ISO 17540:2016

(Main)Space systems — Liquid rocket engines and test stands — Terms and definitions

Space systems — Liquid rocket engines and test stands — Terms and definitions

ISO 17540:2016 provides terms and definitions in scope of design, testing, reliability analysis and quality control of liquid rocket engines. The terms are required for use in all types of documentation and literature including in the scope of standardization or using the results of this activity.

Systèmes spatiaux — Moteurs de fusée liquides et stands d'essai — Termes et définitions

General Information

- Status

- Published

- Publication Date

- 24-Nov-2016

- Technical Committee

- ISO/TC 20/SC 14 - Space systems and operations

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 09-Oct-2025

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 27-Aug-2022

Overview

ISO 17540:2016 - Space systems: Liquid rocket engines and test stands - Terms and definitions - is an international vocabulary standard that establishes clear, consistent terminology for the design, testing, reliability analysis and quality control of liquid rocket engines and associated test stands. It is intended for mandatory use in technical documentation, standards, test plans and literature to avoid ambiguity in engineering and program management across organizations and countries.

Key topics

This standard is a terminology (vocabulary) document rather than a prescriptive test or design standard. Major subject areas covered include:

- Engine classes and types: definitions for liquid rocket engine (LRE), low-thrust engine (LTE - thrust ≤ 5 000 N), clustered engines, expendable/nonexpendable, single-start/multi-start, main/correction/control/retrorocket engines.

- Engine units and components: chamber, turbo-pump (TP), booster turbo-pump (BTP), gas generator, automatic engine controller.

- Operating processes and modes: engines with/without afterburning, single-mode vs multimode, low-thrust subtypes (catalytic, thermo-catalytic, electro-thermal, electrolytic, etc.).

- Performance and parameters: rated performance, mass flow rate, volume flow rate, pre-start consumption (propellant used until thrust reaches 5% of nominal), mixture ratio and other general parameters.

- Nozzle, pump and turbine terminology: nozzle types, characteristics and flow definitions; pump and turbine-pump components and characteristics.

- Testing, reliability and quality: test types (thermal loads, stand-related classifications, test purposes), test technologies, test results, reliability indices, defects, failure modes, quality control and structural/functional reliability analysis.

- Test stands and systems: stand types, system elements, compartments, post-test processing and organizational factors for testing.

Practical applications

ISO 17540:2016 is used to:

- Standardize vocabulary in specifications, design documents, test plans, and test reports for liquid rocket propulsion systems.

- Improve clarity in contracts, procurement documents and cross‑team communications (engineers, test teams, suppliers, regulators).

- Support reliability analysis, quality assurance, and certification activities by ensuring consistent definitions for failure modes, reliability indices and test types.

- Aid standard developers, technical authors and educators when producing instructional materials, standards and technical publications.

Who should use it

- Propulsion and systems engineers

- Test-stand designers and operators

- Quality assurance and reliability engineers

- Project managers, procurement officers and standards writers

- Regulators, certification bodies, researchers and educators in space systems

Related standards

ISO 17540:2016 was prepared by ISO/TC 20/SC 14 (Space systems and operations). It complements other international standards and guidance on space systems, rocket propulsion testing and systems engineering by providing the authoritative terminology needed for interoperable documentation and reporting.

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

ISO 17540:2016 is a standard published by the International Organization for Standardization (ISO). Its full title is "Space systems — Liquid rocket engines and test stands — Terms and definitions". This standard covers: ISO 17540:2016 provides terms and definitions in scope of design, testing, reliability analysis and quality control of liquid rocket engines. The terms are required for use in all types of documentation and literature including in the scope of standardization or using the results of this activity.

ISO 17540:2016 provides terms and definitions in scope of design, testing, reliability analysis and quality control of liquid rocket engines. The terms are required for use in all types of documentation and literature including in the scope of standardization or using the results of this activity.

