ISO 10959:2016

(Main)Aerospace — MJ threads — Gauging

Aerospace — MJ threads — Gauging

ISO 10959:2016 contains information for the gauging of ISO MJ threads in accordance with ISO 5855‑1, ISO 5855‑2, and ISO 5855‑3. Other methods of ensuring that the product is within the specified limits may be used provided correlation with the specified gauges is established [see 8.2, e)].

Aéronautique et espace — Filetage MJ — Vérification par calibres

General Information

Relations

Standards Content (Sample)

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 10959

ISO/TC 20/SC 4

Aerospace — MJ threads — Gauging

Secretariat: DIN

Voting begins Aéronautique et espace — Filetage MJ — Vérification par calibres

on: 20151016

Voting terminates

on: 20151216

RECIPIENTS OF THIS DRAFT ARE INVITED TO

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

Reference number

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO

ISO/FDIS 10959:2015(E)

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN

DARDS TO WHICH REFERENCE MAY BE MADE IN

©

NATIONAL REGULATIONS. ISO 2015

ISO/FDIS 10959:2015(E)

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

ISO/FDIS 10959:2015(E)

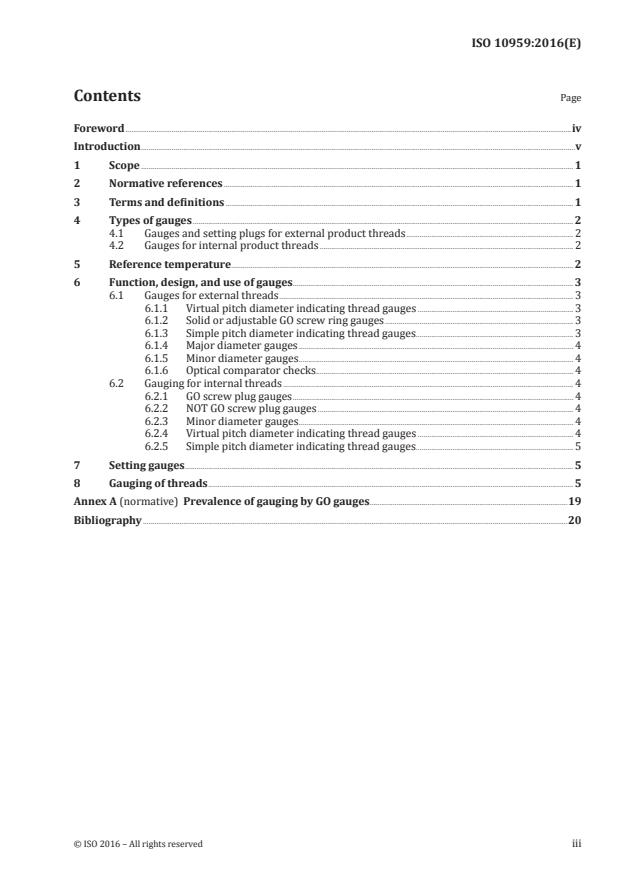

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Types of gauges . 2

4.1 Gauges and setting plugs for external product threads . 2

4.2 Gauges for internal product threads . 2

5 Reference temperature . 2

6 Function, design, and use of gauges . 3

6.1 Gauges for external threads . 3

6.1.1 Virtual pitch diameter indicating thread gauges . 3

6.1.2 Solid or adjustable GO screw ring gauges . 3

6.1.3 Simple pitch diameter indicating thread gauges . . 3

6.1.4 Major diameter gauges . 4

6.1.5 Minor diameter gauges. 4

6.1.6 Optical comparator checks . 4

6.2 Gauging for internal threads . 4

6.2.1 GO screw plug gauges . 4

6.2.2 NOT GO screw plug gauges . 4

6.2.3 Minor diameter gauges. 4

6.2.4 Virtual pitch diameter indicating thread gauges . 4

6.2.5 Simple pitch diameter indicating thread gauges . . 5

7 Setting gauges . 5

8 Gauging of threads . 5

Annex A (normative) Prevalence of gauging by GO gauges .19

Bibliography .20

ISO/FDIS 10959:2015(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and nongovernmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 20, Aircraft and space vehicles, Subcommittee

SC 4, Aerospace fastener systems.

