ISO 9940:2015

(Main)Aerospace series — Fluid, hydraulic, phosphate ester-base, fire resistant — Technical specification

Aerospace series — Fluid, hydraulic, phosphate ester-base, fire resistant — Technical specification

ISO 9940:2015 defines technical requirements, qualification and quality control conditions (product qualification, batch control, acceptance) test and measurement methods to be used by manufacturers for qualification of fire-resistant phosphate-ester-base fluids used for hydraulic transmissions in aircrafts.

Série aérospatiale — Fluide, hydraulique, esters phosphoriques, résistant au feu — Spécification technique

General Information

- Status

- Published

- Publication Date

- 04-Aug-2015

- Technical Committee

- ISO/TC 20/SC 10 - Aerospace fluid systems and components

- Drafting Committee

- ISO/TC 20/SC 10/WG 8 - Hydraulic fluids and fluid contamination control

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 19-Nov-2021

- Completion Date

- 12-Feb-2026

Relations

- Referred By

EN 6141:2020 - Aerospace series - Plug, protective, non-metallic, for EN 6123 fitting ends - Effective Date

- 09-Feb-2026

- Referred By

EN 6139:2020 - Aerospace series - Cap, protective, non-metallic, for EN 6123 fitting ends - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

Overview

ISO 9940:2015 - Aerospace series - Fluid, hydraulic, phosphate ester-base, fire resistant - Technical specification - defines the technical requirements, qualification procedures and quality‑control methods for phosphate‑ester‑base fire‑resistant hydraulic fluids used in aircraft hydraulic transmissions. The standard specifies which tests and measurements manufacturers and approved laboratories must use for product qualification, batch acceptance and in‑service monitoring to ensure safe, reliable hydraulic performance in aerospace applications.

Key topics and technical requirements

ISO 9940:2015 covers a comprehensive set of fluid properties, test methods and production controls, including (but not limited to):

- Fluid types and general technical requirements for phosphate‑ester hydraulic fluids.

- Physical and chemical properties: kinematic viscosity, density, water content, acidity index/acid number, electrical conductivity.

- Chemical composition checks: chlorine and other specified constituents.

- Thermal and flammability characteristics: pour point, flash and fire point, auto‑ignition temperature, and flammability tests (wick flame persistence, spray ignition, manifold‑ignition).

- Mechanical and thermodynamic properties: bulk modulus (isothermal secant), thermal expansion coefficient, specific heat.

- Electrical and contamination controls: dielectric resistance, particulate contamination (particle counting), filterability and foaming behaviour.

- Stability and lifetime tests: shear stability, thermal/corrosion/oxidation stability, ampoule and container tests for service life and fire‑resistance retention.

- Material compatibility: interaction with elastomers, paints, electrical components, metallic and composite structural elements.

- Erosion testing that simulates hydraulic system wear and pumping conditions.

- Quality management elements: batch definitions, acceptance testing, marking, packing and storage requirements.

- Annexes include elastomer compatibility, erosion test guidance and post‑delivery fluid monitoring.

The document references established test standards (e.g., ISO viscosity, density, Karl Fischer water determination, particle counting and specific fire tests) as normative sources for methods.

Practical applications and users

ISO 9940:2015 is intended for:

- Hydraulic fluid manufacturers qualifying phosphate‑ester fire‑resistant products for aerospace use.

- Aircraft OEMs and system integrators specifying fluids for hydraulic transmissions and approving supplier qualification.

- Approved testing laboratories performing qualification and batch acceptance testing.

- MRO organizations and airline maintenance teams for in‑service monitoring and acceptance of replacement fluids.

- Safety engineers and procurement specialists who assess compatibility, fire safety and lifecycle performance.

Applying ISO 9940:2015 helps ensure fluid fire resistance, material compatibility, system reliability and regulatory conformity in aircraft hydraulic systems.

Related standards

ISO 9940:2015 normatively references several ISO methods commonly used in aerospace fluid testing, for example:

- ISO 3104 (viscosity), ISO 12937 (water by Karl Fischer), ISO 2592 (flash/fire point), ISO 14935 (wick flame), ISO 15029 (spray ignition), ISO 4407 / ISO 11500 / ISO 11171 (particle counting) - among others.

