ISO 14649-10:2004

(Main)Industrial automation systems and integration — Physical device control — Data model for computerized numerical controllers — Part 10: General process data

Industrial automation systems and integration — Physical device control — Data model for computerized numerical controllers — Part 10: General process data

ISO 14649-10:2004 specifies the process data which is generally needed for NC-machining and therefore common to several machining technologies. These data elements describe the interface between the programming system (i.e. CAM system or shop-floor programming system) and a computerized numerical controller. The programme for the numerical controller includes geometric and technological information. It can be described using ISO 14649-10:2004 together with the technology-specific parts (ISO 14649-11, ISO 14649-12, etc.). ISO 14649-10:2004 provides the control structures for the sequence of programme execution, mainly the sequence of working steps and associated machine functions. The "machining_schema" defined in ISO 14649-10:2004 contains the definition of data types which are generally relevant for different technologies (e.g. milling, turning, grinding). It includes: the general executables, including workplan, workingsteps and NC-functions; the definition of the workpiece; a feature catalogue containing features which might be referenced by several technologies; the basis for an operation definition. Not included in this schema are the following: geometric items; representations, which are referenced from ISO 10303's generic resources; the technology-specific definitions, which are defined in separate parts of ISO 14649. ISO 14649-10:2004 cannot stand alone. An implementation needs in addition at least one technology-specific part (e.g. ISO 14649-11 for milling, ISO 14649-12 for turning). Additionally, the schema uses machining features similar to ISO 10303-224 and ISO 10303-214. The description of process data is done using the EXPRESS language as defined in ISO 10303-11. The encoding of the data is done using ISO 10303-21.

Systèmes d'automatisation industrielle et intégration — Commande des dispositifs physiques — Modèle de données pour les contrôleurs numériques informatisés — Partie 10: Données des procédés généraux

General Information

- Status

- Published

- Publication Date

- 05-Dec-2004

- Technical Committee

- ISO/TC 184/SC 1 - Industrial cyber and physical device control

- Drafting Committee

- ISO/TC 184/SC 1 - Industrial cyber and physical device control

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 19-Aug-2024

- Completion Date

- 12-Feb-2026

Overview

ISO 14649-10:2004 - part of the ISO 14649 family - defines the general process data model used to describe NC-machining processes and the interface between CAM/programming systems and computerized numerical controllers (CNCs). Known as the machining_schema, this part provides process-independent data types and control structures (workplans, workingsteps and NC-functions) that are common across machining technologies (milling, turning, grinding). ISO 14649-10 is expressed in the EXPRESS language (ISO 10303-11) and encoded using ISO 10303-21 (STEP file format).

Key topics and requirements

- Process data scope: Defines the data elements generally needed for NC-machining (workpiece description, feature catalogue, executables, operations, explicit toolpath constructs).

- Control structures: Provides structures to manage programme execution sequence - primarily workingsteps, workplans and NC-functions that map process intent to machine action.

- Machining features: Supplies a catalogue of manufacturing features (e.g., pockets, slots, holes, profiles) that can be referenced by multiple technologies.

- Data modelling: Uses ISO 10303 EXPRESS for formal schema definition; includes normative EXPRESS listings and implementation guidance.

- Modularity: ISO 14649-10 is not standalone - implementations must combine it with at least one technology-specific part (e.g., ISO 14649-11 for milling, ISO 14649-12 for turning).

- Interoperability rules: Specifies conformance classes and rules for consistent implementation across CAM systems, CNCs and PLM/MES environments.

Practical applications

- CAM-to-CNC data exchange: Replace or augment legacy G/M-code workflows with feature-based, portable NC programs that describe machining intent instead of machine-axis motions.

- Postprocessor reduction: By describing operations and features at a higher level, ISO 14649-10 reduces dependency on machine-specific postprocessing and vendor extensions.

- Multi-vendor integration: Enables consistent transfer of manufacturing process data between CAD/CAM, PLM, MES and open-architecture controllers.

- Advanced automation: Useful for implementers building feature-based programming, automated process planning, and digital manufacturing pipelines.

Who uses it: CAM vendors, CNC manufacturers, system integrators, PLM/MES implementers, machine tool builders, and advanced manufacturers seeking interoperable, feature-oriented NC-programming.

Related standards

- ISO 14649 family (Part 11: Milling, Part 12: Turning)

- ISO 10303 (STEP) - including ISO 10303-11 (EXPRESS) and ISO 10303-21 (STEP file encoding)

- ISO 10303-214 and ISO 10303-224 (related machining feature models)

ISO 14649-10:2004 is a core reference for organizations implementing standardized, portable, and process-aware NC data exchange across modern manufacturing systems.