This second edition cancels and replaces the first edition (ISO 10959:2000), which has been

technically revised.

iv © ISO 2015 – All rights reserved

ISO/FDIS 10959:2015(E)

Introduction

The purpose of this International Standard, which differs from ISO 1502, is to take into account the

basic characteristics of the ISO MJ threads (restricted form variation and increased root radius of

the external thread) as well as the specific tolerances and to standardize the gauging principles for

ISO MJ threads, intended for products for aerospace applications.

FINAL DRAFT INTERNATIONAL STANDARD ISO/FDIS 10959:2015(E)

Aerospace — MJ threads — Gauging

1 Scope

This International Standard contains information for the gauging of ISO MJ threads in accordance with

ISO 58551, ISO 58552, and ISO 58553.

Other methods of ensuring that the product is within the specified limits may be used provided

correlation with the specified gauges is established [see 8.2, e)].

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 1, Geometrical Product Specifications (GPS) — Standard reference temperature for geometrical

product specification and verification

ISO 1502:1996, ISO general-purpose metric screw threads — Gauges and gauging

ISO 5408, Screw threads — Vocabulary

ISO 58551, Aerospace — MJ threads — Part 1: General requirements

ISO 58552, Aerospace — MJ threads — Part 2: Limit dimensions for bolts and nuts

ISO 58553, Aerospace — MJ threads — Part 3: Limit dimensions for fittings for fluid systems

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 5408 and the following apply.

3.1

best wire size

cylinder or sphere which has a radius so that it will contact the thread flanks at the pitch cylinder

intersection

Note 1 to entry: The radius of the best wire or sphere is theoretically equal to 0,288 68 P.

3.2

indicating gauge

device having contacts which will precisely compare the size of a work piece thread to a setting

standard of known dimensions

Note 1 to entry: The value for the indicated characteristic thus established is the dimensional value attributed

to the work piece. An indicating gauge may have contacts designed to measure any thread characteristic. This

International Standard specifies the characteristics and designs for ISO MJ threads.

3.3

simple pitch diameter

diameter of an imaginary cylinder intersecting an actual thread over the width of one groove where

that width is equal to one half of the basic pitch

ISO/FDIS 10959:2015(E)

3.4

virtual pitch diameter

pitch diameter of the smallest (for external threads) or largest (for internal threads) perfect thread

form with GO gauge profile which can engage the product threads for a distance equal to the GO gauge

thread engagement

4 Types of gauges

4.1 Gauges and setting plugs for external product threads

Gauge type Reference

a) GO screw ring gauges 6.1.2

b) Setting plug for adjustable GO screw ring and indicating thread gauges 7.1

c) Virtual pitch diameter indicating thread gauges 6.1.1

d) Simple pitch diameter indicating thread gauges 6.1.3

e) Flat contact gauges for major diameter 6.1.4

f) Point contact indicating thread gauges for minor diameter 6.1.5

g) Optical comparator for root radius and minor diameter 6.1.6

4.2 Gauges for internal product threads

Gauge type Reference

a) GO screw plug gauges 6.2.1

b) NOT GO screw plug gauges 6.2.2

c) Plain gauges for minor diameter (plug gauge) 6.2.3

d) GO full form screw plug gauges 6.2.3.2

e) Virtual pitch diameter indicating thread gauges 6.2.4

f) Simple pitch diameter indicating thread gauges 6.2.5

5 Reference temperature

In accordance with ISO 1, the dimensions of the gauge and the product shall be checked at the

temperature of 20 °C.

If the product and the gauge have the same coefficients of linear expansion, the temperature may

deviate from 20 °C, provided the temperature of the product and the gauge are the same.

If the product and the gauge have different coefficients of linear expansion, the temperature of both, at

the time of gauging, shall be

a) 20 °C ± 2 °C for sizes MJ24 and smaller, and

b) 20 °C ± 1 °C for larger threads.

2 © ISO 2015 – All rights reserved

ISO/FDIS 10959:2015(E)

6 Function, design, and use of gauges

6.1 Gauges for external threads

6.1.1 Virtual pitch diameter indicating thread gauges

6.1.1.1 It measures, on two or three segments or rolls, the maximum material virtual pitch diameter,

taking into account variations of form such as pitch variation, helix and flank variations, roundness, and

taper which produces an enlargement of the virtual pitch diameter. In addition, virtual pitch diameter

control ensures the flank angle contact is sufficient to ensure that the root radius does not exceed the

maximum limit. Measurement of virtual pitch diameter with indicating gauges shall be obtained to

calculate virtualminussimple pitchdiameter differential unless the simple pitch diameter limits, gauged

in accordance with the measurements given in 6.1.3, are within the limits defined by the maximum pitch

diameter and the form variation limits in ISO 58551.

