IEC TS 62862-3-3:2020

(Main)Solar thermal electric plants - Part 3-3: Systems and components - General requirements and test methods for solar receivers

Solar thermal electric plants - Part 3-3: Systems and components - General requirements and test methods for solar receivers

IEC TS 62862-3-3:2020 specifies the technical requirements, tests, durability and technical performance parameters of solar thermal receivers for absorbing concentrated solar radiation and transferring the heat to a fluid used in concentrated solar thermal power plants with linear-focus solar collectors. The receivers addressed consist of an absorber tube and an insulating glass envelope tube.

This document includes the definitions of technical properties and characterization of geometry and performance parameters as well as the test methods for optical characterization, heat loss, and durability. For the sake of clarity, it is stated here that the thermal loss tests described in this document do not deliver the thermal loss of the receiver tubes when they are installed in commercial solar fields.

General Information

- Status

- Published

- Publication Date

- 25-Feb-2020

- Technical Committee

- TC 117 - Solar thermal electric plants

- Drafting Committee

- PT 62862-3-3 - TC 117/PT 62862-3-3

- Current Stage

- PPUB - Publication issued

- Start Date

- 26-Feb-2020

- Completion Date

- 27-Jan-2020

Overview

IEC TS 62862-3-3:2020 is an IEC Technical Specification for solar receivers used in concentrated solar thermal power (CST) plants with linear-focus solar collectors. It specifies technical requirements, test methods, durability criteria and performance parameters for receivers that consist of an absorber tube enclosed by an insulating glass envelope. The document defines geometry and material characteristics, optical and thermal performance metrics, and standardized laboratory tests for optical characterization, heat-loss measurement, and long-term durability. Note: the thermal loss laboratory tests in this TS are for component characterization and do not represent in-field thermal losses when installed in commercial solar fields.

Key topics and technical requirements

- Definitions and characterization: standardized terminology, symbols, geometry and material descriptors for absorber tubes and glass envelopes.

- Heat-loss tests: prescribed setups and two principal methods (resistance heating and Joule effect), thermocouple placement, test stability criteria, thermal emittance measurement (optional) and heat-loss curve models to report results.

- Optical characterization: non‑destructive optical tests, optical efficiency transient methods and solar-simulator based efficiency testing (optional) to quantify receiver optical performance.

- Durability and mechanical tests: antireflective coating durability, abrasion, impact resistance (ice-ball and steel-ball methods), external/internal thermal shock, thermal stability of selective absorber coatings (full tubes and coated samples), thermal cycling and bellows fatigue tests.

- Test reporting and calibration: standardized test-report forms, instrumentation calibration and measurement stability/acceptance criteria.

- Annexes: example test report form and application notes (e.g., temperature measurement offset corrections).

Applications and who uses it

This Technical Specification is intended for:

- Receiver manufacturers - for product development, quality control and factory testing.

- Independent test laboratories and certification bodies - to perform repeatable optical, thermal and durability testing.

- CST plant developers and EPCs - to specify component acceptance criteria and compare supplier offerings.

- R&D teams and materials engineers - to evaluate absorber coating performance and lifetime ageing.

- Procurement and QA managers - to define technical requirements in contracts and supplier audits.

Practical uses include verifying heat-loss coefficients, confirming optical efficiency, validating coating stability under thermal cycling, and documenting conformance for procurement or certification.

Related standards

- IEC TS 62862-3-3 is part of the broader IEC 62862 series addressing systems and components for solar thermal electric plants. Users should consult other parts of the series and referenced normative documents for complete system-level requirements and complementary test methods.

Keywords: IEC TS 62862-3-3:2020, solar receivers, solar thermal electric plants, linear-focus solar collectors, absorber tube, glass envelope, heat loss test, optical characterization, durability tests, concentrated solar thermal power.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC TS 62862-3-3:2020 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Solar thermal electric plants - Part 3-3: Systems and components - General requirements and test methods for solar receivers". This standard covers: IEC TS 62862-3-3:2020 specifies the technical requirements, tests, durability and technical performance parameters of solar thermal receivers for absorbing concentrated solar radiation and transferring the heat to a fluid used in concentrated solar thermal power plants with linear-focus solar collectors. The receivers addressed consist of an absorber tube and an insulating glass envelope tube. This document includes the definitions of technical properties and characterization of geometry and performance parameters as well as the test methods for optical characterization, heat loss, and durability. For the sake of clarity, it is stated here that the thermal loss tests described in this document do not deliver the thermal loss of the receiver tubes when they are installed in commercial solar fields.