ISO 17540:2016 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 17540:2016 has the following relationships with other standards: It is inter standard links to ISO 17540:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 17540:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 17540

First edition

2016-12-15

Space systems — Liquid rocket

engines and test stands — Terms and

definitions

Systèmes spatiaux — Moteurs de fusée liquides et stands d’essai —

Termes et définitions

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

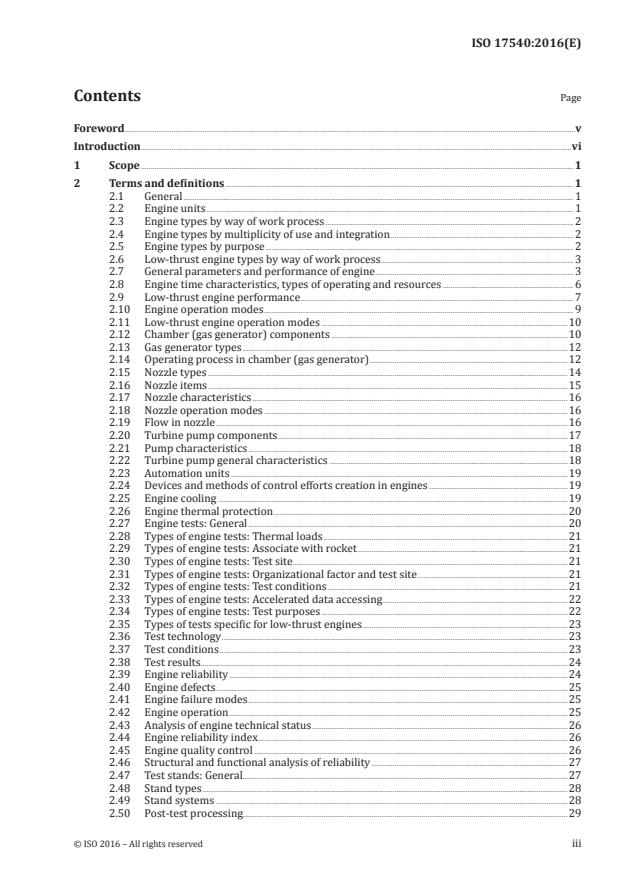

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Terms and definitions . 1

2.1 General . 1

2.2 Engine units . 1

2.3 Engine types by way of work process . 2

2.4 Engine types by multiplicity of use and integration . 2

2.5 Engine types by purpose . 2

2.6 Low-thrust engine types by way of work process . 3

2.7 General parameters and performance of engine . 3

2.8 Engine time characteristics, types of operating and resources . 6

2.9 Low-thrust engine performance . 7

2.10 Engine operation modes . 9

2.11 Low-thrust engine operation modes .10

2.12 Chamber (gas generator) components .10

2.13 Gas generator types .12

2.14 Operating process in chamber (gas generator) .12

2.15 Nozzle types .14

2.16 Nozzle items .15

2.17 Nozzle characteristics .16

2.18 Nozzle operation modes .16

2.19 Flow in nozzle .16

2.20 Turbine pump components . .17

2.21 Pump characteristics .18

2.22 Turbine pump general characteristics .18

2.23 Automation units .19

2.24 Devices and methods of control efforts creation in engines .19

2.25 Engine cooling .19

2.26 Engine thermal protection .20

2.27 Engine tests: General .20

2.28 Types of engine tests: Thermal loads .21

2.29 Types of engine tests: Associate with rocket .21

2.30 Types of engine tests: Test site .21

2.31 Types of engine tests: Organizational factor and test site .21

2.32 Types of engine tests: Test conditions .21

2.33 Types of engine tests: Accelerated data accessing .22

2.34 Types of engine tests: Test purposes .22

2.35 Types of tests specific for low-thrust engines .23

2.36 Test technology .23

2.37 Test conditions .23

2.38 Test results.24

2.39 Engine reliability .24

2.40 Engine defects .25

2.41 Engine failure modes .25

2.42 Engine operation .25

2.43 Analysis of engine technical status .26

2.44 Engine reliability index .26

2.45 Engine quality control .26

2.46 Structural and functional analysis of reliability .27

2.47 Test stands: General .27

2.48 Stand types .28

2.49 Stand systems .28

2.50 Post-test processing.29

2.51 Stand system elements.30

2.52 Stand compartments .31

iv © ISO 2016 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment,

as well as information about ISO’s adherence to the World Trade Organization (WTO) principles in the

Technical Barriers to Trade (TBT) see the following URL: www.iso.org/iso/foreword.html.

The committee responsible for this document is ISO/TC 20, Aircraft and space vehicles, Subcommittee

SC 14, Space systems and operations.

Introduction

This International Standard is intended to be applied for all types of rocket engines which use a liquid

propellant.

The terms in this International Standard are specified in scope of design, testing, reliability analysis

and quality control of liquid rocket engines.