6.1.1.2 Indicating gauges have two or three contacts at 180° or 120° respectively. Gauges with segments

or rolls are designed with the length of the GO virtual maximum material gauging elements equal to the

GO ring gauge length (see Table 1). For configuration and profile requirements, see Figure 1.

6.1.1.3 The minor diameter of the GO virtual maximum material thread segments and the diameter

of the circle surrounded by the roll cluster of GO virtual maximum material rolls shall be equal to the

pitch diameter of the product minus 0,375 H, less the T , minus tolerance when assembled in the gauge

PL

frame, where T is specified in ISO 1502. This corresponds to a flat width of 0,312 5 P on the minor crest

PL

for the thread. The crest shall be flat in an axial plane and parallel to the axis of the segments or rolls.

6.1.1.4 The major diameter of the GO virtual maximum material segments and the root of the GO virtual

maximum material rolls shall be cleared beyond a 0,125 P flat, either by an extension of the flanks of the

thread toward a sharp vee or by an undercut no greater than 0,125 P maximum width and approximately

central. The root clearance shall be such that the major diameter of the full form section of the thread

setting plug gauge is cleared after the assembled gauge has been properly set to size. Optional clearance

specifications given in ISO 1502 may be used.

6.1.1.5 The simple pitch diameter cylinder axis of threaded segments and rolls shall be straight within

the diameter tolerance zone equal to T as specified in ISO 1502. The segment or roll thread profile,

PL

lead, pitch, and the half-angle variations shall be within the limits specified in ISO 1502.

6.1.2 Solid or adjustable GO screw ring gauges

To ensure the ease of assembly of product threads and conformance to the maximum material virtual

pitch diameter limits, GO screw ring gauges with thread form as shown in Figure 1 and setting gauges

in accordance with the details described in 6.1 may be used. Solid GO screw ring gauges shall not be

permitted to exceed the product thread dimensional limits. The gauge thickness/length shall be

standardized as shown in Table 1. The gauge tolerances, W , shall be in accordance with ISO 1502.

GO

6.1.3 Simple pitch diameter indicating thread gauges

The simple pitch diameter indicating gauge with cone and vee rolls or segments or rolls with the

best wire size radius allows to ensure that the pitch diameter is greater than the minimum limit. The

indicators are set to the GO threaded setting plug gauge. Readings indicate the position of the pitch

diameter and the minimum measurement shall be no less than the minimum pitch diameter limit. The

minimum measured pitch diameter shall be within the ISO 58551 form variation limit compared to the

virtual pitch diameter measurement in accordance with the differential value given in 6.1.1.

The simple pitch diameter contacts have cone and vee rolls or segments which contact the product

pitch cylinder. Other designs have two or three rolls with radii on annular ribs on rolls made to best

ISO/FDIS 10959:2015(E)

wire size. The product thread contacts is restricted to 1,5 pitch lengths. See Figures 2 and 3 for design

and contact form.

6.1.4 Major diameter gauges

The maximum limit of the major diameter may be checked with a plain ring gauge, a plain GO calliper,

or plain diameter measuring device (see Figure 4). The minimum limit of the major diameter

...

INTERNATIONAL ISO

STANDARD 10959

Second edition

2016-03-01

Aerospace — MJ threads — Gauging

Aéronautique et espace — Filetage MJ — Vérification par calibres

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Types of gauges . 2

4.1 Gauges and setting plugs for external product threads . 2

4.2 Gauges for internal product threads . 2

5 Reference temperature . 2

6 Function, design, and use of gauges . 3

6.1 Gauges for external threads . 3

6.1.1 Virtual pitch diameter indicating thread gauges . 3

6.1.2 Solid or adjustable GO screw ring gauges . 3

6.1.3 Simple pitch diameter indicating thread gauges . . 3

6.1.4 Major diameter gauges . 4

6.1.5 Minor diameter gauges. 4

6.1.6 Optical comparator checks . 4

6.2 Gauging for internal threads . 4

6.2.1 GO screw plug gauges . 4

6.2.2 NOT GO screw plug gauges . 4

6.2.3 Minor diameter gauges. 4

6.2.4 Virtual pitch diameter indicating thread gauges . 4

6.2.5 Simple pitch diameter indicating thread gauges . . 5

7 Setting gauges . 5

8 Gauging of threads . 5

Annex A (normative) Prevalence of gauging by GO gauges .19

Bibliography .20

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 20, Aircraft and space vehicles, Subcommittee

