IEC 61009-1:2024

(Main)Residual current operated circuit-breakers with integral overcurrent protection for household and similar uses (RCBOs) - Part 1: General rules

Residual current operated circuit-breakers with integral overcurrent protection for household and similar uses (RCBOs) - Part 1: General rules

IEC 61009-1:2024 gives general requirements and tests for residual current operated circuit‑breakers with integral overcurrent protection for household and similar uses (hereafter referred to as RCBOs), for rated operational voltages not exceeding 440 V AC, with rated frequencies of 50 Hz, 60 Hz or 50/60 Hz and rated currents not exceeding 125 A and rated short‑circuit capacities not exceeding 25 000 A.

This fourth edition cancels and replaces the third edition published in 2010, Amendment 1:2012 and Amendment 2:2013. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a) harmonization of all clauses between the IEC 61008, IEC 61009 and IEC 60755 series using blocks and modules approach;

b) harmonization of all tables and figures between the IEC 61008, IEC 61009 and IEC 60755 series;

c) terms and definitions are now referred to IEC 62873-2;

d) modification of Subclause 4.1 for classification according to supply conditions;

e) new Subclauses 8.17 and 9.24 for requirements and tests for the resistance to temporary overvoltages (TOV);

f) improvement of Subclause 9.7 for test of dielectric properties;

g) tests for screwless, flat-quick terminals and aluminium conductors are now referred to in the IEC 62873-3 series.

Interrupteurs automatiques à courant différentiel résiduel avec dispositif de protection contre les surintensités incorporé pour usages domestiques et analogues (DD) – Partie 1: Règles générales

L'IEC 61009-1:2024 spécifie les exigences générales et les essais relatifs aux interrupteurs automatiques à courant différentiel résiduel avec dispositif de protection contre les surintensités incorporé pour usages domestiques et analogues (ci-après appelés DD), de tension d'emploi assignée inférieure ou égale à 440 V en courant alternatif avec une fréquence assignée de 50 Hz, 60 Hz ou 50/60 Hz, un courant assigné inférieur ou égal à 125 A et des pouvoirs de coupure et de fermeture en court‑circuit assignés inférieurs ou égaux à 25 000 A.

Cette quatrième édition annule et remplace la troisième édition parue en 2010, son Amendement 1:2012 et son Amendement 2:2013. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) harmonisation de tous les articles entre les séries IEC 61008, IEC 61009 et IEC 60755 par une approche fondée sur les blocs et les modules;

b) harmonisation de tous les tableaux et de toutes les figures entre les séries IEC 61008, IEC 61009 et IEC 60755;

c) les termes et définitions renvoient désormais à l'IEC 62873-2;

d) modification du 4.1 relatif à la classification selon les conditions d'alimentation;

e) de nouveaux paragraphes 8.17 et 9.24 ont été ajoutés pour les exigences et les essais de résistance aux surtensions temporaires (TOV);

f) amélioration du 9.7 relatif à l'essai des propriétés diélectriques;

g) les essais des bornes sans vis, des bornes plates à connexion rapide et des conducteurs en aluminium renvoient désormais à la série IEC 62873-3.

La présente version bilingue (2025-11) correspond à la version anglaise monolingue publiée en 2024-11.

La version française de cette norme n'a pas été soumise au vote.

General Information

- Status

- Published

- Publication Date

- 20-Nov-2024

- Technical Committee

- SC 23E - Circuit-breakers and similar equipment for household use

- Drafting Committee

- WG 2 - TC 23/SC 23E/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 21-Nov-2024

- Completion Date

- 06-Dec-2024

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61009-1:2024 - Residual current operated circuit‑breakers with integral overcurrent protection (RCBOs) - Part 1: General rules, is the 4th edition international standard that defines general requirements and mandatory tests for RCBOs for household and similar uses. It applies to devices with rated operational voltages up to 440 V AC, rated frequencies 50 Hz, 60 Hz or 50/60 Hz, rated currents up to 125 A, and rated short‑circuit capacities up to 25 000 A. This edition supersedes the 2010 edition and its amendments and constitutes a technical revision with harmonization and new test requirements.

Key Topics and Requirements

The standard establishes construction, performance and testing rules for RCBOs, covering:

- Classification and rated values

- Classification according to supply conditions, number of poles/current paths and adjustable residual operating current.