The terms are intended to be required for use in all types of documentation and literature including in

scope of standardization or using results of this activity.

vi © ISO 2016 – All rights reserved

INTERNATIONAL STANDARD ISO 17540:2016(E)

Space systems — Liquid rocket engines and test stands —

Terms and definitions

1 Scope

The International Standard provides terms and definitions in scope of design, testing, reliability

analysis and quality control of liquid rocket engines. The terms are required for use in all types of

documentation and literature including in the scope of standardization or using the results of this

activity.

2 Terms and definitions

2.1 General

2.1.1

rocket engine

RE

reaction engine producing thrust for vehicle movement with the help of substances and energy sources

contained within the vehicle being moved

2.1.2

liquid rocket engine

LRE

rocket engine (2.1.1) using propellants in liquid form

2.1.3

low-thrust engine

LTE

rocket engine (2.1.1) of a thrust not more than 5 000 N

2.1.4

liquid rocket propulsion system

propulsion system including engine, propellant tanks, avionics for control sub-systems, pressure

vessels and control devices for pneumatic and hydraulic control sub-systems, propellant feed system,

actuators for steering sub-systems, and auxiliary equipment

2.1.5

clustered engine

liquid rocket propulsion system (2.1.4) consisting of multiple rocket engines (2.1.1), common propellant

tanks, and autonomous (independent) propellant feed systems

2.2 Engine units

2.2.1

chamber

engine assembly where propellant and/or gas generation products, as a result of chemical reactions,

are converted into products of combustion, created at the expiration of the reactive force

2.2.2

turbo-pump

TP

engine component designed to pump propellant into the chamber (2.2.1), gas generator sets and

automatic engine

2.2.3

booster turbo-pump

BTP

turbo-pump (2.2.2) engine support designed to increase propellant pressure in the pipelines to pump

(2.20.1)

2.2.4

gas generator

unit of engine wherein propellant, as a result of chemical reaction, is converted in gaseous products of

reaction at relatively low temperature

2.2.5

automatic engine controller

engine assembly designed for automatic control, regulation or maintenance of engine

2.3 Engine types by way of work process

2.3.1

engine with afterburning

engine where gas generation products after their use are used to drive the turbo-pump (2.2.2) assembly

2.3.2

engine without afterburning

engine where gas generation products after their use to drive the turbo-pump (2.2.2) assembly are

released into the environment

Note 1 to entry: Engine without afterburning have a pump (2.20.1) or a pressurized fuel supply.

2.3.3

single-mode engine

engine with one major mode

2.3.4

multimode engine

engine with several basic modes

2.4 Engine types by multiplicity of use and integration

2.4.1

expendable engine

engine intended for a specific purpose and used only one time

2.4.2

nonexpendable engine

engine intended for a specific purpose and used multiple times

2.4.3

single-start engine

engine started only once for a specific purpose

2.4.4

multi-start engine

restartable engine

engine started multiple times for one specific purpose

2.5 Engine types by purpose

2.5.1

main engine

engine intended to accelerate the space vehicle

2 © ISO 2016 – All rights reserved

2.5.2

correction engine

engine intended to correct the speed during the correction of trajectory of the space vehicle

2.5.3

control engine

engine intended to control the correction of the vector of the space vehicle in the active phase of the

trajectory of motion

2.5.4

retrorocket engine

engine intended to reduce the speed of the space vehicle

2.6 Low-thrust engine types by way of work process

2.6.1

catalytic engine

LTE (2.1.3) where the transformation of propellant into gaseous chemical reaction products is

performed with the help of a catalyst

2.6.2

thermo-catalytic engine

catalytic LTE where the catalyst is heated by the external heat source

2.6.3

electro-thermo-catalytic engine

thermo-catalytic LTE using an electrical source of energy

2.6.4

radio-thermo-catalytic engine

thermo-catalytic LTE using a radioactive source of energy

2.6.5

thermal engine

LTE (2.1.3) where the conversion of propellant in the gaseous products of chemical reactions is affected

by heating the fuel from an external source of energy which increases their rate of expiration

Note 1 to entry: Energy is fed to the propellant or products of chemical reactions.

