at intervals sufficient to provide consistency and continuity of

information.

The frequency and visual reinforcement of escape route signs at intermediate and low location shall be

determined by the risk assessment.

Escape route signs positioned at low location shall be close to the way guidance lines or be incorporated

in the guidance line, Wherever practical, escape route signs located at intermediary level shall be

repeated at low location.

5.1.4 Location

Low location shall be the principal position for guidance lines giving perspective over distances of 10 m.

The height of the low location guidance lines shall be no higher than 300 mm from the floor, and lower

may be preferred.

Intermediate guidance lines may be placed at up to 1,20 m from the floor to provide visual reinforcement

and to assist in the identification of guide rails, handrails or other architectural elements along the

escape route. This adds further to the perspective of the escape route over medium observation

distances of approximately 10 m to 20 m.

Escape route signs shall be located to ensure visual reinforcement at medium to long observation

distances of between approximately 10 m and 30 m and to indicate change of escape route direction or

intermediate and final destinations on the escape route.

The visual field between 1,20 m and 1,80 m on the walls of the escape route may be used for visually

reinforcing directional information for medium observation distances of approximately 10 m to 20 m.

5.1.5 Destination

Final and intermediary destinations along the escape route such as exit doors on the route and

assembly/refuge areas/escape windows shall be given specific emphasis by using SWGS components.

Other doors shall not be marked.

5.1.6 Avoidance of confusion at decision points

SWGS shall avoid the presentation to occupants of alternative routes to follow which might create

uncertainty and confusion during evacuation. In the case of equal distances between alternative routes

then, occupants shall be encouraged to move either way by the location of escape route signs some

distance away from the equidistant point.

5.1.7 Dead ends

The frequency of escape route signs at any location shall be increased in dead end areas to progress

occupants away from the dead end towards the escape route.

5.1.8 Minimization of potentially competing or confusing information in the visual field on

escape routes

Public information signs and general building facilities signs shall be subordinate and of distinctively

different colour to components of the SWGS along designated escape routes.

NOTE This can be achieved by increasing size, frequency or luminance of safety way guidance components

or similarly reducing size or luminance of potentially competing information.

6 © ISO 2017 – All rights reserved

5.1.9 Multi-level facilities

SWGS in multi-level facilities shall include a floor/level numbering and stair identification system on all

levels at each level adjacent to the access point and exit points within the stairwell.

5.2 Guidance lines

Guidance lines together with the luminous marking of the full frame of emergency exit doors are the

prime components of a SWGS.

Guidance lines shall be realized by line sources of different sizes and luminances or luminous intensities.

The guidance lines shall be as continuous as possible. No break shall exceed 0,2 m, unless there are

doors along the escape route, in which case the wall or floor guidance line may be interrupted with a

maximum break of 1 m or the lines shall be continued on the floor in front of the door. Door leafs shall

never be marked with a guidance line.

Wall guidance lines which are interrupted by intersecting corridors should be continued by using floor

lines or by continuing the guidance line on the opposite side of the corridor starting the guidance line

with directional signs.

The maximum height of low-located wall guidance lines above floor level shall be 300 mm. If a low-

located wall guidance line is interrupted, it may be continued at floor level for the duration of that

interruption.

An additional horizontal luminous line can be located on the wall at a height between 0,9 m and 1,1 m

from the floor to show the configuration of the exit route.

It is preferable to provide both sides of the escape route with guidance lines. On escape routes up to 2 m

in width it may be sufficient to have only one guidance line. This line may be positioned either on the

floor or on the wall.

In rooms or open areas escape routes shall be marked on both sides with guidance lines or the guidance

lines shall be used to define a travel path through that area.

NOTE The technical design parameters of the individual components are dealt with in Clause 6 for

electrically powered systems and in Clause 7 for phosphorescent systems.

5.3 Escape route signs

5.3.1 Design

SWGS designed to this document shall use the safety signs ISO 7010:2011, E001 or ISO 7010:2011, E002

for emergency exit together with the appropriate supplementary arrow type D from ISO 3864-3 for

directional purposes (see Figure 1).