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

ISO 9940:2015 is a standard published by the International Organization for Standardization (ISO). Its full title is "Aerospace series — Fluid, hydraulic, phosphate ester-base, fire resistant — Technical specification". This standard covers: ISO 9940:2015 defines technical requirements, qualification and quality control conditions (product qualification, batch control, acceptance) test and measurement methods to be used by manufacturers for qualification of fire-resistant phosphate-ester-base fluids used for hydraulic transmissions in aircrafts.

ISO 9940:2015 defines technical requirements, qualification and quality control conditions (product qualification, batch control, acceptance) test and measurement methods to be used by manufacturers for qualification of fire-resistant phosphate-ester-base fluids used for hydraulic transmissions in aircrafts.

ISO 9940:2015 is classified under the following ICS (International Classification for Standards) categories: 49.080 - Aerospace fluid systems and components. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 9940:2015 has the following relationships with other standards: It is inter standard links to EN 6141:2020, EN 6139:2020, EN 6140:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 9940:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 9940

First edition

2015-08-01

Aerospace series — Fluid, hydraulic,

phosphate ester-base, fire resistant —

Technical specification

Série aérospatiale — Fluide, hydraulique, esters phosphoriques,

résistant au feu — Spécification technique

Reference number

©

ISO 2015

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

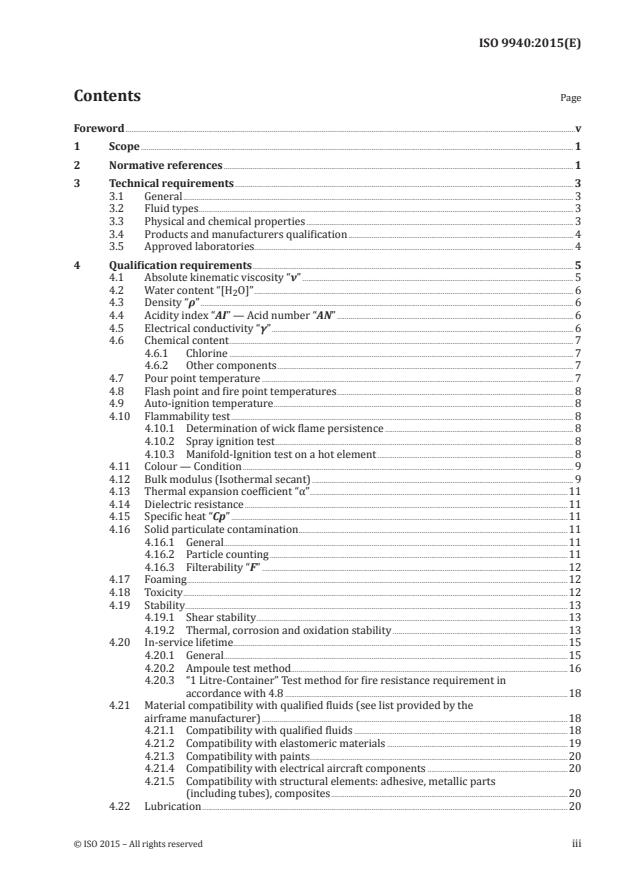

Contents Page

Foreword .v

1 Scope . 1

2 Normative references . 1

3 Technical requirements . 3

3.1 General . 3

3.2 Fluid types. 3

3.3 Physical and chemical properties . 3

3.4 Products and manufacturers qualification . 4

3.5 Approved laboratories. 4

4 Qualification requirements . 5

4.1 Absolute kinematic viscosity “ν” . 5

4.2 Water content “[H O]” . 6

4.3 Density “ρ” . 6

4.4 Acidity index “AI” — Acid number “AN” . 6

4.5 Electrical conductivity “γ” . 6

