ISO 10303-111:2007

(Main)Industrial automation systems and integration — Product data representation and exchange — Part 111: Integrated application resource : Elements for the procedural modelling of solid shapes

Industrial automation systems and integration — Product data representation and exchange — Part 111: Integrated application resource : Elements for the procedural modelling of solid shapes

ISO 10303-111:2007 represents shape elements available in modern CAD systems in a manner suitable for use in procedural or construction history modelling.

Systèmes d'automatisation industrielle et intégration — Représentation et échange de données de produits — Partie 111: Ressources d'application intégrée: Éléments pour la modélisation procédurale des formes solides

General Information

- Status

- Published

- Publication Date

- 14-May-2007

- Technical Committee

- ISO/TC 184/SC 4 - Industrial data

- Drafting Committee

- ISO/TC 184/SC 4/WG 12 - STEP product modelling and resources

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 28-Jun-2024

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 25-Apr-2020

ISO 10303-111:2007 - Overview of the Standard

Standard Reference: ISO 10303-111:2007

Title: Industrial automation systems and integration - Product data representation and exchange - Part 111: Integrated application resource: Elements for the procedural modelling of solid shapes

Overview

ISO 10303-111 (part of the STEP family) defines a schema of solid shape elements for representing complex CAD geometry in a procedural (history- or construction-based) form. Rather than only exchanging final B‑REP geometry, this integrated application resource captures feature‑based modeling operations (creation and modification steps) so CAD models can be exchanged, re‑used or reconstructed with their construction history preserved.

Keywords: ISO 10303-111, STEP, procedural modeling, construction history, CAD data exchange, solid shape elements, integrated application resource.

Key topics and technical scope

- Procedural / construction‑history modelling - supports representation of sequences of operations used to build solid models (feature definitions and modifications).

- Solid shape element schema - a set of element types and entities that represent common CAD features: blends, chamfers, holes, pockets, slots, patterns, shelled solids, extrusions, revolved features, sculptured solids, and more.

- Interoperability constructs - entity definitions, selects, trim/blend conditions, radius/chamfer variants and function definitions for validation and geometry checks.

- Dependency on STEP resources - designed to work with other ISO 10303 integrated resources (geometry, topology, representation, measures, math functions and operation sequencing). Notably it references ISO 10303-55 for capturing sequence semantics and uses EXPRESS-G diagrams and computer‑interpretable listings for machine implementation.

- Normative and informative annexes - include entity short names, registration information, EXPRESS-G diagrams, listings, and modelling justification.

Practical applications and users

Who uses ISO 10303-111:

- CAD and PLM software vendors implementing STEP-based data exchange of feature-based models.

- Systems integrators and developers building translators between CAD systems who need to preserve construction history.

- Manufacturing and CAM toolchains that need to reconstruct feature intent for downstream processes (machining, simulation, inspection).

- Digital archiving and long-term product data management where preserving design intent and editable history is important.

- Standards and interoperability teams in aerospace, automotive, industrial machinery and engineering services.

Benefits:

- Preserves feature semantics and modeling intent across systems.

- Enables reuse, editing, and consistent downstream processing of CAD models.

- Facilitates long-term archiving with richer product data representation than pure geometry exchange.

Related standards

- ISO 10303-1 (Overview and fundamental principles)

- ISO 10303-41, -42, -43 (support, geometry, topology, representation schemas)

- ISO 10303-50 (mathematical functions)

- ISO 10303-55 (operation sequencing / construction history)

- ISO 10303-108 (constraints and sketch resources)

For organizations implementing CAD data exchange or feature-preserving interoperability, ISO 10303-111 is a core resource in the STEP family for procedural solid modeling.

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

ISO 10303-111:2007 is a standard published by the International Organization for Standardization (ISO). Its full title is "Industrial automation systems and integration — Product data representation and exchange — Part 111: Integrated application resource : Elements for the procedural modelling of solid shapes". This standard covers: ISO 10303-111:2007 represents shape elements available in modern CAD systems in a manner suitable for use in procedural or construction history modelling.

ISO 10303-111:2007 represents shape elements available in modern CAD systems in a manner suitable for use in procedural or construction history modelling.

ISO 10303-111:2007 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 10303-111:2007 has the following relationships with other standards: It is inter standard links to ISO 10303-111:2007/Cor 2:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 10303-111:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 10303-111

First edition

2007-05-15

Industrial automation systems and

integration — Product data

representation and exchange —

Part 111:

