ISO 17735:2009

(Main)Workplace atmospheres - Determination of total isocyanate groups in air using 1-(9-anthracenylmethyl)piperazine (MAP) reagent and liquid chromatography

Workplace atmospheres - Determination of total isocyanate groups in air using 1-(9-anthracenylmethyl)piperazine (MAP) reagent and liquid chromatography

ISO 17735:2009 gives general guidance for the sampling and analysis of airborne organic isocyanates in workplace air. ISO 17735:2009 is appropriate for a wide range of organic compounds containing isocyanate groups, including monofunctional isocyanates (e.g. phenyl isocyanate), diisocyanate monomers (e.g. 1,6-hexamethylene diisocyanate (HDI), toluene diisocyanate (TDI), 4,4'-diphenylmethane diisocyanate (MDI), and isophorone diisocyanate (IPDI), prepolymers (e.g. the biuret and isocyanurate of HDI), as well as intermediate products formed during production or thermal breakdown of polyurethane. In mixed systems of HDI and IPDI products, it is impossible to identify and quantify low levels of IPDI monomer using ISO 17735:2009, due to coelution of IPDI monomer with HDI-uretidinedione. The useful range of the method, expressed in moles of isocyanate group per species per sample, is approximately 1 x 10-10 to 2 x 10-7.

Air des lieux de travail — Dosage des groupements isocyanates totaux dans l'air par réaction avec la 1-(9-anthracénylméthyl)pipérazine (MAP) et par chromatographie en phase liquide

General Information

Relations

Frequently Asked Questions

ISO 17735:2009 is a standard published by the International Organization for Standardization (ISO). Its full title is "Workplace atmospheres - Determination of total isocyanate groups in air using 1-(9-anthracenylmethyl)piperazine (MAP) reagent and liquid chromatography". This standard covers: ISO 17735:2009 gives general guidance for the sampling and analysis of airborne organic isocyanates in workplace air. ISO 17735:2009 is appropriate for a wide range of organic compounds containing isocyanate groups, including monofunctional isocyanates (e.g. phenyl isocyanate), diisocyanate monomers (e.g. 1,6-hexamethylene diisocyanate (HDI), toluene diisocyanate (TDI), 4,4'-diphenylmethane diisocyanate (MDI), and isophorone diisocyanate (IPDI), prepolymers (e.g. the biuret and isocyanurate of HDI), as well as intermediate products formed during production or thermal breakdown of polyurethane. In mixed systems of HDI and IPDI products, it is impossible to identify and quantify low levels of IPDI monomer using ISO 17735:2009, due to coelution of IPDI monomer with HDI-uretidinedione. The useful range of the method, expressed in moles of isocyanate group per species per sample, is approximately 1 x 10-10 to 2 x 10-7.

ISO 17735:2009 gives general guidance for the sampling and analysis of airborne organic isocyanates in workplace air. ISO 17735:2009 is appropriate for a wide range of organic compounds containing isocyanate groups, including monofunctional isocyanates (e.g. phenyl isocyanate), diisocyanate monomers (e.g. 1,6-hexamethylene diisocyanate (HDI), toluene diisocyanate (TDI), 4,4'-diphenylmethane diisocyanate (MDI), and isophorone diisocyanate (IPDI), prepolymers (e.g. the biuret and isocyanurate of HDI), as well as intermediate products formed during production or thermal breakdown of polyurethane. In mixed systems of HDI and IPDI products, it is impossible to identify and quantify low levels of IPDI monomer using ISO 17735:2009, due to coelution of IPDI monomer with HDI-uretidinedione. The useful range of the method, expressed in moles of isocyanate group per species per sample, is approximately 1 x 10-10 to 2 x 10-7.

ISO 17735:2009 is classified under the following ICS (International Classification for Standards) categories: 13.040.30 - Workplace atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 17735:2009 has the following relationships with other standards: It is inter standard links to ISO 17735:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 17735:2009 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 17735

First edition

2009-03-15

Workplace atmospheres — Determination

of total isocyanate groups in air using

1-(9-anthracenylmethyl)piperazine (MAP)

reagent and liquid chromatography

Air des lieux de travail — Dosage des groupements isocyanates totaux

dans l'air par réaction avec la 1-(9-anthracénylméthyl)pipérazine (MAP)