The escape route sign does not indicate the decisions or direction that should be made on the other side

of the door. Meanings of escape route signs are given in Figure 1 and Figure 2.

NOTE 1 The addition of supplementary text to a safety sign increases the size and can make the sign more

conspicuous.

The colour of escape route signs shall meet the colorimetric and photometric specifications of

ISO 3864-4 under its specified test conditions related to escape route signs being externally illuminated

or being internally illuminated by electrical power.

NOTE 2 ISO 3864-4 defines colour under certain test conditions and not all conditions of observation of safety

signs. Phosphorescent escape route signs during the luminance decay mode lack colour recognition of the green,

however they are designed such the luminance contrast enables the graphical symbols to be /remain identifiable.

NOTE 3 The technical design parameters of the individual components are dealt with in Clause 6 for

electrically powered systems and in Clause 7 for phosphorescent systems.

Meaning as viewed Using graphical symbol Example using

Example using

from in front and supplementary dual language

supplementary text

of the sign arrow only supplementary text

Proceed down to

the right

(indicating Exit

Exit

change of level).

a) Proceed up to

the right

(indicating

change of level).

b) Proceed

Exit

forward and across

Exit

to the right from

here when

suspended within

an open area.

Proceed down to

the left (indicating

change of level). Exit

Exit

a) Proceed up to

the left (indicating

change of level).

b) Proceed

forward and across

Exit

Exit

to the left from

here when

suspended within

an open area.

a) Proceed

forward from here

(indicating

direction of travel).

b) Proceed

forward and

through from here;

when sign is sited

Exit

at door (indicating Exit

direction of travel).

c) Proceed

forward and up

from here

(indicating change

of level).

Figure 1 (continued)

8 © ISO 2017 – All rights reserved

Meaning as viewed Using graphical symbol Example using

Example using

from in front and supplementary dual language

supplementary text

of the sign arrow only supplementary text

Proceed to the right

from here

Exit

(indicating

Exit

direction of travel).

Proceed to the left

from here

Exit

(indicating

Exit

direction of travel).

Proceed down from

here (indicating

Exit

change of level).

Exit

Figure 1 — Examples of escape route signs to be used with or without

a supplementary sign with text

Figure 2 — Example of escape route sign for floor marking

5.3.2 Consistency of use

The direction given by the arrow is used exclusively to indicate the direction of movement of evacuation.

Directional “escape route signs” (such as those given in Figure 1 and Figure 2) shall be used exclusively

to indicate the direction to be followed by occupants. The safety signs E001 and E002 specified in

ISO 7010 shall always be used with a supplementary arrow and shall be consistently displayed at

all installed positions on the escape route according to be meanings give in Figure 1. All exit signs

at emergency exit doors on the escape route shall be used with an arrow pointing upward, meaning

“forward and through from here”.

5.3.3 Installed position

The exact meaning of an escape route sign is dependent on the installed position. Particular attention

shall be paid to changes of direction, the signing at intermediate doors through which occupants pass

along the escape route and for escape routes requiring movement to an upper level in a building.

Escape route signs at intermediate height location shall be provided at all exits intended to be used

in an emergency and where necessary along escape routes to indicate the direction to the next exit,

emergency exit, safe area or assembly area as well as to indicate the position of the escape route for

occupants in adjacent areas.

Where direct sight of an escape route sign at an emergency exit door is not possible within the

observation distance, a series of escape route signs shall be provided to assist progression toward the

emergency exit. For escape route signs in intermediate location, between 1,2 m and 1,8 m height above

the floor, the maximum distance between these escape route signs shall be 10 m.

Escape route signs at emergency exit doors shall be mounted on the door frame or the wall next to the

door opening device at a height between 1,2 m and 1,5 m above the floor.

Escape route signs shall not be mounted on the door leaf of an exit door. Near the door leaf of an exit

door an escape route sign shall be mounted on or adjacent to the guidance line.

Where escape route signs below 1,2 m from the floor are provided to accompany the guidance line,

escape route signs, as shown in Figure 1 and Figure 2, shall be positioned at maximum intervals of

every 5 m and at critical points such as junctions and changes of direction, along the length of the

guidance line. Where these accompanying escape route signs are installed on a wall, the centre of the

escape route sign shall be not higher than 0,7 m above the floor.