ISO 14649-10:2004 - Industrial automation systems and integration -- Physical device control -- Data model for computerized numerical controllers

ISO 14649-10:2004 - Industrial automation systems and integration -- Physical device control -- Data model for computerized numerical controllers

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

ISO 14649-10:2004 is a standard published by the International Organization for Standardization (ISO). Its full title is "Industrial automation systems and integration — Physical device control — Data model for computerized numerical controllers — Part 10: General process data". This standard covers: ISO 14649-10:2004 specifies the process data which is generally needed for NC-machining and therefore common to several machining technologies. These data elements describe the interface between the programming system (i.e. CAM system or shop-floor programming system) and a computerized numerical controller. The programme for the numerical controller includes geometric and technological information. It can be described using ISO 14649-10:2004 together with the technology-specific parts (ISO 14649-11, ISO 14649-12, etc.). ISO 14649-10:2004 provides the control structures for the sequence of programme execution, mainly the sequence of working steps and associated machine functions. The "machining_schema" defined in ISO 14649-10:2004 contains the definition of data types which are generally relevant for different technologies (e.g. milling, turning, grinding). It includes: the general executables, including workplan, workingsteps and NC-functions; the definition of the workpiece; a feature catalogue containing features which might be referenced by several technologies; the basis for an operation definition. Not included in this schema are the following: geometric items; representations, which are referenced from ISO 10303's generic resources; the technology-specific definitions, which are defined in separate parts of ISO 14649. ISO 14649-10:2004 cannot stand alone. An implementation needs in addition at least one technology-specific part (e.g. ISO 14649-11 for milling, ISO 14649-12 for turning). Additionally, the schema uses machining features similar to ISO 10303-224 and ISO 10303-214. The description of process data is done using the EXPRESS language as defined in ISO 10303-11. The encoding of the data is done using ISO 10303-21.

ISO 14649-10:2004 specifies the process data which is generally needed for NC-machining and therefore common to several machining technologies. These data elements describe the interface between the programming system (i.e. CAM system or shop-floor programming system) and a computerized numerical controller. The programme for the numerical controller includes geometric and technological information. It can be described using ISO 14649-10:2004 together with the technology-specific parts (ISO 14649-11, ISO 14649-12, etc.). ISO 14649-10:2004 provides the control structures for the sequence of programme execution, mainly the sequence of working steps and associated machine functions. The "machining_schema" defined in ISO 14649-10:2004 contains the definition of data types which are generally relevant for different technologies (e.g. milling, turning, grinding). It includes: the general executables, including workplan, workingsteps and NC-functions; the definition of the workpiece; a feature catalogue containing features which might be referenced by several technologies; the basis for an operation definition. Not included in this schema are the following: geometric items; representations, which are referenced from ISO 10303's generic resources; the technology-specific definitions, which are defined in separate parts of ISO 14649. ISO 14649-10:2004 cannot stand alone. An implementation needs in addition at least one technology-specific part (e.g. ISO 14649-11 for milling, ISO 14649-12 for turning). Additionally, the schema uses machining features similar to ISO 10303-224 and ISO 10303-214. The description of process data is done using the EXPRESS language as defined in ISO 10303-11. The encoding of the data is done using ISO 10303-21.

ISO 14649-10:2004 is classified under the following ICS (International Classification for Standards) categories: 25.040.20 - Numerically controlled machines. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 14649-10:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 14649-10

Second edition

2004-12-15

Industrial automation systems and

integration — Physical device control —

Data model for computerized numerical

controllers —

Part 10:

General process data

Systèmes d'automatisation industrielle et intégration — Commande

des dispositifs physiques — Modèle de données pour les contrôleurs

numériques informatisés —

Partie 10: Données des procédés généraux

Reference number

©

ISO 2004

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

This CD-ROM contains:

1) the publication ISO 14649-10:2004 in portable document format (PDF), which can be viewed using

Adobe® Acrobat® Reader;

2) VISIO files of the EXPRESS G diagrams for ISO 14649-10:2004.

Adobe and Acrobat are trademarks of Adobe Systems Incor

...

INTERNATIONAL ISO

STANDARD 14649-10

Second edition

2004-12-15

Industrial automation systems and

integration — Physical device control —

Data model for computerized numerical

controllers —

Part 10:

