ISO 10303-209:2001

(Main)Industrial automation systems and integration — Product data representation and exchange — Part 209: Application protocol: Composite and metallic structural analysis and related design

Industrial automation systems and integration — Product data representation and exchange — Part 209: Application protocol: Composite and metallic structural analysis and related design

Systèmes d'automatisation industrielle et intégration — Représentation et échange de données de produits — Partie 209: Protocole d'application: Analyse structurelle composite et métallique et conception associée

General Information

- Status

- Withdrawn

- Publication Date

- 10-Oct-2001

- Withdrawal Date

- 10-Oct-2001

- Technical Committee

- ISO/TC 184/SC 4 - Industrial data

- Drafting Committee

- ISO/TC 184/SC 4/WG 3 - Oil, Gas, Process and Power

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 01-Dec-2014

- Completion Date

- 12-Feb-2026

Relations

- Consolidated By

ISO 24333:2009 - Cereals and cereal products — Sampling - Effective Date

- 06-Jun-2022

- Effective Date

- 21-May-2011

ISO 10303-209:2001 - Industrial automation systems and integration -- Product data representation and exchange

ISO 10303-209:2001 - Industrial automation systems and integration -- Product data representation and exchange

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

ISO 10303-209:2001 is a standard published by the International Organization for Standardization (ISO). Its full title is "Industrial automation systems and integration — Product data representation and exchange — Part 209: Application protocol: Composite and metallic structural analysis and related design". This standard covers: Industrial automation systems and integration — Product data representation and exchange — Part 209: Application protocol: Composite and metallic structural analysis and related design

Industrial automation systems and integration — Product data representation and exchange — Part 209: Application protocol: Composite and metallic structural analysis and related design

ISO 10303-209:2001 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 10303-209:2001 has the following relationships with other standards: It is inter standard links to ISO 24333:2009, ISO 10303-209:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 10303-209:2001 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 10303-209

First edition

2001-10-01

Industrial automation systems and

integration — Product data representation

and exchange —

Part 209:

Application protocol: Composite and

metallic structural analysis and related

design

Systèmes d'automatisation industrielle et intégration — Représentation et

échange de données de produits —

Partie 209: Protocole d'application: Analyse structurelle composite et

métallique et conception associée

Reference number

©

ISO 2001

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this

file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this

area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

This CD-ROM contains the publication ISO 10303-209 in portable document format (PDF), which can be viewed

using Adobe® Acrobat® Reader.

Adobe and

...

INTERNATIONAL ISO

STANDARD 10303-209

First edition

2001-10-01

Industrial automation systems and

integration — Product data representation

and exchange —

Part 209:

Application protocol: Composite and

metallic structural analysis and related

design

Systèmes d'automatisation industrielle et intégration — Représentation et

échange de données de produits —

Partie 209: Protocole d'application: Analyse structurelle composite et

métallique et conception associée

Reference number

©

ISO 2001

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this

file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this

area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2001

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

ii © ISO 2001 – All rights reserved

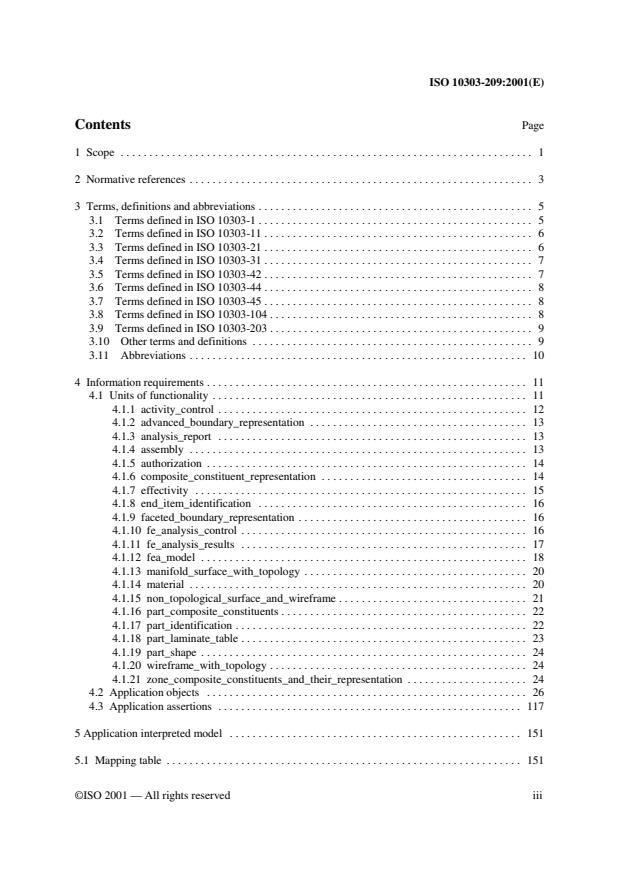

Contents Page

1 Scope . 1

2 Normative references . 3

3 Terms, definitions and abbreviations . 5

3.1 Terms defined in ISO 10303-1. 5

3.2 Terms defined in ISO 10303-11. 6

3.3 Terms defined in ISO 10303-21. 6

3.4 Terms defined in ISO 10303-31. 7

3.5 Terms defined in ISO 10303-42. 7

3.6 Terms defined in ISO 10303-44. 8

3.7 Terms defined in ISO 10303-45. 8

3.8 Terms defined in ISO 10303-104. 8

3.9 Terms defined in ISO 10303-203. 9

3.10 Other terms and definitions . 9

3.11 Abbreviations . 10

4 Information requirements . 11

4.1 Units of functionality . 11

4.1.1 activity_control . 12

4.1.2 advanced_boundary_representation . 13

4.1.3 analysis_report . 13

4.1.4 assembly . 13

4.1.5 authorization . 14

4.1.6 composite_constituent_representation . 14

4.1.7 effectivity . 15

4.1.8 end_item_identification . 16

4.1.9 faceted_boundary_representation . 16

4.1.10 fe_analysis_control . 16

4.1.11 fe_analysis_results . 17

4.1.12 fea_model . 18

4.1.13 manifold_surface_with_topology . 20

4.1.14 material . 20

4.1.15 non_topological_surface_and_wireframe . 21

4.1.16 part_composite_constituents . 22

4.1.17 part_identification . 22

4.1.18 part_laminate_table . 23

4.1.19 part_shape . 24

4.1.20 wireframe_with_topology . 24

4.1.21 zone_composite_constituents_and_their_representation . 24

4.2 Application objects . 26

4.3 Application assertions . 117

5 Application interpreted model . 151

5.1 Mapping table . 151

©ISO 2001 — All rights reserved iii

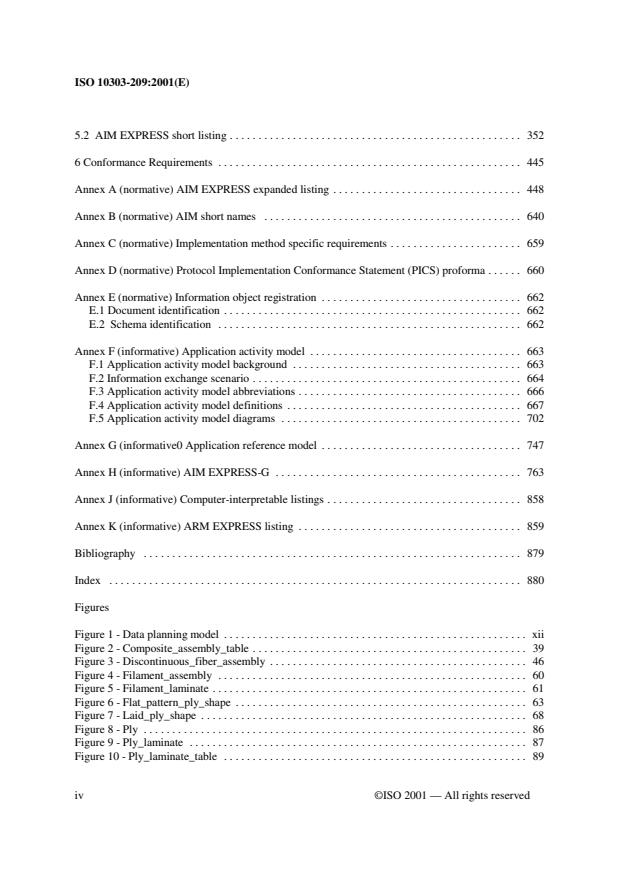

5.2 AIM EXPRESS short listing . 352

6 Conformance Requirements . 445

Annex A (normative) AIM EXPRESS expanded listing . 448

Annex B (normative) AIM short names . 640

Annex C (normative) Implementation method specific requirements . 659

Annex D (normative) Protocol Implementation Conformance Statement (PICS) proforma . 660