Escape route signs can be mounted directly on the wall, when the floor guidance line is not more than

0,5 m from the wall. The position of the escape route sign shall be in this case not higher than 0,3 m

from the floor.

NOTE The technical design parameters of the individual components are dealt with in Clause 6 for

electrically powered systems and in Clause 7 for phosphorescent systems

5.4 Signs, markings and plans

5.4.1 Marking of stairs, ramps and ladders

All nosing of steps, including single steps, shall be marked across the stair width. On ramps, the location

of changes of level shall be marked.

A guidance line should be installed on the handrail and central supports.

5.4.2 Marking of emergency exits

The door frame of emergency exit doors in the course of escape routes and final emergency exit doors

shall be marked.

The frame of emergency windows shall be marked.

The area of the door opening mechanism and the method and direction of operation shall be clearly

identified.

Doors other than emergency exit doors shall not be marked.

If an escape route sign is incorporated in a door marking system it shall be positioned at the height of

the door-opening device.

5.4.3 Marking of fire-fighting, emergency and safety equipment and alarm-initiating devices

Safety signs for fire-fighting equipment and safety equipment shall conform to ISO 7010 and shall be

placed at the location of each piece of equipment. All communication devices intended for use in an

emergency shall be made conspicuous by the use of the appropriate safety sign and shall be placed at

the location of each call point and telephone.

5.4.4 Marking of hazards along the escape route

Warning signs conforming to ISO 7010 shall be placed to identify the nature and location of hazards.

such as location of electrical equipment, and location of pressure vessels.

Obstacles in escape routes such as wall projections, pillars and obstructing fitments shall be marked by

the appropriate warning marking in accordance with ISO 3864-1.

The guidance line should lead occupants around obstacles and any protruding architectural features.

10 © ISO 2017 – All rights reserved

5.4.5 Marking of assembly areas and safe areas at the end of the escape route

Areas intended to be used for the assembly of occupants shall be identified by the safety sign in

accordance with ISO 7010 (see ISO 7010:2011, E007). Escape route signs shall lead occupants from all

exits to assembly areas.

5.4.6 Marking of escape routes for the specific use of disabled persons

If there are escape routes designated for the specific use of disabled persons, they shall be specifically

signed as such. If refuges and equipment for the assistance of persons with special needs are provided

then these shall be specifically signed as such in accordance with ISO 7010 (e.g. ISO 7010:2011, E024,

“Evacuation temporary refuge” or ISO 7010:2011, E060, “Evacuation chair”).

5.4.7 Escape and evacuation plan signs

The escape and evacua

...

INTERNATIONAL ISO

STANDARD 16069

Second edition

2017-11

Graphical symbols — Safety signs —

Safety way guidance systems (SWGS)