2.6.6

electro-thermal engine

thermal LTE using an electrical energy source

2.6.7

radio-thermal engine

thermal LTE using a radioactive energy source

2.6.8

electrolytic engine

one-component of the LTE (2.1.3) where the electrolysis of the propellant is part of operating process

2.6.9

adjustable engine

low-thrust engine (2.1.3) that has a device to change the thrust

2.7 General parameters and performance of engine

2.7.1

rated performance

set of nominal values of the engine designated in the specifications

2.7.2

mass flow rate

mass of fluid passing a specified line or gate in unit time

2.7.3

volume flow rate

volume of fluid passing a specified line or gate in unit time

2.7.4

pre-start consumption

propellant mass consumption during the time interval from the first start command until the thrust

build-up to a specified value equal to 5 % of the nominal

2.7.5

mixture ratio

ratio of oxidizer mass flow rate (2.7.2) to the fuel mass flow rate

2.7.6

volume ratio

ratio of oxidizer volume flow rate (2.7.3) to the fuel volume rate

2.7.7

pressure

average static pressure of combustion products at the beginning of the combustion

chamber (2.12.1) at the mixing system chamber

2.7.8

pressure

average static pressure of gas generation at the beginning of the combustion chamber

(2.12.2) at the mixing system gas generator

2.7.9

combustion temperature

stagnation temperature of combustion products at the exit from the combustion chamber

(2.12.1)

2.7.10

combustion temperature

stagnation temperature of gas generation at the exit from the gas generator (2.2.4)

2.7.11

exhaust velocity

velocity of exhaust stream through the nozzle (2.12.16) or a reaction engine, relative to the nozzle

2.7.12

engine reactive force

gas and fluid flow resultant force acting on the thrust chamber internal surfaces resulting from the

combustion gases

2.7.13

engine thrust

resultant of the engine reactive force (2.7.12) and the environment pressure forces acting on the engine

external surfaces (excluding external aerodynamic drag forces)

2.7.14

engine impulse

time integral of engine thrust

2.7.15

cut-off impulse

impulse (2.9.5) of engine thrust for the time interval defining the engine tail-off

4 © ISO 2016 – All rights reserved

2.7.16

specific impulse

R

ratio of engine thrust to the mass flow of propellant I =

s

m

Note 1 to entry: Thrust engine (chamber) specific impulse is converted in a vacuum and at sea level.

Note 2 to entry: Thrust engine (chamber) specific impulse is also an equalled derivative from the thrust engine

(chamber) impulse by weight or volume of propellant consumed.

Note 3 to entry: For LTE (2.1.3), the term “specific impulse” is used for steady-state continuous mode, single

inclusions mode and the steady-state impulse mode.

2.7.17

volume specific impulse

R

ratio of engine thrust to the propellant volume flow rate I =

sv,

v

2.7.18

thrust coefficient

ratio of chamber thrust to the product of the nozzle stagnation pressure (or chamber total pressure at

nozzle inlet) and the area of nozzle throat

2.7.19

coefficient of specific impulse

ratio of actual specific impulse to the theoretical value that is defined by the same values of mixture

ratio (2.7.5), the nozzle stagnation pressure or chamber total pressure at nozzle inlet

2.7.20

total coefficient of specific impulse

coefficient of specific impulse (2.7.16) defined at the mixture ratio (2.7.5) to be the maximum ideal value

2.7.21

consumable complex of chamber

consumable complex

product of the combustion pressure in a given section of the chamber (2.2.1) to a nozzle throat area,

referred to the mass flow of the propellant in chamber

Note 1 to entry: Given section of the chamber (2.2.1) is in analysis of camera characteristics stability during

serial production [initial section of combustion chamber (2.12.1) at (near) mixing system (2.12.3)] and in analysis

of multiphase flows (2.19.4) [initial section of nozzle (2.12.16)].

2.7.22

thrust complex

ratio of engine thrust chamber pressure and the product of combustion products in a given section of

the chamber (2.2.1) for an area of minimum section of the nozzle (2.12.16)

Note 1 to entry: Thrust complex is also equal to the ratio of camera-specific impulse to consumable complex

(2.7.19).

2.7.23

coefficient of consumable complex

ratio of the actual spending of the complex chamber rocket engine to the ideal that defined the same

values of the ratio components fuel pressure in the chamber (2.2.1)

2.7.24

coefficient of nozzle flow

coefficient of flow

ratio of the actual flow of gas through the rocket engine nozzle to the theoretical value, as defined under

the same temperature and total pressure in the nozzle throat, under the conditions for the gas constant

and the local adiabatic exponent

2.7.25

nozzle coefficient

ratio of the actual thrust coefficient in a vacuum to the ideal that defined the same values of the mixture

ratio (2.7.5) and combustion pressure in the chamber (2.2.1) and the geometric expansion ratio nozzle