4.6 Chemical content . 7

4.6.1 Chlorine . 7

4.6.2 Other components . 7

4.7 Pour point temperature . 7

4.8 Flash point and fire point temperatures . 8

4.9 Auto-ignition temperature . 8

4.10 Flammability test . 8

4.10.1 Determination of wick flame persistence . 8

4.10.2 Spray ignition test . 8

4.10.3 Manifold-Ignition test on a hot element . 8

4.11 Colour — Condition . 9

4.12 Bulk modulus (Isothermal secant) . 9

4.13 Thermal expansion coefficient “α” .11

4.14 Dielectric resistance .11

4.15 Specific heat “Cp” .11

4.16 Solid particulate contamination .11

4.16.1 General.11

4.16.2 Particle counting .11

4.16.3 Filterability “F” .12

4.17 Foaming .12

4.18 Toxicity .12

4.19 Stability .13

4.19.1 Shear stability .13

4.19.2 Thermal, corrosion and oxidation stability .13

4.20 In-service lifetime .15

4.20.1 General.15

4.20.2 Ampoule test method.16

4.20.3 “1 Litre-Container” Test method for fire resistance requirement in

accordance with 4.8 .18

4.21 Material compatibility with qualified fluids (see list provided by the

airframe manufacturer) .18

4.21.1 Compatibility with qualified fluids .18

4.21.2 Compatibility with elastomeric materials .19

4.21.3 Compatibility with paints .20

4.21.4 Compatibility with electrical aircraft components .20

4.21.5 Compatibility with structural elements: adhesive, metallic parts

(including tubes), composites .20

4.22 Lubrication .20

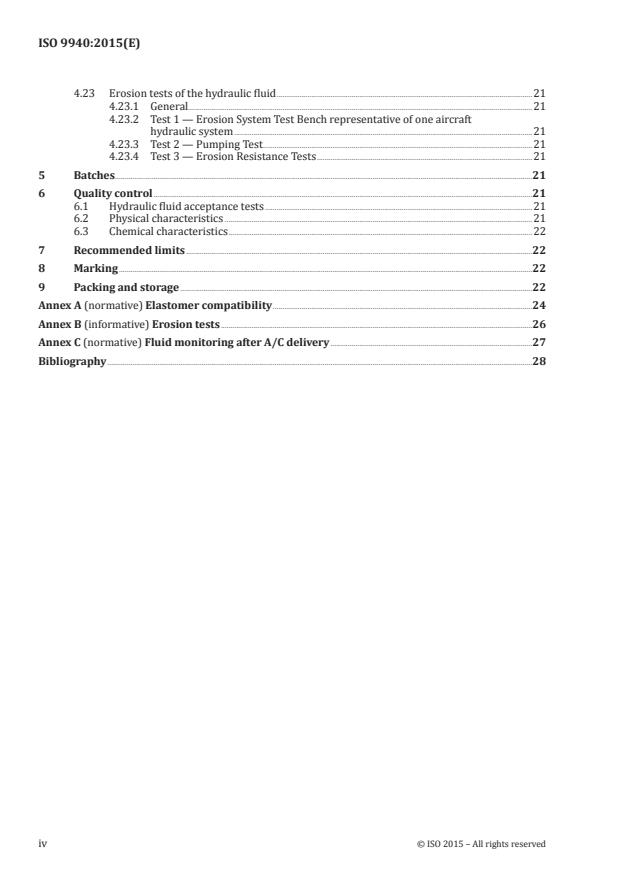

4.23 Erosion tests of the hydraulic fluid .21

4.23.1 General.21

4.23.2 Test 1 — Erosion System Test Bench representative of one aircraft

hydraulic system .21

4.23.3 Test 2 — Pumping Test .21

4.23.4 Test 3 — Erosion Resistance Tests .21

5 Batches .21

6 Quality control .21

6.1 Hydraulic fluid acceptance tests .21

6.2 Physical characteristics .21

6.3 Chemical characteristics .22

7 Recommended limits .22

8 Marking .22

9 Packing and storage .22

Annex A (normative) Elastomer compatibility .24

Annex B (informative) Erosion tests .26

Annex C (normative) Fluid monitoring after A/C delivery .27

Bibliography .28

iv © ISO 2015 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 20, Aircraft and space vehicles, Subcommittee

SC 10, Aerospace fluid systems and components.