et par chromatographie en phase liquide

Reference number

©

ISO 2009

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2009

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2009 – All rights reserved

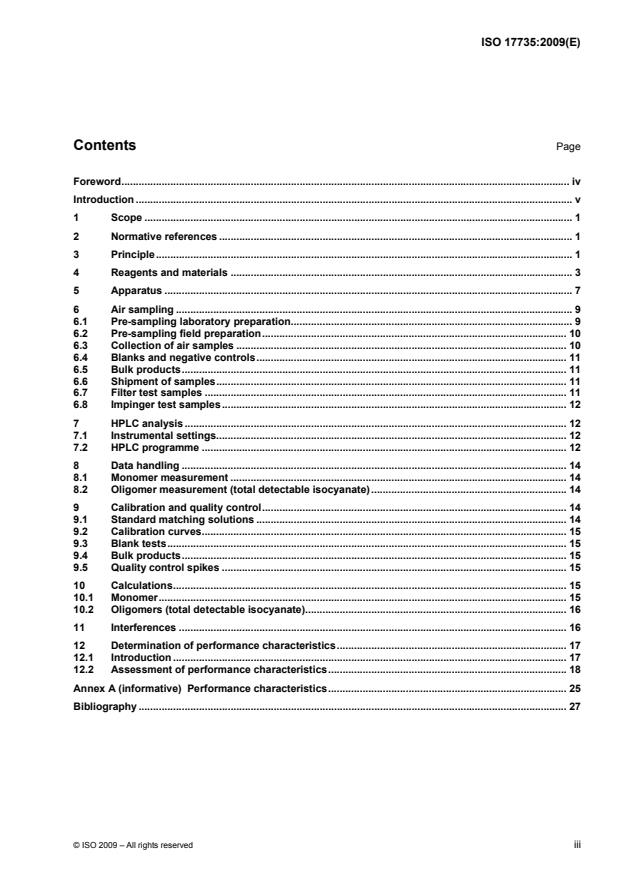

Contents Page

Foreword. iv

Introduction . v

1 Scope . 1

2 Normative references . 1

3 Principle. 1

4 Reagents and materials . 3

5 Apparatus . 7

6 Air sampling . 9

6.1 Pre-sampling laboratory preparation. 9

6.2 Pre-sampling field preparation. 10

6.3 Collection of air samples . 10

6.4 Blanks and negative controls. 11

6.5 Bulk products. 11

6.6 Shipment of samples. 11

6.7 Filter test samples . 11

6.8 Impinger test samples. 12

7 HPLC analysis . 12

7.1 Instrumental settings. 12

7.2 HPLC programme . 12

8 Data handling . 14

8.1 Monomer measurement . 14

8.2 Oligomer measurement (total detectable isocyanate). 14

9 Calibration and quality control. 14

9.1 Standard matching solutions . 14

9.2 Calibration curves. 15

9.3 Blank tests. 15

9.4 Bulk products. 15

9.5 Quality control spikes . 15

10 Calculations. 15

10.1 Monomer. 15

10.2 Oligomers (total detectable isocyanate). 16

11 Interferences . 16

12 Determination of performance characteristics. 17

12.1 Introduction . 17

12.2 Assessment of performance characteristics. 18

Annex A (informative) Performance characteristics. 25

Bibliography . 27

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 17735 was prepared by Technical Committee ISO/TC 146, Air quality, Subcommittee SC 2, Workplace

atmospheres.

iv © ISO 2009 – All rights reserved

Introduction

This International Standard specifies the use of 1-(9-anthracenylmethyl)piperazine (MAP) to measure

monomeric and oligomeric isocyanate species in workplace atmospheres. MAP was designed to improve the

reliability of identification of isocyanate species in sample chromatograms and to improve the accuracy of

quantification of these species relative to established reagents. The high performance liquid chromatography

(HPLC) analysis uses a pH gradient to selectively accelerate the elution of MAP derivatives of oligomeric

isocyanates that might be unobservable in an isocratic analysis. The performance of MAP has been compared

to other reagents used for total isocyanate analysis (Reference [7]). MAP has been found to react with phenyl

isocyanate (used as a model isocyanate) as fast or faster than other reagents commonly used for isocyanate

analysis. The UV response of MAP derivatives is comparable to that of 9-(methylaminomethyl)anthracene

(MAMA) derivatives and considerably greater than other commonly used reagents [approximately three times

greater than 1-(2-methoxyphenyl)piperazine (1-2MP) derivatives of aromatic isocyanates and 14 times greater

than 1-2MP derivatives of aliphatic isocyanates]. The compound-to-compound variability of UV response per

isocyanate group for MAP derivatives is smaller than the variability of any other commonly used

reagent/detector combination (the coefficient of variation is 3,5 % for five model isocyanates). This results in

accurate quantification of detectable non-monomeric isocyante species based on a calibration curve

generated from analysing standards of monomeric species. The monomeric species used for calibration is

generally the one associated with the product being analysed, but others could be used due to the very small

compound-to-compound response variability of the MAP derivatives. The intensity of fluorescence response of

MAP derivatives is comparable to that of MAMA derivatives and considerably greater than other reagents (e.g.

approximately 30 times more intense than that of tryptamine derivatives). The compound-to-compound

variability in fluorescence response has been found to be smaller than that of MAMA derivatives but larger

than that of tryptamine derivatives (MAMA = 59 % coefficient of variation, MAP = 33 % coefficient of variation,

and tryptamine = 16 % coefficient of variation for 5 model isocyanates). The compound-to-compound

fluorescence variability of MAP derivatives is considered too great for accurate quantification of non-

monomeric isocyanate species based on calibration with monomer standards. However, the sensitivity of the

fluorescence detection makes it especially suitable for quantification of low levels of monomer, and the

selectivity is very useful to designate an unidentified HPLC peak as a MAP derivative. MAP derivatives also

give a strong response by electrochemical detection. The pH gradient used in the HPLC analysis selectively

accelerates the elution of amines (MAP derivatives are amines), and is very strong (it accelerates MDI more

than 100-fold). Re-equilibration to initial conditions is almost immediate. Many oligomeric species can be

measured in the 30 min MAP analysis that may be unobservable in a much longer isocratic analysis.