2.7.26

chamber coefficient

ratio of the real characteristic velocity in the chamber (2.2.1) to the ideal defined by the same values of

the mixture ratio (2.7.5) and the combustion chamber pressure

2.7.27

characteristic velocity

product of the nozzle stagnation pressure and nozzle throat area, referred to the mass consumption of

propellant in chamber

2.7.28

ideal parameter value

parameter value of chamber (2.2.1), corresponding to the equilibrium flow of combustion

products in the absence outlet heat and friction

2.7.29

ideal parameter value

parameter value of gas generator (2.2.4), corresponding to the equilibrium flow of

products gas generation in the absence outlet heat and friction

2.7.30

wet mass

mass of engine designed with propellants and other consumption articles filling its pipelines and

aggregates

2.7.31

relative mass

ratio of the wet mass (2.7.30) to the maximum thrust on the main steady-state operation

2.7.32

engine altitude characteristic

dependence of the thrust rocket engine on the environment pressure at constant values of the ratio of

the propellant components and the pressure in the chamber (2.2.1)

2.7.33

engine throttle characteristic

dependence of the engine thrust from the chamber pressure at constant values of the mixture ratio

(2.7.5) of propellants and the ambient pressure

2.8 Engine time characteristics, types of operating and resources

2.8.1

period of propellant flow

time interval from the moment of complete opening of the solenoid valve until it is completely closed

2.8.2

designed operating life

period of time during which the engine is expected to operate within its specified design parameters

2.8.3

engine operating time

operation duration and/or operation cycle number of the engine

6 © ISO 2016 – All rights reserved

2.8.4

engine verification time

mean time engine specified in the request for the proposal

2.8.5

engine specified resource

engine operating time (2.8.3) specified in the request for the proposal

2.8.6

engine working resource

total running time of engine during a specified period of service, used as directed

2.8.7

engine single working resource

work resource of engines, or part thereof, during one cycle operation

2.8.8

engine designated resource

total operating time after the expiry of which the use of the engine should be stopped

2.8.9

LTE total designated resource

operation duration assigned for continuous and pulse modes

Note 1 to entry: In addition to total designated resourse, for LTE (2.1.3), it is also determined designated resource

according to the following:

— number of inclusions (2.9.8);

— duration at impulse mode;

— duration at continuous mode;

— total propellant consumption for catalytic LTE.

2.9 Low-thrust engine performance

2.9.1

full thruster impulse

thruster impulse of LTE (2.1.3) at which the mean integrated value of thrust, or chamber pressure, is

more or equal to 0,9 of the steady-state value of the thrust, or chamber pressure, for the firing

2.9.2

part-thrust impulse

thruster impulse of LTE (2.1.3) at which the average integral value of thrust, or pressure (2.7.7) in the

chamber (2.2.1), is less than 0,9 the steady-thrust, or pressure in the chamber, at a switch

2.9.3

unit impulse

thruster impulse of LTE (2.1.3) or one firing (on-time (2.9.10)) in the pulse or single firing operation mode

2.9.4

total impulse

thruster impulse of LTE (2.1.3) over the operating duration

2.9.5

impulse

forceful impact of LTE (2.1.3) characterized by changes in traction or pressure (2.7.7) in the chamber

(2.2.1) at the time of a switch

2.9.6

rated thrust

designed thrust level in a steady-state condition mode under nominal working conditions

2.9.7

conditional rated thrust

rated thrust of LTE (2.1.3) in a vacuum at an initial temperature of 288 K where structures and the

geometric expansion ratio of the nozzle is equal to 50

2.9.8

inclusion

on-time

time interval from the moment of voltage being applied to the thruster electric valve up to the moment

of reenergizing the LTE (2.1.3)

2.9.9

aftereffect

thruster electric valve reenergizing up to the moment when the thrust of the chamber pressure fall to a

value equal to 0,1 of the thrust of the chamber pressure in the steady-state continuous operation mode

2.9.10

off-time

pause between inclusions

time interval from the moment of the thruster electric valve reenergizing up to the moment of the next

voltage being applied

2.9.11

cycle period

on-time (2.9.8) and off-time (2.9.10) sum

2.9.12

inclusion frequency

reciprocal of cycle period (2.9.11)