IEC TS 62862-3-3:2020 specifies the technical requirements, tests, durability and technical performance parameters of solar thermal receivers for absorbing concentrated solar radiation and transferring the heat to a fluid used in concentrated solar thermal power plants with linear-focus solar collectors. The receivers addressed consist of an absorber tube and an insulating glass envelope tube. This document includes the definitions of technical properties and characterization of geometry and performance parameters as well as the test methods for optical characterization, heat loss, and durability. For the sake of clarity, it is stated here that the thermal loss tests described in this document do not deliver the thermal loss of the receiver tubes when they are installed in commercial solar fields.

IEC TS 62862-3-3:2020 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 62862-3-3:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TS 62862-3-3 ®

Edition 1.0 2020-02

TECHNICAL

SPECIFICATION

colour

inside

Solar thermal electric plants –

Part 3-3: Systems and components – General requirements and test methods

for solar receivers

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TS 62862-3-3 ®

Edition 1.0 2020-02

TECHNICAL

SPECIFICATION

colour

inside

Solar thermal electric plants –

Part 3-3: Systems and components – General requirements and test methods

for solar receivers

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 27.160 ISBN 978-2-8322-7784-3

– 2 – IEC TS 62862-3-3:2020 © IEC 2020

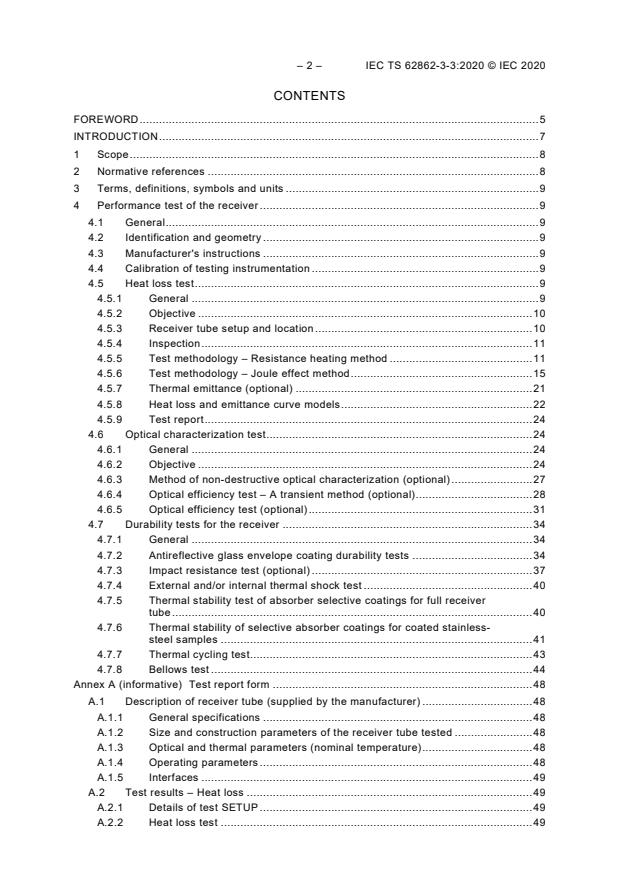

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms, definitions, symbols and units . 9