INTERNATIONAL STANDARD ISO 9940:2015(E)

Aerospace series — Fluid, hydraulic, phosphate ester-base,

fire resistant — Technical specification

1 Scope

This International Standard defines technical requirements, qualification and quality control

conditions (product qualification, batch control, acceptance) test and measurement methods to be

used by manufacturers for qualification of fire-resistant phosphate-ester-base fluids used for hydraulic

transmissions in aircrafts.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 37, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties

ISO 48, Rubber, vulcanized or thermoplastic — Determination of hardness (hardness between 10 IRHD

and 100 IRHD)

ISO 1817, Rubber, vulcanized or thermoplastic — Determination of the effect of liquids

ISO 2592, Determination of flash and fire points — Cleveland open cup method

ISO 2921, Rubber, vulcanized — Determination of low-temperature retraction (TR test)

ISO 3016, Petroleum products — Determination of pour point

ISO 3104, Petroleum products — Transparent and opaque liquids — Determination of kinematic viscosity

and calculation of dynamic viscosity

ISO 3116, Magnesium and magnesium alloys — Wrought magnesium alloys

ISO 3675, Crude petroleum and liquid petroleum products — Laboratory determination of density —

Hydrometer method

ISO 3696, Water for analytical laboratory use — Specification and test methods

ISO 4407, Hydraulic fluid power — Fluid contamination — Determination of particulate contamination by

the counting method using an optical microscope

ISO 6247, Petroleum products — Determination of foaming characteristics of lubricating oils

ISO 6618, Petroleum products and lubricants — Determination of acid or base number — Colour-indicator

titration method

ISO 6619, Petroleum products and lubricants — Neutralization number — Potentiometric titration method

ISO 11171, Hydraulic fluid power — Calibration of automatic particle counters for liquids

ISO 11218, Aerospace — Cleanliness classification for hydraulic fluids

ISO 11500, Hydraulic fluid power — Determination of the particulate contamination level of a liquid sample

by automatic particle counting using the light-extinction principle

ISO 12185, Crude petroleum and petroleum products — Determination of density — Oscillating U-tube

method

ISO 12937, Petroleum products — Determination of water — Coulometric Karl Fischer titration method

ISO 13357-2, Petroleum products — Determination of the filterability of lubricating oils — Part 2:

Procedure for dry oils

ISO 13573:2012, Corrosion of metals and alloys — Test method for thermal-cycling exposure testing under

high-temperature corrosion conditions for metallic materials

ISO 14935, Petroleum and related products — Determination of wick flame persistence of fire-resistant fluids

ISO 15029-1, Petroleum and related products — Determination of spray ignition characteristics of fire-

resistant fluids — Part 1: Spray flame persistence — Hollow-cone nozzle method

ISO 15597, Petroleum and related products — Determination of chlorine and bromine content —

Wavelength-dispersive X-ray fluorescence spectrometry

ISO 20823, Petroleum and related products — Determination of the flammability characteristics of fluids

in contact with hot surfaces — Manifold ignition test

EN 1652, Copper and copper alloys — Plate, sheet, strip and circles for general purposes

EN 2395, Aerospace series — Aluminium alloy AL-P2024A — T4 or T42 — Sheet and strip — 0,4 mm ≤ a ≤

6 mm

EN 10130, Cold rolled low carbon steel flat products for cold forming — Technical delivery conditions

1)

ASTM D 92 , Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester

1)

ASTM D 97 , Standard Test Method for Pour Point of Petroleum Products

1)

ASTM D 445 , Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and

Calculation of Dynamic Viscosity)

1)

ASTM D 664 , Standard Test Method for Acid Number of Petroleum Products by Potentiometric Titration

1)

ASTM D 877 , Standard Test Method for Dielectric Breakdown Voltage of Insulating Liquids Using

Disk Electrodes

1)

ASTM D 892 , Standard Test Method for Foaming Characteristics of Lubricating Oils

1)

ASTM D 974 , Standard Test Method for Acid and Base Number by Color-Indicator Titration

1)

ASTM D 1217 , Standard Test Method for Density and Relative Density (Specific Gravity) of Liquids by

Bingham Pycnometer

1)

ASTM D 1298 , Standard Test Method for Density, Relative Density, or API Gravity of Crude Petroleum and

Liquid Petroleum Products by Hydrometer Method

1)

ASTM D 2155 , Standard Test Method for Determination of Fire Resistance of Aircraft Hydraulic Fluids by

Autoignition Temperature

1)

ASTM D 4052 , Standard Test Method for Density, Relative Density, and API Gravity of Liquids by Digital

Density Meter

1)

ASTM D 4172 , Standard Test Method for Wear Preventive Characteristics of Lubricating Fluid (Four-

Ball Method)

1)

ASTM D 4636 , Standard Test Method for Corrosiveness and Oxidation Stability of Hydraulic Oils, Aircraft