Symboles graphiques — Signaux de sécurité — Systèmes de guidage

pour cheminement d'évacuation de sécurité

Reference number

©

ISO 2017

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Planning a SWGS . 4

5 Basic principles for the design of SWGS . 5

5.1 Design objectives . 5

5.1.1 General. 5

5.1.2 Continuity . 5

5.1.3 Visual reinforcement . 6

5.1.4 Location . 6

5.1.5 Destination . 6

5.1.6 Avoidance of confusion at decision points . 6

5.1.7 Dead ends . 6

5.1.8 Minimization of potentially competing or confusing information in the

visual field on escape routes . 6

5.1.9 Multi-level facilities . 7

5.2 Guidance lines . 7

5.3 Escape route signs . 7

5.3.1 Design . 7

5.3.2 Consistency of use . 9

5.3.3 Installed position . 9

5.4 Signs, markings and plans .10

5.4.1 Marking of stairs, ramps and ladders .10

5.4.2 Marking of emergency exits .10

5.4.3 Marking of fire-fighting, emergency and safety equipment and alarm-

initiating devices .10

5.4.4 Marking of hazards along the escape route .10

5.4.5 Marking of assembly areas and safe areas at the end of the escape route .11

5.4.6 Marking of escape routes for the specific use of disabled persons .11

5.4.7 Escape and evacuation plan signs .11

5.4.8 Access platforms .11

6 Specific requirements for electrically powered components .11

6.1 General .11

6.2 Requirements for guidance lines and escape route signs .12

6.2.1 Escape route sign luminaire .12

6.2.2 Guidance lines made by point sources and accompanying escape route signs .12

6.2.3 Guidance lines made by line sources and accompanying escape route signs .12

6.2.4 Guidance lines made of discrete luminaires .12

6.3 Marking .12

6.3.1 Marking of stairs and ramps .12

6.3.2 Marking of emergency exits .13

6.3.3 Marking of hazards along the escape route .13

6.4 Emergency power supply and operating conditions for the electrical components .13

6.5 Documentation and logbook .13

6.6 Inspection and maintenance .14

7 Specific requirements for phosphorescent components .14

7.1 General .14

7.2 Luminance requirements for phosphorescent components of a SWGS .14

7.2.1 Minimum luminance properties . .14

7.2.2 Minimum luminance required in installed position .15

7.3 Guidance lines and escape route signs and their location within a SWGS .15

7.3.1 Guidance lines .15

7.3.2 Escape route signs .15

7.4 Marking .16

7.4.1 Marking of stairs, ramps and ladders .16

7.4.2 Marking of door frames of emergency exits . .16

7.4.3 Marking of hazards along the route .16

7.4.4 Marking of fire-fighting, emergency and safety equipment along the

escape route .16

7.4.5 Floor numbering and stairwell identification for multi-storey building.16

7.5 Illumination requirements .17

7.6 Verification of illumination and luminance .17

7.7 Documentation and logbook .17

7.8 Inspection and maintenance .17

Annex A (normative) Measurement of photopic luminance of phosphorescent components

in the laboratory .19

Annex B (normative) On-site measurement of luminance performance of phosphorescent

components of a SWGS .25

Annex C (informative) Visibility and identifiability of phosphorescent safety way guidance

components and their sizing and location .29

Bibliography .39

iv © ISO 2017 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see the following

URL: www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 145, Graphical symbols, Subcommittee

SC 2, Safety identifications, signs, shapes, symbols, and colours.

This second edition cancels and replaces the first edition (ISO 16069:2004) which has been technically

revised.

The main changes compared with the previous edition are as follows:

a) the component luminance requirements of the electrical systems have been updated;

b) the component luminance and dimensions of non-electrical phosphorescent systems have been

updated;

c) the document and its requirements have been simplified to improve ease of use and eliminate

ambiguity;

d) all example figures which by definition could not cover all arrangements have been removed;

e) an informative annex for designers of non-electrical phosphorescent systems regarding observation

distances has been added.

Introduction

Safety way guidance systems need to be standardized so that they communicate the information

necessary to allow people to be able to evacuate a building efficiently and, if necessary, to assemble in

designated safe areas in cases of fire or other emergencies.

Through the consistent and uniform international application of common SWGS design principles,

persons in all countries will be better able to recognize and follow the directional information provided

by such systems to assist in providing a safe evacuation. As an additional benefit, a standardized SWGS

will assist fire fighters and other rescue teams to evacuate occupied areas during emergency situations.

In order to communicate safety way guidance information efficiently across language barriers, the

systems defined in this document incorporate the use of graphical symbols and markings such as

arrows, conforming to ISO 7010 and ISO 3864-3.

Illumination of escape routes is not part of the SWGS and is therefore not covered by this document;

a SWGS is not intended to replace emergency escape lighting. There will be certain situations where

emergency escape lighting is not needed, and other situations, for example where smoke is present,

where emergency escape lighting can lose its efficiency and a SWGS will be more effective in assisting

emergency evacuation, but it is generally recommended that SWGS be used in combination with the

illumination of escape routes to provide additional benefits for the whole system.

The principles given in this document are intended to provide consistent design elements irrespective

of whether they use electrically powered or phosphorescent components. Consistent use will improve

public awareness of the systems and assist rapid recognition and effectiveness in the case of an

emergency.

vi © ISO 2017 – All rights reserved

INTERNATIONAL STANDARD ISO 16069:2017(E)

Graphical symbols — Safety signs — Safety way guidance

systems (SWGS)

IMPORTANT — The colours represented in the electronic file of this document can be neither

viewed on screen nor printed as true representations. For the purposes of colour matching,

see ISO 3864-4 which provides colorimetric and photometric properties together with, as a

guideline, references from colour order systems.