2.9.13

cycle period to on-time ratio

duty cycle

reciprocal of duty cycle

2.9.14

coefficient of fill cycle operation

inclusion relation of LTE (2.1.3) to switching cycles

2.9.15

thrust build-up time

time interval from the ignition signal to the moment when the thrust or chamber pressure reaches a

value of 90 % of the steady-state thrust or the chamber pressure

2.9.16

thrust delay

time interval from the cut-off signal until the thrust or chamber pressure decreases to 10 % of steady-

state thrust or chamber pressure

2.9.17

propellant expansion delay

interval time from the start entry of the second component of propellant cell LTE (2.1.3) until the

pressure (2.7.7) in the chamber (2.2.1) reaches a value equal to the pressure in the absence of fuel

decomposition

8 © ISO 2016 – All rights reserved

2.9.18

propellant ignition delay

time interval from the moment the second propellant enters the chamber (2.2.1) up to ignition

2.9.19

average mass flow of propellant

ratio of the mass flow of propellant (fuel, oxidizer) LTE (2.1.3) for one inclusion (2.9.8) to the next

2.10 Engine operation modes

2.10.1

engine operation

engine operating for thrust creating or changing its value and/or for providing the operation conditions

of the vehicle components in accordance with the engine requirements

2.10.2

engine operation mode

set of the engine parameter values defined by the processes occurring in the engine

2.10.3

engine main mode

mode engine is in when a major problem is carried

2.10.4

engine firing

engine operation (2.10.1) from the firing command up to when the specified mode is reached

2.10.5

engine steady-state mode

engine operation mode (2.10.2) where the mean thrust and mixture ratio values remain constant

2.10.6

engine unsteady mode

engine operating mode where the average thrust or the ratio of propellant components varies in time

2.10.7

engine preview mode

setting of the engine thrust with less traction on the main mode

Note 1 to entry: Advance regime is part of the launching engine.

2.10.8

engine cut-off

engine operation (2.10.1) from the cut-off command up to when the thrust disappears

2.10.9

engine final mode

setting of the engine before stopping with a thrust with less traction on the main mode

2.10.10

break between engine inclusions

time interval from the engine stop multiple power-up to the first team for the subsequent inclusion (2.9.8)

2.10.11

engine emergency cut-off

engine cut-off caused by a failure of the engine, the propulsion system, the test stand systems or the

vehicle systems

2.11 Low-thrust engine operation modes

2.11.1

continuous operation mode

LTE operation mode of one firing with the specific impulse value constant in time

2.11.2

pulse mode

LTE operation mode of many firing (on-times (2.9.8)) where the specific impulse (2.7.16) depends on each

firing (on-time)

Note 1 to entry: Minimum duration of the pulses is limited by the time taken for the thruster valves to open and

close, since this limits the repeatability of the process.

2.11.3

steady-state pulse mode

LTE pulse mode where the pulse shape is stabilized with a constant value of the on-time frequency

2.11.4

operation mode with connected pulses

LTE pulse mode where, during the off-time (2.9.10), the thrust or the chamber pressure falls to a value

higher than 0,1 of the thrust or the chamber pressure of the steady-state continuous mode

2.11.5

cyclic mode

LTE mode consisting of repeating combinations of continuous and pulsed modes (2.11.2) or combinations

of inclusion (2.9.8) and repetitive pauses of varying lengths

2.11.6

separate firing mode

isolated firing mode

LTE operation mode where the engine returns to the initial state during the off-time (2.9.10)

2.12 Chamber (gas generator) components

2.12.1

combustion chamber

part of the chamber (2.2.1) between the internal bottom of the mixing system (2.12.3)

and the initial section of the nozzle (2.12.16), which is intended for mixture generation (2.14.3) and

propellant combustion

2.12.2

combustion chamber

part of the gas generator (2.2.4) intended for mixture generation (2.14.4) and

propellant components transformation into gas generation products

2.12.3

mixing system

part of the chamber (2.2.1) representing the device for propellant components and/or

gas generation products input into the combustion chamber (2.12.1) and their initial mixing

2.12.4

mixing system

part of the gas generator (2.2.4) representing the device for propellant components

input into the combustion chamber (2.12.2) and their initial mixing

10 © ISO 2016 – All rights reserved

2.12.5

mixing system bottom

item of the engine chamber mixing system, dividing cavities of propellant components

or gas generation products among themselves, or separating them from fire space and the external

environment

2.12.6

mixing system bottom

item of the gas generator mixing system, dividing cavities of propellant components

among themselves, or separating them from fire space and external environment

Note 1 to entry: Distinguish the external, average and internal bottoms.

Note 2 to entry: External bottom function in the engine chamber, with reburning, can perform gas passage.