SC 4, Aerospace fastener systems.

This second edition cancels and replaces the first edition (ISO 10959:2000), which has been technically

revised.

iv © ISO 2016 – All rights reserved

Introduction

The purpose of this International Standard, which differs from ISO 1502, is to take into account the

basic characteristics of the ISO MJ threads (restricted form variation and increased root radius of

the external thread) as well as the specific tolerances and to standardize the gauging principles for

ISO MJ threads, intended for products for aerospace applications.

INTERNATIONAL STANDARD ISO 10959:2016(E)

Aerospace — MJ threads — Gauging

1 Scope

This International Standard contains information for the gauging of ISO MJ threads in accordance with

ISO 5855-1, ISO 5855-2, and ISO 5855-3.

Other methods of ensuring that the product is within the specified limits may be used provided

correlation with the specified gauges is established [see 8.2, e)].

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 1, Geometrical Product Specifications (GPS) — Standard reference temperature for geometrical

product specification and verification

ISO 1502:1996, ISO general-purpose metric screw threads — Gauges and gauging

ISO 5408, Screw threads — Vocabulary

ISO 5855-1, Aerospace — MJ threads — Part 1: General requirements

ISO 5855-2, Aerospace — MJ threads — Part 2: Limit dimensions for bolts and nuts

ISO 5855-3, Aerospace — MJ threads — Part 3: Limit dimensions for fittings for fluid systems

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 5408 and the following apply.

3.1

best wire size

cylinder or sphere which has a radius so that it will contact the thread flanks at the pitch cylinder

intersection

Note 1 to entry: The radius of the best wire or sphere is theoretically equal to 0,288 68 P.

3.2

indicating gauge

device having contacts which will precisely compare the size of a work piece thread to a setting

standard of known dimensions

Note 1 to entry: The value for the indicated characteristic thus established is the dimensional value attributed

to the work piece. An indicating gauge may have contacts designed to measure any thread characteristic. This

International Standard specifies the characteristics and designs for ISO MJ threads.

3.3

simple pitch diameter

diameter of an imaginary cylinder intersecting an actual thread over the width of one groove where

that width is equal to one half of the basic pitch

3.4

virtual pitch diameter

pitch diameter of the smallest (for external threads) or largest (for internal threads) perfect thread

form with GO gauge profile which can engage the product threads for a distance equal to the GO gauge

thread engagement

4 Types of gauges

4.1 Gauges and setting plugs for external product threads

Gauge type Reference

a) GO screw ring gauges 6.1.2

b) Setting plug for adjustable GO screw ring and indicating thread gauges 7.1

c) Virtual pitch diameter indicating thread gauges 6.1.1

d) Simple pitch diameter indicating thread gauges 6.1.3

e) Flat contact gauges for major diameter 6.1.4

f) Point contact indicating thread gauges for minor diameter 6.1.5

g) Optical comparator for root radius and minor diameter 6.1.6

4.2 Gauges for internal product threads

Gauge type Reference

a) GO screw plug gauges 6.2.1

b) NOT GO screw plug gauges 6.2.2

c) Plain gauges for minor diameter (plug gauge) 6.2.3

d) GO full form screw plug gauges 6.2.3.2

e) Virtual pitch diameter indicating thread gauges 6.2.4

f) Simple pitch diameter indicating thread gauges 6.2.5

5 Reference temperature

In accordance with ISO 1, the dimensions of the gauge and the product shall be checked at the

temperature of 20 °C.

If the product and the gauge have the same coefficients of linear expansion, the temperature may

deviate from 20 °C, provided the temperature of the product and the gauge are the same.