Annex E (normative) Information object registration . 662

E.1 Document identification . 662

E.2 Schema identification . 662

Annex F (informative) Application activity model . 663

F.1 Application activity model background . 663

F.2 Information exchange scenario . 664

F.3 Application activity model abbreviations . 666

F.4 Application activity model definitions . 667

F.5 Application activity model diagrams . 702

Annex G (informative0 Application reference model . 747

Annex H (informative) AIM EXPRESS-G . 763

Annex J (informative) Computer-interpretable listings . 858

Annex K (informative) ARM EXPRESS listing . 859

Bibliography . 879

Index . 880

Figures

Figure 1 - Data planning model . xii

Figure 2 - Composite_assembly_table . 39

Figure 3 - Discontinuous_fiber_assembly . 46

Figure 4 - Filament_assembly . 60

Figure 5 - Filament_laminate . 61

Figure 6 - Flat_pattern_ply_shape . 63

Figure 7 - Laid_ply_shape . 68

Figure 8 - Ply . 86

Figure 9 - Ply_laminate . 87

Figure 10 - Ply_laminate_table . 89

iv ©ISO 2001 — All rights reserved

Figure 11 - Processed_core . 94

Figure 12 - Projection_method . 98

Figure 13 - Surface_ply_shape . 109

Figure 14 - View_ply_shape . 113

Figure F.1 - PAS-C Suite Concept . 664

Figure F.2 - AP209 scenario from a structural designer’s viewpoint . 665

Figure F.3 - AP209 scenario from an analysis viewpoint . 667

Figure F.4 - A-0 Develop, procure, build, use and maintain an SP . 703

Figure F.5 - A0 Develop, procure, build, use and maintain an SP . 704

Figure F.6 - A2 manage, design, build, and support an SP . 705

Figure F.7 - A22 design and analyze an SP . 706

Figure F.8 - A223 perform structural part detail design and analysis . 707

Figure F.9 - A2232 create detail structural part design . 708

Figure F.10 - A22323 prepare SP models and drawing . 709

Figure F.11 - A223232 create SP geometry layouts and models . 710

Figure F.12 - A2232321 receive and review SP geometry data . 711

Figure F.13 - A2232322 build SP layouts and models . 712

Figure F.14 - A223233 create SP drawing data . 713

Figure F.15 - A2232332 prepare detail SP item drawings . 714

Figure F.16 - A22323322 prepare SP details . 715

Figure F.17 - A2232332233 create SP data . 716

Figure F.18 - A2232332231 prepare SP composite detail . 717

Figure F.19 - A22323322316 produce CSP ply stack-up . 718

Figure F.20 - A223233223162 create CSP ply tables . 719

Figure F.21 - A2232332232 prepare CSP core details . 720

Figure F.22 - A22323322322 develop CSP core periphery . 721

Figure F.23 - A22323322323 Design CPS core thickness, density, and material features . 722

Figure F.24 - A2233 conduct detail SP analysis . 723

Figure F.25 - A22335 conduct SP static stress analysis . 724

Figure F.26 - A223352 conduct SP finite element analysis . 725

Figure F.27 - A2233521 generate SP finite element models . 726

Figure F.28 - A22335211 generate SP node geometry . 727

Figure F.29 - A22335213 generate and assign SP element attributes . 728

Figure F.30 - A223352131 generate SP geometric attributes . 729

Figure F.31 - A2233521311 generate beam geometric attributes . 730

Figure F.32 - A2233521312 generate contoured panel geometric attributes . 731

Figure F.33 - A2233521313 generate core stiffened panel geometric attributes . 732

Figure F.34 - A223352133 generate/import SP material properties . 733

Figure F.35 - A2233521334 input SP anisotropic material property matrices . 734

Figure F.36 - A22335213341 input beam anisotropic material property . 735

Figure F.37 - A22335213342 input contoured panels anisotropic material property . 736

Figure F.38 - A22335123343 input core stiffened panel anisotropic material property . 737