General process data

Systèmes d'automatisation industrielle et intégration — Commande

des dispositifs physiques — Modèle de données pour les contrôleurs

numériques informatisés —

Partie 10: Données des procédés généraux

Reference number

©

ISO 2004

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2004

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2004 – All rights reserved

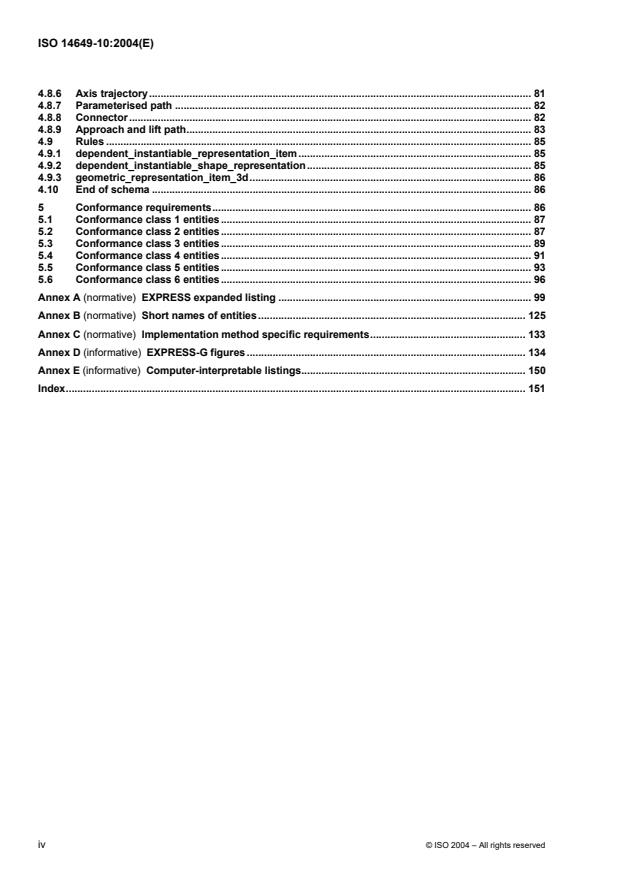

Contents Page

Foreword .v

Introduction.vi

1 Scope.1

2 Normative references.1

3 Terms and definitions .2

4 General Process data.3

4.1 Header and references.3

4.2 General types and definitions .4

4.2.1 Measure units .4

4.2.2 Other general types.6

4.3 Where to start: Project.6

4.3.1 Person and address .7

4.4 What to machine: Workpiece and manufacturing feature.7

4.4.1 Workpiece .7

4.4.2 Manufacturing feature.9

4.5 Catalogue of manufacturing features.10

4.5.1 Region .10

4.5.2 Two5D manufacturing feature.12

4.5.3 Machining feature.12

4.5.4 Planar face .13

4.5.5 Pocket.14

4.5.6 Slot.17

4.5.7 Step.21

4.5.8 Profile feature .22

4.5.9 Round hole.27

4.5.10 Toolpath feature .31

4.5.11 Boss.31

4.5.12 Spherical cap .32

4.5.13 Rounded end.33

4.5.14 Compound feature.33

4.5.15 Replicate feature.35

4.5.16 Transition feature .40

4.5.17 Thread.42

4.5.18 Profile .45

4.5.19 Travel path .52

4.5.20 Surface texture parameter.53

4.6 To make things happen: Executables.54

4.6.1 Executable.54

4.6.2 Workingstep.55

4.6.3 NC function .61

4.6.4 Program structure .62

4.7 How to machine: Operations.71

4.7.1 Operation.72

4.7.2 Machining operation .73

4.8 To be in full control: Explicit toolpath definition .76

4.8.1 Toolpath .76

4.8.2 Feedstop.79

4.8.3 Trajectory .79

4.8.4 Cutter location trajectory.79

4.8.5 Cutter contact trajectory.80

4.8.6 Axis trajectory. 81

4.8.7 Parameterised path . 82

4.8.8 Connector. 82

4.8.9 Approach and lift path. 83

4.9 Rules . 85

4.9.1 dependent_instantiable_representation_item. 85

4.9.2 dependent_instantiable_shape_representation. 85

4.9.3 geometric_representation_item_3d. 86

4.10 End of schema . 86

5 Conformance requirements. 86

5.1 Conformance class 1 entities. 87

5.2 Conformance class 2 entities. 87

5.3 Conformance class 3 entities. 89

5.4 Conformance class 4 entities. 91

5.5 Conformance class 5 entities. 93

5.6 Conformance class 6 entities. 96

Annex A (normative) EXPRESS expanded listing . 99

Annex B (normative) Short names of entities . 125

Annex C (normative) Implementation method specific requirements. 133

Annex D (informative) EXPRESS-G figures . 134

Annex E (informative) Computer-interpretable listings. 150

Index. 151

iv © ISO 2004 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 14649-10 was prepared by Technical Committee ISO/TC 184, Industrial automation systems and

integration, Subcommittee SC 1, Physical device control.

This second edition cancels and replaces the first edition (ISO 14649-10:2003), of which it constitutes a minor

revision.

ISO 14649 consists of the following parts, under the general title Industrial automation systems and

integration — Physical device control — Data model for computerized numerical controllers:

Part 1: Overview and fundamental principles

Part 10: General process data

Part 11: Process data for milling

Part 12: Process data for turning

Part 111: Tools for milling machines

Part 121: Tools for turning

Gaps in the numbering of parts were left to allow further additions. The future Parts 2 and 3 will be for

language bindings according to ISO 10303 methods. Part 10 is the ISO 10303 Application Reference Model

(ARM) for process-independent data. ISO 10303 ARMs for specific technologies are added after Part 10. The

future Part 50 will be the ISO 10303 Application Interpreted Model (AIM) for process-independent data.