If the product and the gauge have different coefficients of linear expansion, the temperature of both, at

the time of gauging, shall be

a) 20 °C ± 2 °C for sizes MJ24 and smaller, and

b) 20 °C ± 1 °C for larger threads.

2 © ISO 2016 – All rights reserved

6 Function, design, and use of gauges

6.1 Gauges for external threads

6.1.1 Virtual pitch diameter indicating thread gauges

6.1.1.1 It measures, on two or three segments or rolls, the maximum material virtual pitch diameter,

taking into account variations of form such as pitch variation, helix and flank variations, roundness, and

taper which produces an enlargement of the virtual pitch diameter. In addition, virtual pitch diameter

control ensures the flank angle contact is sufficient to ensure that the root radius does not exceed the

maximum limit. Measurement of virtual pitch diameter with indicating gauges shall be obtained to

calculate virtual-minus-simple pitch-diameter differential unless the simple pitch diameter limits, gauged

in accordance with the measurements given in 6.1.3, are within the limits defined by the maximum pitch

diameter and the form variation limits in ISO 5855-1.

6.1.1.2 Indicating gauges have two or three contacts at 180° or 120° respectively. Gauges with segments

or rolls are designed with the length of the GO virtual maximum material gauging elements equal to the

GO ring gauge length (see Table 1). For configuration and profile requirements, see Figure 1.

6.1.1.3 The minor diameter of the GO virtual maximum material thread segments and the diameter

of the circle surrounded by the roll cluster of GO virtual maximum material rolls shall be equal to the

pitch diameter of the product minus 0,375 H, less the T , minus tolerance when assembled in the gauge

PL

frame, where T is specified in ISO 1502. This corresponds to a flat width of 0,312 5 P on the minor crest

PL

for the thread. The crest shall be flat in an axial plane and parallel to the axis of the segments or rolls.

6.1.1.4 The major diameter of the GO virtual maximum material segments and the root of the GO virtual

maximum material rolls shall be cleared beyond a 0,125 P flat, either by an extension of the flanks of the

thread toward a sharp vee or by an undercut no greater than 0,125 P maximum width and approximately

central. The root clearance shall be such that the major diameter of the full form section of the thread

setting plug gauge is cleared after the assembled gauge has been properly set to size. Optional clearance

specifications given in ISO 1502 may be used.

6.1.1.5 The simple pitch diameter cylinder axis of threaded segments and rolls shall be straight within

the diameter tolerance zone equal to T as specified in ISO 1502. The segment or roll thread profile,

PL

lead, pitch, and the half-angle variations shall be within the limits specified in ISO 1502.

6.1.2 Solid or adjustable GO screw ring gauges

To ensure the ease of assembly of product threads and conformance to the maximum material virtual

pitch diameter limits, GO screw ring gauges with thread form as shown in Figure 1 and setting gauges

in accordance with the details described in 6.1 may be used. Solid GO screw ring gauges shall not be

permitted to exceed the product thread dimensional limits. The gauge thickness/length shall be

standardized as shown in Table 1. The gauge tolerances, W , shall be in accordance with ISO 1502.

GO

6.1.3 Simple pitch diameter indicating thread gauges

The simple pitch diameter indicating gauge with cone and vee rolls or segments or rolls with the

best wire size radius allows to ensure that the pitch diameter is greater than the minimum limit. The

indicators are set to the GO threaded setting plug gauge. Readings indicate the position of the pitch

diameter and the minimum measurement shall be no less than the minimum pitch diameter limit. The

minimum measured pitch diameter shall be within the ISO 5855-1 form variation limit compared to the

virtual pitch diameter measurement in accordance with the differential value given in 6.1.1.

The simple pitch diameter contacts have cone and vee rolls or segments which contact the product

pitch cylinder. Other designs have two or three rolls with radii on annular ribs on rolls made to best

wire size. The product thread contacts is restricted to 1,5 pitch lengths. See Figures 2 and 3 for design

and contact form.

6.1.4 Major diameter gauges

The maximum limit of the major diameter may be checked with a plain ring gauge, a plain GO calliper,

or plain diameter measuring device (see Figure 4). The minimum limit of the major diameter shall be

measured with a plain diameter measuring device set to a plain diameter plug with H tolerance in

P

accordance with ISO 1502. Plain micrometer calliper may be used to measure the major diameter and

may have standard ga

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...