Figure F.39 - A2233522 generate SP FE analysis environment and controls . 738

Figure F.40 - A2233523 perform SP mechanical and themo-mechanical analysis . 739

Figure F.41 - A2233524 create/document SP internal loads/stress data . 740

Figure F.42 - A223353 conduct SP detail stress analyses . 741

Figure F.43 - A223351 conduct SP static strength analyses . 742

Figure F.44 - A22335311 conduct beam static strength analysis . 743

©ISO 2001 — All rights reserved v

Figure F.45 - A22335312 conduct panel static strength analysis . 744

Figure F.46 - A2233532 conduct SP fine grid finite element analysis . 745

Figure F.47 - A4 develop and provide SP materials . 746

Figure G.1 - ARM EXPRESS-G diagram 1 of 15 . 748

Figure G.2 - ARM EXPRESS-G diagram 2 of 15 . 749

Figure G.3 - ARM EXPRESS-G diagram 3 of 15 . 750

Figure G.4 - ARM EXPRESS- G diagram 4 of 15 . 751

Figure G.5 - ARM EXPRESS-G diagram 5 of 15 . 752

Figure G.6 - ARM EXPRESS-G diagram 6 of 15 . 753

Figure G.7 - ARM EXPRESS-G diagram 7 of 15 . 754

Figure G.8 - ARM EXPRESS-G diagram 8 of 15 . 755

Figure G.9 - ARM EXPRESS-G diagram 9 of 15 . 756

Figure G.10 - ARM EXPRESS-G diagram 10 of 15 . 757

Figure G.11 - ARM EXPRESS-G diagram 11 of 15 . 758

Figure G.12 - ARM EXPRESS-G diagram 12 of 15 . 759

Figure G.13 - ARM EXPRESS-G diagram 13 of 15 . 760

Figure G.14 - ARM EXPRESS-G diagram 14 of 15 . 761

Figure G.15 - ARM EXPRESS-G diagram 15 of 15 . 762

Figure H.1 - AIM EXPRESS-G diagram 1 of 94 . 764

Figure H.2 - AIM EXPRESS-G diagram 2 of 94 . 765

Figure H.3 - AIM EXPRESS-G diagram 3 of 94 . 766

Figure H.4 - AIM EXPRESS-G diagram 4 of 94 . 767

Figure H.5 - AIM EXPRESS-G diagram 5 of 94 . 768

Figure H.6 - AIM EXPRESS-G diagram 6 of 94 . 769

Figure H.7 - AIM EXPRESS-G diagram 7 of 94 . 770

Figure H.8 - AIM EXPRESS-G diagram 8 of 94 . 771

Figure H.9 - AIM EXPRESS-G diagram 9 of 94 . 772

Figure H.10 - AIM EXPRESS-G diagram 10 of 94 . 773

Figure H.11 - AIM EXPRESS-G diagram 11 of 94 . 774

Figure H.12 - AIM EXPRESS-G diagram 12 of 94 . 775

Figure H.13 - AIM EXPRESS-G diagram 13 of 94 . 776

Figure H.14 - AIM EXPRESS-G diagram 14 of 94 . 777

Figure H.15 - AIM EXPRESS-G diagram 15 of 94 . 778

Figure H.16 - AIM EXPRESS-G diagram 16 of 94 . 779

Figure H.17 - AIM EXPRESS-G diagram 17 of 94 . 780

Figure H.18 - AIM EXPRESS-G diagram 18 of 94 . 781

Figure H.19 - AIM EXPRESS-G diagram 19 of 94 . 782

Figure H.20 - AIM EXPRESS-G diagram 20 of 94 . 783

Figure H.21 - AIM EXPRESS-G diagram 21 of 94 . 784

Figure H.22 - AIM EXPRESS-G diagram 22 of 94 . 785

Figure H.23 - AIM EXPRESS-G diagram 23 of 94 . 786

Figure H.24 - AIM EXPRESS-G diagram 24 of 94 . 787

Figure H.25 - AIM EXPRESS-G diagram 25 of 94 . 788

Figure H.26 - AIM EXPRESS-G diagram 26 of 94 . 789

Figure H.27 - AIM EXPRESS-G diagram 27 of 94 . 790

Figure H.28 - AIM EXPRESS-G diagram 28 of 94 . 791

Figure H.29 - AIM EXPRESS-G diagram 29 of 94 . 792

Figure H.30 - AIM EXPRESS-G diagram 30 of 94 . 793

vi ©ISO 2001 — All rights reserved

Figure H.31 - AIM EXPRESS-G diagram 31 of 94 . 794

Figure H.32 - AIM EXPRESS-G diagram 32 of 94 . 795

Figure H.33 - AIM EXPRESS-G diagram 33 of 94 . 796

Figure H.34 - AIM EXPRESS-G diagram 34 of 94 . 797

Figure H.35 - AIM EXPRESS-G diagram 35 of 94 . 798

Figure H.36 - AIM EXPRESS-G diagram 36 of 94 . 799

Figure H.37 - AIM EXPRESS-G diagram 37 of 94 . 800

Figure H.38 - AIM EXPRESS-G diagram 38 of 94 . 801

Figure H.39 - AIM EXPRESS-G diagram 39 of 94 . 802

Figure H.40 - AIM EXPRESS-G diagram 40 of 94 . 803

Figure H.41 - AIM EXPRESS-G diagram 41 of 94 . 804

Figure H.42 - AIM EXPRESS-G diagram 42 of 94 . 805

Figure H.43 - AIM EXPRESS-G diagram 43 of 94 . 806

Figure H.44 - AIM EXPRESS-G diagram 44 of 94 . 807

Figure H.45 - AIM EXPRESS-G diagram 45 of 94 . 808

Figure H.46 - AIM EXPRESS-G diagram 46 of 94 . 809