1 Scope

This document describes the principles governing the design and application of visual components

used to create a safety way guidance system (SWGS).

This document contains general principles valid both for electrically powered and for phosphorescent

components. Special information which is related to the type of component is given to assist in defining

the environment of use, choice of material, layout, installation and maintenance of SWGS.

This document does not cover risk assessment. Applications with different risks to the occupants

typically require different layouts and types of SWGS. The specific application and exact final design of

SWGS is entrusted to those persons responsible for this task.

This document also does not include the special considerations of possible tactile or audible components

of SWGS, nor does it include requirements for high mounted components of the emergency escape route

lighting, especially the design and application of emergency escape route lighting.

This document is intended, by collaboration and coordination, to be used by all other Technical Committees

within ISO and IEC charged with developing SWGS for their specific requirements. This document is not to

be used for ships falling under regulations of the International Maritime Organization (IMO).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3864-1, Graphical symbols — Safety colours and safety signs — Part 1: Design principles for safety

signs and safety markings

ISO 3864-3, Graphical symbols — Safety colours and safety signs — Part 3: Design principles for graphical

symbols for use in safety signs

ISO 3864-4:2011, Graphical symbols — Safety colours and safety signs — Part 4: Colorimetric and

photometric properties of safety sign materials

ISO 7010:2011, Graphical symbols — Safety colours and safety signs — Registered safety signs

ISO 23601, Safety identification — Escape and evacuation plan signs

IEC 60364-5-56, Low-Voltage electrical Installations — Part 5-56: Selection and erection of electrical

equipment — Safety services

IEC 60598-2-22, Luminaires — Part 2-22: Particular requirements — Luminaires for emergency lighting

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at http://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

3.1

assembly area

designated safe area outside the occupied area where occupants are expected to assemble

3.2

dead end

corridor, or part of a corridor whose depth is greater than its width from which there is only one

escape route

[SOURCE: ISO 15370:2010, 3.5]

3.3

emergency escape lighting

that part of emergency lighting (3.4) that provides illumination for the safety of people leaving a location

or attempting to terminate a potentially dangerous process before doing so

3.4

emergency lighting

lighting provided for use when the supply to the normal lighting fails

3.5

factor of distance

z

relationship between the height (h) of a sign and observation distance (l), used to determine observation

distances of signs

l

z =

h

[SOURCE: ISO 3864-1:2011, 3.2]

3.6

guidance line

line of luminous material on or close to the floor provided to clearly delineate an escape route or define

an escape path through an open area

3.7

high location

installation position above doors or at or close to ceiling level for safety signs and other safety way

guidance components

3.8

intermediate location

installation position between a low location (3.9) and a high location (3.7) especially at eye level for

safety signs and other safety way guidance components

3.9

low location

installation position at or close to floor level for safety signs and other safety way guidance components

2 © ISO 2017 – All rights reserved

3.10

luminance contrast

luminance of the brightest element of the safety way guidance component divided by the

luminance of the surrounding environment

3.11

marking

method of highlighting and identifying specific building components or equipment

3.12

observation distance

l

distance from which a sign is identifiable and conspicuous

3.13

observation distance

l

distance from which guidance lines (3.6) and door frames are visible

3.14

period of use

time over which the safety way guidance system is expected to be operational

3.15

phosphorescent material

material incorporating phosphors that, if excited by UV or visible radiation, store energy, which is

emitted as light over a period of time

Note 1 to entry: A phosphorescent sign is the same as “photoluminescent” commonly used in the literature of the

photoluminescent safety sign industry.

[SOURCE: ISO 3864-4:2011, 3.12, modified — Note 1 to entry has been added.]