MAP has been used in several studies comparing it side-by-side with other methods. Reference [8] found

MAP impingers and NIOSH 5521 impingers (comparable to MDHS 25) to give comparable results in spray

painting environments. Reference [8] used MAP reagent, but the pH gradient was not employed.

Reference [9] compared MAP impingers with several other impinger methods (NIOSH 5521 and NIOSH 5522)

and the double filter method. The average MAP oligomer value was substantially higher than the other

impinger methods and slightly higher than the double filter method. The pH gradient was used in these MAP

analyses.

The MAP method is currently available as NIOSH Method 5525 (Reference [11]). The performance

characteristics of the method have been evaluated in Reference [12].

INTERNATIONAL STANDARD ISO 17735:2009(E)

Workplace atmospheres — Determination of total isocyanate

groups in air using 1-(9-anthracenylmethyl)piperazine (MAP)

reagent and liquid chromatography

1 Scope

This International Standard gives general guidance for the sampling and analysis of airborne organic

isocyanates in workplace air.

This International Standard is appropriate for a wide range of organic compounds containing isocyanate

groups, including monofunctional isocyanates (e.g. phenyl isocyanate), diisocyanate monomers (e.g.

1,6-hexamethylene diisocyanate (HDI), toluene diisocyanate (TDI), 4,4’-diphenylmethane diisocyanate (MDI),

and isophorone diisocyanate (IPDI), prepolymers (e.g. the biuret and isocyanurate of HDI), as well as

intermediate products formed during production or thermal breakdown of polyurethane.

In mixed systems of HDI and IPDI products, it is impossible to identify and quantify low levels of IPDI

monomer using this International Standard, due to coelution of IPDI monomer with HDI-uretidinedione.

The useful range of the method, expressed in moles of isocyanate group per species per sample, is

−10 −7

approximately 1 × 10 to 2 × 10 .

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 5725-2, Accuracy (trueness and precision) of measurement methods and results — Part 2: Basic method

for the determination of repeatability and reproducibility of a standard measurement method

ISO 16200-1, Workplace air quality — Sampling and analysis of volatile organic compounds by solvent

desorption/gas chromatography — Part 1: Pumped sampling method

3 Principle

A measured volume of air is drawn through either an impinger containing a solution of

1-(9-anthracenylmethyl)piperazine (MAP), a filter impregnated with MAP, or a sampling train consisting of an

impinger followed by an impregnated filter. The choice of sampler depends on the chemical and physical

characteristics of the airborne isocyanate (Reference [13]). If an impinger is used, the solution is subjected to

solid-phase extraction (SPE) and the eluate is concentrated and analysed by reverse phase high performance

liquid chromatography (HPLC) with ultraviolet (UV) absorbance and fluorescence (FL) detection in series. If an

impregnated filter is used for sampling, it is extracted with solvent either in the field after completion of

sampling or in the laboratory. Waiting to extract the filter until after the sample has been received by the

analytical laboratory is acceptable only for analysis of isocyanates collected as vapour. This solution is filtered

and analysed by HPLC/UV/FL. Isocyanate-derived peaks are identified based on their UV and FL responses

and by comparison with the chromatogram of a derivatised bulk isocyanate product if available. Quantification

of compounds for which analytical standards are available (generally monomers) is achieved by comparison

of the FL peak height of the sample peak with the FL peak height of standard matching solutions.

Quantification of compounds for which analytical standards are not available is achieved by comparison of the

UV area of the sample peak with the UV area of the appropriate monomer standard (i.e. the monomer from

which the isocyanate product is derived).

Structures of some common diisocyanate monomers are shown in Figure 1.

Key

1 methyl isocyanate

2 butyl isocyanate

3 phenyl isocyanate

4 4,4’-MDI

5 2,6-TDI

6 HDI

7 2,4-TDI

8 IPDI

9 HMDI

Figure 1 — Structures of some common isocyanates

2 © ISO 2009 – All rights reserved

4 Reagents and materials

CAUTION — Observe appropriate safety precautions when preparing reagents. Carry out preparations

under a fume hood to avoid exposure to solvents, isocyanates or other volatile reagents. Wear nitrile

gloves when manipulating reagents and solvents.

During the analysis, unless otherwise stated, use only reagents of HPLC grade or better, and water of HPLC

grade.

4.1 MAP reagent

MAP is prepared by the reaction of 9-(chloromethyl)anthracene with piperazine as shown in Figure 2.