Figure H.47 - AIM EXPRESS-G diagram 47 of 94 . 810

Figure H.48 - AIM EXPRESS-G diagram 48 of 94 . 811

Figure H.49 - AIM EXPRESS-G diagram 49 of 94 . 812

Figure H.50 - AIM EXPRESS-G diagram 50 of 94 . 813

Figure H.51 - AIM EXPRESS-G diagram 51 of 94 . 814

Figure H.52 - AIM EXPRESS-G diagram 52 of 94 . 815

Figure H.53 - AIM EXPRESS-G diagram 53 of 94 . 816

Figure H.54 - AIM EXPRESS-G diagram 54 of 94 . 817

Figure H.55 - AIM EXPRESS-G diagram 55 of 94 . 818

Figure H.56 - AIM EXPRESS-G diagram 56 of 94 . 819

Figure H.57 - AIM EXPRESS-G diagram 57 of 94 . 820

Figure H.58 - AIM EXPRESS-G diagram 58 of 94 . 821

Figure H.59 - AIM EXPRESS-G diagram 59 of 94 . 822

Figure H.60 - AIM EXPRESS-G diagram 60 of 94 . 823

Figure H.61 - AIM EXPRESS-G diagram 61 of 94 . 824

Figure H.62 - AIM EXPRESS-G diagram 62 of 94 . 825

Figure H.63 - AIM EXPRESS-G diagram 63 of 94 . 826

Figure H.64 - AIM EXPRESS-G diagram 64 of 94 . 827

Figure H.65 - AIM EXPRESS-G diagram 65 of 94 . 828

Figure H.66 - AIM EXPRESS-G diagram 66 of 94 . 829

Figure H.67 - AIM EXPRESS-G diagram 67 of 94 . 830

Figure H.68 - AIM EXPRESS-G diagram 68 of 94 . 831

Figure H.69 - AIM EXPRESS-G diagram 69 of 94 . 832

Figure H.70 - AIM EXPRESS-G diagram 70 of 94 . 833

Figure H.71 - AIM EXPRESS-G diagram 71 of 94 . 834

Figure H.72 - AIM EXPRESS-G diagram 72 of 94 . 835

Figure H.73 - AIM EXPRESS-G diagram 73 of 94 . 836

Figure H.74 - AIM EXPRESS-G diagram 74 of 91 . 837

Figure H.75 - AIM EXPRESS-G diagram 75 of 94 . 838

Figure H.76 - AIM EXPRESS-G diagram 76 of 94 . 839

Figure H.77 - AIM EXPRESS-G diagram 77 of 94 . 840

Figure H.78 - AIM EXPRESS-G diagram 78 of 94 . 841

©ISO 2001 — All rights reserved vii

Figure H.79 - AIM EXPRESS-G diagram 79 or 94 . 842

Figure H.80 -AIM EXPRESS-G diagram 80 of 94 . 843

Figure H.81 - AIM EXPRESS-G diagram 81 of 94 . 844

Figure H.82 - AIM EXPRESS-G diagram 82 of 94 . 845

Figure H.83 - AIM EXPRESS-G diagram 83 of 94 . 846

Figure H.84 - AIM EXPRESS-G diagram 84 of 94 . 847

Figure H.85 - AIM EXPRESS-G diagram 85 of 94 . 848

Figure H.86 - AIM EXPRESS-G diagram 86 of 94 . 849

Figure H.87 - AIM EXPRESS-G diagram 87 of 94 . 850

Figure H.88 - AIM EXPRESS-G diagram 88 of 94 . 851

Figure H.89 - AIM EXPRESS-G diagram 89 of 94 . 852

Figure H.90 - AIM EXPRESS-G diagram 90 of 94 . 853

Figure H.91 - AIM EXPRESS-G diagram 91 of 94 . 854

Figure H.92 - AIM EXPRESS-G diagram 92 of 94 . 855

Figure H.93 - AIM EXPRESS-G diagram 93 of 94 . 856

Figure H.94 - AIM EXPRESS-G diagram 94 of 94 . 857

Tables

Table 1 - Mapping table for activity_control UoF . 153

Table 2 - Mapping table for advanced_boundary_representation UoF . 161

Table 3 - Mapping table for analysis_report UoF. 162

Table 4 - Mapping table for analysis_report UoF . 165

Table 5 - Mapping table for authorization UoF . 177

Table 6 - Mapping table for composite_constituent_representation UoF . 182

Table 7 - Mapping table for effectivity UoF . 201

Table 8 - Mapping table for end_item_identification UoF . 211

Table 9 - Mapping table for faceted_boundary_representation UoF . 212

Table 10 - Mapping table for fe_analysis_control UoF . 213

Table 11 - Mapping table for fe_analysis_results UoF . 232

Table 12 - Mapping table for fea_model UoF . 251

Table 13 - Mapping table for manifold_surface_with_topology UoF . 280

Table 14 - Mapping table for material UoF . 281

Table 15 - Mapping table for non_topological_surface_and_wireframe UoF . 288

Table 16 - Mapping table for part_composite_constituents UoF . 289

Table 17 - Mapping table for part_identification UoF . 316

Table 18 - Mapping table for part_laminate_table UoF . 327

Table 19 - Mapping table for part_shape UoF . 333

Table 20 - Mapping table for wireframe_with_topology UoF . 338

Table 21 - Mapping table for zone_composite_constituents_and_their_representation UoF . 339