- Rated voltages, rated currents (In ≤ 125 A), rated frequency and rated short‑circuit capacity (Icn ≤ 25 000 A).

- Construction and safety

- Mechanical design, terminals (including screwless and flat‑quick), clearances and creepage, and protection against electric shock.

- Electrical performance

- Operating characteristics for residual currents, overcurrent response, temperature‑rise limits and mechanical/electrical endurance.

- Dielectric and transient requirements

- Improved dielectric property tests (Subclause 9.7) and resistance to temporary overvoltages (TOV) (new Subclauses 8.17 and 9.24).

- Short‑circuit and making/breaking capability

- Tests for short‑circuit behaviour, verification of I²t and peak current, and rated residual making and breaking capacity (IΔm).

- Reliability and environmental robustness

- Resistance to mechanical shock/impact, heat, fire behaviour, EMC and marking/installation conditions.

- Harmonization and references

- Harmonized clause structure, tables and figures with IEC 61008 and IEC 60755 using a blocks/modules approach; terms and definitions now referenced to IEC 62873-2; terminal and conductor tests referenced to IEC 62873-3.

Applications and Who Uses This Standard

IEC 61009-1:2024 is essential for:

- RCBO manufacturers designing products for household and similar applications.

- Test laboratories and certification bodies performing compliance testing and type approval.

- Electrical safety engineers and product designers specifying protective devices in distribution boards.

- Specifiers, utilities and regulators referencing internationally harmonized safety and performance criteria.

- Installers and OEMs selecting compliant RCBOs for residential and light commercial applications.

Related Standards

- IEC 61008 (residual current circuit-breakers without integral overcurrent protection)

- IEC 60755 (series related requirements)

- IEC 62873-2 (terms and definitions)

- IEC 62873-3 (terminal and conductor tests)

Keywords: IEC 61009-1:2024, RCBOs, residual current operated circuit-breaker, overcurrent protection, TOV, dielectric tests, rated short‑circuit capacity, household electrical safety.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 61009-1:2024 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Residual current operated circuit-breakers with integral overcurrent protection for household and similar uses (RCBOs) - Part 1: General rules". This standard covers: IEC 61009-1:2024 gives general requirements and tests for residual current operated circuit‑breakers with integral overcurrent protection for household and similar uses (hereafter referred to as RCBOs), for rated operational voltages not exceeding 440 V AC, with rated frequencies of 50 Hz, 60 Hz or 50/60 Hz and rated currents not exceeding 125 A and rated short‑circuit capacities not exceeding 25 000 A. This fourth edition cancels and replaces the third edition published in 2010, Amendment 1:2012 and Amendment 2:2013. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) harmonization of all clauses between the IEC 61008, IEC 61009 and IEC 60755 series using blocks and modules approach; b) harmonization of all tables and figures between the IEC 61008, IEC 61009 and IEC 60755 series; c) terms and definitions are now referred to IEC 62873-2; d) modification of Subclause 4.1 for classification according to supply conditions; e) new Subclauses 8.17 and 9.24 for requirements and tests for the resistance to temporary overvoltages (TOV); f) improvement of Subclause 9.7 for test of dielectric properties; g) tests for screwless, flat-quick terminals and aluminium conductors are now referred to in the IEC 62873-3 series.

IEC 61009-1:2024 gives general requirements and tests for residual current operated circuit‑breakers with integral overcurrent protection for household and similar uses (hereafter referred to as RCBOs), for rated operational voltages not exceeding 440 V AC, with rated frequencies of 50 Hz, 60 Hz or 50/60 Hz and rated currents not exceeding 125 A and rated short‑circuit capacities not exceeding 25 000 A. This fourth edition cancels and replaces the third edition published in 2010, Amendment 1:2012 and Amendment 2:2013. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) harmonization of all clauses between the IEC 61008, IEC 61009 and IEC 60755 series using blocks and modules approach; b) harmonization of all tables and figures between the IEC 61008, IEC 61009 and IEC 60755 series; c) terms and definitions are now referred to IEC 62873-2; d) modification of Subclause 4.1 for classification according to supply conditions; e) new Subclauses 8.17 and 9.24 for requirements and tests for the resistance to temporary overvoltages (TOV); f) improvement of Subclause 9.7 for test of dielectric properties; g) tests for screwless, flat-quick terminals and aluminium conductors are now referred to in the IEC 62873-3 series.