4 Performance test of the receiver . 9

4.1 General . 9

4.2 Identification and geometry . 9

4.3 Manufacturer's instructions . 9

4.4 Calibration of testing instrumentation . 9

4.5 Heat loss test . 9

4.5.1 General . 9

4.5.2 Objective . 10

4.5.3 Receiver tube setup and location . 10

4.5.4 Inspection . 11

4.5.5 Test methodology – Resistance heating method . 11

4.5.6 Test methodology – Joule effect method . 15

4.5.7 Thermal emittance (optional) . 21

4.5.8 Heat loss and emittance curve models . 22

4.5.9 Test report . 24

4.6 Optical characterization test . 24

4.6.1 General . 24

4.6.2 Objective . 24

4.6.3 Method of non-destructive optical characterization (optional) . 27

4.6.4 Optical efficiency test – A transient method (optional) . 28

4.6.5 Optical efficiency test (optional) . 31

4.7 Durability tests for the receiver . 34

4.7.1 General . 34

4.7.2 Antireflective glass envelope coating durability tests . 34

4.7.3 Impact resistance test (optional) . 37

4.7.4 External and/or internal thermal shock test . 40

4.7.5 Thermal stability test of absorber selective coatings for full receiver

tube . 40

4.7.6 Thermal stability of selective absorber coatings for coated stainless-

steel samples . 41

4.7.7 Thermal cycling test . 43

4.7.8 Bellows test . 44

Annex A (informative) Test report form . 48

A.1 Description of receiver tube (supplied by the manufacturer) . 48

A.1.1 General specifications . 48

A.1.2 Size and construction parameters of the receiver tube tested . 48

A.1.3 Optical and thermal parameters (nominal temperature) . 48

A.1.4 Operating parameters . 48

A.1.5 Interfaces . 49

A.2 Test results – Heat loss . 49

A.2.1 Details of test SETUP . 49

A.2.2 Heat loss test . 49

A.2.3 Linear fit of heat loss results to absorber temperature . 50

A.2.4 Linear fit of emittance data to absorber temperature . 50

A.3 Test results, optical characterization test . 50

A.4 Test results, optical efficiency test . 51

A.4.1 General . 51

A.4.2 Details of test SETUP . 51

A.4.3 Solar simulator test (if relevant, depending on test method) . 51

A.5 Test results – Stationary abrasion resistance test . 51

A.5.1 Test conditions . 51

A.5.2 Results . 51

A.6 Test results – Condensation test . 51

A.7 Test results – Impact resistance test: Method 1 – Ice balls . 52

A.7.1 Test conditions . 52

A.7.2 Procedure . 52

A.7.3 Test results. 52

A.8 Test results – Impact resistance test: Method 2 – Steel balls . 52

A.8.1 Test conditions . 52

A.8.2 Procedure . 52

A.8.3 Test results. 52

A.9 Test results – Thermal stability test of absorber selective coating for full

receiver tube . 52

A.9.1 Test conditions . 52

A.9.2 Test results. 52

A.10 Test results – Thermal stability test of absorber selective coated stainless-

steel samples . 53

A.10.1 Instrumentation . 53

A.10.2 Test conditions . 53

A.10.3 Test results. 53

A.11 Test results – Thermal cycling test . 53

A.11.1 Test conditions . 53

A.11.2 Test results. 53

A.12 Test results – Bellows test . 53

A.12.1 Test conditions . 53

A.12.2 Test results. 53

Annex B (informative) Application notes: Temperature measurement in heat-loss test

with cartridge heater – Temperature measurement offset correction . 54

Bibliography . 55

Figure 1 – Solar receiver schematic sketch . 7

Figure 2 – Resistance heating method schematic sketch . 16

Figure 3 – Test bench for heat loss measurements of solar receiver tubes . 18

Figure 4 – Position of thermocouples and sections of voltage measurement . 19

Figure 5 – Example heat loss curve . 23

Figure 6 – Measurement principle . 27

Figure 7 – Test bench for optical efficiency – Transient method . 29

Figure 8 – Schematic of abrasion equipment . 35

Figure 9 – Drawing of receiver rotation in abrasion equipment for a tube or piece . 35

Figure 10 – Example of a test bench for testing bellows fatigue . 45

– 4 – IEC TS 62862-3-3:2020 © IEC 2020

Table 1 – Evaluation periods . 12

Table 2 – Stability requirements . 12

Table 3 – Evaluation periods . 19

Table 4 – Stability requirements . 20

Table 5 – Permitted deviation of measured parameters during a measurement period . 30

Table 7 – Ice ball test mass and speed . 38

Table 8 – Monitored parameters during waiting period . 41

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SOLAR THERMAL ELECTRIC PLANTS –

Part 3-3: Systems and components –

General requirements and test methods for solar receivers

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a Technical

Specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical Specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC TS 62862-3-3, which is a Technical Specification, has been prepared by IEC technical

committee 117: Solar thermal electric plants.