Table 22 - Conformance Classes . 447

Table B.1 - AIM short names of entities . 640

viii ©ISO 2001 — All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work. ISO

collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

Draft International Standards adopted by the technical committees are circulated to the member bodies

for voting. Publication as an International Standard requires approval by at least 75% of the member

bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this part of ISO 10303 may be the

subject of patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

International Standard ISO 10303-209 was prepared by Technical Committee ISO/TC 184,

Industrial automation systems and integration, Subcommittee SC 4, Industrial data.

This International Standard is organized as a series of parts, each published separately. The structure of

this International Standard is described in ISO 10303-1.

Each part of this International Standard is a member of one of the following series: description methods,

implementation methods, conformance testing methodology and framework, integrated generic resources,

integration application resources, application protocols, abstract tests suites, application interpreted

constructs, and application modules.

This part is a member of the application protocol series.

A complete list of parts of ISO 10303 is available from the Internet:

.

Annexes A, B, C, D, and E form a normative part of this part of ISO 10303. Annexes F, G, H, J, and K

are for information only.

©ISO 2001 — All rights reserved ix

Introduction

ISO 10303 is an International Standard for the computer-interpretable representation and exchange of

product data. The objective is to provide a neutral mechanism capable of describing products throughout

their life cycle. This mechanism makes it suitable not only for neutral file exchange, but also as a basis

for implementing and sharing product databases, and as a basis for archiving.

This part of ISO 10303 is a member of the application protocol series. This part of ISO 10303 specifies

an application protocol (AP) for the exchange of computer-interpretable composite and metallic

structural product definitions, including product shape, associated finite element analysis (FEA) models

and analysis results, and the material properties of these products.

The shape of a composite or metallic product definition includes the part and its constituents, including

any ply shapes necessary for FEA node and mesh generation of boundary definitions. This information

is suitable for the automated generation of composite material properties and geometric properties for

finite elements. The shape definitions for design and analysis are each independently configuration

controlled.

The finite element model idealizes a product or aspects of a product so that it may be analyzed to validate

the structural performance and structural integrity of a product.

Finite elements of homogenous (isotropic) metallic and adhesive material properties are treated in this

part of ISO 10303 as a subset of anisotropic composite material response. The differences between these

two material response idealizations are: 1) a simplified material response, and 2) having no associated

composite constituent information.

Assembly information provides the relationships necessary to identify analysis boundary conditions, and

when combined with part geometry, topology, and finite element analysis output, provides the input

necessary for detail analyses such as those for fastened structural joints.

This part of ISO 10303 satisfies the need for exchange of information between the iterative design and

analysis stages of the product life cycle. Product configuration information provides the audit trail

necessary to control the designed shape, its associated finite element model, and any related analysis

shape information during these iterative stages of the product life cycle.

This application protocol defines the context, scope, and information requirements for the exchange of

the information necessary to perform the design through analysis stages of the life cycle of composite

and metallic structural parts, and specifies the integrated resources necessary to satisfy these

requirements.

Application protocols provide the basis for developing implementations of ISO 10303 and abstract test

suites for the conformance testing of AP implementations.

Clause 1 defines the scope of the application protocol and summarizes the functionality and data covered

by the AP. Clause 3 lists the words defined in this part of ISO 10303 and gives pointers to words defined

elsewhere. An application activity model that is the basis for the definition of the scope is provided in

x ©ISO 2001 — All rights reserved

annex F. The information requirements of the application are specified in clause 4 using terminology

appropriate to the application. A graphical representation of the information requirements, referred to

as the application reference model, is given in annex G.

Resource constructs are interpreted to meet the information requirements. This interpretation produces

the application interpreted model (AIM). This interpretation, given in 5.1, shows the correspondence

between the information requirements and the AIM. The short listing of the AIM specifies the interface

to the integrated resources and is given in 5.2. Note that the definitions and EXPRESS provided in the

integrated resources for constructs used in the AIM may include select list items and subtypes which are

not imported into the AIM. The expanded listing given in annex A contains the complete EXPRESS for

the AIM without annotation. A graphical representation of the AIM is given in annex H. Additional

requirements for specific implementation methods are given in annex C.