IEC 61009-1:2024 is classified under the following ICS (International Classification for Standards) categories: 29.120.50 - Fuses and other overcurrent protection devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61009-1:2024 has the following relationships with other standards: It is inter standard links to IEC 61009-1:2010/AMD2:2013, IEC 61009-1:2010/AMD1:2012, IEC 61009-1:2010/AMD2:2013/COR1:2014, IEC 61009-1:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61009-1:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61009-1 ®

Edition 4.0 2024-11

INTERNATIONAL

STANDARD

Residual current operated circuit-breakers with integral overcurrent protection

for household and similar uses (RCBOs) –

Part 1: General rules

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61009-1 ®

Edition 4.0 2024-11

INTERNATIONAL

STANDARD

Residual current operated circuit-breakers with integral overcurrent protection

for household and similar uses (RCBOs) –

Part 1: General rules

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.120.50 ISBN 978-2-8327-0011-2

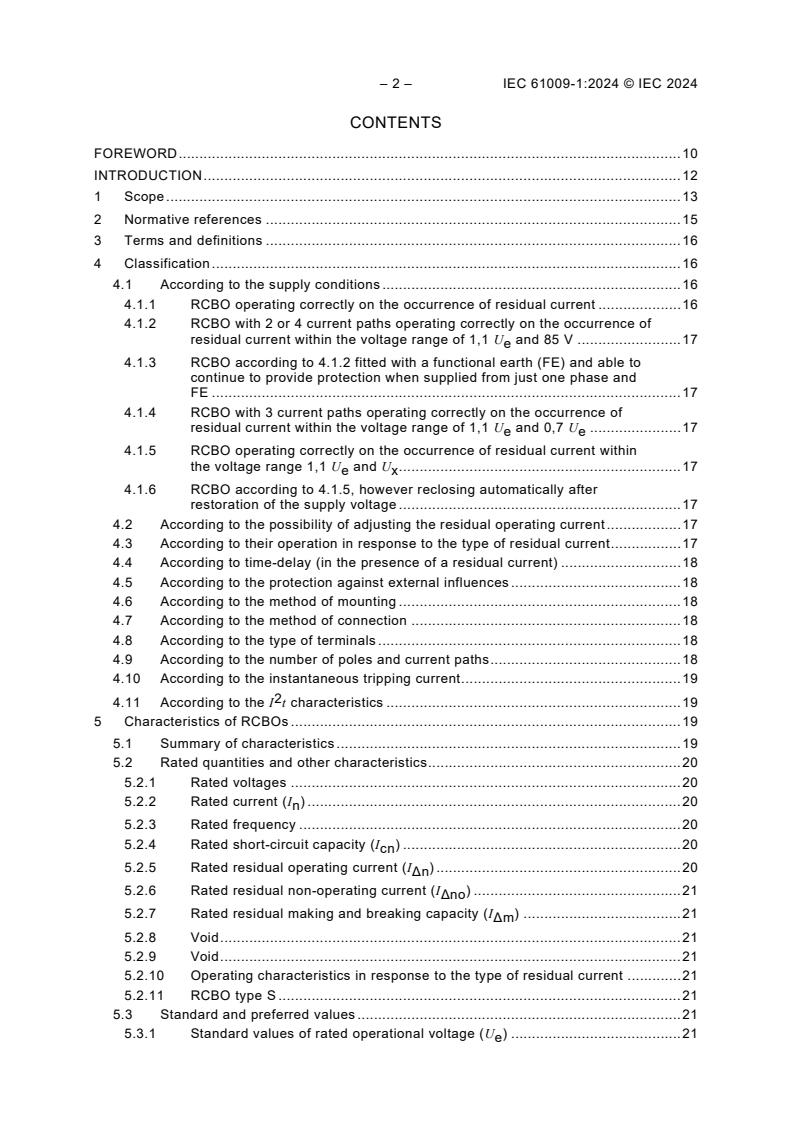

– 2 – IEC 61009-1:2024 © IEC 2024

CONTENTS

FOREWORD . 10

INTRODUCTION . 12

1 Scope . 13

2 Normative references . 15

3 Terms and definitions . 16

4 Classification . 16

4.1 According to the supply conditions . 16

4.1.1 RCBO operating correctly on the occurrence of residual current . 16

4.1.2 RCBO with 2 or 4 current paths operating correctly on the occurrence of

residual current within the voltage range of 1,1 U and 85 V . 17

e

4.1.3 RCBO according to 4.1.2 fitted with a functional earth (FE) and able to

continue to provide protection when supplied from just one phase and

FE . 17

4.1.4 RCBO with 3 current paths operating correctly on the occurrence of

residual current within the voltage range of 1,1 U and 0,7 U . 17

e e

4.1.5 RCBO operating correctly on the occurrence of residual current within

the voltage range 1,1 U and U . 17

e x

4.1.6 RCBO according to 4.1.5, however reclosing automatically after

restoration of the supply voltage . 17

4.2 According to the possibility of adjusting the residual operating current . 17

4.3 According to their operation in response to the type of residual current . 17

4.4 According to time-delay (in the presence of a residual current) . 18

4.5 According to the protection against external influences . 18

4.6 According to the method of mounting . 18

4.7 According to the method of connection . 18

4.8 According to the type of terminals . 18

4.9 According to the number of poles and current paths . 18

4.10 According to the instantaneous tripping current . 19

4.11 According to the I t characteristics . 19

5 Characteristics of RCBOs . 19

5.1 Summary of characteristics . 19

5.2 Rated quantities and other characteristics . 20

5.2.1 Rated voltages . 20

5.2.2 Rated current (I ) . 20

n

5.2.3 Rated frequency . 20

5.2.4 Rated short-circuit capacity (I ) . 20

cn

5.2.5 Rated residual operating current (I ) . 20

Δn

5.2.6 Rated residual non-operating current (I ) . 21

Δno

5.2.7 Rated residual making and breaking capacity (I ) . 21

Δm

5.2.8 Void . 21

5.2.9 Void . 21

5.2.10 Operating characteristics in response to the type of residual current . 21

5.2.11 RCBO type S . 21