Integrated application resource: Elements

for the procedural modelling of solid

shapes

Systèmes d'automatisation industrielle et intégration — Représentation

et échange de données de produits —

Partie 111: Ressources d'application intégrée: Éléments pour la

modélisation procédurale des formes solides

Reference number

©

ISO 2007

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2007

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2007 – All rights reserved

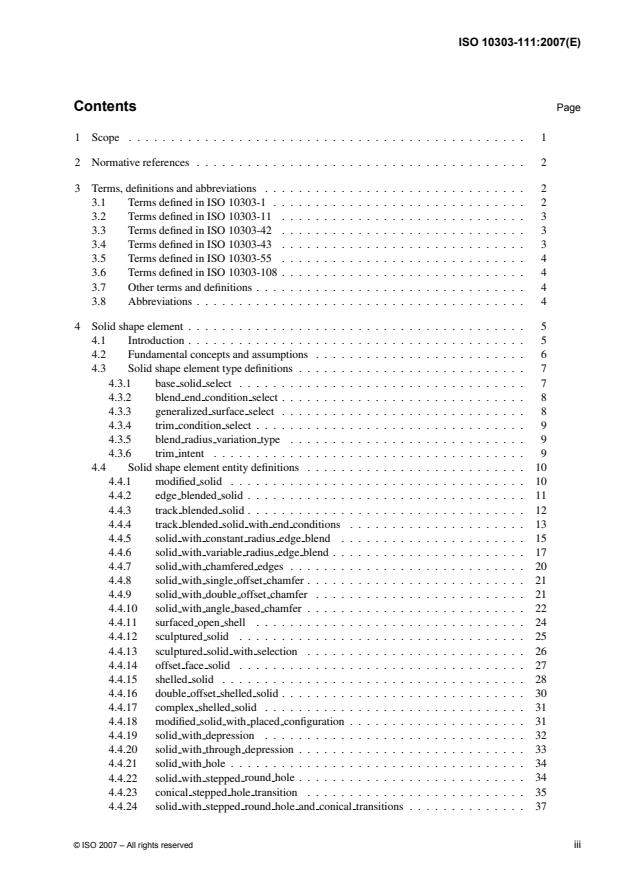

Contents Page

1 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Normative references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 Terms, definitions and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.1 Terms defined in ISO 10303-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.2 Terms defined in ISO 10303-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.3 Terms defined in ISO 10303-42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.4 Terms defined in ISO 10303-43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.5 Terms defined in ISO 10303-55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.6 Terms defined in ISO 10303-108 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.7 Other terms and definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.8 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 Solid shape element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.2 Fundamental concepts and assumptions . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.3 Solid shape element type definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3.1 base solid select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3.2 blend end condition select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.3.3 generalized surface select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.3.4 trim condition select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3.5 blend radius variation type . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3.6 trim intent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.4 Solid shape element entity definitions . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.4.1 modified solid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.4.2 edge blended solid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.4.3 track blended solid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.4.4 track blended solid with end conditions . . . . . . . . . . . . . . . . . . . . . 13

4.4.5 solid with constant radius edge blend . . . . . . . . . . . . . . . . . . . . . . 15

4.4.6 solid with variable radius edge blend . . . . . . . . . . . . . . . . . . . . . . . 17

4.4.7 solid with chamfered edges . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.4.8 solid with single offset chamfer . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4.9 solid with double offset chamfer . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4.10 solid with angle based chamfer . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4.11 surfaced open shell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.4.12 sculptured solid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4.13 sculptured solid with selection . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4.14 offset face solid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.4.15 shelled solid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.4.16 double offset shelled solid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.4.17 complex shelled solid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.4.18 modified solid with placed configuration . . . . . . . . . . . . . . . . . . . . . 31

4.4.19 solid with depression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.4.20 solid with through depression . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.4.21 solid with hole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.4.22 solid with stepped round hole . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.4.23 conical stepped hole transition . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.4.24 solid with stepped round hole and conical transitions . . . . . . . . . . . . . . 37

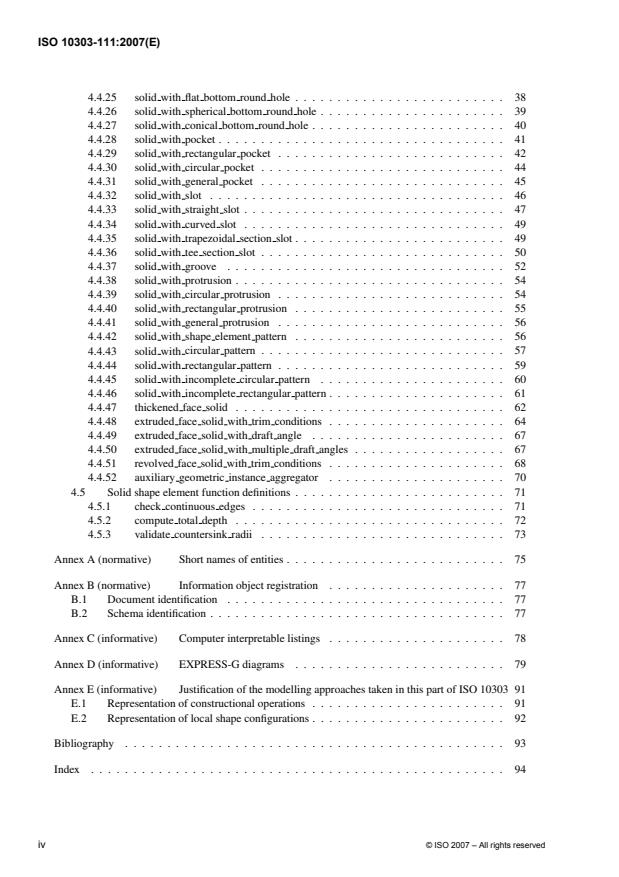

4.4.25 solid with flat bottom round hole . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.4.26 solid with spherical bottom round hole . . . . . . . . . . . . . . . . . . . . . . 39