Turbine Engine Lubricants, and Other Highly Refined Oils

1) Published by: ASTM International www.astm.org

2 © ISO 2015 – All rights reserved

1)

ASTM D 5621 , Standard Test Method for Sonic Shear Stability of Hydraulic Fluids

1)

ASTM D 6304 , Standard Test Method for Determination of Water in Petroleum Products, Lubricating Oils,

and Additives by Coulometric Karl Fischer Titration

2)

ASTM D 6443 , Test Method for Determination of Calcium, Chlorine, Copper, Magnesium, Phosphorus,

Sulfur, and Zinc in Unused Lubricating Oils and Additives by Wavelength Dispersive X-ray Fluorescence

Spectrometry (Mathematical Correction Procedure)

2)

ASTM D 6793 , Standard Test Method for Determination of Isothermal Secant and Tangent Bulk Modulus

2)

ASTM E 1269 , Standard Test Method for Determining Specific Heat Capacity by Differential Scanning

Calorimetry

3)

DEF STAN 03-19 , Electro-Deposition of Cadmium

3 Technical requirements

3.1 General

The product shall be a fire resistant, phosphate ester-base fluid for hydraulic power transmissions. Its

chemical composition (additives, contaminants) and intrinsic physical and chemical properties shall be

in strict compliance with the requirements of this International Standard.

All delivered hydraulic fluids shall be fully compatible with any other phosphate ester-base fluid

already qualified, whatever the mixture proportions.

In the following clauses, the International Standard appearing in brackets shall be considered as an

alternative method to the preceding standard, e.g. ISO 3104 (ASTM D 445); ASTM D 445 is an alternative

standard to ISO 3104.

3.2 Fluid types

Fluids types covered by this International Standard are listed in the Table 1 with their corresponding

properties.

Table 1 — Type of fluid and properties

Type of fluid Fluid properties

“HD”

Fire resistant, low water content, anti-erosion, high viscosity at low

temperature and high density

IV

(High Density)

Fire resistant, low water content, anti-erosion, low density

“LD”

Fire resistant, low water content, low density, anti-erosion, improved

V (Low Density)

thermal stability and in service lifetime.

3.3 Physical and chemical properties

The main physical and chemical properties of the fluid covered by this International Standard are listed

in the Table 2.

2) Published by: ASTM International www.astm.org

3) Published by: MINISTRY OF DEFENCE (United Kingdom) www.gov.uk/government/organisations/ministry-

of-defence

3.4 Products and manufacturers qualification

The qualified products list appears in the AMM (Aircraft Maintenance Manual).

3.5 Approved laboratories

All laboratories used should be ISO 9001 registered and AS/EN/JIS Q 9100 compliant.

Table 2 — Main characteristics and properties

Unit Requirements Test method(s)

Sub

Preferred Alternative

Property Condition

clause

Symbol TYPE IV TYPE V International International

Standard Standard

−54 °C (−65 °F)

HD: ≤ 2 900

LD: ≤ 2 000

2 −1

Absolute mm ·s 38 °C (100 °F)

LD: ≤ 2 000

kinematic (centiStokes) 99 °C (210 °F) ISO 3104 ASTM D 445 4.1

∈ [ 9,00; 12,50]

viscosity ”ν” Atmospheric

∈ [3,00; 4,00]

pressure

Water H O % mass ≤0,20

b

— ISO 12937 ASTM D 6304 4.2

a

content or ppm or 2 000

1 021 ≤ HD ≤ ASTM D 1298

ISO 3675 or

-3

Density kg·m “ρ” (23 ± 3) °C 1 066 LD:≤ 1 020 D 4052 4.3

ISO 12185

LD: ≤ 1 020 or D 1217

Acid number

mg KOH ISO 6618 or ASTM D 974 or

— ≤0,10 4.4

per g of fluid ISO 6619 D 664

Acidity index

20 °C

−1

Electrical μS·cm ≥0,30

(−10 °C to ISO 9940 — 4.5

conductivity ”γ” ∈ [0,02 ; 6,00]

100 °C)

