ISO 14531-4:2006

(Main)Plastics pipes and fittings — Crosslinked polyethylene (PE-X) pipe systems for the conveyance of gaseous fuels — Metric series — Specifications — Part 4: System design and installation guidelines

Plastics pipes and fittings — Crosslinked polyethylene (PE-X) pipe systems for the conveyance of gaseous fuels — Metric series — Specifications — Part 4: System design and installation guidelines

ISO 14531-4:2006 provides guidance for the design, construction, installation and on-site testing of PE-X pipeline systems. The standard deals with trenchless and open-trench installation methods. ISO 14531-4:2006, when used in conjunction with the other parts of ISO 14531, provides the basis for the design, manufacture and installation of PE-X piping systems (PE-X pipes, and PE-X and PE heat-fusion fittings and mechanical fittings) for the supply of category D and category E hydrocarbon-based fuels.

Tubes et raccords en matières plastiques — Systèmes de tubes en polyéthylène réticulé (PE-X) pour le transport de combustibles gazeux — Série métrique — Spécifications — Partie 4: Lignes directrices pour la conception et l'installation du système

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 14531-4

First edition

2006-04-01

Plastics pipes and fittings — Crosslinked

polyethylene (PE-X) pipe systems for the

conveyance of gaseous fuels — Metric

series — Specifications —

Part 4:

System design and installation guidelines

Tubes et raccords en matières plastiques — Systèmes de tubes en

polyéthylène réticulé (PE-X) pour le transport de combustibles

gazeux — Série métrique — Spécifications —

Partie 4: Lignes directrices pour la conception et l'installation du

système

Reference number

©

ISO 2006

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2006

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2006 – All rights reserved

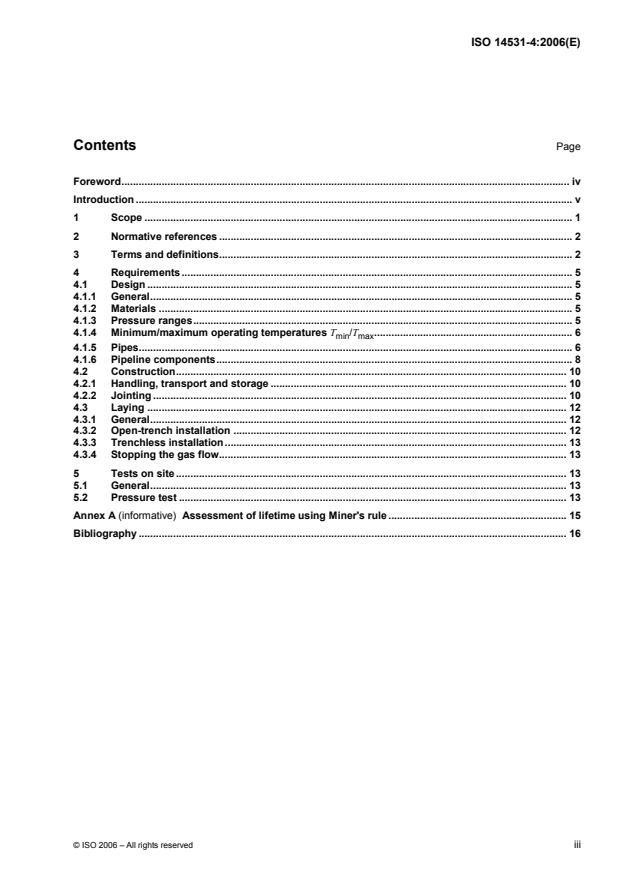

Contents Page

Foreword. iv

Introduction . v

1 Scope . 1

2 Normative references . 2

3 Terms and definitions. 2

4 Requirements . 5

4.1 Design . 5

4.1.1 General. 5

4.1.2 Materials . 5

4.1.3 Pressure ranges. 5

4.1.4 Minimum/maximum operating temperatures T /T . 6

min max

4.1.5 Pipes. 6

4.1.6 Pipeline components. 8

4.2 Construction. 10

4.2.1 Handling, transport and storage . 10

4.2.2 Jointing . 10

4.3 Laying . 12

4.3.1 General. 12

4.3.2 Open-trench installation . 12

4.3.3 Trenchless installation. 13

4.3.4 Stopping the gas flow. 13

5 Tests on site . 13

5.1 General. 13

5.2 Pressure test . 13

Annex A (informative) Assessment of lifetime using Miner's rule . 15

Bibliography . 16

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 14531-4 was prepared by Technical Committee ISO/TC 138, Plastics pipes, fittings and valves for the

transport of fluids, Subcommittee SC 4, Plastic pipes and fittings for the supply of gaseous fuels.

ISO 14531 consists of the following parts, under the general title Plastics pipes and fittings — Crosslinked

polyethylene (PE-X) pipe systems for the conveyance of gaseous fuels — Metric series — Specifications:

⎯ Part 1: Pipes

⎯ Part 2: Fittings for heat-fusion jointing

⎯ Part 3: Fittings for mechanical jointing (including PE-X/metal transitions)

⎯ Part 4: System design and installation guidelines

iv © ISO 2006 – All rights reserved

Introduction

Further to the publication of International Standards for crosslinked polyethylene (PE-X) hot-water pipes, it has

become evident that the properties of PE-X, in particular its high fracture resistance and a recently established

socket and saddle fusion-jointing capability, render it suitable for use in high-performance gas-distribution

systems. The philosophy of ISO 14531 is to provide the basis for the introduction of PE-X gas pipe systems by

the specification of a performance envelope beyond that covered by existing PE standards in order to take its

application into regimes of higher operating pressures and extremes of operating temperature.