4.4.27 solid with conical bottom round hole . . . . . . . . . . . . . . . . . . . . . . . 40

4.4.28 solid with pocket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.4.29 solid with rectangular pocket . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.4.30 solid with circular pocket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.4.31 solid with general pocket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.4.32 solid with slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.4.33 solid with straight slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.4.34 solid with curved slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.4.35 solid with trapezoidal section slot . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.4.36 solid with tee section slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.4.37 solid with groove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.4.38 solid with protrusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.4.39 solid with circular protrusion . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.4.40 solid with rectangular protrusion . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.4.41 solid with general protrusion . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.4.42 solid with shape element pattern . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.4.43 solid with circular pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.4.44 solid with rectangular pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.4.45 solid with incomplete circular pattern . . . . . . . . . . . . . . . . . . . . . . 60

4.4.46 solid with incomplete rectangular pattern . . . . . . . . . . . . . . . . . . . . . 61

4.4.47 thickened face solid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.4.48 extruded face solid with trim conditions . . . . . . . . . . . . . . . . . . . . . 64

4.4.49 extruded face solid with draft angle . . . . . . . . . . . . . . . . . . . . . . . 67

4.4.50 extruded face solid with multiple draft angles . . . . . . . . . . . . . . . . . . 67

4.4.51 revolved face solid with trim conditions . . . . . . . . . . . . . . . . . . . . . 68

4.4.52 auxiliary geometric instance aggregator . . . . . . . . . . . . . . . . . . . . . 70

4.5 Solid shape element function definitions . . . . . . . . . . . . . . . . . . . . . . . . . 71

4.5.1 check continuous edges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4.5.2 compute total depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4.5.3 validate countersink radii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Annex A (normative) Short names of entities . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Annex B (normative) Information object registration . . . . . . . . . . . . . . . . . . . . . 77

B.1 Document identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

B.2 Schema identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Annex C (informative) Computer interpretable listings . . . . . . . . . . . . . . . . . . . . . 78

Annex D (informative) EXPRESS-G diagrams . . . . . . . . . . . . . . . . . . . . . . . . . 79

Annex E (informative) Justification of the modelling approaches taken in this part of ISO 10303 91

E.1 Representation of constructional operations . . . . . . . . . . . . . . . . . . . . . . . 91

E.2 Representation of local shape configurations . . . . . . . . . . . . . . . . . . . . . . . 92

Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

iv © ISO 2007 – All rights reserved

Figures

Figure 1 Schema level diagram of relationships between the solid - shape element schema

of this part of ISO 10303 and other resource schemas . . . . . . . . . . . . . . . . . . . . viii

Figure 2 L-section block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 3 L-section block of Figure 2 with constant radius edge blend . . . . . . . . . . . . . 16

Figure 4 A track blended solid with a constant radius edge blend . . . . . . . . . . . . . . . 17

Figure 5 L-section block of Figure 2 with variable radius edge blend . . . . . . . . . . . . . 19

Figure 6 A track blended solid with end conditions for which the blend radius is variable . . 19

Figure 7 Solid with double offset chamfer . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 8 Solid with angle based chamfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 9 Solid and generalized surface defining a sculptured solid . . . . . . . . . . . . . . . 26

Figure 10 The sculptured solid after the partitioning operation . . . . . . . . . . . . . . . . . 26

Figure 11 Offset face solid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 12 Shelled solid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 13 Cross-section of solid with stepped round hole . . . . . . . . . . . . . . . . . . . . 36

Figure 14 Cross-section of solid with stepped round hole and conical transitions . . . . . . . . 38

Figure 15 Bottom conditions for blind round holes . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 16 Solid with rectangular pocket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 17 Solid with straight slot, having two closed ends . . . . . . . . . . . . . . . . . . . 48

Figure 18 Straight slot with multiple entries and exits from part material . . . . . . . . . . . . 48

Figure 19 Trapezoidal and T slot sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 20 Solid with groove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 21 The effect of radial alignment in solid with circular pattern . . . . . . . . . . . . . 58

Figure 22 Solid with rectangular pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 23 Solid with incomplete circular pattern . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 24 Solid with incomplete rectangular pattern . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 25 Thickened face solid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 26 Extruded face solid with draft angle . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure D.1 solid shape element schema – EXPRESS-G diagram 1 of 11 . . . . . . . . . . . . 80

Figure D.2 solid shape element schema – EXPRESS-G diagram 2 of 11 . . . . . . . . . . . . 81