5.3 Standard and preferred values . 21

5.3.1 Standard values of rated operational voltage (U ) . 21

e

5.3.2 Preferred values of rated current (I ) . 21

n

5.3.3 Standard values of rated residual operating current (I ) . 21

Δn

5.3.4 Standard value of residual non-operating current (I ) . 22

Δno

5.3.5 Preferred values of rated frequency . 22

5.3.6 Standard values of rated impulse withstand voltage (U ) . 22

imp

5.3.7 Standard limit values of break time and non-actuating time for RCBO of

type AC and A . 22

5.3.8 Void . 22

5.3.9 Void . 22

5.3.10 Void . 22

5.3.11 Minimum value of the rated residual making and breaking capacity

(I ) . 22

Δm

5.3.12 Void . 22

5.3.13 Void . 22

5.3.14 Values of rated short-circuit capacity . 22

5.3.15 Standard ranges of overcurrent instantaneous tripping . 23

6 Marking and other product information . 23

7 Standard conditions for operation in service and for installation . 24

7.1 Standard conditions . 24

7.2 Conditions of installation . 24

7.3 Pollution degree . 24

8 Requirements for construction and operation . 24

8.1 Mechanical design . 24

8.1.1 General . 24

8.1.2 Mechanism . 25

8.1.3 Clearances, creepage distances and solid insulation . 26

8.1.4 Screws, current-carrying parts and connections . 27

8.1.5 Terminals for external conductors . 28

8.1.6 Non-interchangeability . 30

8.2 Protection against electric shock . 30

8.3 Dielectric properties and isolating capability . 31

8.4 Temperature-rise . 31

8.4.1 General . 31

8.4.2 Temperature-rise limits . 31

8.4.3 Ambient air temperature . 31

8.5 Operating characteristics . 31

8.5.1 General . 31

8.5.2 Operation in response to the type of residual current . 31

8.5.3 Operation in presence of a residual current equal to or greater than I . 32

Δn

8.5.4 Operation under overcurrent conditions . 32

8.6 Mechanical and electrical endurance . 33

8.7 Performance at short-circuit currents . 33

8.8 Resistance to mechanical shock and impact . 33

8.9 Resistance to heat . 33

8.10 Resistance to abnormal heat and to fire . 34

8.11 Test device . 34

8.12 Void . 34

8.13 Void . 34

– 4 – IEC 61009-1:2024 © IEC 2024

8.14 Behaviour of RCBOs in the event of current surges caused by impulse

voltages . 34

8.15 Reliability . 35

8.16 Electromagnetic compatibility (EMC) . 35

8.17 Resistance to temporary overvoltages (TOV) . 35

9 Tests . 35

9.1 General . 35

9.2 Test conditions . 35

9.3 Test of indelibility of marking . 36

9.4 Test of reliability of screws, current-carrying parts and connections . 37

9.5 Test of reliability of screw-type terminals for external copper conductors . 37

9.6 Verification of protection against electric shock . 39

9.7 Test of dielectric properties . 39

9.7.1 Resistance to humidity . 39

9.7.2 Insulation resistance of the main circuit . 40

9.7.3 Dielectric strength of the main circuit . 41

9.7.4 Insulation resistance and dielectric strength of auxiliary circuits. 41

9.7.5 Secondary circuit of detection transformers . 42

9.7.6 Capability of control circuits connected to the main circuit to withstand

high DC voltages due to insulation measurements . 42

9.7.7 Verification of impulse withstand voltages . 42

9.8 Test of temperature-rise . 44

9.8.1 Ambient air temperature . 44

9.8.2 Test procedure . 44