The procedure using HPLC grade solvents is as follows.

Dissolve 10,8 mmol (2,47 g) of 9-(chloromethyl)anthracene (98 % mass fraction) in 25 ml methylene chloride.

Place this solution in a dropping funnel.

Dissolve 54,4 mmol (4,69 g) of piperazine (99 % mass fraction) and 21,8 mmol (3,04 ml) of triethylamine

(99,5 % mass fraction) in 37 ml methylene chloride. Place this solution in a 250 ml 2-necked round-bottomed

flask with a magnetic stirring bar.

While stirring this solution, add the 9-(chloromethyl)anthracene solution dropwise over a 30 min period. Rinse

down the dropping funnel with an additional 10 ml of methylene chloride. Allow the reaction to continue while

stirring for at least 2 h.

Using a separating funnel, wash the reaction mixture three times with 130 ml water by shaking vigorously for

1 min. Discard the emulsion that forms after the first wash, which contains primarily an impurity and not MAP.

Discard the aqueous washings.

Place the washed MAP solution in a weighed round-bottomed flask. Allow the methylene chloride to evaporate

under a steady stream of nitrogen. Weigh the flask with the residue to obtain an approximate yield. This crude

MAP can be safely stored in a freezer until further purification.

MAP is purified by column chromatography followed by sublimation. Using a glass chromatography column of

internal diameter approximately 50 mm, add a slurry of silica gel in toluene until the silica gel bed is

approximately 80 mm deep. Wash the sides of the column down with toluene and allow the toluene to run

through the column until the toluene is even with the silica gel surface.

Dissolve the crude MAP in 80 ml of toluene. Sonicate the mixture for 5 min and filter through filter paper. Save

the filtrate. Resuspend the residue in 20 ml toluene, sonicate for 5 min, and filter through filter paper. Discard

the residue. Combine the filtrates and carefully load them onto the top of the silica gel bed. Pass an additional

bed volume of toluene through the column. Discard the toluene eluate.

Begin to elute with ethyl acetate. Begin collecting 20 ml fractions in disposable vials with caps lined with

polytetrafluoroethylene (PTFE). Monitor the fractions by spotting 1 µl of each on a thin layer chromatography

(TLC) sheet (see below) and viewing the intensity of the spot under UV light after the solvent has evaporated.

This procedure indicates the presence of compounds in the fraction, which may or may not be MAP. Elute

with ethyl acetate until the yellow colour has been eluted, which requires about 400 ml ethyl acetate. The MAP

should be completely retained on the column at this point. After elution of the yellow colour, begin eluting with

methanol, which requires 1,0 l to 1,5 l methanol.

The elution of the MAP can be readily followed by TLC. A portion of the fractions that had given a significant

spot on the TLC sheet are analysed by TLC to determine which fractions contain MAP.

The TLC procedure is carried out as follows. Use commercially available TLC sheets coated with silica gel

and containing a fluorescent indicator. A portion of a sheet measuring 100 mm × 30 mm is adequate. Spot

aliquots of volume 1 µl of several fractions adjacent to each other approximately 15 mm from the bottom of the

sheet and place the sheet in a small jar containing methanol 10 mm deep. Cover the jar and allow the

methanol to climb up the sheet to 5 mm from the top. Remove the sheet and allow the methanol saturating the

sheet to evaporate. MAP produces a dark spot when viewed under short wavelength UV light which glows

under irradiation with long wavelength UV. Identify the MAP spot by comparing the retention factor, R , of the

f

aliquot spots with the R of a MAP standard.

f

Based on TLC analyses, combine the fractions containing pure MAP. Weigh a round-bottomed flask to be

used for rotary evaporation. Add the combined fractions to the flask, but do not exceed half the volume of the

flask at any given time. Heat the evaporator bath to 35 °C to 40 °C and use water aspirator vacuum. After

evaporation and trace solvent removal from all of the combined MAP fractions under high vacuum, weigh the

flask and its contents to assess the yield.

Purify the MAP powder further by sublimation. Dissolve the MAP in a small volume of methylene chloride

(< 20 ml) and transfer the solution to a sublimation apparatus. Allow the methylene chloride to evaporate

under a gentle stream of nitrogen, keeping the MAP below the level of the bottom of the coldfinger. When the

methylene chloride has evaporated, seal the vessel and reduce the pressure with a vacuum pump to

1)

6,67 mPa or less. Begin a slow flow of cold water through the coldfinger and place the sublimation vessel in

a wax bath maintained at 125 °C to 130 °C. Sublimation takes many hours and may need to continue

overnight. Sublimation is complete when there is no further growth of MAP crystals on the coldfinger and the

small amount of material remaining at the bottom of the apparatus appears constant. When complete, remove

the crystals from the coldfinger with a spatula. A typical yield is 2,236 g (74 % mass fraction). The melting

point of the MAP is 146 °C to 147 °C. The purity of MAP as assessed by HPLC is typically 99 % mass fraction.