Figure D.3 solid shape element schema – EXPRESS-G diagram 3 of 11 . . . . . . . . . . . . 82

Figure D.4 solid shape element schema – EXPRESS-G diagram 4 of 11 . . . . . . . . . . . . 83

Figure D.5 solid shape element schema – EXPRESS-G diagram 5 of 11 . . . . . . . . . . . . 84

Figure D.6 solid shape element schema – EXPRESS-G diagram 6 of 11 . . . . . . . . . . . . 85

Figure D.7 solid shape element schema – EXPRESS-G diagram 7 of 11 . . . . . . . . . . . . 86

Figure D.8 solid shape element schema – EXPRESS-G diagram 8 of 11 . . . . . . . . . . . . 87

Figure D.9 solid shape element schema – EXPRESS-G diagram 9 of 11 . . . . . . . . . . . . 88

Figure D.10 solid shape element schema – EXPRESS-G diagram 10 of 11 . . . . . . . . . . . 89

Figure D.11 solid shape element schema – EXPRESS-G diagram 11 of 11 . . . . . . . . . . . 90

Tables

A.1 Short names of entities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical com-

mittee has been established has the right to be represented on that committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates

closely with the International Electrotechnical Commission (IEC) on all matters of electrotechnical stan-

dardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Stan-

dards adopted by the technical committees are circulated to the member bodies for voting. Publication

as an International Standard requires approval by at least 75% of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 10303–111 was prepared by Technical Committee ISO/TC184/SC4, Industrial automation systems

and integration, Subcommittee SC4, Industrial data.

ISO 10303 is organized as a series of parts, each published separately. The structure of ISO 10303 is

described in ISO 10303-1.

Each part of ISO 10303 is a member of one of the following series: description methods, implementation

methods, conformance testing methodology and framework, integrated generic

resources, integrated application resources, application protocols, abstract test suites, application

interpreted constructs, and application modules. ISO 10303-111 is a member of the integrated appli-

cation resources series. The integrated generic resources and the integrated application resources specify

a single conceptual product data model.

A complete list of parts of ISO 10303 is available from the following URL:

vi © ISO 2007 – All rights reserved

Introduction

ISO 10303 is an International Standard for the computer-interpretable representation of product infor-

mation and for the exchange of product data. The objective is to provide a neutral mechanism capable of

describing products throughout their life cycle. This mechanism is suitable not only for neutral file ex-

change, but also as a basis for implementing and sharing product databases, and as a basis for archiving.

This part of ISO 10303 is a member of the integrated resources series. This part of ISO 10303 specifies

the solid shape element schema.

A set of solid modelling shape elements is defined that provide a capability for the exchange of feature-

based CAD solid models, expressed in terms of the sequence of successive creation or modification

operations used to build them. This kind of representation of a product shape model is referred to as

a procedural, history-based or construction history model. The essential underlying resource for the

representation of models of this type is ISO 10303-55, which provides the mechanism for capturing the

sequence of operations, and defines the intended interpretation of the entities defined in this part of ISO

10303 as modelling operations. This part of ISO 10303 contains a single schema, the solid shape -

element schema, which defines a set of complex geometric elements that can be incorporated into a

solid shape model. The relationship of this schema to other schemas that define the integrated resources

of ISO 10303 is illustrated in Figure 1 using the EXPRESS-G notation. EXPRESS-G is defined in annex

D of ISO 10303-11:2004. The schemas occurring in Figure 1 are components of ISO 10303 integrated

resources, and they are specified in the following resource parts:

support resource schema ISO 10303-41

measure schema ISO 10303-41

geometry schema ISO 10303-42

topology schema ISO 10303-42

geometric model schema ISO 10303-42

representation schema ISO 10303-43

mathematical functions schema ISO 10303-50

explicit geometric constraint schema ISO 10303-108

sketch schema ISO 10303-108

Figure 1 – Schema level diagram of relationships between the solid -

shape element schema of this part of ISO 10303 and other resource

schemas

viii © ISO 2007 – All rights reserved

INTERNATIONAL STANDARD ISO 10303-111:2007(E)

Industrial automation systems and integration — Product data

representation and exchange —

Part 111:

Integrated application resource: Elements for the procedural

modelling of solid shapes

1 Scope

This part of ISO 10303 specifies resource constructs for representing the complex shape elements, some-

times known as form features, that are supported by the solid modelling capabilities of modern CAD

systems. The elements are defined in such a way as to facilitate the exchange of solid models of products

represented in terms of their constructional history.

NOTE 1 Procedural or constructional history models of solids can also include operations based directly on

entities defined in ISO 10303-42, in particular Boolean operations and operations based on the various subtypes of

swept face solid and swept area solid.