– 6 – IEC TS 62862-3-3:2020 © IEC 2020

The text of this Technical Specification is based on the following documents:

Draft TS Report on voting

117/104/DTS 117/107/RVDTS

Full information on the voting for the approval of this Technical Specification can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62862 series, published under the general title Solar thermal

electric plants, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

The receiver is one of the most important and most sensitive components of Fresnel and

parabolic trough power plants. Large mirrors are aligned to concentrate solar radiation up to

80 times along the focal line of the mirrors onto the specially coated, evacuated receivers.

The generated heat is transported to a power generation unit, using a heat transfer fluid, and

converted to electricity.

The quality and long-term performance stability of the receiver has a decisive influence on

how effectively solar radiation can be converted into heat. For the power plant to achieve

maximum efficiency, the receiver has to absorb as much solar radiation as possible and

convert it into heat with minimized losses.

The solar receiver (see schematic in Figure 1) mainly consists of:

• a steel absorber tube: heat transfer fluid flows through the stainless-steel absorber tube. A

high-quality absorber coating converts the solar radiation into heat and minimizes infrared

heat loss at the same time;

• a glass cover tube: the cover is made from borosilicate glass and is coated with an

antireflective film to increase solar transmittance;

• evacuated space (annulus) or filled with noble gas between absorber tube and glass cover

tube: the vacuum between steel absorber and glass cover is essential to suppress gas

heat convection;

• bellows: the bellows are necessary to compensate for different rates of heat expansion of

the steel absorber and the glass cover. In contrast to the glass cover, the hot absorber

expands considerably when operating.

Figure 1 – Solar receiver schematic sketch

– 8 – IEC TS 62862-3-3:2020 © IEC 2020

SOLAR THERMAL ELECTRIC PLANTS –

Part 3-3: Systems and components –

General requirements and test methods for solar receivers

1 Scope

This document specifies the technical requirements, tests, durability and technical

performance parameters of solar thermal receivers for absorbing concentrated solar radiation

and transferring the heat to a fluid used in concentrated solar thermal power plants with

linear-focus solar collectors. The receivers addressed consist of an absorber tube and an

insulating glass envelope tube.

NOTE 1 Most of the test methods included in this document apply to solar receivers used both in solar thermal

electric plants with parabolic-trough and Fresnel collectors.

This document includes the definitions of technical properties and characterization of

geometry and performance parameters as well as the test methods for optical

characterization, heat loss, and durability.

NOTE 2 The experience accumulated so far regarding the different test methods currently available for receiver

tubes is not extensive enough to determine which test method is the best; this document describes all the different

methods currently available without defining one recommended method.

For the sake of clarity, it is stated here that the thermal loss tests described in this document

do not deliver the thermal loss of the receiver tubes when they are installed in commercial

solar fields.

Thermal losses obtained by indoor testing on a single receiver are significantly lower than the

thermal losses in outdoor, real operating conditions at commercial solar fields. However, the

indoor test procedures described in this document are suitable for receiver tube performance

comparison.

The thermal losses taken into account for solar field design are obtained by testing complete

collectors operating under real solar conditions.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC TS 62862-1-1, Solar thermal electric plants – Part 1-1: Terminology

ISO 6270-2:2017, Paints and varnishes – Determination of resistance to humidity – Part 2:

Condensation (in-cabinet exposure with heated water reservoir)

ISO 9806:2017, Solar energy – Solar thermal collectors – Test methods

ISO 9488:1999, Solar energy – Vocabulary

MIL-E-12397 – Eraser, Rubber-Pumice (for testing coated optical elements)

ASTM G173 – 03 – Standard Tables for Reference Solar Spectral Irradiances: Direct Normal

and Hemispherical on 37º Tilted Surface

3 Terms, definitions, symbols and units

For the purposes of this document, the terms, definitions, symbols and units contained in

ISO 9488 and IEC 62862-1-1 apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

4 Performance test of the receiver

4.1 General

As receivers are one of the most important components in the solar field, they have a big

impact on the performance of the entire solar field. In order to be able to best simulate the

lifetime performance of the receiver as well as that of the solar field, it is crucial to perform

tests that characterize the receiver and its performance.