9.8.3 Measurement of the temperature of parts . 45

9.8.4 Temperature-rise of a part . 45

9.9 Verification of the operating characteristics . 45

9.9.1 Verification of the operating characteristics under residual current

conditions . 45

9.9.2 Verification of the operating characteristic under overcurrent conditions . 45

9.10 Verification of mechanical and electrical endurance . 47

9.10.1 General test conditions . 47

9.10.2 Test procedure . 47

9.10.3 Condition of the RCBO after test . 48

9.11 Short-circuit tests . 48

9.11.1 General conditions for test . 48

9.11.2 Test circuit for short-circuit performance . 49

9.11.3 Values of test quantities . 50

9.11.4 Tolerances on test quantities . 50

9.11.5 Power factor of the test circuit . 50

9.11.6 Measurement and verification of I t and of the peak current (I ) . 50

p

9.11.7 Calibration of the test circuit . 51

9.11.8 Interpretation of records . 51

9.11.9 Condition of the RCBO for test. 51

9.11.10 Behaviour of the RCBO during short-circuit tests . 52

9.11.11 Test procedure . 53

9.11.12 Verification of the RCBO after short-circuit test . 56

9.11.13 Verification of the rated residual making and breaking capacity (I ) . 56

Δm

9.12 Verification of resistance to mechanical shock and impact . 57

9.12.1 Mechanical shock . 57

9.12.2 Mechanical impact . 58

9.13 Test of resistance to heat . 60

9.13.1 Test on complete RCBOs . 60

9.13.2 Ball pressure test . 61

9.14 Test of resistance to abnormal heat and to fire . 62

9.15 Verification of the trip-free mechanism . 63

9.16 Verification of the operation of the test device at the limits of rated

operational voltage . 63

9.17 Void . 63

9.18 Void . 63

9.19 Verification of the behaviour of RCBOs in the event of current surges caused

by impulse voltages . 63

9.19.1 Current surge test for all RCBOs (0,5 µs/100 kHz ring wave test) . 63

9.19.2 Verification of the behaviour at surge currents up to 3 000 A (8/20 µs

surge current test) . 64

9.20 Verification of reliability . 65

9.20.1 Climatic test. 65

9.20.2 Test with temperature of 40 °C . 66

9.21 Verification of withstand against ageing . 67

9.22 Electromagnetic compatibility (EMC) . 67

9.23 Test of resistance to rusting . 67

9.24 Verification of the behaviour of the RCBO under temporary overvoltage

(TOV) conditions . 68

9.24.1 General . 68

9.24.2 TOV test for all RCBOs . 68

9.24.3 Additional tests for RCBOs with a terminal intended to be connected to

the PE . 68

9.24.4 Verification after the tests . 68

Annex A (normative) Test sequence and number of samples to be submitted for

certification purposes . 99

Annex B (normative) Determination of clearances and creepage distances . 100

B.1 General . 100

B.2 Creepage distances where more than one material is used . 100

B.3 Creepage distances split by floating conductive part . 100

B.4 Measurement of creepage distances and clearances . 100

Annex C (normative) Arrangement for the detection of the emission of ionized gases

during short-circuit tests . 105

Annex D (normative) Routine tests . 108

D.1 General . 108

D.2 Tripping test . 108

D.3 Dielectric strength test . 108

D.4 Performance of the test device . 108

Annex E (informative) Methods for determination of short-circuit power-factor . 109