The following are within the scope of this part of ISO 10303:

— the representation of solids having shape configurations resulting from blending and chamfering

operations;

— the representation of solids with shape configurations resulting from offsetting, thickening, shelling

and sculpturing operations;

— the representation of solids having shape configurations characteristic of certain manufacturing fea-

tures, including several types of holes, pockets, slots and grooves;

— the representation of solids having circular and rectangular patterns of the types of shape configura-

tions mentioned in the previous item of this list;

— the representation of solids that are generalizations of the solids of extrusion and revolution defined

in ISO 10303-42.

The following are outside the scope of this part of ISO 10303:

— the representation of shape configurations on a model as aspects of the shape of the model, in the

sense defined by ISO 10303-41;

NOTE 2 For design purposes the configurations specified in this part of ISO 10303 are regarded as shape ele-

ments in their own right, and not as local aspects of more complex shapes. These configurations can be created,

subjected to modification and even subsequently deleted during the design process, so that they do not in general

appear in their original form as shape aspects of the final model.

— the representation of features relating to manufacturing or other applications downstream of design.

NOTE 3 Such features have associated semantics that are absent from the shape configurations defined in this

part of ISO 10303, which are purely concerned with the form of the modelled object.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO/IEC 8824-1, Information technology — Abstract Syntax Notation One (ASN.1) - Part 1: Specifica-

tion of basic notation

ISO 10303-1, Industrial automation systems and integration — Product data representation and ex-

change — Part 1: Overview and fundamental principles

ISO 10303-11:2004, Industrial automation systems and integration — Product data representation and

exchange — Part 11: Description methods: The EXPRESS language reference manual

ISO 10303-41, Industrial automation systems and integration — Product data representation and ex-

change — Part 41: Integrated generic resource: Fundamentals of product description and support

ISO 10303-42, Industrial automation systems and integration — Product data representation and ex-

change — Part 42: Integrated generic resource: Geometric and topological representation

ISO 10303-43, Industrial automation systems and integration — Product data representation and ex-

change — Part 43: Integrated generic resource: Representation structures

ISO 10303-50, Industrial automation systems and integration — Product data representation and ex-

change — Part 50: Integrated generic resource: Mathematical constructs

ISO 10303-55:2005, Industrial automation systems and integration — Product data representation and

exchange — Part 55: Integrated generic resource: Procedural and hybrid representation

ISO 10303-108, Industrial automation systems and integration — Product data representation and ex-

change — Part 108: Integrated application resource: Parameterization and constraints for explicit geo-

metric product models

3 Terms, definitions and abbreviations

3.1 Terms defined in ISO 10303-1

For the purposes of this document, the following terms defined in ISO 10303-1 apply.

— application;

— application context;

— application protocol (AP);

— data exchange;

2 © ISO 2007 – All rights reserved

— exchange structure;

— implementation method;

— integrated resource (IR);

— product;

— product data.

3.2 Terms defined in ISO 10303-11

For the purposes of this document, the following terms defined in ISO 10303-11 apply.

— entity;

— entity data type;

— entity (data type) instance;

— instance;

— value.

3.3 Terms defined in ISO 10303-42

For the purposes of this document, the following terms defined in ISO 10303-42 apply.

— boundary representation solid model (B-rep);

— constructive solid geometry (CSG);

— coordinate space;

— dimensionality;

— model space.

3.4 Terms defined in ISO 10303-43

For the purposes of this document, the following terms defined in ISO 10303-43 apply.

— context of representation;

— element of representation;

— representation.

3.5 Terms defined in ISO 10303-55

For the purposes of this document, the following terms defined in ISO 10303-55 apply.

— design rationale.

3.6 Terms defined in ISO 10303-108

For the purposes of this document, the following terms defined in ISO 10303-108 apply.

— design intent;

— element;

— feature;

— history-based model;

— procedural model;

— sketch.

3.7 Other terms and definitions

For the purposes of this document, the following definition applies.

3.7.1

track

continuous chain of edges

NOTE The ISO 10303-42 entity path has a similar definition, but requires all the edges in the chain to be

consistently oriented, which is not a requirement for a track.

3.8 Abbreviations

For the purposes of this document, the following abbreviations apply:

AP application protocol (of ISO 10303)

B-rep boundary representation

CAD computer aided design

CSG constructive solid geometry

IR integrated resource (of ISO 10303)

4 © ISO 2007 – All rights reserved

4 Solid shape element

4.1 Introduction

The following EXPRESS declaration begins the solid shape element schema and identifies the necessary

external references.