Key

1 9-(chloromethyl)anthracene

2 piperazine

3 MAP

Figure 2 — Preparation of MAP

4.2 Reagent solutions

4.2.1 Impinger solution

Butyl benzoate, 99 % mass fraction, is used as the impinger solvent. The butyl benzoate is further purified by

passing it through a bed of chromatography-grade silica gel. Dissolve MAP in the butyl benzoate to make a

−4

1 × 10 mol/l solution (27,6 mg/l). Store the solution in a refrigerator until use.

1) 1 Pa = 7,5 torr.

4 © ISO 2009 – All rights reserved

4.2.2 Solution for filter impregnation

MAP is dissolved in acetonitrile to make a solution of 2 mg/ml. Store in a freezer until use.

4.2.3 Filter extraction solution

−4

MAP is dissolved in acetonitrile to make a 1 × 10 mol/l solution (27,6 mg/l). Store in a freezer until use.

4.2.4 Stability of reagent solutions

It is best to make filter-spiking solution immediately before use, but this solution can be stored for up to

2 weeks in a freezer. The impinger and filter extraction solutions are stable for at least 1 month in a

refrigerator.

4.3 Standard matching solutions

The UV detector response is nearly identical for all MAP-derivatised isocyanate groups. This allows the use of

the MAP-derivatised monomer of the isocyanate product of interest as a standard for quantification of the

other unknown oligomeric MAP-derivatised species in the chromatogram. A calibration curve, plotting UV

response as a function of number or concentration of isocyanate groups, can then be used to quantify the

oligomeric species for which there is no standard available. For this reason, it is conceptually simpler to use

standard matching solutions quantified in terms of their concentration of isocyanate groups rather than in

terms of mass concentration of isocyanate compound.

An equivalent is the amount of substance of isocyanate compound containing a mole of isocyanate group or

the amount of substance of MAP-derivatised isocyanate compound containing a mole of bound MAP groups.

The equivalent mass of an isocyanate compound is the relative molecular mass divided by the number of

isocyanate groups per molecule, n. The equivalent mass of a MAP-derivatised isocyanate compound is the

relative molecular mass divided by the number of MAP groups per molecule. The number of isocyanate

groups, irrespective of their attachment, can be measured in moles per litre. Table 1 lists relative molecular

masses and equivalent masses for common isocyanates and their MAP derivatives.

4.3.1 Preparation of monomer derivatives

Accurately weigh approximately 0,5 mmol (1 milliequivalent) of diisocyanate or 1 mmol (1 milliequivalent) of a

monoisocyanate and record the amount of substance to four decimal places. Dissolve in 10 ml of toluene.

Weigh approximately 1,2 mmol of MAP (20 % mass fraction excess) and record the amount of substance to

four decimal places. Dissolve in 20 ml of toluene. While stirring the MAP solution, add the isocyanate solution

dropwise over a period of 10 min to 15 min. Continue to stir for at least 1 h. Tightly cover the solution and

store overnight in a freezer to maximise precipitation of product. Collect the precipitate using a Büchner funnel.

Wash the precipitate several times with cold toluene to remove residual MAP, then wash it several times with

cold hexane to displace the toluene. Transfer the solid derivative to a preweighed 20 ml disposable vial.

Subject the vial to high vacuum until constant mass is obtained and seal with a PTFE-lined cap. Yields are

typically > 95 % mass fraction and purity is sufficient to use this material for standard matching solutions.

Experience shows that when stored in the dark in a freezer, these derivatives are stable for several years.

4.3.2 Preparation of standard solutions of monomer derivatives for HPLC analysis

−5 −5

Of a MAP derivative, weigh approximately 5,0 × 10 mol (monoisocyanate) or 2,5 × 10 mol (diisocyanate)

−5 [1]

(5,0 × 10 equivalents) into a 10 ml one-mark volumetric flask, ISO 1042 , class A. Dissolve in several

millilitres dimethyl formamide (DMF) and fill to the mark with DMF. Methylene chloride can be used instead, if

desired, for MAP derivatives that are very soluble in methylene chloride (aliphatic diisocyanates and 2,4-TDI).

−3 −3

The stock solutions are of approximate concentration 5,0 × 10 mol/l (monoisocyanate) or 2,5 × 10 mol

(diisocyanate). Store the stock solutions in a freezer. Working standards are made by dilution into acetonitrile,

−4

with the highest concentration standard being approximately 2,0 × 10 mol/l (monoisocyanate) or

−4

1,0 × 10 mol/l (diisocyanate). Other concentrations can be made by serial dilution, typically the lowest

−7 −7

concentration being approximately 1 × 10 mol/l (monoisocyanate) or 0,5 × 10 mol/l (diisocyanate). These

stock solutions and dilutions are stable for up to 3 months when stored in a refrigerator.