E.1 General . 109

E.2 Method I – Determination from DC components . 109

E.3 Method II – Determination with pilot generator . 110

Annex F (informative) Co-ordination under short-circuit conditions between an RCBO

and another short-circuit protective device (SCPD) associated in the same circuit . 111

F.1 General . 111

– 6 – IEC 61009-1:2024 © IEC 2024

F.2 Overview. 112

F.3 General requirements for the co-ordination of an RCBO with another SCPD . 112

F.3.1 General consideration . 112

F.3.2 Take-over current . 112

F.3.3 Behaviour of C in association with another SCPD . 112

F.4 Type and characteristics of the associated SCPD . 112

F.5 Verification of selectivity . 113

F.6 Verification of back-up protection . 113

F.6.1 Determination of the take-over current . 113

F.6.2 Verification of back-up protection . 114

F.6.3 Tests for verification of back-up protection . 114

F.6.4 Results to be obtained . 115

Annex G (normative) Additional requirements and tests for RCBOs consisting of a

circuit-breaker and a residual current unit designed for assembly on site . 119

G.1 General . 119

G.2 Marking and other product information . 119

G.2.1 Manufacturer's name or trade mark . 119

G.2.2 Marking . 119

G.2.3 Instructions for assembly and operation . 120

G.3 Constructional requirements . 120

G.3.1 General . 120

G.3.2 Degree of protection . 120

G.3.3 Mechanical requirements . 121

G.3.4 Electrical compatibility . 121

G.4 Type tests and verifications . 121

G.4.1 Tests on circuit-breakers . 121

G.4.2 Tests on RC units . 121

G.4.3 Tests on assembled circuit-breaker and RC unit (RCBO) . 121

G.4.4 Verification of marking and constructional requirements of RCBOs . 121

G.5 Routine tests on the RC unit . 122

Annex H (informative) Examples of terminal designs . 123

Annex I (informative) Correspondence between ISO and AWG copper conductors . 126

Annex J (informative) Follow-up testing program for RCBOs . 127

J.1 General . 127

J.2 Follow-up testing program . 127

J.2.1 General . 127

J.2.2 Quarterly follow-up testing program . 127

J.2.3 Annual follow-up testing program . 127

J.2.4 Sampling procedure . 128

Bibliography . 131

Figure 1 – Standard test finger . 81

Figure 2 – Void . 82

Figure 3 – Void . 82

Figure 4 – Void . 82

Figure 5 – Typical diagram for all short circuit tests except for the verification of the

suitability in IT systems . 83

Figure 6 – Typical diagram for the verification of the suitability in IT systems . 84

Figure 7 – Detail of impedances Z, Z and Z . 84

1 2

Figure 8 – Mechanical shock test apparatus . 85

Figure 9 – Mechanical impact test apparatus . 86

Figure 10 – Striking element for pendulum impact test apparatus. 87

Figure 11 – Mounting support for sample for mechanical impact test. 88

Figure 12 – Example of mounting an unenclosed or flush-type RCBO for mechanical

impact test . 89

Figure 13 – Example of mounting of panel mounting type RCBO for the mechanical

impact test . 90

Figure 14 – Application of force for mechanical test of rail mounted RCBO . 91

Figure 15 – Ball-pressure test apparatus. 91

Figure 16 – Current ring wave 0,5 µs/100 kHz . 92

Figure 17 – Test circuit for the ring wave test on RCBOs . 92

Figure 18 – Surge current impulse 8/20 µs . 93

Figure 19 – Test circuit for the surge current test of RCBOs . 93

Figure 20 – Stabilizing period for reliability test . 94

Figure 21 – Reliability test cycle . 95

Figure 22 – Void . 95

Figure 23 – Example of records for short-circuit tests . 96

Figure 24 – Test circuit for the verification of the behaviour under temporary over