EXPRESS specification:

)

*

SCHEMA solid_shape_element_schema;

REFERENCE FROM support_resource_schema -- ISO 10303-41

(text);

REFERENCE FROM measure_schema -- ISO 10303-41

(length_measure,

plane_angle_measure,

positive_length_measure,

positive_plane_angle_measure);

REFERENCE FROM geometry_schema -- ISO 10303-42

(axis2_placement_3d,

bounded_curve,

bounded_surface,

curve_bounded_surface,

geometric_representation_item,

point,

point_on_curve,

surface);

REFERENCE FROM topology_schema --ISO 10303-42

(connected_face_set,

edge_curve,

face_surface,

open_shell,

topological_representation_item,

vertex);

REFERENCE FROM geometric_model_schema --ISO 10303-42

(boolean_result,

csg_primitive,

extruded_face_solid,

primitive_2d,

revolved_face_solid,

solid_model,

swept_face_solid);

REFERENCE FROM representation_schema --ISO 10303-43

(representation_item,

using_items);

REFERENCE FROM mathematical_functions_schema --ISO 10303-50

(positive_integer);

REFERENCE FROM explicit_geometric_constraint_schema --ISO 10303-108

(non_negative_length_measure);

REFERENCE FROM sketch_schema --ISO 10303-108

(positioned_sketch);

(

*

NOTE 1 The schemas referenced above can be found in the following parts of ISO 10303:

support resource schema ISO 10303-41

measure schema ISO 10303-41

geometry schema ISO 10303-42

topology schema ISO 10303-42

geometric model schema ISO 10303-42

representation schema ISO 10303-43

mathematical functions schema ISO 10303-50

explicit geometric constraint schema ISO 10303-108

sketch schema ISO 10303-108

NOTE 2 See annex D for a graphical presentation of this schema using the EXPRESS-G notation.

NOTE 3 A listing of the complete EXPRESS schema specified in this part of ISO 10303, without comments or

other explanatory text, is available from the Internet – see annex C.

4.2 Fundamental concepts and assumptions

The fundamental types of operation available to the user of a modern CAD system are

a) Extrusion and revolution operations based on 2D sketches;

b) Boolean operations, for the combination of simpler shapes into more complex ones;

c) ‘Local operations’ that create local modifications on a pre-existing solid.

The use of ISO 10303-55, which provides the mechanisms needed for the capture and transfer of proce-

dural models, allows operations of the types (a) and (b) to be represented by means of entities defined in

ISO 10303-42, although the range of extrusion possibilities provided there is rather limited.

This part of ISO 10303 is mainly concerned with operations of type (c). It provides representations for

complex geometric elements that can be used to create local modifications of a solid shape model during

the course of a design procedure. Again, the essential underlying resource is ISO 10303-55, whose

primary mechanism is based on the interpretation of an instance of a geometric element, if it occurs in

the specialized context of a procedural representation sequence (as defined in ISO 10303-55), as an

instruction to the receiving system to create such an element.

A type (c) operation assumes the pre-existence of a solid that will be modified by the operation. For that

reason, many of the entities defined in the solid shape element schema define a solid that has a new

shape configuration of a specific type created upon it. The shape configurations available are described as

features in the documentation of many CAD systems, but in a strict sense they are not features because

they have no associated application semantics. The system user doubtless has some intended design

functionality in mind when creating such a configuration on the model, but with current systems that

6 © ISO 2007 – All rights reserved

intended functionality is not recorded. All that is captured by the system is the modified shape, and so it

is better to think of the operations as shape creation operations rather than feature creation operations.

For the above reason, and also for more technical reasons spelled out in annex E, the use of the word

‘feature’ is henceforth avoided as far as possible in this part of ISO 10303.

NOTE 1 Some of the shape configurations defined in this schema have names that reflect methods of manufacture

that might be used to produce them when the modelled part is actually made. This is because such names are

typically employed in the user interfaces of CAD systems to denote those configurations; their use in this schema

is not intended to imply any manufacturing-related semantics.

EXAMPLE Shape configurations such as slots, grooves, countersunk and counterbored holes provide illustra-

tions of commonly occurring shape configurations named in terms of manufacturing processes.

Other operations defined in the solid shape element schema are type (a) operations that generalize the

basic extrusion and revolution operations specified in ISO 10303-42.

Some of the entities defined in this schema specify operations which, in the originating system, required

the user to select one or more elements from the model as displayed on the screen of that system. In all

such cases, the selection operations are captured and transferred by requiring the originating system to

transmit explicit representations of the selected entities that enable the receiving system to reconstruct

the selection procedure. The mechanism underlying this process is fully described in ISO 10303-55, a

knowledge of which is fundamental to the understanding of this part of ISO 10303.

NOTE 2 Proof-of-concept transfers have confirmed that all major CAD systems can support the ISO 10303-55

approach for the capture and transfer of user-selected elements in exchanges of procedurally defined models.

The initial application context for the shape configurations defined in this part of ISO 10303 is the detail

design of mechanical engineering parts without complex sculptured geometry. The use of ISO 10303-55

allows the procedural modelling of that type of geometry, if required, through the direct invocation of

B-spline and related types of geometric entities defined in ISO 10303-42. That approach is possibly not

optimal, and more convenient procedures for the creation and modification of free-form surface geometry

may be included in a future edition of this document.

4.3 Solid shape element type definitions

4.3.1 base solid select

The base solid select type specifies those types of entity which may be used as the base solid for the

creation of shape elements defined in this schema. The selection solid model includes solids of extrusion

and revolution generated by sweeping 2D sketches.