ISO 10303 AIMs for specific technologies are added after Part 50.

ISO 14649 is harmonised with ISO 10303 in the common field of Product Data over the whole life cycle.

Figure 1 of ISO 14649-1 shows the different fields of standardisation between ISO 14649, ISO 10303 and CNC

manufacturers with respect to implementation and software development.

Introduction

Modern manufacturing enterprises are built from facilities spread around the globe, which contain equipment

from hundreds of different manufacturers. Immense volumes of product information must be transferred

between the various facilities and machines. Today’s digital communications standards have solved the

problem of reliably transferring information across global networks. For mechanical parts, the description of

product data has been standardised by ISO 10303. This leads to the possibility of using standard data

throughout the entire process chain in the manufacturing enterprise. Impediments to realising this principle are

the data formats used at the machine level. Most computer numerical control (CNC) machines are

programmed in the ISO 6983 “G and M code” language. Programs are typically generated by computer-aided

manufacturing (CAM) systems that use computer-aided design (CAD) information. However, ISO 6983 limits

program portability for three reasons. First, the language focuses on programming the tool center path with

respect to machine axes, rather than the machining process with respect to the part. Second, the standard

defines the syntax of program statements, but in most cases leaves the semantics ambiguous. Third, vendors

usually supplement the language with extensions that are not covered in the limited scope of ISO 6983.

ISO 14649 is a new model of data transfer between CAD/CAM systems and CNC machines, which replaces

ISO 6983. It remedies the shortcomings of ISO 6983 by specifying machining processes rather than machine

tool motion, using the object-oriented concept of Workingsteps. Workingsteps correspond to high-level

machining features and associated process parameters. CNCs are responsible for translating Workingsteps to

axis motion and tool operation. A major benefit of ISO 14649 is its use of existing data models from ISO

10303. As ISO 14649 provides a comprehensive model of the manufacturing process, it can also be used as

the basis for a bi- and multi-directional data exchange between all other information technology systems.

ISO 14649 represents an object oriented, information and context preserving approach for NC-programming,

that supersedes data reduction to simple switching instructions or linear and circular movements. As it is

object- and feature oriented and describes the machining operations executed on the workpiece, and not

machine dependent axis motions, it will be running on different machine tools or controllers. This compatibility

will spare all data adaptations by postprocessors, if the new data model is correctly implemented on the NC-

controllers. If old NC programs in ISO 6983 are to be used on such controllers, the corresponding interpreters

shall be able to process the different NC program types in parallel.

ISO TC184/SC1/WG7 envisions a gradual evolution from ISO 6983 programming to portable feature-based

programming. Early adopters of ISO 14649 will certainly support data input of legacy “G and M codes”

manually or through programs, just as modern controllers support both command-line interfaces and graphical

user interfaces. This will likely be made easier as open-architecture controllers become more prevalent.

Therefore, ISO 14649 does not include legacy program statements, which would otherwise dilute the

effectiveness of the standard.

vi © ISO 2004 – All rights reserved

INTERNATIONAL STANDARD ISO 14649-10:2004(E)

Industrial automation systems and integration — Physical

device control — Data model for computerized numerical

controllers —

Part 10:

General process data

1 Scope

This part of ISO 14649 specifies the process data which is generally needed for NC-programming within all

machining technologies. These data elements describe the interface between a computerised numerical

controller and the programming system (i.e. CAM system or shop-floor programming system). On the

programming system, the programme for the numerical controller is created. This programme includes

geometric and technological information. It can be described using this part of ISO 14649 together with the

technology-specific parts (ISO 14649-11, etc.). This part of ISO 14649 provides the control structures for the

sequence of programme execution, mainly the sequence of working steps and associated machine functions.

The “machining_schema” defined in this part of ISO 14649 contains the definition of data types which are

generally relevant for different technologies (e.g. milling, turning, grinding). The features for non-milling

technologies like turning, EDM, etc. will be introduced when the technology specific parts like ISO 14649-12

for turning, ISO 14649-13 for EDM, and ISO 14649-14 for contour cutting of wood and glass are published. It

includes the definition of the workpiece, a feature catalogue containing features which might be referenced by

several technologies, the general executables and the basis for an operation definition. Not included in this

schema are geometric items and representations, which are referenced from ISO 10303’s generic resources,

and the technology-specific definitions, which are defined in separate parts of ISO 14649.

This part of ISO 14649 cannot stand alone. An implementation needs in addition at least one technology-

specific part (e.g. ISO 14649-11 for milling, ISO 14649-12 for turning).