Table 1 — Relative molecular masses and equivalent masses of some common isocyanates

and their MAP derivatives

Equivalent

Relative MAP derivative

Short MAP derivative

mass

Compound molecular relative molecular

form equivalent mass

mass mass

m[eq]

1-(9-Anthracenylmethyl)piperazine MAP 276,38 276,38 — —

Methyl isocyanate 57,05 57,05 333,43 333,43

Butyl isocyanate 99,13 99,13 375,51 375,51

Phenyl isocyanate 119,12 119,12 395,50 395,50

1,6-Hexamethylene diisocyanate

HDI 168,20 84,10 720,96 360,48

1,6-diisocyanatohexane

Toluene diisocyanate (both 2,4-

TDI 174,16 87,08 726,92 363,46

and 2,6-diisocyanatotoluene)

Isophorone diisocyanate

1-isocyanato-3-isocyanatomethyl- IPDI 222,29 111,14 775,05 387,52

3,5,5-trimethylcyclohexane

4,4’-Diphenylmethane diisocyanate 4,4’-

250,26 125,13 803,02 401,51

Di-(4-isocyanatophenyl)methane MDI

Hydrogenated MDI

Methylenebis(cyclohexyl-4-isocyanate)HMDI 262,35 131,18 815,11 407,56

4,4’-Dicyclohexylmethane diisocyanate

Isocyanate group NCO 42 42 — —

4.3.3 Preparation of standard solutions of monomer derivatives for solid-phase extraction (SPE)

Evaluate recovery of MAP-derivatised monomers through solid-phase extraction (SPE) cartridges periodically.

Stock solutions in DMF cannot be used to make SPE standards because even low concentrations of DMF

appear to cause premature elution of MAP derivatives. Standards to be passed through an SPE cartridge

should be derived from methylene chloride stock solutions. MAP-derivatives of aliphatic diisocyanates and

2,4-TDI are quite soluble in methylene chloride. MAP derivatives of 2,6-TDI and MDI are less soluble. All

−3

MAP-derivatives except the MAP derivative of MDI are sufficiently soluble to prepare 1 × 10 mol/l

−3 −4

(monoisocyanate) or 0,5 × 10 mol/l (diisocyanate) stock solutions. A stock solution of concentration 2 × 10

mol/l can be made for the MAP derivative of MDI. These stock solutions can be further diluted into butyl

benzoate to simulate impinger solutions.

4.3.4 Preparation of derivative solutions of bulk isocyanate products

This procedure has been found to be suitable for HDI- and IPDI-based products, and may be suitable for other

products as well.

Weigh approximately 0.5 g of bulk isocyanate product into a 7 ml vial. Then add 4,5 g (3,4 ml) methylene

chloride to this, and mix until the solution is homogeneous. Determine the density of this stock solution, unless

subsequent analyses are for qualitative purposes only. Dilute the stock solution 1 → 100 (10 µl → 1 ml) in

methylene chloride. Mix until the solution is homogeneous, then immediately add 25 µl of this dilution to

−4

975 µl of 5 × 10 mol/l MAP in acetonitrile. It is important to make this second dilution into the derivatising

solution as quickly as possible because dilute solutions of free isocyanates are not stable. Allow this final

solution to react overnight in the dark. The next day, add 5 µl of acetic anhydride and allow to react at least

2 h at room temperature or overnight in a refrigerator before analysing by HPLC.

6 © ISO 2009 – All rights reserved

4.4 HPLC mobile phase

The HPLC analysis utilises a pH gradient. The weak and the strong mobile phases have identical

aqueous:organic compositions. They differ only by the pH of the aqueous portions. The fluorescence

response of the MAP derivatives is greatly affected by the mobile phase pH. Therefore, an acidic solution is

added to the mobile phase between the analytical column and the detectors to give a fluorescence response

independent of the mobile phase pH.

4.4.1 Mobile phase buffer solutions

To 3 840 ml water is added 46,1 g 85 % mass fraction phosphoric acid (approximately 27 ml, 0,4 mol) and

15,1 ml 96 % mass fraction formic acid (0,4 mol). The initial pH should be approximately 1,6. Add

triethylamine (99,5 % mass fraction) to this solution in 10 ml aliquots, mixing after each addition, until a total of

117 ml triethylamine has been added. The pH should be 6,0. Adjust to 6,0 with additional triethylamine if

necessary. Split this solution into two 2 l portions. To one of these portions, add 33,5 ml concentrated HCl. Mix

thoroughly. The final pH should be 1,6. To the second 2 l portion, add 33,5 ml water. This procedure yields

buffers that contain approximate concentrations of 0,1 mol/l phosphoric acid and 0,1 mol/l formic acid, one

with a pH of approximately 1,6 and the other with a pH approximately 6,0. Experience shows that the buffers

are stable for 6 months when stored in a refrigerator.

4.4.2 Primary mobile phases

The weak mobile phase (mobile phase A) is produced by mixing 65 % volume fraction acetonitrile and 35 %

volume fraction pH 6,0 buffer. The strong mobile phase (mobile phase B) is produced by mixing 65 % volume

fraction acetonitrile and 35 % volume fraction pH 1,6 buffer. The mobile phases are filtered through 0,45 µm

nylon filters. Degas the mobile phase prior to use either by vacuum degassing or by helium sparging.