-

Cl

Chlorine

Tot. chlorine ≤50 ISO 15597 ASTM D 6443 4.6

content

a

ppm

Pour point

≤ −62 (−80) ISO 3016 ASTM D 97 4.7

temperature

Flash point

≥160 ( 320)

temperature

ISO 2592 ASTM D 92 4.8

°C (°F) —

Fire point

≥177 (350)

temperature

≥399 (750)

Auto ignition

≥460 (860) for HD

≥399 (750) ASTM D 2155 — 4.9

temperature

5 s, 10 s, 20 s and Mean persistence time of the

Seconds ISO 14935 — 4.10.1

30 s flame < 7,5 s

Time elapsed between removal

of the igniting flame and

Flammability Seconds — ISO 15029-1 — 4.10.2

extinction of the spray along the

spray pattern ≤ 4 s

Ignition

700 °C ± 5 °C k ≥ 10 ISO 20823 — 4.10.3

m

category

a -1 -6

ppm = parts per million = µg∙g (10 ).

b

Deviation to ISO 12937 is granted for water content above 0,1.

4 © ISO 2015 – All rights reserved

Table 2 (continued)

Unit Requirements Test method(s)

Sub

Preferred Alternative

Property Condition

clause

Symbol TYPE IV TYPE V International International

Standard Standard

Colour Purple

— — — — 4.11

condition Clear appearance

Isothermal

38 °C, 20,6∙10

secant Bulk Pa Mini value: 1 450·10 Pa ASTM D 6793 — 4.12

Pa

Modulus

−3

−25 °C to 99 °C ≤1·10

Thermal

−1

°C “α” ASTM D 1217 — 4.13

expansion

−54 °C to 110 °C Curve to provide

≤7

ISO 11218

Solid particu-

Cleanliness ISO 11171

late contamina- — —

class ISO 11500

4.16

tion (counting)

or ISO 4407

Filterability F — ∈ [1,00 ; 1,60] ISO 13357-2 —

24 °C After 5 min Persistence

93 °C ≤250 ≤100 s

24 °C ≤150 ≤50 s

Foaming cm ISO 6247 ASTM D 892 4.17

≤450 250 s

a -1 -6

ppm = parts per million = µg∙g (10 ).

b

Deviation to ISO 12937 is granted for water content above 0,1.

4 Qualification requirements

4.1 Absolute kinematic viscosity “ν”

Absolute kinematic viscosity “ν” of the fluid shall be determined at the temperatures indicated

below and at atmospheric pressure using viscosimetric capillary tubes in accordance with ISO 3104

2 -1

(ASTM D 445). The limits values are in mm ·s (centiStokes), see Table 3.

Table 3 — Viscosity limit values

Temperatures Type

°C °F IV High Density IV & V Low Density

−54 −65 ν ≤ 2 900 ν ≤ 2 000

−40 −40

Values to be measured and provided

−15 5

38 100 9,00 ≤ ν ≤ 12,50

99 210 3,00 ≤ ν ≤ 4,00

Measurements shall be taken in a thermostatic bath at accurate temperatures, controlled using an

accurate contacting thermometer in accordance with ISO 3104 (ASTM D 445).

NOTE At low temperatures, viscosimetric tubes may be connected to dehydration tubes to avoid

condensation forming inside.

An evolution curve “Viscosity vs. Temperature” from −54 °C to 99 °C is requested.

4.2 Water content “[H O]”

The water content [H O] shall be determined

— by using the electrochemical method “KARL FISCHER” in compliance with ISO 12937 (ASTM D 6304).

The limit value shall be

— [H O] ≤ 0,20 % mass, or

— [H O] ≤ 2 000 ppm.

4.3 Density “ρ”

The density “ρ” shall be determined at (23 ± 3) °C in compliance with ISO 3675 (ASTM D 1298) or

ASTM D 1217 (Pycnometer) or ISO 12185 (ASTM D 4052) (this method is based on the measurement of

the harmonic period of fluid in a U-shape tube).

-3

The corrected limit values at 20 °C, in kg·m , shall be as follows:

— Type IV High Density: 1 021 ≤ ρ ≤ 1 066;

— Type IV & V Low Density: ρ ≤ 1 020.

An evolution curve “Density vs. Temperature” from −40 °C to 100 °C is requested.

4.4 Acidity index “AI” — Acid number “AN”

The Acid number “AN” of the fluid shall be determined using the colour indicator titration method in

accordance with ISO 6618 (ASTM D 974) or the Acidity index “AI” of the fluid shall be determined using

the potentiometric titration method in accordance with ISO 6619 (ASTM D 664).