2.12.7

injector

device for propellant components or gas generation products that input into the combustion chamber

(2.12.1) of chamber (2.2.1) and/or gas generator (2.2.4)

2.12.8

jet injector

engine injector whereby liquid or gas escapes in the form of one or several streams

2.12.9

centrifugal injector

engine injector whereby liquid or gas escape in the form of a veil generated as result of liquid or gas

rotating in a vortex chamber

2.12.10

gas-distributing grid

item of the chamber (2.2.1) or gas generator mixing system that provides gas distribution in areas

of the mixing system (2.12.3) and increases the operating process stability in the chamber or gas

generator (2.2.4)

2.12.11

anti-pulsating partition

partition established in the combustion chamber (2.12.1) of the engine chamber or gas generator (2.2.4)

for cross-section fluctuations suppression

2.12.12

chamber gas generator case

wall of engine chamber (gas generator) without mixing system (2.12.4)

2.12.13

gas generator chamber cooling tract

set of channels in the case and chamber (gas generator) mixing system with one-through (2.25.2)

(direct-flow) or transpiration cooling (2.25.7)

2.12.14

veil belt zone

item of engine chamber intended for one of the propellant components or gas generation

products to input into the wall area of the fire space for the creation of a liquid or gas protective layer

2.12.15

veil belt zone

item of the engine gas generator (2.2.4) intended for one of the propellant

components to input into the wall area of fire space for the creation of a liquid or gas protective layer

2.12.16

nozzle

part of the engine that converts the thermal energy of the combustion gases into the kinetic energy of

the exhaust plume

Note 1 to entry: The engine nozzle may be stationary and rotational, relative to the stationary parts of the

chamber (2.2.1), and also have a rotational section for performance control.

2.13 Gas generator types

2.13.1

оne-zone gas generator

gas generator (2.2.4) where all phases of the operating process are provided with items of the mixture

generation constructional units placed on the internal bottom of the mixing system (2.12.4)

2.13.2

multizone gas generator

gas generator (2.2.4) where some phases of the operating process are provided with items of the

mixture generation constructional units placed on the internal bottom of mixing system (2.12.4)

2.14 Operating process in chamber (gas generator)

2.14.1

operating process

set of processes in the combustion chamber (2.12.1) of an engine chamber for the

transformation of propellant components and/or gas generation products to combustion products

2.14.2

operating process

set of processes in the combustion chamber (2.12.2) of an engine gas generator for

the transformation of propellant components to gas generation products

2.14.3

mixture generation

dispersion and mixing of propellant components or gas generation products

2.14.4

mixture generation

dispersion and mixing of propellant components

2.14.5

wall layer in chamber

part of the propellant flow in a chamber (2.2.1) (gas generator) that adjoins to

the combustion chamber walls but different in terms of the chemical composition, thermophysical

characteristics and speed

2.14.6

propellant flow core

central part of propellant flow and/or gas generation products in the chamber (2.2.1) or gas generator

(2.2.4) where combustion chamber walls and wall layer do not influence the operating process

2.14.7

flow rate tension

ratio of combustion products mass flow to the area of the chamber cross-section at the

mixing system (2.12.3)

2.14.8

flow rate tension

ratio of gas generation products mass flow to the area of the gas generator cross-

section at the mixing system (2.12.4)

12 © ISO 2016 – All rights reserved

2.14.9

relative flow rate tension of chamber

ratio of flow rate tension (2.14.7) to the pressure (2.7.8) in the chamber (2.2.1) (gas

generator)

2.14.10

average time of propellant being

time interval defined by ratio of product weight in the combustion chamber (2.12.1) to the propellant

mass flow by the chamber (2.2.1)

2.14.11

high-frequency oscillation

pressure oscillation in the combustion chamber (2.12.1) with frequencies that are equal to or exceeding

the minimum natural acoustic frequency

2.14.12

high-frequency self-oscillation

pressure self-oscillation in the combustion chamber (2.12.1) with a frequency that is similar to one of

the natural acoustic frequencies

2.14.13

longitudinal oscillation

pressure high-frequency self-oscillation in combustion chamber (2.12.1) along combustion chamber axis

2.14.14

transverse oscillation

pressure high-frequency self-oscillation in combustion chamber (2.12.1) in a plane that is perpendicular

to the combustion chamber axis

Note 1 to entry: Distinguish the tangential, radial and mixed cross-section oscillations depending on the

oscillatory motion direction.