3.16

safety sign

sign which gives a general safety message, obtained by a combination of colour and geometric shape

and which, by the addition of a graphical symbol, gives a particular safety message

[SOURCE: ISO 3864-1:2011, 3.12]

3.17

safety way guidance system

SWGS

system that provides luminous markings and direction information for the safety of people leaving a

location

3.18

sign height

diameter of a circular geometric shape or height of a rectangular or triangular geometric shape

Note 1 to entry: Registered safety sign originals in ISO 7010 are in a uniform 70 mm size with corner marks to

enable accurate enlargement and reduction scaling. A border is not shown.

[SOURCE: ISO 3864-1:2011, 3.13, modified — Note 1 to entry has been added.]

3.19

supplementary sign

sign that is supportive of a safety sign and the main purpose of which is to provide additional

clarification

[SOURCE: ISO 3864-1:2011, 3.14]

4 Planning a SWGS

This document provides guidelines for the installation of the guidance system in buildings where it has

been decided as the result of risk assessment to install a luminous safety way guidance system.

Since SWGS can consist of a variety of possible components, steps shall be taken at the planning stage to

determine appropriate designs.

The SWGS shall take into account the following factors:

a) the characteristics of the exit path of the horizontal and stairwell sections of the defined escape

route and exit paths to them, including through open areas;

b) the location of emergency exit doors and how the door frame can be marked and the placement of

escape route signs;

c) the location of assembly stations and refuge areas;

d) the location of all possible escape routes (emergency stairwell, escape windows, ladders);

e) the location of escape and evacuation plan signs at a prominent place;

f) the location of hazards such as machinery, dangerous goods, steps and obstacles;

g) the location of safety equipment and fire equipment;

h) the characteristics of the installed emergency lighting in terms of designed illuminance

performance and duration;

i) the location and type of high mounted emergency exit signs installed as part of the emergency

lighting system;

j) for phosphorescent systems, the type of light source of the normal and emergency lighting and

designed/in situ illuminance at potential placement of guidance lines and safety signs;

k) for phosphorescent systems, the time management of the normal light sources in the location

(occupancy floor and stairwells) for phosphorescent components to be sufficiently exposed to an

illumination source in order to function in dark surroundings;

l) for electrically powered systems, the potential locations for the independent power supply, the

potential locations for routing of the power cables and devices for detection of failure of power

supply and/or smoke;

m) the possible combinations of components in SWGS to assist evacuation under specific risk

conditions such as presence of diffused or stratified smoke, earthquakes, and presence of obstacles

or specific crowding conditions;

n) the fire compartmentalization provisions;

o) the location of opening devices for doors, e.g. sliding doors, door handle, push bars, emergency push

buttons;

p) the design of existing escape route signs.

4 © ISO 2017 – All rights reserved

5 Basic principles for the design of SWGS

5.1 Design objectives

5.1.1 General

Safety way guidance systems shall provide the users of the building with consistent, coherent

information so that they can be evacuated efficiently from any occupancy unit to a safe area.

Luminous safety way guidance systems can be installed in addition to high located emergency lighting

and its associated high located escape route signs. Safety way guidance systems shall be installed

and activated in all risk situations that have been defined by risk assessments. Examples of situations

include blackout of the exit path and escape route signs due to potential failure of the power supply to

the escape route lighting or the risk of smoke obscuring the exit path and emergency exit doors.

The approach of both phosphorescent or electrically powered safety way guidance systems is luminous

marking of the exit path and changes of level of the emergency exit path, not the illumination of the

floor or steps. Consequently, for the safety way guidance systems specified in this document there is

not a requirement to specify the horizontal illuminance on the centre line of the escape path or vertical

illuminance at safety equipment.

Activation/charging of phosphorescent components to produce light emission in dark surroundings

requires pre-exposure of the components to the installed light sources. The luminance performance

during the decay mode of the phosphorescent components depends upon the light spectral

characteristics of the light source, the excitation illuminance at the location of the phosphorescent

component and the duration of the excitation.

All the components of an activated safety way guidance system shall have a luminance contrast with

the surroundings of >3 when in use and for at least the time allocated for escape in clear air conditions.

For the same performance of luminous material, the observation distance for visibility of emergency

exit door marking is longer than the distance for identification of the escape route sign at the exit door.