Additionally, the schema uses machining features similar to ISO 10303-224 and ISO 10303-214. The

description of process data is done using the EXPRESS language as defined in ISO 10303-11. The encoding

of the data is done using ISO 10303-21.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 286-1:1988, ISO system of limits and fits — Part 1: Bases of tolerances, deviations and fits

ISO 10303-11, Industrial automation systems and integration — Product data representation and exchange —

Part 11: Description methods: The EXPRESS language reference manual

ISO 10303-21, Industrial automation systems and integration — Product data representation and exchange —

Part 21: Implementation methods: Clear text encoding of the exchange structure

ISO 10303-41, Industrial automation systems and integration — Product data representation and exchange —

Part 41: Integrated generic resource: Fundamentals of product description and support

ISO 10303-42, Industrial automation systems and integration — Product data representation and exchange —

Part 42: Integrated generic resource: Geometric and topological representation

ISO 10303-43, Industrial automation systems and integration — Product data representation and exchange —

Part 43: Integrated generic resource: Representation structures

ISO 10303-214, Industrial automation systems and integration — Product data representation and

exchange — Part 214: Application protocol: Core data for automotive mechanical design processes

ISO 10303-224:2001, Industrial automation systems and integration — Product data representation and

exchange — Part 224: Application protocol: Mechanical product definition for process planning using machining

features

ISO 10303-514:1999, Industrial automation systems and integration — Product data representation and

exchange — Part 514: Application interpreted construct: Advanced boundary representation

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

2D

Geometry in a xy-plane, where all the geometry’s points have only x and y coordinates.

3.2

2½D machining

Machining of a prismatic part. Typically, the workpiece is processed in several layers which are located

perpendicular to the tool axis. In the EXPRESS listing of ISO14649, the term "two5D" is used for entity and

attribute names.

3.3

3D

Geometry in three-dimensional space, where all points have x, y, and z coordinates.

3.4

freeform machining

Machining of freeform surfaces. For this kind of machining, the tool has to move in at least three axes

simultaneously while processing the workpiece. Sometimes five-axes milling machines are used to reach an

optimised angle between the tool and the workpiece surface.

3.5

CAM

Computer Aided Manufacturing

3.6

CNC

Computer Numerical Control

3.7

EDM

Electrical Discharge Machining

3.8

EXPRESS

The language described in ISO10303-11

2 © ISO 2004 – All rights reserved

3.9

EXPRESS-G

The graphic representation of the EXPRESS language as described in ISO10303-11

3.10

Feature

A geometric entity of a workpiece which has semantic significance. In the context of ISO 14649,

manufacturing features are used

3.11

SI

International system of units

4 General Process data

4.1 Header and references

The following listing gives the header and the list of entities which are referenced within this schema.

SCHEMA machining_schema;

(*

Version of April 30, 2004

Author: ISO TC184/SC1/WG7

*)

REFERENCE FROM approval_schema (*ISO 10303-41e3*)

( approval,

approval_status);

REFERENCE FROM date_time_schema (*ISO 10303-41e3*)

( date_and_time,

date);

REFERENCE FROM person_organization_schema (*ISO10303-41e3*)

( person,

address);

REFERENCE FROM support_resource_schema (*ISO10303-41e3*)

( bag_to_set,

identifier,

label,

text);

REFERENCE FROM measure_schema (*ISO10303-41e3*)

( length_measure,

parameter_value,

plane_angle_measure,

positive_length_measure);

REFERENCE FROM product_property_representation_schema (*ISO10303-41e3*)

( shape_representation);

REFERENCE FROM representation_schema (*ISO10303-43e2*)

( definitional_representation);

REFERENCE FROM geometry_schema (*ISO10303-42e3*)

( trimming_select,

trimming_preference,

transition_code,

trimmed_curve,

composite_curve,

composite_curve_segment,

axis2_placement_3d,

bounded_curve,

bounded_surface,

cartesian_point,

circle,

conic,

curve,

direction,

elementary_surface,

plane,

polyline

);

REFERENCE FROM topology_schema (*ISO10303-42e3*)

( edge, edge_curve, edge_loop, face, loop);

REFERENCE FROM geometric_model_schema (*ISO10303-42e3*)

( block,

right_circular_cylinder

);

REFERENCE FROM aic_advanced_brep (*ISO10303-514*)

(advanced_brep_shape_representation

);

4.2 General types and definitions

4.2.1 Measure units

The types of units supported by ISO 14649 are SI units as well as derived or conversion based units as

defined in ISO 10303-41. If no units are given then, the following units are assumed:

length_measure millimetres [mm],

time_measure seconds [s],

plane_angle_measure degrees [°],

pressure_measure Pascal [pa],

speed_measure meters per second [m/sec],

rot_speed_measure revolutions per second [1/sec].

4.2.1.1 Toleranced length measure

Length measure with tolerance.

ENTITY toleranced_length_measure; (* m1 *)

theoretical_size: positive_length_measure;

implicit_tolerance: tolerance_select;

END_ENTITY;

4 © ISO 2004 – All rights reserved

theoretical_size: The theoretical length.

implicit_tolerance: The type of tolerance to apply to theoretical_size.