4.2 Identification and geometry

The receiver usually has a brand name for the product and is also defined by the outer

diameter of the stainless-steel tube. Another important identifier/parameter is the length of the

receiver, which may vary depending on the trough for which it is designed. Additional

parameters such as absorptance, emittance, transmittance, vacuum pressure, stainless-steel

material, design temperature and pressure and the Heat Transfer Fluid for which it is

designed, can be obtained from the manufacturer. These parameters/characteristics should

be noted as part of the report for the receiver being tested.

4.3 Manufacturer's instructions

In addition to the parameters in 4.2, the manufacturer may have additional instructions for the

use/preparation of the receiver or parts thereof for testing, for example, the cleaning of

samples prior to carrying out optical measurements. These instructions shall be noted as part

of the test procedure in case they have an effect on the results.

4.4 Calibration of testing instrumentation

Unless otherwise indicated by the manufacturer of the testing device, all instruments used

should be calibrated at least once a year. In the event that a device is used that requires

special calibration (i.e. spectrophotometer requiring calibration using a "golden sample"), this

should be noted in the report including the date of calibration and the specimen used.

4.5 Heat loss test

4.5.1 General

NOTE In 2016, a round robin test was carried out within the European project STAGE-STE (European Union

Seventh Framework Program FP7 (2007-2013) under grant agreement ID 609837) with five different tubes from

different manufacturers. From this round robin, the heat loss testing results showed standard deviations in the

order of 6 % to 12 % for most temperatures and receivers (see [1] ).

____________

Numbers in square brackets refer to the Bibliography.

– 10 – IEC TS 62862-3-3:2020 © IEC 2020

These differences should be considered when comparing results by different laboratories

using different methodologies. It is recommended when trying to compare receivers from

different manufacturers to test all receivers in the same method at the same institute, to get

comparable results.

For the thermal loss test, one of the following methods shall be used (both are described

below):

• resistance heating method;

• Joule effect method.

4.5.2 Objective

The purpose of this test is the thermal characterization of a solar receiver tube including

determination of the heat loss curve and calculation of thermal emittance (optional) based on

test data.

The application of this test is associated with the needs of solar thermal power plant projects

using parabolic-trough technology and, by analogy, also Fresnel technology. It is applicable to

solar receiver tubes forming part of a parabolic-trough collector or a Fresnel collector.

4.5.3 Receiver tube setup and location

4.5.3.1 General

The way in which the receiver tube is set up on the test bench has a determining influence on

the heat loss test results, so it is therefore recommended that the test bench is set up as

described in the following subclauses of 4.5.3. The tests shall be performed indoors to

minimize any possible environmental influence on the test samples. In addition, the space

around the receiver, equal to at least 50 cm on all sides, should be free from big obstacles to

avoid limiting natural air circulation.

In the event that the test is carried out under vacuum conditions, the surroundings are not

important as air circulation is negligible.

The general principle of measurement is based on the conversion of electricity into heat under

stationary conditions. Under these conditions, the heat loss is equivalent to the power

necessary to maintain the receiver at a constant temperature. Determination of the power

required at different temperatures leads to the heat loss curve characteristic of the receiver

test sample.

There are different methods for heating the receiver. For example, by Joule effect, by

electrical heated elements or by IR resistance attached to a copper tube inserted inside the

absorber tube (see example in [2]).

4.5.3.2 Receiver tube setup and initial inspection

The receiver tube to be tested shall be placed horizontally in the test support frame holders.

The absorber tube shall be visually inspected, and any damage or modification observed shall

be recorded in the test report.