This part of ISO 14531 is therefore one part of a four-part system standard covering pipes, fittings for

heat-fusion jointing, fittings for mechanical jointing and design and installation guidelines. The content is

suitable for use by procurement authorities and distribution engineers responsible for the design, installation

and operation of pipeline systems.

INTERNATIONAL STANDARD ISO 14531-4:2006(E)

Plastics pipes and fittings — Crosslinked polyethylene (PE-X)

pipe systems for the conveyance of gaseous fuels — Metric

series — Specifications —

Part 4:

System design and installation guidelines

1 Scope

This part of ISO 14531 provides guidance for the design, construction, installation and on-site testing of PE-X

pipeline systems. The standard deals with trenchless and open-trench installation methods.

This part of ISO 14531, when used in conjunction with the other parts of ISO 14531, provides the basis for the

design, manufacture and installation of PE-X piping systems (PE-X pipes, and PE-X and PE heat-fusion fittings

and mechanical fittings) for the supply of category D and category E hydrocarbon-based fuels (see

ISO 13623) at

1)

a) maximum operating pressures (MOPs) up to and including 16 bar and

b) a maximum operating temperature of +60 °C and

c) a minimum operating temperature of

1) −50 °C

2) −35 °C

3) −20 °C.

This part of ISO 14531 provides for the jointing and installation of PE-X and PE heat-fusion fittings and

mechanical fittings to PE-X pipes within the temperature range −5 °C to +40 °C. The jointing of pipes and

fittings outside the stated temperature range should be the subject of consultation between the pipeline

operator and the pipe, fitting and equipment manufacturers.

Users of this part of ISO 14531 should be aware that useful supplementary information is given in the

standards listed in the bibliography.

5 2

1) 1 bar = 10 N/m = 100 kPa.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 4065, Thermoplastic pipes — Universal wall thickness table

ISO 8085-3, Polyethylene fittings for use with polyethylene pipes for the supply of gaseous fuels — Metric

series — Specifications — Part 3: Electrofusion fittings

ISO 9080, Plastics piping and ducting systems — Determination of the long-term hydrostatic strength of

thermoplastics materials in pipe form by extrapolation

ISO 10838 (all parts), Mechanical fittings for polyethylene piping systems for the supply of gaseous fuels

ISO/TS 10839:2000, Polyethylene pipes and fittings for the supply of gaseous fuels — Code of practice for

design, handling and installation

ISO 12162, Thermoplastics materials for pipes and fittings for pressure applications — Classification and

designation — Overall service (design) coefficient

ISO 12176-2, Plastics pipes and fittings — Equipment for fusion jointing polyethylene systems — Part 2:

Electrofusion

ISO 13623, Petroleum and natural gas industries — Pipeline transportation systems

ISO 13760, Plastics pipes for the conveyance of fluids under pressure — Miner's rule — Calculation method

for cumulative damage

ISO 14531-1:2002, Plastics pipes and fittings — Crosslinked polyethylene (PE-X) pipe systems for the

conveyance of gaseous fuels — Metric series — Specifications — Part 1: Pipes

ISO 14531-2, Plastics pipes and fittings — Crosslinked polyethylene (PE-X) pipe systems for the conveyance

of gaseous fuels — Metric series — Specifications — Part 2: Fittings for heat-fusion jointing

ISO 14531-3, Plastics pipes and fittings — Crosslinked polyethylene (PE-X) pipe systems for the conveyance

of gaseous fuels — Metric series — Specifications — Part 3: Fittings for mechanical jointing (including

PE-X/metal transitions)

EN 12007-1, Gas supply systems — Pipelines for maximum operating pressure up to and including 16 bar —

Part 1: General functional recommendations

EN 12007-2, Gas supply systems — Pipelines for maximum operating pressure up to and including 16 bar —

Part 2: Specific functional recommendations for polyethylene (MOP up to and including 10 bar)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

nominal outside diameter

d

n

numerical designation of size which is common to all components in a thermoplastics piping system other than

flanges and components designated by thread size

NOTE 1 It is a convenient round number for reference purposes.

2 © ISO 2006 – All rights reserved

NOTE 2 The nominal outside diameter expressed in millimetres is the minimum mean outside diameter d of pipe

e,min

produced in accordance with ISO 14531-1.

3.2

nominal wall thickness

e

n

nominal designation of wall thickness of a pipe in millimetres in accordance with ISO 4065

3.3

standard dimension ratio

SDR

ratio of the nominal outside diameter of a pipe to its nominal wall thickness

d

n

SDR =

e

n

NOTE The value of the SDR is selected from Table 5 in ISO 14531-1:2002.

3.4

gaseous fuel

fuel which is in a gaseous state at a temperature of +15 °C and a pressure of 1 bar

3.5

category D gaseous fuel

natural gas

NOTE Categories of gaseous and liquid fuels are defined in detail in ISO 13623.

3.6

category E gaseous fuel

LPG vapour or natural gas conveyed in association with liquid condensate

NOTE Categories of gaseous and liquid fuels are defined in detail in ISO 1362

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.