Note that all geometric properties of the workpiece are specified using toleranced_length_measure. If the NC

controller has the ability to generate toolpaths or to make decisions about the tool used, it is the controller's

responsibility to meet these tolerance requirements. On the other hand, data provided to the NC controller for

explicit specification of movements will have no tolerances as the controller cannot do more than try to follow

the given theoretical values to the best of its abilities. The same is true for offsets and other data referring to

already toleranced dimensions.

4.2.1.1.1 Tolerance select

Select type offering different etities to describe tolerances for scalar values.

TYPE tolerance_select = SELECT(plus_minus_value, limits_and_fits);

END_TYPE;

4.2.1.1.2 Plus minus value

The plus_minus_value describes the upper and lower limits valid for a scalar dimension referencing this entity.

ENTITY plus_minus_value; (* m1 *)

upper_limit: positive_length_measure;

lower_limit: positive_length_measure;

significant_digits: INTEGER;

END_ENTITY;

upper_limit: The value of the tolerance that shall be added to the exact value to establish

the maximum allowed value.

lower_limit: the value of the tolerance that shall be subtracted from the exact value to

establish the minimum allowed value.

significant_digits: The number of decimal digits indicating the accuracy of the lower_bound

and upper_bound values.

4.2.1.1.3 Limits and fits

A limits_and_fits contains the necessary information to express a tolerance of the limits-and-fits system

standardised by ISO 286.

ENTITY limits_and_fits; (* m1 *)

deviation: length_measure;

grade: length_measure;

its_fitting_type: OPTIONAL fitting_type;

END_ENTITY;

deviation: The difference between a measured actual size and the corresponding basic

size as defined in ISO 286-1.

grade: The grade specifies the quality or the accuracy grade of a tolerance. The

grade is based on the international standard tolerance grades IT01 to IT18 as

defined in ISO 286-1.

fitting_type: Specification whether the tolerance declaration applies to a shaft or to a hole.

4.2.1.1.4 Fitting type

The enumeration used to specify the type of fitting.

TYPE fitting_type = ENUMERATION OF (shaft,hole);

END_TYPE;

4.2.1.2 Speed measure

A measure for a linear speed used for cutting speeds and feed rates.

TYPE speed_measure = REAL;

END_TYPE;

4.2.1.3 Rotational speed measure

A measure for a rotational speed. Positive values indicate rotation in the mathematical positive sense, i. e.

counter-clockwise motion.

TYPE rot_speed_measure = REAL;

END_TYPE;

4.2.1.4 Pressure measure

A measure for pressure.

TYPE pressure_measure = REAL;

END_TYPE;

4.2.2 Other general types

4.2.2.1 Rotational direction

Enumeration used to identify the direction (sense) of the tool’s rotation or of the direction of a circular

movement. It should not be used in conjunction with rot_speed_measure which carries its own sense of

rotation.

TYPE rot_direction = ENUMERATION OF (cw,ccw);

END_TYPE;

Note: cw means clockwise, ccw means counter-clockwise.

4.2.2.2 Shape tolerance

Type for definition of shape tolerance.

TYPE shape_tolerance = length_measure;

END_TYPE;

4.3 Where to start: Project

Each part programme, i.e. data model, based on ISO14649 must include exactly one top-level entity, called

project. The project indicates the workplan to be executed upon interpretation of this model (as several

6 © ISO 2004 – All rights reserved

workplans might be included), and it may also provide the workpiece(s) upon which actions are to be

performed.

ENTITY project; (* m0 *)

its_id: identifier;

main_workplan: workplan;

its_workpieces: SET [0:?] OF workpiece;

its_owner: OPTIONAL person_and_address;

its_release: OPTIONAL date_and_time;

its_status: OPTIONAL approval;

(* Informal proposition:

its_id shall be unique within the part programme.

*)

END_ENTITY;

its_id: The project’s identifier. It shall be unique within the part programme.

main_workplan: The top-level workplan in this model.

its_workpieces: The workpieces upon which actions are to be performed.

its_owner: Optional information on the owner of the project.

its_release: Optional date and time reference of the project.

its_status: Optional attribute to indicate the current status of the project.

4.3.1 Person and address

Entity includes data to name and reference a person, who for instance is responsible for creating a project.

ENTITY person_and_address; (* m0 *)

its_person: person;

its_address: OPTIONAL address;

END_ENTITY;

4.4 What to machine: Workpiece and manufacturing feature

4.4.1 Workpiece

The workpiece entity contains the entire description of the workpiece, if available. This includes material,

surface condition and geometric data. Each workpiece has only one surface condition and one material.

Dependent on the conformance class the workpiece entity includes the raw part dimension only as an

including box or cylinder, or, in a higher class, as a representation which can be a complete geometric model,

e.g. the state after previous manufacturing operations.