Additionally, this application protocol enumerates the conformance requirements which identify the

implementation options for the abstract test suite. This application protocol may be implemented as a

whole, or as one of the allowed conformance classes. These conformance classes state the

implementation options for the representation of finite element analysis models, controls and results,

analysis reports, geometric models, composite material constituents and their representations, materials,

and configuration control.

A high level planning information model for this application protocol is shown in Figure 1. At this level,

the product can be conceptualized as a part that has both design and analysis product definitions. Each

definition has one or more shape representations. The analysis product definition has an associated finite

element model, analysis controls, and analysis results in addition to its shape representations.

The three possible product shape representations in this application protocol include the nominal design

shape, an idealized analysis shape, and a finite element model node shape. The nominal design shape

includes geometry and topology for the part and its constituents, such as ply boundaries. The idealized

analysis shape includes only the geometry and topology for mesh generation boundaries and associated

node geometry. The node shape includes only the node geometry, with no association to design shape

or to analysis idealized shape.

The five types of geometric and topological models that may be used to represent part shape in this

application protocol are: wireframe and surface without topology, wireframe geometry with topology,

manifold surfaces with topology, faceted boundary representation, and advanced boundary

representation.

The finite element analysis model consists of nodes, elements, and the associated element properties. The

finite element properties include shape aspects and material properties.

The finite element analysis material properties are specified with respect to an environment. The material

response matrices of the material properties may have an associated laminate table. The laminate table

specifies the constituents, such as plies in a laminate. Each constituent has a boundary, stock material,

and specifications. A separate geometric representation is used for composite material constituent

representations.

©ISO 2001 — All rights reserved xi

fe_analysis_

results

product_

part effectivity

configuration

fe_analysis_ fe_analysis_

results_step control_step

approval

stock_

material_

material

property

fe_analysis

environment constraint

percentage_

material_

ply

specification

analysis_report_

fea_model

representation

fea_material_

ply specification

zone_

element

structural_

makeup

fea_

material_

part_

definition

node

laminate_

table

element_

laminate_

shape_

analysis_

table

fea_ relationship

analysis_ discipline_

constituent_

material_

version product_

part

property

definition

node_shape_

analysis_

relationship

part_ design_

version version_

relationship

work_request

geometry_

analysis_

element

design_or_

shape

analysis

work_order

idealized_

assembly

analysis_

node_shape point_model

shape

design_

discipline_

product_

definition

shape_

shape

aspect geometric_

model_

nominal_

representation

design_shape

Figure 1 - Data planning model

xii ©ISO 2001 — All rights reserved

The finite element analysis controls and results are associated with a finite element model. The analysis

controls specify the operations to be carried out upon the model as a series of analysis steps. The analysis

results specify the state of the analysis variables at an instant in time. The state information includes

nodal solution variables such as deflections, the field variables within the elements, and the values of

constraints at a node. An analysis report of the finite analysis results may be presented in tabular and

graphical form. The analysis report also documents the detail analyses upon which the finite element

analysis results are based.

©ISO 2001 — All rights reserved xiii

INTERNATIONAL STANDARD ISO 10303-209:2001(E)

Industrial automation systems and integration —

Product data representation and exchange —

Part 209:

Application protocol: Composite and metallic structural

analysis and related design

1 Scope

This part of ISO 10303 specifies the use of integrated resources necessary for the scope and information

requirements for the analysis and related design of composite and metallic structural parts. This part of

ISO 10303 satisfies the need for the exchange of computer-interpretable composite and metallic

structural product definitions, including product shape, associated finite element analysis (FEA) models,

material properties, and analysis results.

NOTE The application activity model (AAM) in annex F provides a graphical representation of the processes and

information flows which are the basis for the definition of the scope of this part of ISO 10303.

The following are within the scope of this part of ISO 10303:

— the definition of composite structural parts;

— the definition of metallic structural parts;

— linear static finite element analysis;

— linear modes and frequencies finite element analysis;

— the product definition and configuration control information pertaining to the design through analysis

stages of a product's development;

— the information relating the part to the adjoining components in an assembly by either explicit or

external reference;

— the 2D and 3D models depicting the product shape;

— the five types of geometric and topologic model representations:

— wireframe and surface without topology;

— wireframe geometry with topology;

©ISO 2001 — All rights reserved 1

— manifold surfaces with topology;

— faceted boundary representation;

— advanced boundary representation.