4.5.3.3 Temperature measurements

The receiver tube temperature shall be measured with temperature sensors touching the

absorber from the inside in at least six positions along it, arranged symmetrically from the

centre, with a gap of no more than 1 m between sensors. Additional sensors shall be located

near the ends of the tube and be in contact with the tube, in order to control gradients towards

the ends. Three sensors are recommended for measuring the glass surface temperature.

The ambient temperature sensor shall be placed not more than 2 m from the sample, in a

location where it is not affected by hot spots or air currents. The positions of the sensors shall

be recorded in the report.

The temperature sensors shall be calibrated according to the temperature range to be tested.

The expanded uncertainties of the average temperatures of each sensor shall be less than:

• ±2 °C for the absorber tube;

• ±2 °C for the glass envelope tube;

• ±1 °C for ambient or surrounding air.

Uncertainty calculations are determined in accordance with ISO 9806:2017, Annex D.

The contact shall be suitable to ensure correct measurement. Correction methods for

compensating the influence temperature gradients near the sensors might be applicable.

Pressing temperature sensors on the absorber or glass often leads to inadequate

measurements as temperature sensors are influenced by air temperature and radiation

temperature in the annulus and heat conduction along the thermocouple wires. Reference

measurements can be used to ensure the validity of the measurement setup or to correct the

measurements, see Annex B. The temperature corrections, if done, shall be noted in the test

report.

4.5.3.4 Power measurements

The measurement equipment for electric heating power shall have an accuracy of at least 3 %

of the actual reading.

4.5.3.5 Data acquisition frequency

Power sensors used in the test shall be calibrated. Data recording frequency shall be no less

than 1 recording per 20 s and the minimum number of records shall ensure the statistical

representativeness of the test.

4.5.4 Inspection

When the test has finished, the receiver tube shall be inspected and note taken of any change

observed. Changes observed shall be recorded in the test report; photographs can be added.

4.5.5 Test methodology – Resistance heating method

4.5.5.1 Measurements

At least the following data shall be measured.

Before the test:

• the length of the metal receiver absorber tube measured at ambient temperature using a

measuring instrument (e.g. measuring tape) with an uncertainty of 1 mm. The instrument

should be inserted into the tube and measured from one end to the other;

• diameter (inner and outer) of the absorber tube measured at ambient temperature using a

caliper with an accuracy of at least 1/10 mm;

• position of temperature sensors using a measuring instrument (e.g. measuring tape) with

an uncertainty of at least 1 mm, with reference to a specific end/position on the absorber

tube.

– 12 – IEC TS 62862-3-3:2020 © IEC 2020

During the test:

• temperatures of the absorber tube;

• temperatures of the glass envelope tube (optional);

• temperature of the surrounding air;

• electrical power supplied by the resistance heaters or any other element used.

4.5.5.2 Procedure and test time

The measurement is performed at a steady state of stable absorber temperature and heating

power. Therefore, the following arithmetic means of evaluation of the measured quantities

over a longer evaluation period, which will also be called measurement point, are used.

Minimum evaluation periods are given in Table 1.

Table 1 – Evaluation periods

Absorber tube temperature in °C Minimum evaluation period in min

100 to 200 240

200 to 300 120

300 to 400 60

400 to 500 30

> 500 15

Table 2 shows the criteria for stability and homogeneity that shall be met for the duration of

the evaluation period.

Table 2 – Stability requirements

Parameter to be monitored Stability requirement

Absorber tube temperatures ±0,5 ºC

Absorber tube temperature homogeneity S < 0,04 T

TH abs,mean,°C

Heat loss (Equation (2)) ±1 %

Ambient temperature 20 °C ± 10 °C

Criteria in Table 2 refer to simple moving means (without weights) over 1 min for the

quantities of interest. The criterion for absorber tube temperatures refers to the temporal

stability for each temperature sensor.

Absorber tube temperature homogeneity S (t) at time, t, is defined as the difference of the

TH

highest and smallest measured temperature at t divided by the mean temperature:

TT−

abs,max abs,min

(1)

S =

TH

T

abs,mean

The maximum difference measured during one measurement between the different absorber

temperatures along the tube is important as it may indicate the uniformity of the coating.