ENTITY workpiece; (* m1 *)

its_id: identifier;

its_material: OPTIONAL material;

global_tolerance: OPTIONAL shape_tolerance;

its_rawpiece: OPTIONAL workpiece;

its_geometry: OPTIONAL advanced_brep_shape_representation;

its_bounding_geometry: OPTIONAL bounding_geometry_select;

clamping_positions: SET [0:?] OF cartesian_point;

END_ENTITY;

its_id: The unique identification of a workpiece.

its_material: The material attribute identifies the workpiece material. This data shall be

used for determining the technological process parameters for the

manufacturing process. It can be done by the machine operator or by an

automatic feed rate/cutting condition selection (from a table or a data base

on the CNC).

global_tolerance: Tolerance for the workpiece, valid where no other tolerances are specified.

its_rawpiece: The rawpiece geometry of the workpiece may be described here. A recursive

description is used, i.e. the rawpiece is of type workpiece itself.

its_geometry: An exact description of the final workpiece geometry according to ISO

10303-514.

its_bounding_geometry: By this attribute the workpiece´s bounding geometry might be defined as a

box, a cylinder or a geometry according to the definition of the entity

advanced_brep_shape_representation (ISO 10303--514).

clamping_positions: Positions of the clamping device on the workpiece’s surface.

All attribute’s locations, directions and geometrical information are defined relatively to the workpiece’s

coordinate system.

4.4.1.1 Material

This entity is for identifying the workpiece material.

ENTITY material; (* m1 *)

standard_identifier: label;

material_identifier: label;

material_property: SET [0:?] OF property_parameter;

END_ENTITY;

standard_identifier: The standard used for identifying the material. This can be a national

standard or one used internally in the company.

material_identifier: The name which identifies the material.

material_property: The parameter which describes the properties of material. Since the demand

for material properties varies, a generic type „property parameter” is used.

4.4.1.2 Property parameter

Generic property parameter which may be used to characterise any kind of property any kind of parameter

might have. Subtypes are descriptive parameters (strings) and numeric parameters.

8 © ISO 2004 – All rights reserved

ENTITY property_parameter (* m0 *)

SUPERTYPE OF (ONEOF (descriptive_parameter,numeric_parameter));

parameter_name: label;

END_ENTITY;

parameter_name: The name of the parameter to be described.

4.4.1.2.1 Descriptive parameter

A parameter description using a string to characterise the parameter.

ENTITY descriptive_parameter (* m0 *)

SUBTYPE OF (property_parameter);

descriptive_string: text;

END_ENTITY;

descriptive_string: String value which describes the parameter.

4.4.1.2.2 Numeric parameter

A parameter description using a numeric value. Both the number and the unit shall be given.

ENTITY numeric_parameter (* m0 *)

SUBTYPE OF (Property_parameter);

its_parameter_value: parameter_value;

its_parameter_unit: label;

END_ENTITY;

its_parameter_value: The value which describes the parameter.

its_parameter_unit: The units associated with the value.

4.4.1.3 Bounding geometry select

This type offers three different entities to describe the bounding geometry of a workpiece. Depending on the

conformance class the bounding geometry is described as a block or a cylinder using the geometric items of

ISO 10303-42 or as a complex shape conformable to ISO 10303-514. All coordinates and directions given in

bounding_geometry are defined in the given workpiece’s coordinate system.

TYPE bounding_geometry_select =

SELECT (block, right_circular_cylinder, (* m1 *)

advanced_brep_shape_representation); (* t1 *)

END_TYPE;

4.4.2 Manufacturing feature

This entity is the supertype of all manufacturing features. When considering 2½D-manufacturing, features are

of type two5D_manufacturing_feature and may be holes, pockets, etc. When considering freeform

manufacturing, regions are used in the same sense.

The manufacturing feature describes the feature as such, e.g. by its geometric properties. It does not give any

instruction on how the workpiece is manufactured. Such process related information is contained only in the

operations and depends on the manufacturing method. The methods are described in the technology specific

parts of ISO 14649. For example, plunging into a pocket, roughing the pocket and finishing the pocket bottom

may all be individual operations, as well as the finishing of a portion of a freeform surface. For the concept of

operations, please refer to section 4.7.1.

ENTITY manufacturing_feature (* m1 *)

ABSTRACT SUPERTYPE OF (ONEOF(region, two5D_manufacturing_feature,

transition_feature));

its_id: identifier;

its_workpiece: workpiece;

its_operations: SET [0:?] OF machining_operation;

END_ENTITY;

its_id: Each feature has an unique identifier.

its_workpiece: The workpiece which the feature is part of.

its_operations: A set of all operations associated with the feature required for the

manufacturing of the feature. Note that the operations are not necessarily

executed immediately after each other. Only the workplan determines the

final order of operations of all operations included in a given programme,

and manufacturing will typically not occur feature by feature but rather

according to technological criteria like minimised tool change. However, it

should be guaranteed by the CAM system (or by the controller, if the order

of execution is determined by an intelligent CNC) that the order given in

this attribute is never violated.