Experience shows that the primary mobile phase is stable for 6 months if evaporation is prevented.

4.4.3 Post-column acid mobile phase

Dilute 35 ml of 85 % mass fraction phosphoric acid to 350 ml final volume with water. Mix this dilute

phosphoric acid with 650 ml acetonitrile. Filter the solution through a 0,45 µm nylon filter. Degas the mobile

phase prior to use either by vacuum degassing or by helium sparging. Experience shows that the acid mobile

phase is stable for 6 months if evaporation is prevented.

5 Apparatus

5.1 Sampler

The choice of sampler depends on the chemical and physical properties of the airborne isocyanate

(Reference [13]). If little is known about the physical and chemical nature of the isocyanates in the

atmosphere, then the sampler should consist of a midget impinger followed by a MAP impregnated filter

[3]

(ISO/TR 17737 ). If the isocyanate is present only as vapour, either a MAP-coated filter or a midget impinger

may be used. If isocyanate species are present in particles < 2 µm in diameter (condensation or combustion

aerosol), then filters should be used. If isocyanate is present in particles > 2 µm (e.g. spray painting), the

recommended choice of impinger or filter depends on the reactivity of the aerosol. Typically aerosols

containing aliphatic isocyanates react relatively slowly and can be collected using a MAP-impregnated filter as

described in Reference [14]. Aerosols > 2 µm containing aromatic isocyanates, such as those generated by

MDI spray operations (Reference [15]), frequently react fast and shall be collected using an impinger. If both

particles < 2 µm and relatively fast-curing particles > 2 µm are present, then the recommended sampler

consists of an impinger followed by a MAP-coated filter.

5.1.1 Filters

The filter material should be glass fibre (binder-free) and the filter should allow no more than 5 % mass

fraction breakthrough of the aerosol being sampled. The choice of filter size and filter holder is primarily

dependent on the physical state of the isocyanate. Vapour and relatively small aerosol can be collected

efficiently with any of the common filter samplers (e.g. open- or closed-face 37 mm polystyrene cassettes,

13 mm polypropylene filter holders). For relatively large aerosol (> 20 µm), an inhalation sampler [e.g. that

developed by the Institute of Occupational Medicine (IOM), UK] is recommended. Because isocyanates are

strong sensitisers, it is appropriate to measure isocyanate in particles that will be deposited anywhere in the

respiratory tract, i.e. the inhalable fraction (Reference [16]).

5.1.2 Midget impingers

A midget impinger consists of a graduated receiver and a tapered inlet tube. The two parts should be matched

so that the distance between the inlet and the receiver bottom is 1 mm to 2 mm. Non-spill impingers are

commercially available.

5.2 Sampling pump

[6]

The sampling pump shall be able to pump up to 2 l/min and shall fulfil the requirements of EN 1232 or

equivalent.

5.3 Tubing

Use plastic, rubber, or other suitable tubing about 900 mm long and of appropriate diameter to ensure a leak-

proof fit to both the pump and the sampler outlet. Clips shall be provided to secure the sampler and the

connecting tubing to the wearer. It has been observed that impinger solvents (in particular, toluene) can leach

substances from the tubing that ultimately interfere in the sample analysis. It is not known if butyl benzoate

leaches interfering compounds from tubing under normal sampling conditions, but it has been found that the

2)

problem with toluene is greatly reduced when using fluoroelastomer tubing. Therefore, fluoroelastomer

tubing is recommended for impinger sampling. A short length of fluoroelastomer tubing inserted before the

3)

plastic, rubber or other suitable tubing is sufficient.

5.4 Flowmeter

A portable flowmeter capable of measuring the appropriate volume flow rate to within ± 5 % is used in the field.

This flowmeter is calibrated against a primary standard before taking it into the field.

5.5 Filtration and solid-phase extraction equipment

HPLC solvent is filtered through a solvent-resistant vacuum filtration apparatus using 0,45 µm nylon filters

prior to use. Filter samples are passed through 0,45 µm PTFE syringe filters prior to analysis. Impinger

samples are subjected to solid-phase extraction (SPE) using a SPE vacuum manifold. Disposable PTFE liners

are inserted into the ports of the vacuum manifold to eliminate sample contamination. SPE cartridges of

capacity 6 ml containing 500 mg silica gel are inserted into the inlets of the disposable PTFE liners.

2) Fluran is an example of a suitable product available commercially. This information is given for the convenience of

users of this International Standard and does not constitute an endorsement by ISO of this product.

3) Tygon R-3603 is an example of a suitable product available commercially. This information is given for the

convenience of users of this International Standard and does not constitute an endorsement by ISO of this product.

8 © ISO 2009 – All rights reserved

5.6 Liquid chromatographic system

5.6.1 Autosampler

Any commercially available autosampler capable of making sample injections of acceptable accuracy and

precision.