The limit value, in mg KOH per gram of fluid shall be:

AI or AN ≤ 0,10

4.5 Electrical conductivity “γ”

Test equipment:

— cell immersed in hydraulic fluid

— impedance bridge (conductimeter)

Measurement conditions:

— frequency: 50 Hz

— temperature = (20 ± 3) °C

— cell constant K ∈ [0,7; 1,2] cm

Electrical resistance “R” shall be measured across the terminals of the cell.

6 © ISO 2015 – All rights reserved

The electrical conductivity is:

−−11

γ =⋅LR ⋅=SK ⋅R (1)

where

R is the resistance, in Ohms (Ω);

-1

K is the cell constant, in cm = S∙L ;

S is the surface area of electrodes, in cm ;

L is the gap between electrodes, in cm.

-1

The corrected value at 20 °C in μS cm , shall be

— Normal limit: γ ≥ 0,30.

-1

The value between −10 °C and 100 °C in μS cm , shall be

-6 -6 -1 -6

— γ ∈ [0,02; 6,00] (μS = microSiemens = 10 Siemens = 10 Ω = 10 Mho).

An evolution curve “Conductivity vs. Temperature” from −40 °C to 100 °C is requested.

4.6 Chemical content

4.6.1 Chlorine

The Total Chlorine concentration limit shall be:

Total Chlorine ≤ 50 ppm

Methods to be used are Wavelength dispersive X-ray fluorescence spectrometry (see ISO 15597 or

ASTM D 6443) or other methods provided acceptable to aircraft manufacturer.

4.6.2 Other components

-1 -6

During qualification, chemical contents (all fluids) in ppm (parts per million) or µg∙g (10 ) as Calcium,

Potassium, Sulphur, Sodium shall be duly identified when these elements are formulation additives and

their fluid limit concentration shall be determined by fluid manufacturers. All other additives not duly

identified in the fluid manufacturer formulation will be considered as contaminant and consequently

prohibited, except total chlorine when its concentration is as follows:

— TYPE IV/[CL] ≤ 50 ppm;

— TYPE V/[CL] ≤ 50 ppm.

Method to be used is Wavelength Dispersive X-Ray Fluorescence spectrometry (ASTM D 6443) or other

methods provided acceptable to aircraft manufacturer.

4.7 Pour point temperature

Pour point temperature shall be determined in compliance with ISO 3016 (ASTM D 97).

— Pour point ≤ −62 °C (−80 °F)

4.8 Flash point and fire point temperatures

Flash point and fire point temperatures shall be determined in an open vessel using the CLEVELAND

method in compliance with ISO 2592 (ASTM D 92).

— Flash point: ≥160 °C (320 °F)

— Fire point: ≥177 °C (351 °F)

To determine degradation of these characteristics, fluid shall be tested in laboratory conditions in

accordance with “1 Litre-Container” test method described in 4.20.3 until an Acidity index of 1,5 ± 0,3

has been reached (in keeping with the required time-temperature exposure under linked water and

chlorine contamination conditions).

4.9 Auto-ignition temperature

Auto-ignition temperature shall be determined in compliance with ASTM D 2155.

— Auto-ignition: ≥399 °C (750 °F) Type IV Low Density and Type V

— Auto-ignition: ≥460 °C (860 °F) Type IV High Density

4.10 Flammability test

4.10.1 Determination of wick flame persistence

This determination of wick flame persistence is in accordance with ISO 14935, except the limits and

pass criteria.

The limits and pass criteria shall be

— mean persistence time of flame MP < (7,5 ± 0,1) s.

4.10.2 Spray ignition test

This spray ignition test is in accordance with ISO 15029-1, except the limits and pass criteria.

Limits and pass criteria shall be as follows:

— flashes readily and self-extinguishes;

— maximum time, to the nearest 0,1 s, between removal of the igniting flame and extinction of the

spray combustion, at different positions along the length of a pressurized spray of fluid under the

conditions specified in ISO 15029-1 shall not exceed 4 s.

4.10.3 Manifold-Ignition test on a hot element

The test equipment is in accordance with ISO 20823, except the limits and pass criteria.

The limits and pass cr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...