4.5 Catalogue of manufacturing features

4.5.1 Region

The region is the equivalent of a feature in freeform machining. It describes a bounded area of the final

workpiece surface to which the associated operations will be applied. Note that for freeform surfaces the

regions for different operations (e.g. roughing, finishing) may have different shapes based upon technological

decisions.

ENTITY region (* m1 *)

ABSTRACT SUPERTYPE OF (ONEOF (region_surface_list, region_projection,

topological_region))

SUBTYPE OF (manufacturing_feature);

feature_placement: OPTIONAL axis2_placement_3d;

END_ENTITY;

feature_placement: The placement of the feature relative to the workpiece co-ordinate system.

The placement is a translation and/or a rotation which transforms the origin

of the workpiece co-ordinate system origin into the origin of the feature’s

local co-ordinate system. If no feature_placement is given, the region will

use workpiece co-ordinates. Regarding coordinate systems see also Section

4.6.4.1.2.

10 © ISO 2004 – All rights reserved

4.5.1.1 Region projection

A type of bounded region generated by projecting a closed curve on a surface. Thus, a region can easily be

defined on an existing surface description. The region projection applies to any workpiece surface it hits when

moving in space along proj_dir. This is a very simplistic region definition for situations where the use of

topology is not desired.

ENTITY region_projection (* m1 *)

SUBTYPE OF (region);

proj_curve: bounded_curve;

proj_dir: direction;

depth: toleranced_length_measure;

END_ENTITY;

proj_curve: A curve in space, used for specifying the boundary for a surface through its

projection on the surface. It must be a closed curve and will usually be in

one plane.

proj_dir: Direction used for projecting the above curve on the surface.

depth: The depth is a positive scalar value. It describes the distance of material

removal into negative z-direction of the region’s local coordinate system.

The depth is measured from the raw piece’s surface, onto which the

proj_curve has been projected, to the bottom to be machined. The depth is

equal for the whole region. In case the bottom’s shape shall not be equal to

the raw piece’s surface, the entity pocket and its subtypes have to be used.

4.5.1.2 Region surface list

A type of region specified by a list of surfaces. This allows for the most general description of regions. The

region is bounded by the borders of the surfaces it encloses.

ENTITY region_surface_list (* m1 *)

SUBTYPE OF (region);

surface_list: LIST [1:?] OF bounded_surface;

END_ENTITY;

surface_list: List of general surfaces, allowing for various descriptions.

4.5.1.3 Topological region

A type of region specified by a topological representation. Only faces of type advanced_face are allowed as

they are certain to carry their own geometric representation.

ENTITY topological_region (* t0 t1 *)

SUBTYPE OF (region, open_shell);

WHERE

WR1: SIZEOF(QUERY(it <* SELF.cfs_faces |

NOT('MACHINING_SCHEMA.ADVANCED_FACE' IN TYPEOF(it)))) = 0;

END_ENTITY;

4.5.2 Two5D manufacturing feature

The entity two5D_manufacturing_feature is the abstract supertype of all 2½D features. This structure is

defined in close resemblance to ISO 10303-224.

ENTITY two5D_manufacturing_feature (* m1 *)

ABSTRACT SUPERTYPE OF (ONEOF(machining_feature, replicate_feature,

compound_feature))

SUBTYPE OF (manufacturing_feature);

feature_placement: axis2_placement_3d;

END_ENTITY;

feature_placement: The placement of the feature relative to the workpiece co-ordinate system.

The placement is a translation and/or a rotation which transforms the origin

of the workpiece co-ordinate system origin into the origin of the feature’s

local co-ordinate system. For information on coordinate systems refer to

Section 4.6.4.1.2. If the manufacturing feature is part of a compound_feature,

then its placement is defined relative to the compound_feature´s origin.

4.5.3 Machining feature

The entity machining_feature is the abstract supertype of all features used for feature based 2½D machining.

In this part the following features are foreseen as they are used in different technology specific parts of ISO

14649: planar face, pocket, slot, step, hole, generic feature, and compound feature. The features are defined

in close resemblance to ISO 10303-224.

2½D machining is characterised by the fact that most tool movements occur only in the xy plane while the z

axis is preset to a certain depth in order to remove a layer of material. For this reason, all machining features

have a depth.

All feature geometry, e.g. the contour describing the outline of a pocket, is described in a local xyz co-ordinate

system. The definition of the coordinate system’s orientation is given in the machining method specific parts.

The surrounding surface of the workpiece and the definition of the planar contour of the feature are assumed

to lie in the xy plane (z = 0). The material is assumed to be in negative z direction of the xy-plane. In other

words, a positive depth within a machining operation requires t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...