The value of uniformity of S should be mentioned in the report. In addition, if during the

TH

measurement it was found that S > 2 % a warning should be mentioned in the report.

TH

• Method to achieve steady state:

PI or PID controllers can be used to control electric power input to reach target temperature

and a steady state. Steady state is achieved when heater set points do not change and the

centre-of-glass and absorber temperatures vary by less than 0,5 °C for a period of at least

15 min.

• This criterion of uniformity shall be followed throughout the steady-state period.

Once the desired absorber tube test temperature is reached and the adiabaticity of the

process at the ends of the tube is verified, measurements for steady-state periods shall be

performed. A measurement steady-state period shall have a duration of 15 min during which

the stability conditions listed in Table 2 shall be verified. Before each steady-state period, a

30-min period shall verify the same stability conditions listed in Table 2.

4.5.5.3 Heat loss (HL) calculations

Calculations shall be done using measurement point means.

The uncertainty of measurement shall be calculated in accordance with ISO 9806:2017,

Annex D.

The coefficient of loss in a receiver tube is defined as:

Pow + HL

∑ i ends

i

(2)

HL =

L

HCE()25 °C

where

HL is the heat loss of the tube [W/m];

Pow is the electrical power consumed by heating element i [W];

i

HL is the heat loss at the tube ends [W].

ends

Example of a test bench with a copper tube as heater type:

For this type of test bench, only the ends are insulated; the heat loss of the ends should be

calculated, for example, in the following way:

kA kA

HL (T ––T )+ (T T )

(3)

ends 1 2 NN –1

∆∆xx

where

T indicates the temperatures measured by sensors at the ends [°C] assuming N

1/2/N/N-1

sensors. In the case of a test bench based on electrical heating elements, the

sensors at the ends of the copper tube would be taken;

k is the coefficient of conductivity of copper [W/m °C];

A is the surface area of copper tube (heater) [m ];

∆x is the distance between sensors at ends [m];

L is the length of receiver tube at ambient temperature (25 °C ± 10 °C) [m]. The

HCE(25 °C)

length of the receiver tube aperture shall be measured.

The mean temperature of the absorber is calculated by weighting the distance that each

sensor covers along the absorber tube:

=

– 14 – IEC TS 62862-3-3:2020 © IEC 2020

Tp

∑ abs i

i

i

T =

[°C] (4)

abs

p

i

∑

i

where

T

is the absorber tube temperature measured by sensor i [°C];

abs

i

p

is the weight applied [-].

i

The mean temperature of the glass envelope tube is:

Tp

∑ gl,o i

i

i

T =

(5)

gl,o

p

∑ i

i

where

is the outer temperature of the glass envelope tube measured by sensor i [°C];

T

gl,o

i

p

is the weight applied [-].

i

Weights used to find the absorber and glass temperatures are calculated by the following

equations:

A

i

P = (6)

i

A

abs

where

A d × l , RT (7)

abs abs abs

is the area of the absorber at room temperature and A is that fraction of the absorber area for

i

which the temperature sensor i is the closest sensor.

Optional: In general the result of a measurement point is a pair of heat loss HL and mean

absorber temperatures, T . Both have associated uncertainties u(HL) and u(T ).

abs abs

Interpreting heat loss HL as a function of temperature T it is beneficial to have only HL

abs

associated with uncertainty. Uncertainty of temperature u(T ) and uncertainty of heat loss

abs

u(HL) can be merged to form a combined uncertainty of heat loss u (HL) by:

c

∂HL T

( )

22 abs 2

(8)

u (HL) u (HL)+ × u (T )

c abs

∂T

abs

The partial derivative can be determined from the interpolation polynomials,

∂∂HL T / T

( )

abs abs

for example.

4.5.5.4 Thermal emittance calculation (optional)

Emittance can only be calculated if the annulus between the steel tube and glass cover is

evacuated (not filled with noble gas).

=

=

Emittance is calculated (optional) in several steps starting with the test results.