— the representations for design and analysis disciplines and the association of nominal design shape,

idealized analysis shape, and finite element node shape representations;

— the association of the constituents of composite and metallic parts with the constituent shape model;

— the depiction of composite laminate tables describing the material, stacking sequence, ply orientation,

and constituents of the composite or a portion of the composite with a defined shape;

— the identification of material specifications from internal and external sources and their properties for

a specific operating environment;

— the finite element analysis model, analysis controls, and analysis results information;

— the plane stress and simple plane strain types of linear static and linear modes and frequencies finite

element structural analyses;

— the graphical presentation of:

— finite element model maps;

— analysis output information displays on top of the finite element model mesh;

— line drawings or images which document the part aspects subjected to detail analysis.

— the tabular presentation of the analysis assumptions, loadings, and critical locations in finite element

and detail analysis performed for the assessment of the margin of safety;

— the administrative information necessary to track the approval and configuration control of the design

and analysis of a product at a point in the life cycle when approval and configuration control are

necessary;

—- the identification of the supplier of a product, design, or analysis and, where required by an

organization, the qualification information for the supplier;

— a change to a design and an analysis, including information to identify the change, at a point in the

life cycle when tracking a change is necessary;

— the identification, when required, of the contract under which a design is developed and an analysis

is performed;

— the identification of the security classification of a part;

2 © ISO 2001 — All rights reserved

— the explicit representation of a bill-of-material.

The following are outside the scope of this part of ISO 10303:

— the business information for the management of a design and analysis project;

— the product definition and configuration control information pertaining to any information other than

that necessary for design and analysis;

— alternate representation of the information by disciplines outside of design and analysis such as

manufacturing;

— the use of constructive solid geometry for the representation of the shape of the product;

— the other types of finite element analysis beyond linear analysis, such as non-linear static analysis;

— the explicit graphical presentations derivable from design or analysis product representations;

— the composite fabrication process information;

— the product definition of initial or in-process part shapes.

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute

provisions of this part of ISO 10303. For dated references, subsequent amendments to, or revisions

of, any of these publications do not apply. However, parties to agreements based on this part of

ISO 10303 are encouraged to investigate the possibility of applying the most recent editions of the

normative documents indicated below. For undated references, the latest edition of the normative

document referred to applies. Members of ISO and IEC maintain registers of currently valid

International Standards.

ISO 31:1992, Quantities and units

ISO 1000:1992, SI units and recommendations for the use of their multiples and of certain other units

ISO/IEC 8824-1:1998, Information technology - Abstract Syntax Notation One (ASN.1): Specification

of basic notation

ISO 10303-1:1994, Industrial automation systems and integration - Product data representation and

exchange - Part 1: Overview and fundamental principles

ISO 10303-11:1994, Industrial automation systems and integration - Product data representation and

exchange - Part 11: Description methods: The EXPRESS language reference manual

ISO 10303-21:1994, Industrial automation systems and integration - Product data representation and

exchange - Part 21: Clear text encoding of the exchange structure

ISO 10303-31:1994, Industrial automation systems and integration - Product data representation and

exchange - Part 31: Conformance testing methodology and framework: General concepts

ISO 10303-41:1994, Industrial automation systems and integration - Product data representation and

exchange - Part 41: Integrated generic resources: Fundamentals of product description and support

ISO 10303-42:1994, Industrial automation systems and integration - Product data representation and

exchange - Part 42: Integrated generic resources: Geometric and topological representation

ISO 10303-43:1994, Industrial automation systems and integration - Product data representation and

exchange - Part 43: Integrated generic resources: Representation structures

ISO 10303-44:1994, Industrial automation systems and integration - Product data representation and

exchange - Part 44: Integrated generic resources: Product structure configuration

ISO 10303-45:1998, Industrial automation systems and integration - Product data representation and

exchange - Part 45: Integrated generic resource: Materials

ISO 10303-47:1997, Industrial automation systems and integration - Product data representation and

exchange - Part 47: Integrated generic resource: Shape variation tolerances

ISO 10303-104:2000 Industrial automation systems and integration - Product data representation and

exchange - Part 104: Integrated application resource: Finite element analysis

ISO 10303-501:2000 Industrial automation systems and integration - Product data representation and

exchange - Part 501: Application interpreted construct: Edge-based wireframe

ISO 10303-502:2000 Industrial automation systems and integration - Product data representation and

exchange - Part 502: Application interpreted construct: Shell-based wireframe

ISO 10303-507:2001 Industrial automation systems and integration - Product data representation and

exchange - Part 507: Application interpreted construct: Geometrically bounded surface

ISO 10303-509:2001 Industrial automation systems and integration - Product data representation and

exchange - Part 509: Application interpreted construct: Manifold surface

ISO 10303-510:2000 Industrial automation systems and integration - Product data representation and

exchange - Part 510: Application interpret

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...