voltage (TOV) conditions for RCBOs with a terminal intended to be connected

to the PE . 97

Figure 25 – Void . 97

Figure 26 – Void . 97

Figure 27 – Diagrammatic representation for glow-wire test . 98

Figure B.1 – Measuring creepage distances and clearances: Example 1 . 101

Figure B.2 – Measuring creepage distances and clearances: Example 2 . 101

Figure B.3 – Measuring creepage distances and clearances: Example 3 . 101

Figure B.4 – Measuring creepage distances and clearances: Example 4 . 102

Figure B.5 – Measuring creepage distances and clearances: Example 5 . 102

Figure B.6 – Measuring creepage distances and clearances: Example 6 . 102

Figure B.7 – Measuring creepage distances and clearances: Example 7 . 103

Figure B.8 – Measuring creepage distances and clearances: Example 8 . 103

Figure B.9 – Measuring creepage distances and clearances: Example 9 . 103

Figure B.10 – Measuring creepage distances and clearances: Example 10 . 104

Figure B.11 – Measuring creepage distances and clearances: Example 11 . 104

Figure C.1 – Example of test arrangement . 106

Figure C.2 – Grid . 107

Figure C.3 – Grid circuit . 107

Figure F.1 – Overcurrent co-ordination between an RCBO and a fuse or back-up

protection by a fuse – Operating characteristics . 116

Figure F.2 – Total selectivity . 117

Figure F.3 – Back-up protection – Operating characteristics . 118

Figure H.1 – Examples of pillar terminals . 123

– 8 – IEC 61009-1:2024 © IEC 2024

Figure H.2 – Examples of screw terminals and stud terminals . 124

Figure H.3 – Examples of saddle terminals . 125

Figure H.4 – Examples of lug terminals . 125

Table 1 – Marking . 69

Table 2 – Void . 70

Table 3 – Void . 70

Table 4 – Void . 70

Table 5 – Void . 70

Table 6 – Void . 70

Table 7 – Void . 70

Table 8 – Void . 70

Table 9 – Void . 70

Table 10 – Void . 70

Table 11 – Standard limit values of break time and non-actuating time for alternating

residual currents (RMS values) for type AC and A . 70

Table 12 – Standard maximum values of break time for half-wave residual currents

(RMS values) for type A . 70

Table 13 – Void . 71

Table 14 – Tripping current limits . 71

Table 15 – Void . 71

Table 16 – Void . 71

Table 17 – Void . 71

Table 18 – Void . 71

Table 19 – Rated impulse withstand voltage as a function of the nominal voltage of the

installation . 71

Table 20 – Minimum clearances and creepage distances . 72

Table 21 – Test voltage of auxiliary circuits . 73

Table 22 – Test voltage for verification of rated impulse withstand voltage. 73

Table 23 – Test voltage for verifying the suitability for isolation, with reference to the rated

impulse withstand voltage of the RCBO and the altitude where the test is carried out . 74

Table 24 – Connectable cross-sections of copper conductors for screw-type terminals . 74

Table 25 – Test copper conductors corresponding to the rated currents . 74

Table 26 – Screw thread diameters and applied torques . 75

Table 27 – Pulling forces . 75

Table 28 – Temperature-rise values . 75

Table 29 – Power factor ranges of the test circuit . 76

Table 30 – Withstand values and duration of temporary overvoltages . 76

Table 31 – Void . 76

Table 32 – Void . 76

Table 33 – Void . 76

Table 34 – Void . 76

Table 35 – Void . 76

Table 36 – Void . 76

Table 37 – Standard values of rated short circuit capacity. 76

Table 38 – Ranges of overcurrent instantaneous tripping . 77

Table 39 – Time-current operating characteristics . 77

Table 40 – List of short-circuit tests . 77

Table 41 – Ratio between service short-circuit capacity (I ) and rated short-circuit

cs

capacity (I ) – (factor k) . 78

cn

Table 42 – Test procedure for I in the case of single- and two-pole RCBOs . 78

cs

Table 43 – Test procedure for I in the case of three- and four-pole RCBOs . 78

cs

Table 44 – Test procedure for I . 78

cn

Table 45 – Void . 78

Table 46 – Standard values of rated operational voltage . 79

Table 47 – Values of influencing quantities . 80

Table J.1 – Test sequences during follow-up inspections . 128

Table J.2 – Number of samples to be tested . 130

– 10 – IEC 61009-1:2024 © IEC 2024

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

RESIDUAL CURRENT OPERATED CIRCUIT-BREAKERS

WITH INTEGRAL OVERCURRENT PROTECTION

FOR HOUSEHOLD AND SIMILAR USES (RCBOs) –

Part 1: General rules

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...