First the outside absorber tube temperature is calculated:

r

abs,o

HL ln

r

abs,i

TT −

(9)

abs,o abs,i

2π k

abs

where

HL is heat loss measured during the test at a given T [W/m];

abs

r is the outer radius of the absorber tube [m];

abs,o

r is the inner radius of the absorber tube [m];

abs,I

k is the thermal conductivity of the absorber [m/°C] – to be received from

abs

manufacturer;

T is the inner absorber temperature [°C] (also called T ).

abs,i abs

NOTE The radii, r and r are supplied by the manufacturer, as are those for the glass tube in Formula (10).

abs,i abs,o

Second, the temperature inside the glass envelope tube is calculated:

r

gl,o

HL ln

r

gl,i

TT +

(10)

gl,,iogl

2π k

gl

where

r is the outer radius of the glass envelope tube [m];

gl,o

is the inner radius of the glass envelope tube [m];

r

gl,i

k is the thermal conductivity of glass [m/°C] – to be received from manufacturer;

gl

is the outer temperature of the glass envelope tube [°C].

T

gl,o

Finally, the absorber tube emittance is calculated using the Forristal equation (Equation (11)):

HL

ε =

abs

(11)

1− ε

r

gl

abs,o

2πσr T −−T HL

( )

abs,o abs,oK() gl,i()K

ε r

gl gl,i

where

ε glass emittance [-] (use value provided by manufacturer; if none provided, use 0,89);

gl

σ Stefan-Boltzman constant [].

4.5.6 Test methodology – Joule effect method

4.5.6.1 Testing apparatus schematic layout

The Joule effect heating method consists in using the steel tube itself as a heater in order to

provide the required power to bring the receiver to a certain temperature.

Its schematic layout is shown in Figure 2. The receiver ends are mechanically and electrically

connected with two pieces of well insulated steel tube (220 mm minimum length) with the

same outer diameter and thickness as the tube under test.

=

=

– 16 – IEC TS 62862-3-3:2020 © IEC 2020

The ends of these tube extensions are connected to a current (preferred) or voltage

generator. During the test the voltage differences in some critical points as well as the current

flowing into the circuit are measured in order to determine the exact amount of power

transferred to the tube in the different sections.

Figure 2 – Resistance heating method schematic sketch

4.5.6.2 Effective voltage measurements

The effective voltage on the receiver tube shall be measured with suitable probes touching

the absorber tube from the inside, where the steel tube is not accessible, and/or from the

outside in the other positions shown in Figure 2.

The effective voltage difference should at a minimum be measured in the following positions

using the low-voltage reference at one end of the testing equipment set-up: at point 1 in

Figure 2; close to the other current connection clamp at other end of the set-up (point 2); as

close as possible to both the receiver tube ends (points 3 and 4); at least in 3 other positions

along it (points 5 to 7), arranged symmetrically from the centre to evaluate the central HL

value.

The expanded uncertainties of each voltage sensor shall be less than ±1 mV.

Uncertainty calculations are determined in accordance with ISO 9806:2017, Annex D.

4.5.6.3 Current measurements

The current flowing into the receiver tube shall be measured with a suitable instrument to be

connected in series in the electric loop.

The expanded uncertainties of the current sensor shall be less than ±0,1 A.

Uncertainty calculations are determined in accordance with ISO 9806:2017, Annex D.

4.5.6.4 Power measurements

The equipment for measuring electric heating power (based on calculations from the voltage

and current measurements) shall have an accuracy of 2 % to 3 % of the actual reading.

4.5.6.5 Data acquisition frequency

Power sensors used in the test shall be calibrated. Data recording frequency shall be no less

than 1 recording per 20 s and the minimum number of records shall ensure the statistical

representativeness of the test.

4.5.6.6 Measurements

At least the following data shall be measured.

Before the test:

• the length of the metal receiver absorber tube measured at ambient temperature using a

measuring instrument (e.g. measuring tape) with an uncertainty of 1 mm. The instrument

should be inserted into the tube and measured from one end to the other;

• diameter (inner and outer) of the absorber tube, measured at ambient temperature using a

caliper with an acc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...