2.14.15

low-frequency oscillation

pressure oscillation in the chamber (2.2.1) (gas generator) with frequencies that are smaller than the

minimum natural acoustic frequency

2.14.16

nozzle impedance

complex value in which the module is the ratio of pressure oscillations amplitude to the speed in the

nozzle’s initial section and the phase is the displacement between pressure (2.7.7) and speed oscillations

2.14.17

mixing system impedance

complex value in which the module is the ratio of pressure oscillations amplitude to the speed at the

chamber (gas generator) mixing system and the phase is the displacement between pressure (2.7.8) and

speed oscillations

2.14.18

soft excitation of self-oscillation

appearance of pressure self-oscillation in the combustion chamber (2.12.1) from small disturbances

2.14.19

hard excitation of self-oscillation

appearance of pressure self-oscillation in the combustion chamber (2.12.1) from disturbances that

exceed critical value

2.14.20

stable operating process

operating process in the chamber (gas generator) without pressure self-oscillations

2.14.21

unstable operating process

operating process in the chamber (gas generator) with pressure self-oscillations

2.14.22

frequencies identification

identification of pressure oscillation frequencies in the chamber (2.2.1) (gas generator) corresponding

to maximum of amplitude spectrum with natural frequencies

2.14.23

stability range of operating process

values range (area) of the chamber (gas generator) operating mode parameters that provide a

stable process

2.14.24

stability boundary of operating process

set of chamber (gas generator) operating mode parameter values that divide the operating process

stability and instability ranges (areas)

2.15 Nozzle types

2.15.1

axisymmetric nozzle

engine nozzle in which the surface, from the side where combustion products flow, is symmetric

relative to its axis

2.15.2

round nozzle

axisymmetric nozzle (2.15.1) in which any combustion products flow section perpendicular to symmetry

axis is a circle

2.15.3

conical nozzle

round nozzle (2.15.2) in which the expanding part from the similar to the nominal section has a

rectilinear contour

2.15.4

shaped nozzle

engine nozzle in which the expanding part has a curvilinear contour shaped for increasing nozzle

efficiency

2.15.5

ring nozzle

axisymmetric nozzle (2.15.1) in which some or all perpendicular symmetry axes of the combustion

products flow section are rings

2.15.6

pin nozzle

nozzle with external expansion

ring nozzle (2.15.5) in which the external zone is almost or completely absent at the expanding part

contour

2.15.7

disk nozzle

nozzle with internal expansion

ring nozzle (2.15.5) in which the internal zone is almost or completely absent at the expanding part contour

14 © ISO 2016 – All rights reserved

2.15.8

sliding nozzle

extending nozzle

nozzle (2.12.16) with one or several sliding attachments which are nozzle expanding part continuation

in extended position

2.15.9

nozzle with oblique cut

nozzle (2.12.16) whose cut is inclined to nozzle axis, different from right angle

Note 1 to entry: A nozzle with an oblique cut consists of a major axisymmetric part and small non-

axisymmetric part.

2.15.10

adjustable nozzle

nozzle (2.12.16) whose expansion ratio can be changed in the process of operation

2.16 Nozzle items

2.16.1

nozzle contour

intercepting line of the nozzle surface with the plane passing through central axis

2.16.2

extremal nozzle contour

shaped nozzle contour (2.16.1) whose expanding part is determined by various methods

2.16.3

nozzle contour with uniform characteristic

shaped nozzle contour (2.16.1) whose expanding part provides parallel flow at the nozzle exit section

(2.16.10) with constant speed at any point of the section

2.16.4

shorter contour nozzle

shaped nozzle contour (2.16.1) whose extending part represents the initial site of the nozzle contour

extending part with uniform characteristic

2.16.5

nozzle contour with corner point

nozzle contour (2.16.1) that has a break (turn)

2.16.6

nozzle exit section contour

closed line drawn through exit endpoints of all nozzle contours (2.16.1)

2.16.7

nozzle inlet section

engine chamber flow section behind where the sharp reduction of flow section area begins

2.16.8

nozzle throat section

nozzle flow section with minimum area

2.16.9

nozzle critical section

nozzle flow section where combustion product speed is equal to the local sound speed

2.16.10

nozzle exit section

end of nozzle (2.12.16) of the divergent, bell-shaped part of a rocket exhaust nozzle that converts the

thermal energy of the combustion gases to the kinetic energy of the exhaust plume and controls the

expansion of the plume

Note 1 to entry: The nozzle exit section is perpendicular to the central axis and pas

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...