In conditions of smoke on the emergency exit path, the light from luminous way guidance components

is attenuated exponentially with smoke density and light is scattered producing a luminous veil. As

the smoke density increases, an emergency exit door may no longer be visible but the guidance lines

and escape route signs in short distance from the evacuee can be visible to direct evacuees towards an

emergency exit door. In smoke conditions evacuees may bend forward or crawl, reducing their speed of

movement and increasing the evacuation time to a safe area.

The technical design of the different luminous safety way guidance systems is discussed in Clause 6 for

electrically powered systems and in Clause 7 for phosphorescent systems.

SWGS is intended to be installed throughout a building but may be restricted to certain parts of the

escape route where supported by a risk analysis.

5.1.2 Continuity

SWGS components shall be arranged as continuously and unbroken as possible from within the

occupied area to the assembly area. Way guidance lines shall be used to provide a visually continuous,

conspicuous line from within the building to a final point of the escape route and shall preferably be a

complete delineation of the boundaries of the escape route.

NOTE 1 Four dots or chevrons per linear metre with diameter of at least 100 mm can be accepted as

continuous line.

NOTE 2 The final point of the escape route can be inside or outside the building, depending on the evacuation

strategy.

5.1.3 Visual reinforcement

Escape route signs shall be placed at intervals sufficient to provide consistency and continuity of

information.

The frequency and visual reinforcement of escape route signs at intermediate and low location shall be

determined by the risk assessment.

Escape route signs positioned at low location shall be close to the way guidance lines or be incorporated

in the guidance line, Wherever practical, escape route signs located at intermediary level shall be

repeated at low location.

5.1.4 Location

Low location shall be the principal position for guidance lines giving perspective over distances of 10 m.

The height of the low location guidance lines shall be no higher than 300 mm from the floor, and lower

may be preferred.

Intermediate guidance lines may be placed at up to 1,20 m from the floor to provide visual reinforcement

and to assist in the identification of guide rails, handrails or other architectural elements along the

escape route. This adds further to the perspective of the escape route over medium observation

distances of approximately 10 m to 20 m.

Escape route signs shall be located to ensure visual reinforcement at medium to long observation

distances of between approximately 10 m and 30 m and to indicate change of escape route direction or

intermediate and final destinations on the escape route.

The visual field between 1,20 m and 1,80 m on the walls of the escape route may be used for visually

reinforcing directional information for medium observation distances of approximately 10 m to 20 m.

5.1.5 Destination

Final and intermediary destinations along the escape route such as exit doors on the route and

assembly/refuge areas/escape windows shall be given specific emphasis by using SWGS components.

Other doors shall not be marked.

5.1.6 Avoidance of confusion at decision points

SWGS shall avoid the presentation to occupants of alternative routes to follow which might create

uncertainty and confusion during evacuation. In the case of equal distances between alternative routes

then, occupants shall be encouraged to move either way by the location of escape route signs some

distance away from the equidistant point.

5.1.7 Dead ends

The frequency of escape route signs at any location shall be increased in dead end areas to progress

occupants away from the dead end towards the escape route.

5.1.8 Minimization of potentially competing or confusing information in the visual field on

escape routes

Public information signs and general building facilities signs shall be subordinate and of distinctively

different colour to components of the SWGS along designated escape routes.

NOTE This can be achieved by increasing size, frequency or luminance of safety way guidance components

or similarly reducing size or luminance of potentially competing information.

6 © ISO 2017 – All rights reserved

5.1.9 Multi-level facilities

SWGS in multi-level facilities shall include a floor/level numbering and stair identification system on all

levels at each level adjacent to the access point and exit points within the stairwell.

5.2 Guidance lines

Guidance lines together with the luminous marking of the full frame of emergency exit doors are the

prime components of a SWGS.

Guidance lines shall be realized by line sources of different sizes and luminances or luminous intensities.

The guidance lines shall be as continuous as possible. No break shall exceed 0,2 m, unless there are

doors along the escape route, in which case the wall or floor guidance line may be interrupted with a

maximum break of 1 m or the lines shall be continued on the floor in front of the door. Door leafs shall

never be marked with a guidance line.