The entity csg primitive in the SELECT list is itself a SELECT type, allowing the entity primitive 2d as

a choice. This two-dimensional entity is out of scope for the modelling of solid shapes, and a WHERE

rule is therefore imposed to disallow primitive 2d as a value of base solid select.

EXPRESS specification:

)

*

TYPE base_solid_select = SELECT

(solid_model,

csg_primitive,

boolean_result);

WHERE

WR1: NOT(’GEOMETRIC_MODEL_SCHEMA.PRIMITIVE_2D’ IN TYPEOF(SELF));

END_TYPE;

(

*

Formal propositions:

WR1: The entity primitive 2d shall not be permitted as a choice of base solid select.

4.3.2 blend end condition select

The blend end condition select enumerates possibilities for the termination conditions on a blend of a

continuous track of edges on a solid. It is used by the entity track blended solid with end conditions

(see clause 4.4.4, where the interpretations of the three possibilities are detailed).

EXPRESS specification:

)

*

TYPE blend_end_condition_select = SELECT

(point_on_curve,

edge_curve,

vertex);

END_TYPE;

(

*

4.3.3 generalized surface select

The generalized surface select type specifies surfaces and other surface-based geometric elements suit-

able for use as the sculpturing element in a sculptured solid (see clause 4.4.12) or as the base entity for

a thickened face solid (see clause 4.4.47).

EXPRESS specification:

)

*

TYPE generalized_surface_select = SELECT

(surface,

face_surface,

surfaced_open_shell);

END_TYPE;

(

*

8 © ISO 2007 – All rights reserved

4.3.4 trim condition select

The trim condition select type allows a choice between different types of trimming conditions in the

creation of a swept configuration. It is used in the definitions of extruded face solid with trim condi-

tions (see clause 4.4.48) and revolved face solid with trim conditions (see clause 4.4.51).

EXPRESS specification:

)

*

TYPE trim_condition_select = SELECT

(length_measure,

plane_angle_measure,

generalized_surface_select,

solid_model);

END_TYPE;

(

*

4.3.5 blend radius variation type

The blend radius variation type enumerates possibilities for the variation of the radius of a blend along

an edge, or a sequence of edges, between points at which specific values are given.

EXPRESS specification:

)

*

TYPE blend_radius_variation_type = ENUMERATION OF

(linear,

cubic,

unspecified);

END_TYPE;

(

*

Enumerated item definitions:

linear: the blend radius varies linearly between radius definition points.

cubic: the blend radius varies as a cubic between radius definition points.

unspecified: the blend radius variation is not specified.

NOTE The interpretation of these three possibilities is detailed in clause 4.4.6, in the specification of the entity

solid with variable radius edge blend.

4.3.6 trim intent

The type trim intent enumerates descriptive specifications of termination conditions on solids of lin-

ear extrusion. These supplement the explicitly specified termination elements specified in the entity

extruded face solid with trim conditions (see clause 4.4.48).

EXPRESS specification:

)

*

TYPE trim_intent = ENUMERATION OF

(blind,

offset,

through_all,

unspecified,

up_to_next);

END_TYPE;

(

*

Enumerated item definitions:

blind: The extrusion terminates at an extent determined by the value of a trim condition of type length -

measure, before it meets any other geometric element of the model under construction;

offset: The extrusion terminates at a given distance from a specified surface in the model;

through all: The extrusion extends through the entire model, possibly making multiple entries to and

exits from the part material;

unspecified: No descriptive specification is given.

up to next: The extrusion terminates when it first meets a surface in the model.

4.4 Solid shape element entity definitions

4.4.1 modified solid

A modified solid is a type of solid model (as defined in ISO 10303-42) resulting from the creation of

a new constructional element on an existing solid. Its attribute base solid specifies the original solid

upon which the modification is created. An attribute rationale is provided for the capture of textual

information, if available, explaining the reasons for the use of the particular constructional operation

concerned in the design sequence where it occurs.

EXPRESS specification:

)

*

ENTITY modified_solid

ABSTRACT SUPERTYPE OF (ONEOF

(edge_blended_solid,

sculptured_solid,

shelled_solid,

offset_face_solid,

modified_solid_with_placed_configuration))

SUBTYPE OF (solid_model);

rationale : text;

base_solid : base_solid_select;

END_ENTITY;

(

*

10 © ISO 2007 – All rights reserved

Attribute definitions:

rationale: explanatory text detailing the reasons for the use of an instance of this entity.

base solid: the initial solid before the new constructional element is created on it.

NOTE In common with the present entity, procedural representation sequence as defined in ISO 10303-55

also has an attribute rationale of type text. For modified solid this attribute allows for the capture of the rationale

underlying the designer’s creation of an instance of a particular entity data type in the construction process. In

the case of procedural representation sequence the corresponding attribute allows the capture of the rationale

associated with a design procedure involving a sequence of such operations, where the designer’s choice of a

particular sequence may have significance.