5.6.2 Pumping system

An HPLC capable of gradient elution is required. It is preferable that the HPLC system have highly inert fluid

paths [polyetheretherketone (PEEK) or titanium] after the point of sample introduction. If the HPLC has

stainless steel fluid paths after the point of sample introduction, it is desirable to replace as much of this as

possible with PEEK tubing.

5.6.3 Analytical column

4)

The analytical column is 150 mm × 4,6 mm with the stationary phase consisting of 5 µm C8 high purity silica .

The use of a short, replaceable guard column containing the same stationary phase in front of the analytical

column is advisable.

5.6.4 Column oven

The analytical column is contained within a column oven maintained at 30 °C, or at least 5 °C above ambient

temperature.

5.6.5 Post-column acid delivery pump

An HPLC pump is used that is capable of delivering a single mobile phase at 0,7 ml/min into a mixing tee

immediately downstream of the analytical column. Because the back pressure is low downstream of the

analytical column, a pulse dampener may be necessary between this pump and the mixing tee to get pulse-

free delivery.

5.6.6 Detectors

This method uses two detectors in series for identification and quantification: a variable wavelength UV/visible

absorbance detector (UV) and a fluorescence detector. It is preferable to use a fluorescence detector with a

xenon source because of the wider range of excitation wavelengths available. However, a fluorescence

detector with a deuterium source is acceptable.

6 Air sampling

6.1 Pre-sampling laboratory preparation

6.1.1 Cleaning of sampling equipment

Reusable sampling apparatus shall be carefully cleaned prior to use. Impingers containing residual butyl

benzoate should be rinsed with acetone, allowed to dry, and, if necessary, soaked in a

non-chromate/concentrated sulfuric acid-based cleaning solution. After 30 min, thoroughly rinse with water

and dry in an oven. IOM stainless steel cassettes (not the entire sampler body) are immersed in methylene

chloride in a small beaker, sonicated for 15 min, removed and allowed to dry. They are then rinsed with water,

immersed in 6 mol/l nitric acid for 30 min (with 10 min sonication), rinsed with water, and oven dried.

4) C8 Inertsil is an example of a suitable product available commercially. This information is given for the convenience of

users of this International Standard and does not constitute an endorsement by ISO of this product.

6.1.2 Preparation of MAP-coated filter samplers

With a microlitre syringe, in an area free of isocyanates, add the appropriate volume of the 2 mg/ml filter

impregnation solution to a glass-fibre or quartz-fibre filter so that the reagent coverage is 1,0 µg/mm (e.g.

250 µl for a 25 mm filter). After allowing solvent to evaporate, store in a freezer until ready for use. When

ready to use, load the filters into the appropriate filter holder.

6.1.3 Preparation of extraction solution jars

−4

Distribute an appropriate amount of MAP filter extraction solution (1 × 10 mol/l MAP in acetonitrile) into a

wide-mouth jar with a PTFE-lined cap. The size of the jar and amount of solution will depend on the filter size

being used and the nature of the sampler. For IOM samplers, the entire stainless steel cassette is submerged

in extraction solution, requiring 10 ml solution. If only the filter is being extracted, considerably less solution is

required (e.g. 5,0 ml for 37 mm filters).

6.2 Pre-sampling field preparation

6.2.1 Calibration of pump

Calibrate the pump with a representative sampling train in line, using a portable flow meter. If an impinger is

used, it shall contain the appropriate solution during calibration.

6.2.2 Preparation of samplers

−4

Prepare for sampling in an area free of isocyanates. If using impingers, add 15 ml of the 1 × 10 mol/l

solution of MAP in butyl benzoate to each impinger. Connect the outlet of each loaded sampler to a sampling

pump using appropriate tubing, ensuring that no leaks can occur. Switch on the pump, attach the calibrated

flow meter to the sampler inlet, and set the appropriate flow rate. Switch off the pump and seal the sampler

during transport to the sampling site.

6.3 Collection of air samples

6.3.1 Filter sampling

In an area free of isocyanates, attach the sampler to the worker close to the breathing zone. Place the

sampling pump on the worker’s belt or another secure location. When ready to begin sampling, switch on the

pump. Record the time at the start of the sampling period. Draw a measured volume of air at a sampling rate

of 1 l/min to 2 l/min (1 l/min for 37 mm filter cassettes, 2 l/min for IOM samplers). The minimum recommended

volume is 1 l. The maximum volume depends on the ability of the pump to continue without significant drop in

air sampling rate, but 960 l (an 8 h shift at 2 l/min) should be achievable. The filter may become clogged from

heavy loading, resulting in a drop in the flow rate. If this is suspected, test the flow rate of the sampler.

Terminate sampling and consider the sample to be invalid if the volume flow rate is not maintained to within

± 5 % of the nominal value throughout the sampling period. At the end of the sampling period, measure the

volume flow rate, turn off the sampling pump, and record the time. If it is possible that some of the isocyanate

collected was in particulate form, place the filter immediately in a jar containing filter extraction solution. If

there is good reason to believe only isocyanate vapour was collected, the filter need not be extracted prior to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...