Wall guidance lines which are interrupted by intersecting corridors should be continued by using floor

lines or by continuing the guidance line on the opposite side of the corridor starting the guidance line

with directional signs.

The maximum height of low-located wall guidance lines above floor level shall be 300 mm. If a low-

located wall guidance line is interrupted, it may be continued at floor level for the duration of that

interruption.

An additional horizontal luminous line can be located on the wall at a height between 0,9 m and 1,1 m

from the floor to show the configuration of the exit route.

It is preferable to provide both sides of the escape route with guidance lines. On escape routes up to 2 m

in width it may be sufficient to have only one guidance line. This line may be positioned either on the

floor or on the wall.

In rooms or open areas escape routes shall be marked on both sides with guidance lines or the guidance

lines shall be used to define a travel path through that area.

NOTE The technical design parameters of the individual components are dealt with in Clause 6 for

electrically powered systems and in Clause 7 for phosphorescent systems.

5.3 Escape route signs

5.3.1 Design

SWGS designed to this document shall use the safety signs ISO 7010:2011, E001 or ISO 7010:2011, E002

for emergency exit together with the appropriate supplementary arrow type D from ISO 3864-3 for

directional purposes (see Figure 1).

The escape route sign does not indicate the decisions or direction that should be made on the other side

of the door. Meanings of escape route signs are given in Figure 1 and Figure 2.

NOTE 1 The addition of supplementary text to a safety sign increases the size and can make the sign more

conspicuous.

The colour of escape route signs shall meet the colorimetric and photometric specifications of

ISO 3864-4 under its specified test conditions related to escape route signs being externally illuminated

or being internally illuminated by electrical power.

NOTE 2 ISO 3864-4 defines colour under certain test conditions and not all conditions of observation of safety

signs. Phosphorescent escape route signs during the luminance decay mode lack colour recognition of the green,

however they are designed such the luminance contrast enables the graphical symbols to be /remain identifiable.

NOTE 3 The technical design parameters of the individual components are dealt with in Clause 6 for

electrically powered systems and in Clause 7 for phosphorescent systems.

Meaning as viewed Using graphical symbol Example using

Example using

from in front and supplementary dual language

supplementary text

of the sign arrow only supplementary text

Proceed down to

the right

(indicating Exit

Exit

change of level).

a) Proceed up to

the right

(indicating

change of level).

b) Proceed

Exit

forward and across

Exit

to the right from

here when

suspended within

an open area.

Proceed down to

the left (indicating

change of level). Exit

Exit

a) Proceed up to

the left (indicating

change of level).

b) Proceed

forward and across

Exit

Exit

to the left from

here when

suspended within

an open area.

a) Proceed

forward from here

(indicating

direction of travel).

b) Proceed

forward and

through from here;

when sign is sited

Exit

at door (indicating Exit

direction of travel).

c) Proceed

forward and up

from here

(indicating change

of level).

Figure 1 (continued)

8 © ISO 2017 – All rights reserved

Meaning as viewed Using graphical symbol Example using

Example using

from in front and supplementary dual language

supplementary text

of the sign arrow only supplementary text

Proceed to the right

from here

Exit

(indicating

Exit

direction of travel).

Proceed to the left

from here

Exit

(indicating

Exit

direction of travel).

Proceed down from

here (indicating

Exit

change of level).

Exit

Figure 1 — Examples of escape route signs to be used with or without

a supplementary sign with text

Figure 2 — Example of escape route sign for floor marking

5.3.2 Consistency of use

The direction given by the arrow is used exclusively to indicate the direction of movement of evacuation.

Directional “escape route signs” (such as those given in Figure 1 and Figure 2) shall be used exclusively

to indicate the direction to be followed by occupants. The safety signs E001 and E002 specified in

ISO 7010 shall always be used with a supplementary arrow and shall be consistently displayed at

all installed positions on the escape route according to be meanings give in Figure 1. All exit signs

at emergency exit doors on the escape route shall be used with an arrow pointing upward, meaning

“forward and through from here”.

5.3.3 Installed position

The exact meaning of an escape route sign is dependent on the installed position. Particular attention

shall be paid to changes of direction, the signing at intermediate doors through which occupants pass