4.4.2 edge blended solid

An edge blended solid is a type of modified solid representing the result of blending one or more edges

of the original base solid. The blend may take the form of a chamfer, in which case the result will not be

a smooth transition between the faces adjoining along the edges concerned. Alternatively, it may take the

form of a blend that gives a smooth (tangent-continuous) transition between the surfaces of those faces.

NOTE 1 Strictly speaking, a chamfer is not a blend, since its surface is not tangent-continuous with the faces on

either side of the modified edge. However, blends and chamfers otherwise have very similar semantics, and for

that reason they have been grouped together in this entity.

NOTE 2 Various types of blends may be defined between two or more solids, or between two or more surfaces

not belonging to a solid model, but such blends are currently excluded from this schema.

In manifold solid modelling, no more than two faces adjoin at an edge. The blending modification causes

that edge to disappear from the modified model; it is replaced by an interpolated face that blends the two

faces previously separated by the edge concerned.

The exchange of a procedural representation of the blended model requires the exchange file to contain

explicit representations of the original unblended edges, as defined in the sending system, to enable the

corresponding edges to be identified in the receiving system. The identification mechanism is detailed in

the definition of user selected elements in ISO 10303-55. An attribute blended edges is provided for

the capture and transfer of the explicit edges concerned.

NOTE 3 The base solid may in fact be of type solid model, csg primitive or boolean result. The only case

for which explicitly defined edges exist in the base solid is that where its type is manifold solid brep, a specific

subtype of solid model. The use of this entity therefore requires that the sending system, if it uses some form

of representation other than manifold solid brep as its primary representation for the base solid, can generate a

secondary representation of that form from which the necessary explicit edge information may be derived.

NOTE 4 This part of ISO 10303 provides no specifications for vertex blends, smooth transitions in regions where

blend surfaces for adjoining edges of the base solid meet. The geometry generated by CAD systems for vertex

blends is highly system-dependent. It is assumed that the receiving system will treat vertex blends in some default

manner; they may subsequently be reconfigured using the system’s native capabilities.

NOTE 5 This part of ISO 10303 provides no specifications for blend caps, small bounded surface regions created

by CAD systems to complete a closed boundary shell after creation of a blend. Figures 2 and 3 in clause 4.4.5

provide an example. Simple replacement of the blended edge by the blend surface, and then trimming back the

horizontal and vertical faces affected, would leave a small triangular gap on either side of the L-block. In this case

the gaps are filled by modifying the boundaries of the side faces of the block to cover them, but in more complex

cases less simple system-dependent strategies are used. It is assumed that the receiving system will treat blend

caps in some default manner; they may subsequently be reconfigured using the system’s native capabilities.

EXPRESS specification:

)

*

ENTITY edge_blended_solid

ABSTRACT SUPERTYPE OF (track_blended_solid ANDOR (ONEOF

(solid_with_constant_radius_edge_blend,

solid_with_variable_radius_edge_blend,

solid_with_chamfered_edges)))

SUBTYPE OF (modified_solid);

blended_edges : LIST [1:?] OF UNIQUE edge_curve;

END_ENTITY;

(

*

Attribute definitions:

blended edges: a list of distinct edge curve instances specifying unblended edges of a manifold bound-

ary representation of the original base solid.

4.4.3 track blended solid

A track blended solid is a type of edge blended solid in which the edges to be blended form a contin-

uous open or closed track. A WHERE rule is imposed to ensure this condition.

NOTE 1 A track is related to a path as defined in ISO 10303-42 in that it consists of a list of distinct edges

connected end to end so that it is possible to traverse all the edges in the list continuously from an initial vertex to

a final vertex. The initial and final vertices may be the same in the case of a closed track. The difference is that a

path consists of instances of oriented edge, so that there is a sense associated with the path as a whole. A track,

by contrast, is made up of unoriented edges.

NOTE 2 This ABSTRACT entity may only be instantiated as a complex instance with one of the instantiable

subtypes of edge blended solid.

NOTE 3 Figure 4 in clause 4.4.5 shows an example of a track blended solid, in which the blended track is

a sequence of five edges of the volume created by extruding a rectangle with two rounded corners. Since the

blend is a constant radius blend, this solid can be represented by a complex instance of track blended solid and

solid with constant radius edge blend.

EXPRESS specification:

)

*

ENTITY track_blended_solid

ABSTRACT SUPERTYPE OF (track_blended_solid_with_end_conditions)

SUBTYPE OF (edge_blended_solid);

WHERE

WR1: check_continuous_edges(SELF\edge_blended_solid.blended_edges);

END_ENTITY;

(

*

12 © ISO 2007 – All rights reserved

Formal propositions:

WR1: One vertex of each member of the list of edge curve instances (except the last instance, in the

case of an open track) shall be identical with one vertex of the following member.

4.4.4 track blended solid with end conditions

A track blended solid with end conditions is a type of track blended solid in which the blend does

not both start and terminate at the end points of the specified track of edges. For this type of blended

end condition select (see

solid, the extremities of the blend are defined by the SELECT type bl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...